liquidh8

Comic Book Super Hero

Awesome, I fixed my other post, yes, the auto correct kills me at times.

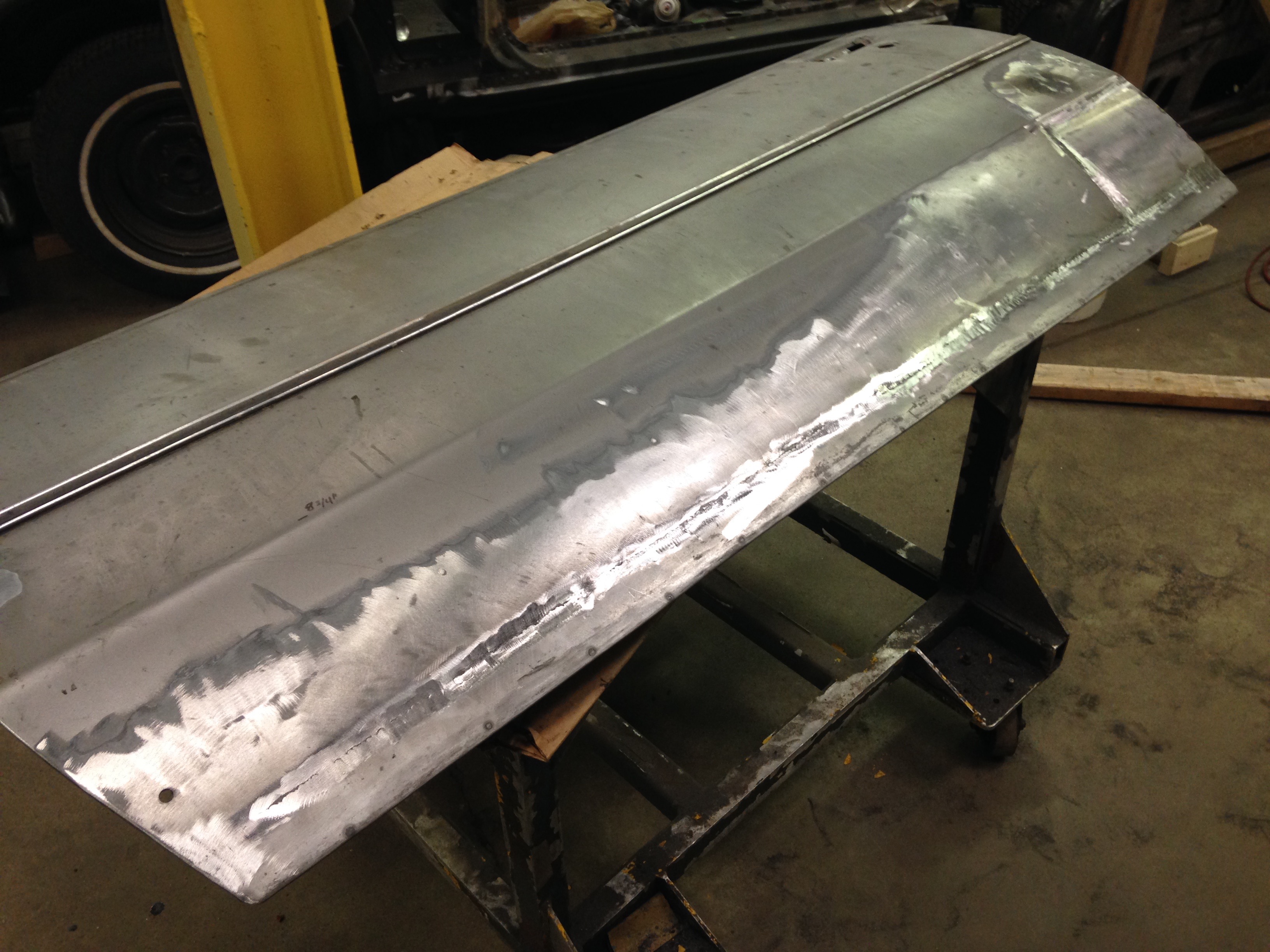

