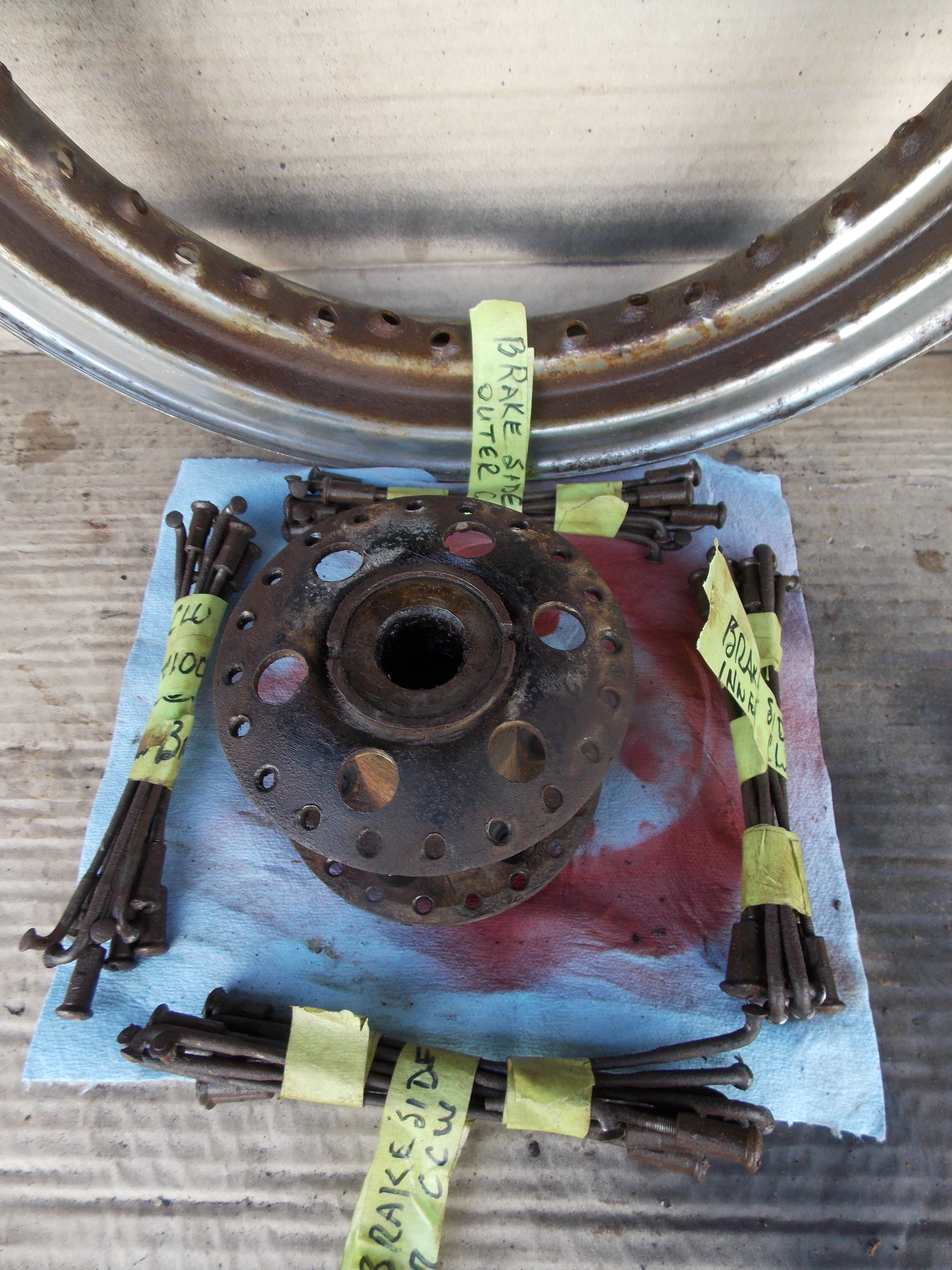

So, just by way of backstory here, this was the up close shot for that Chief wheel that I took apart last week. At the time, all I did was to separate it into its major subcomponents. After some further thought on the matter and little digging around in the chemical stash, I rediscovered a half full gallon of Evapo-Rust. Deciding that this would be as good a test as any, I cleaned out my S/S bowl that I use for Rust Mort, put the hub in it, and poured in just enough of the Evapo to cover the lower flange and part of the hub's central barrel. Soaked a heavy blue paper hand towel to cover the exposed end and then covered the whole bowl with a sheet of saran wrap. Left it to sit for a day or two, went back, swapped ends to get the other end submerged, and repeated the whole process.

And, after rinsing it off and using the air gun to get into all the cracks and crevises and air dry it all out. this is what I was left with. One, only, late 1947-1953 Indian Chief, Motocycle wheel hub. it still needs some wire wheel work to remove the last vestiges of the paint from the flanges but the paint on the central body or barrel of it is almost intact and nearly brand new. if the need was urgent, this could be just sanded to feather down the remaining paint, shot in primer, final sanded and primer sealed, and then color shot .

So, okay, you may have to get out your reading glasses for this but this final shot is a close up of the wheel bearings post swim. As a test of sorts, using a paper towel driven by one of my fingers, I attempted to spin the bearings, and they spun; fairly freely in fact. Again, in a state of emergency, they could be left as is and re-used. However, although the close up doesn't show it, they are marked; no rust or nicks, but a lot of rolling wear scuffing that is a sure sign of age. This wheel did come to me as an alleged survivor and, for the most part, the allegation was true. Since the hub is on the bench, it will get dismantled. The retaining clip is already gone so flipping the hub over and drifting the bearing assembly out as a unit is fairly easy. That gives me the roller bearing still loaded into their cages and inserted into the outer bearing shell, along with the inner and outer thrust washers and grease seal, all in one package. I have new units on the shelf and, if the cages are intact and undamaged, I can also just buy new rollers the same dia as what was in there and reload the cages. Same for the thrust washers, although they mean making a call to Greer's to see if they have new ones in stock. I don't like reusing the old ones even though they may appear pristine; they are still as much as 70 years old, and I know what shape I am in for a 70 year old.

