Let me say this right up front: one of the '4's in 4-4-2 IS 4 SPEED. Now, this isn't a G project, but a few of you run a Muncie, so let's talk about jammin' gears. My arch nemesis for quite some time has been the Muncie in my 67 442. This thing has tested me in ways that I do not appreciate. I guess the beginning really involves the discovery of the crooked frame and breaking z-bars around 2001 or so. Then, I found the limits of old gears in the burnout box one Friday night. I later learned that a 2.20 1st gear in a "performance", close ratio trans is pointless on a dragstrip with a 3.70 rear. I now have an M22W gearset from AutoGear along with their Supercase, sealed bearings, iron mid plate, side cover and forks, and front bearing support.

My Muncie Adventures (what not to do?)

- Thread starter fleming442

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I work in Syracuse where AutoGear is headquartered.... I walked in one day years ago when I needed a reverse idler for my M21. Guy turns around and picks one up off his desk & says what else? LOL the guy that owns it is weird, but very smart and knowledgeable about Munchies. On the other hand he doesn't believe overdrive's are needed and you should just change your rear end gears and lose take off. LMAO

I built this thing, and if anything, I WILL make it work right! I'll provide some real world experience. My latest problem was a sticky gear problem. It was very strange and took a rebuild to discover it. Under part throttle, it would stick in "gear" (all of them). Once you got the shifter freed up, push the clutch in, put in neutral, whack the throttle, and it was good. Only after watching a GearBox video on YouTube did I realize that I reverse engineered my problem. Paul C. was talking about shimming the input shaft and how it can weld the shafts together, I inspected the main shaft once it was broken down and found my fatal error. 2nd rests on a step, the slider hub sits on that, then the first gear sleeve goes on. My sleeve wasn't tight against the hub, which means the main bearing was pushing on the sleeve, which crashes the output shaft into the input shaft. This was my latest problem.

Here you see the shiny ring where the 2 shafts kept welding and breaking.

It created a lip on the end of the main shaft and you can see how far off the rollers were riding.

These fit together, sort of..

.

Next installment will be pressure venting and a countershaft lock bolt- both of which require drilling the cast iron mid plate.

Here you see the shiny ring where the 2 shafts kept welding and breaking.

It created a lip on the end of the main shaft and you can see how far off the rollers were riding.

These fit together, sort of..

.

Next installment will be pressure venting and a countershaft lock bolt- both of which require drilling the cast iron mid plate.

Jesus. I have been building 4 speeds for a long time and never seen anything like that. Paul mentioned about gasket thickness under the front bearing retainer. Was it related to that?

No, the sleeve wasn't pressed tight to the slider hub. Paul clued me in by talking about shimming the input.

yep been there done that.No, the sleeve wasn't pressed tight to the slider hub. Paul clued me in by talking about shimming the input.

OH YEAI now have an M22W gearset from AutoGear along with their Supercase, sealed bearings, iron mid plate, side cover and forks, and front bearing support.

