Strippers, crimpers, sh*t like that.

what do yall use?

also, where yall buy good bulk battery cable?

what do yall use?

also, where yall buy good bulk battery cable?

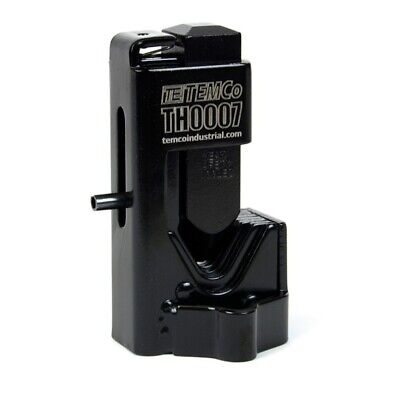

This ^^^^. I used to goof around crimping until I started soldering cable ends. You can do pullups on a #2 or larger cable if it's soldered and the joint will never corrode. Once you get into 4/0 stuff, the crimper tool talks two bulky humans to run lol, so soldering is much easier and a better joint. Now if it's in the car or truck, then the crimper starts looking better.Tools to make heavy duty/battery cables:

1. Razor knife to cut-off/strip 1/2" of insulation from cable

2. Copper ends or tips to be soldered onto cable

3. Solder

4. MAP gas torch

Source for these parts NAPA for copper ends and either 0 or 1 AWG cable. Home Depot, Lowes, or any hardware store for solder and MAP gas torch.

Secure the copper ends in vise to heat and melt solder with MAP gas torch. Melt solder until cup is half full before removing heat and inserting cable. Let the solder cool to secure the cable.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.