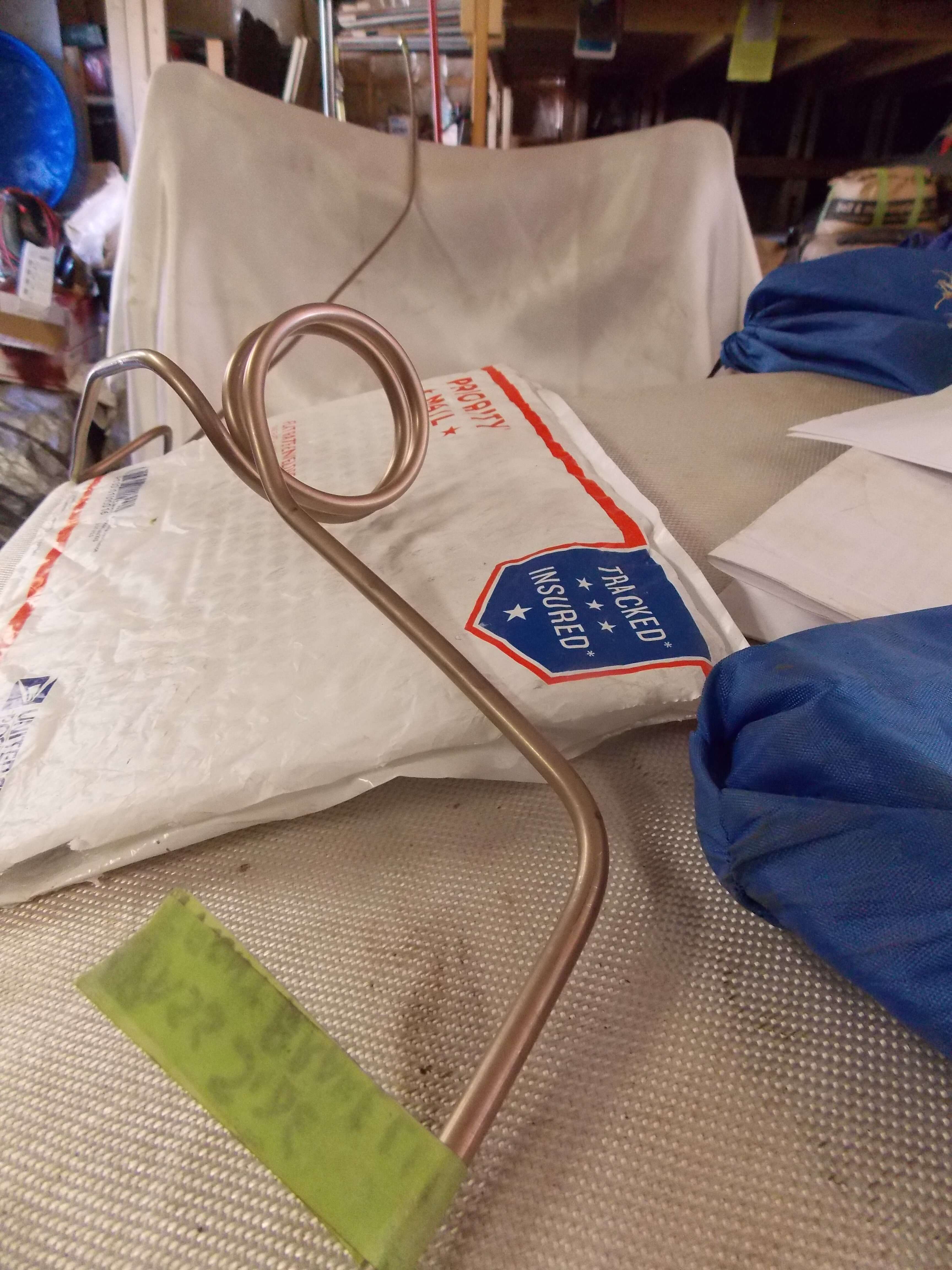

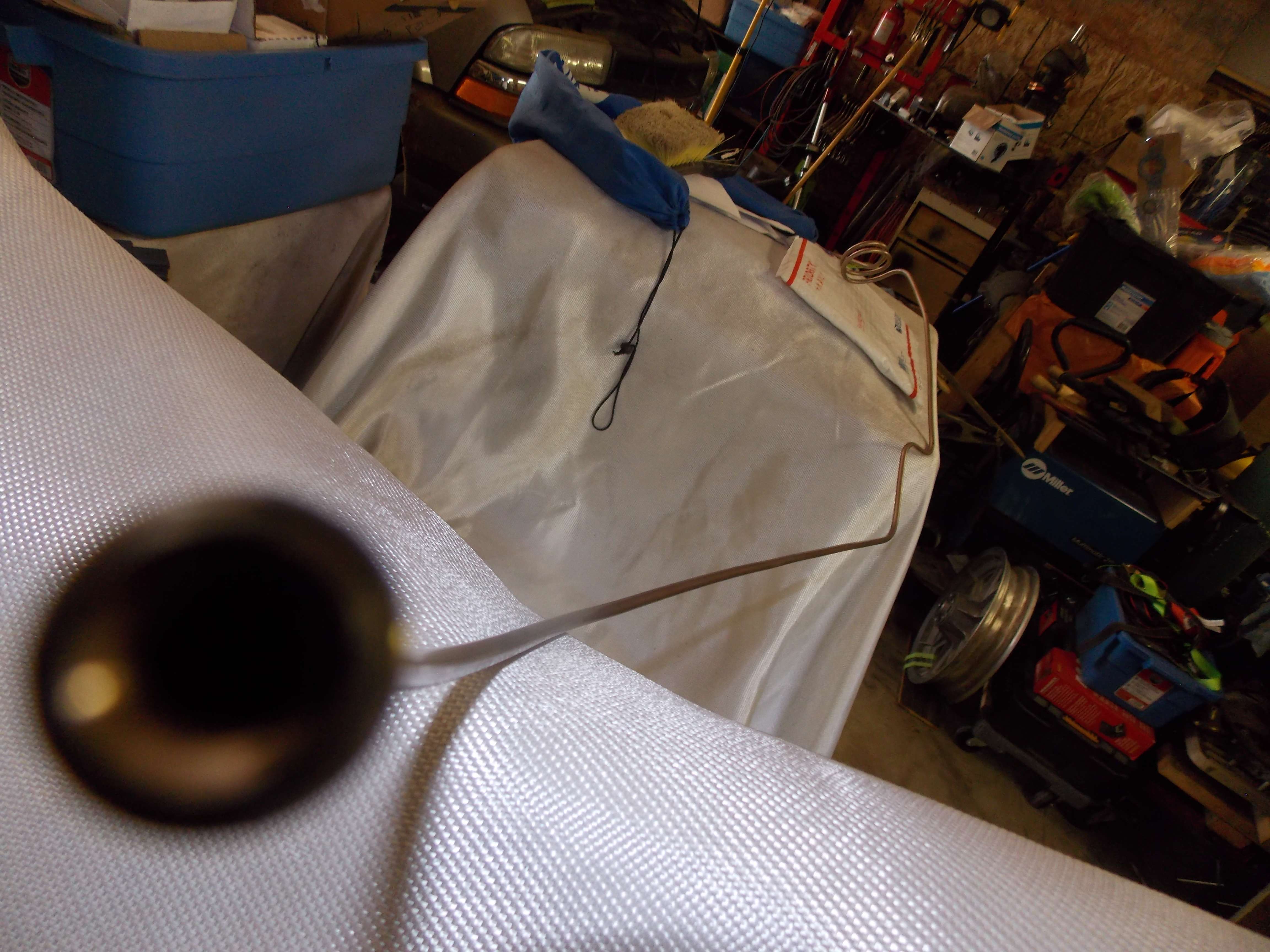

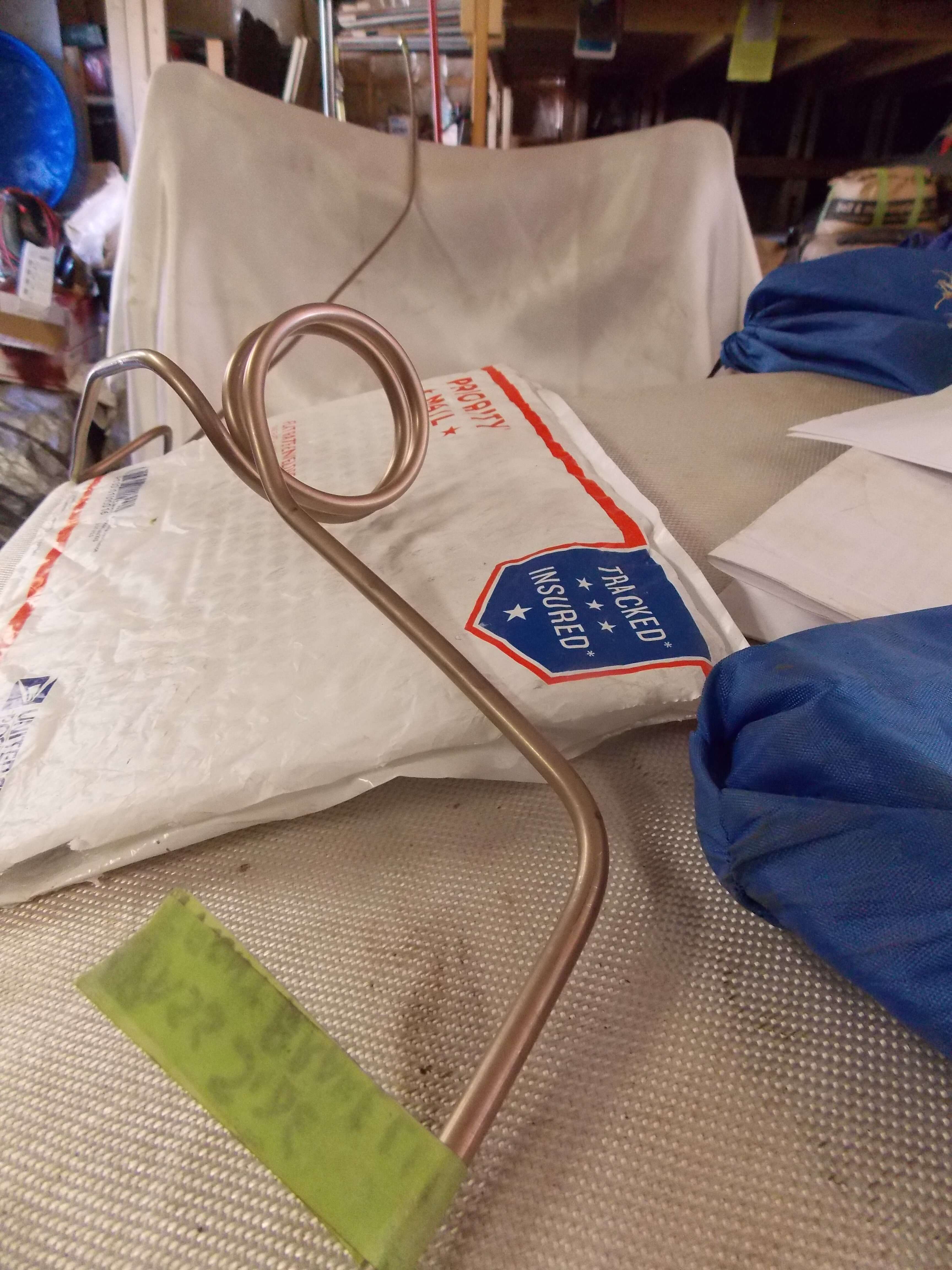

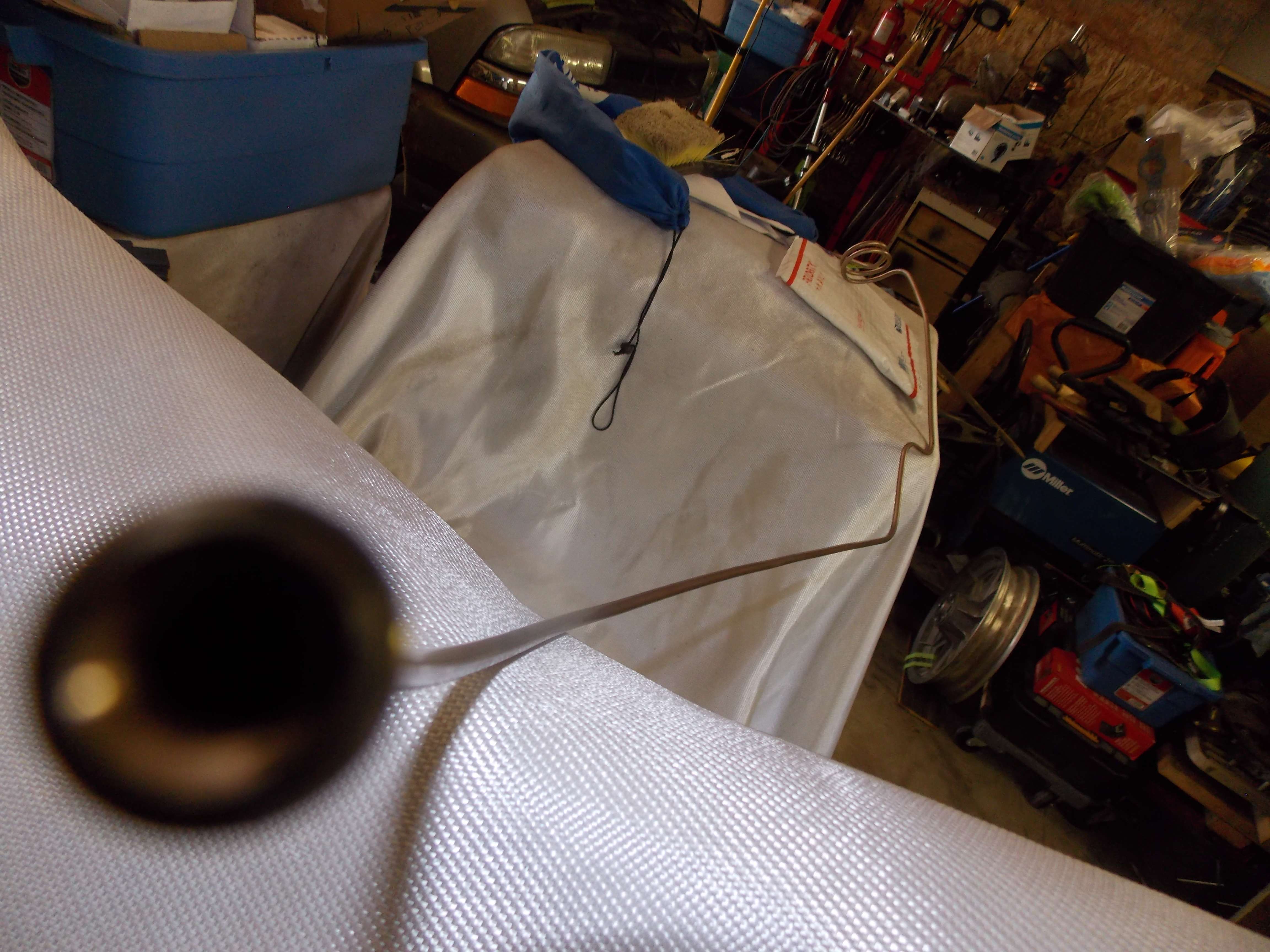

Finally, a shot or two of the new front passenger's side brake line. For the curious, this is not being created from steel tube; what you see here is Ni-Copp, or Nickel Copper alloy tubing. I've mentioned it before as my option of choice for this work. The advantages to it are longer useable life, greater resistance to damage and rust, plus, for the visual effect up in the engine bay, the copper finish makes the installation look more professional and neat. The down sides to it are that it can't be bent as