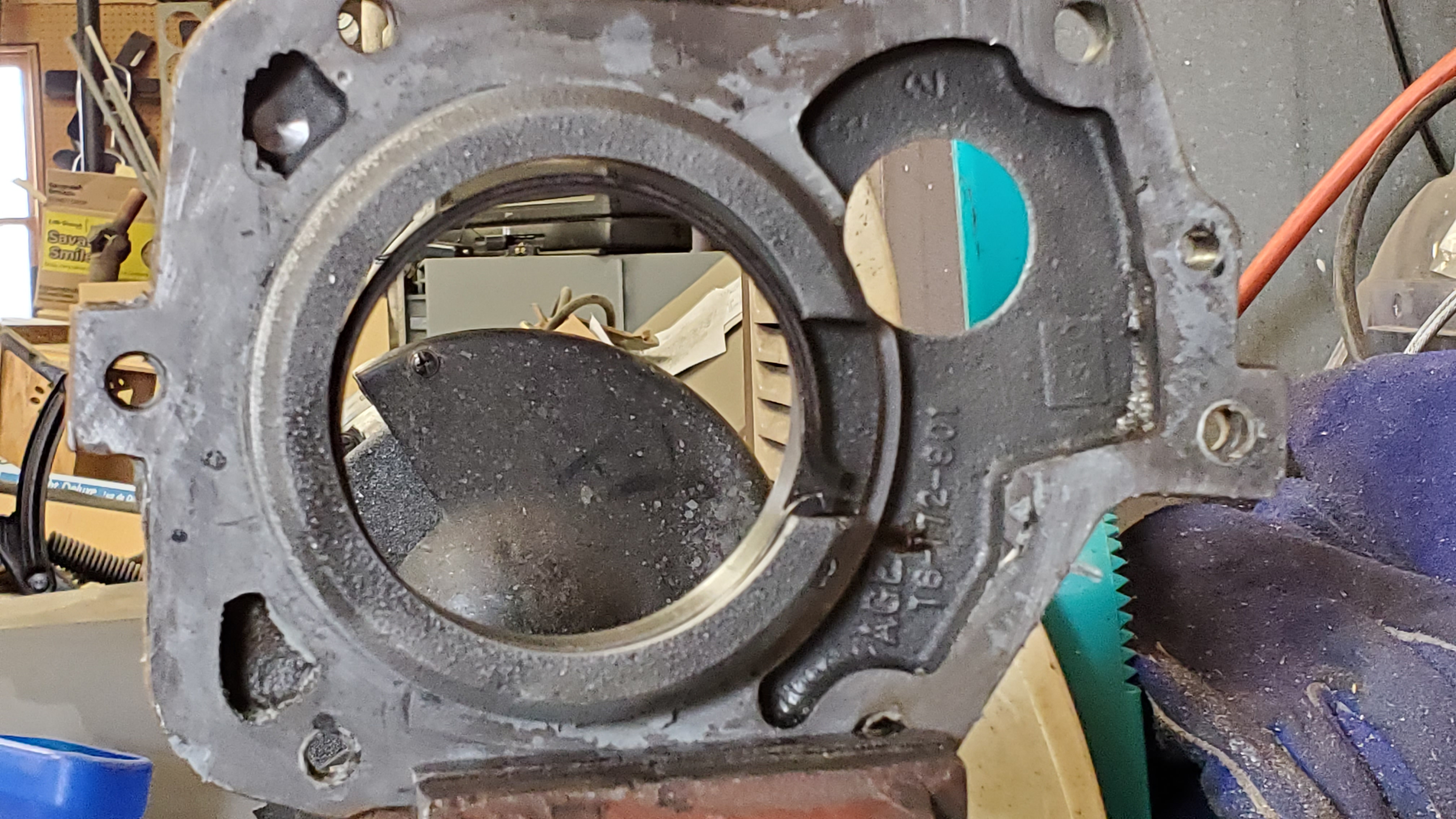

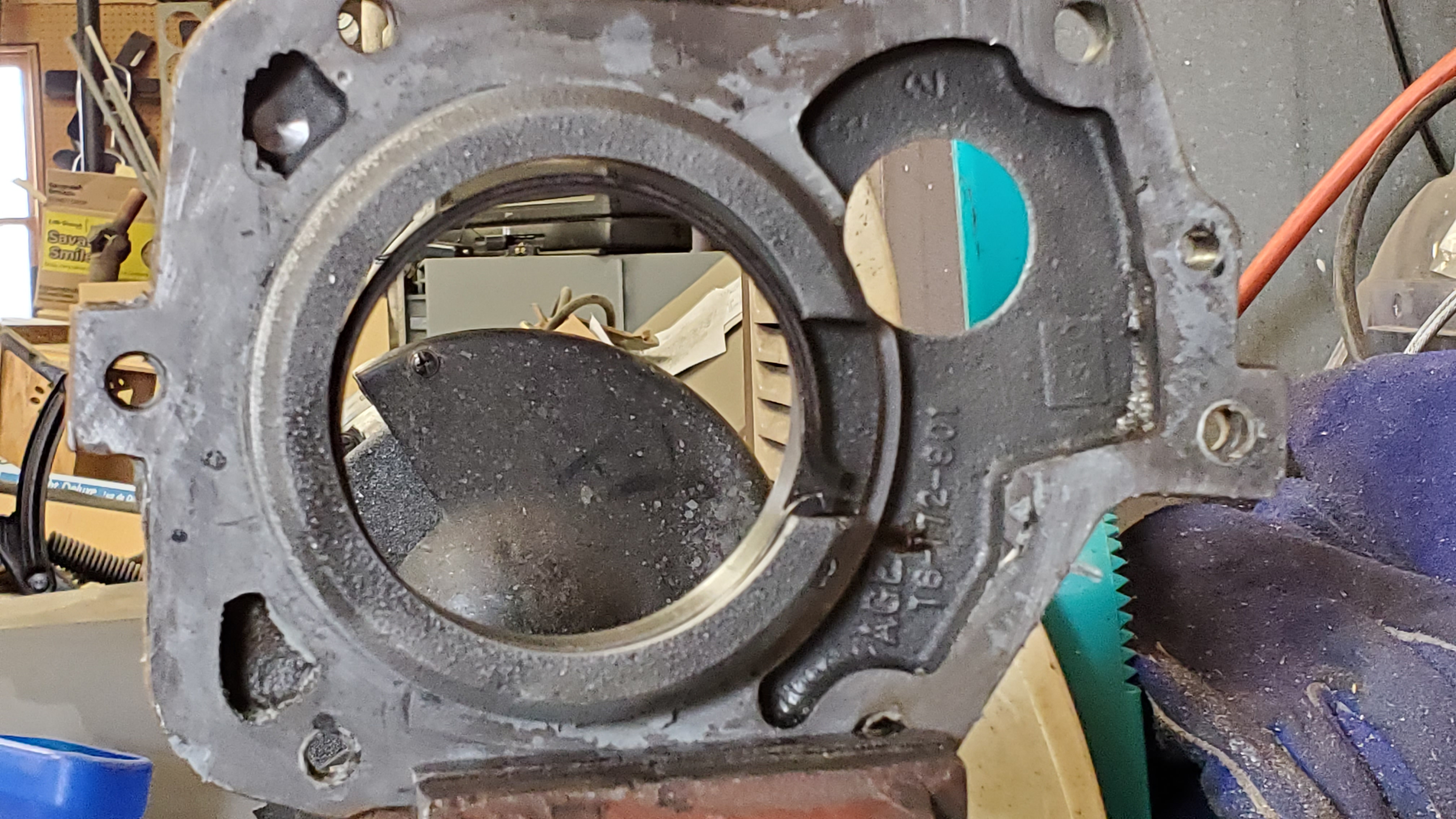

Today, I set about opening up the upper air passageways. I've had the sealed main bearings in for a while and installed the vent in the tail shaft housing, but didn't realize that it wouldn't work right. Watching the GearBox videos by Paul C. showed cavities in the top of his billet mid plate. I have an iron mid, and it was not opened. So, I set about making the vent work as it should.

So, newer countershaft pins are drilled and tapped for a 3/8-16 retention bolt. If you look at the pic of the mid plate, you can see where the pin had walked forward and started to spin. The flat rests on a ledge in the mid plate. I scribed the bore from the backside, drilled a pilot, and still ended up off. GRRRRR! Fortunately, it's non-loadbearing and basically unseen. I'll grab a wafer or button head Allen bolt to throw in it. Just need to keep the pin flat seated on the ledge...

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 875

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.