tight in terms of curves or angles, you need to make the bends shallower over a longer distance to avoid kinking. That said, the spiral in the picture has a 2.5 inch diameter and it was hand formed pretty much without using a jig or other mechanical assistance. The other aspect is flaring it. Starting and getting the first bend of the double flare even takes more prep work to the tube in order for it to accept the flaring insert and get a consistent edge to form. The tube itself both has to be deburred internally and I use a fine tooth rat-tail file for that, but the outer edge also has to be chamfered from a square cut to about 30-45 degrees by eyeball. This step is necessary as having the chamfer both lets the flaring adapter centre in the tube better but the tapered edge actually tracks the shoulder cut into the adapter better and diminishes the chance of the adapter tracking off centre and buggering the initial bend. Once the flare is off centre to start, that is where it will finish and then the next step is get out the tubing cutter and amputate the corpse so you can try again.

The final thing I found out along the way was that the flaring clamp that holds the tube likes it if it is sitting flat when in the vise. That also helps the adapter to lay flat and centered for the initial squeeze.

At this point the line is only semi-shaped. i am going to wait until i can get it stuffed more or less into where i want it and where it ought to be before i create the final bends and curves. I may not end up using the stock tubing clamps to secure the line as they are the work of the devil (engineers) and the amount of effort needed to create the factory bends to access them is hazardous to the physical health and well being of the tube.!! As an alternative, I can go with the "P" style of tubing clamp like the G-bodies used and get it in either stainless or aluminum with the rubber anti-chafe liner. They would take drilling a couple of holes but, Hey, I do happen to have an air drill. Hee, hee, hee.

Nick