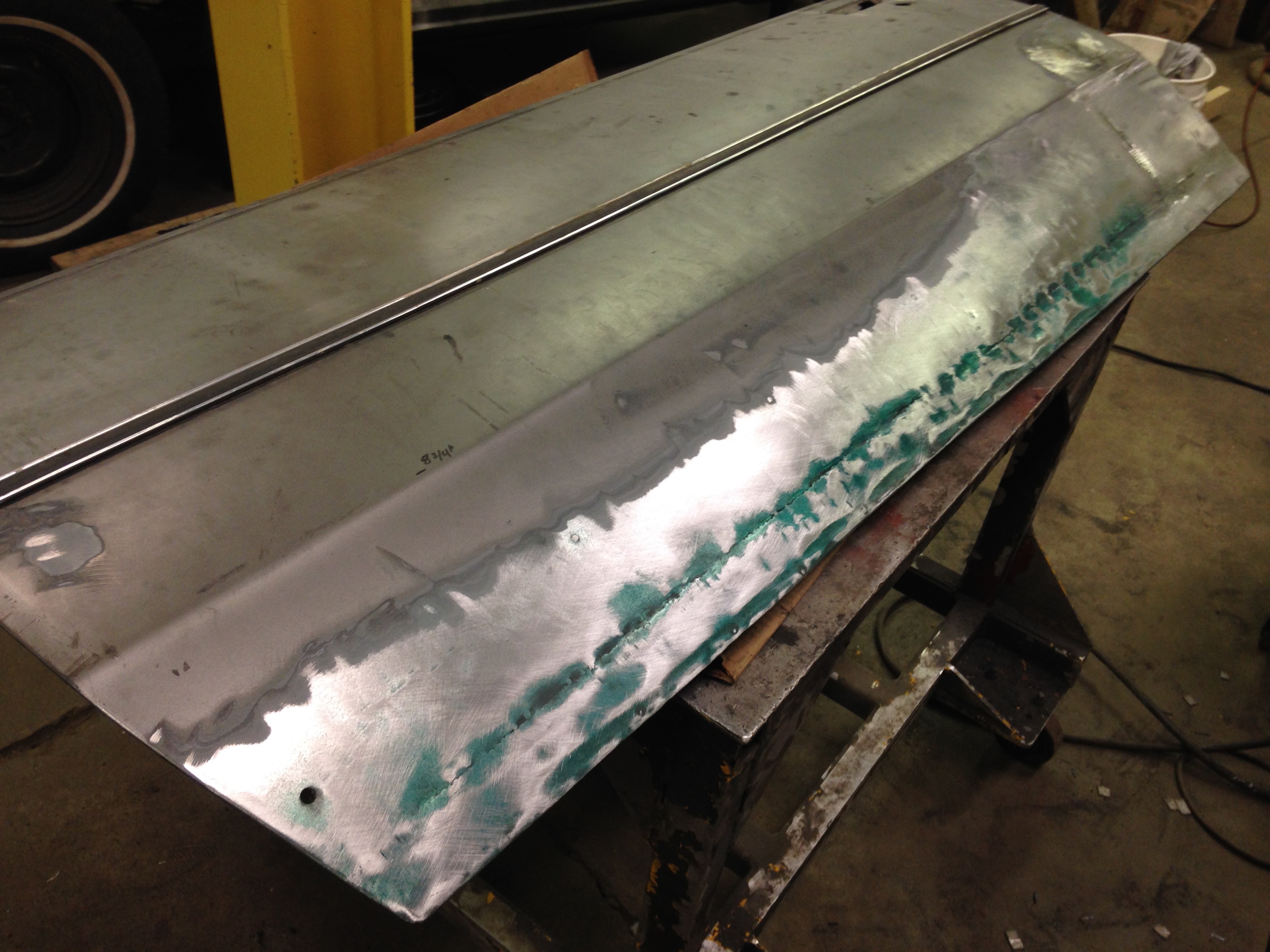

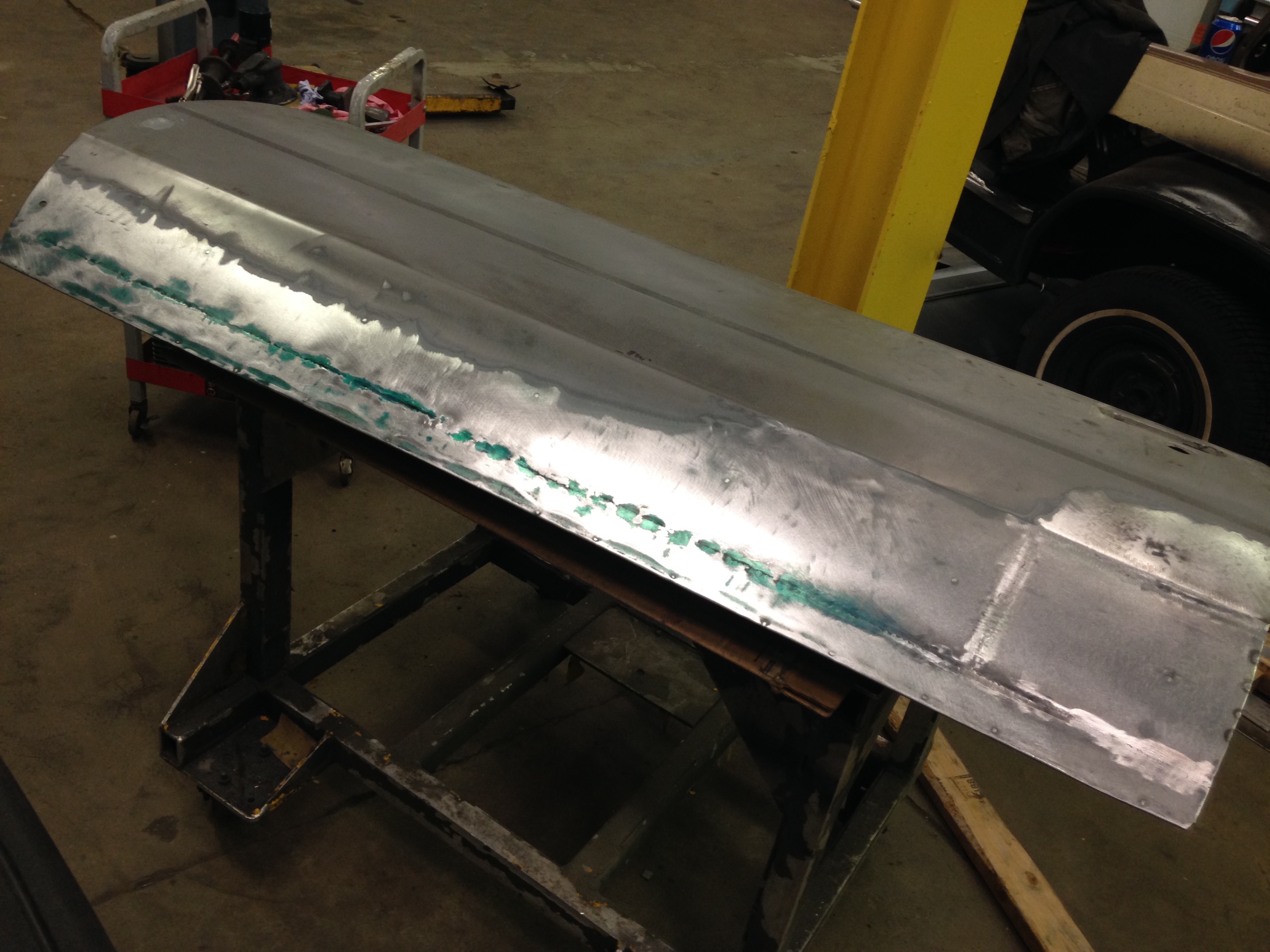

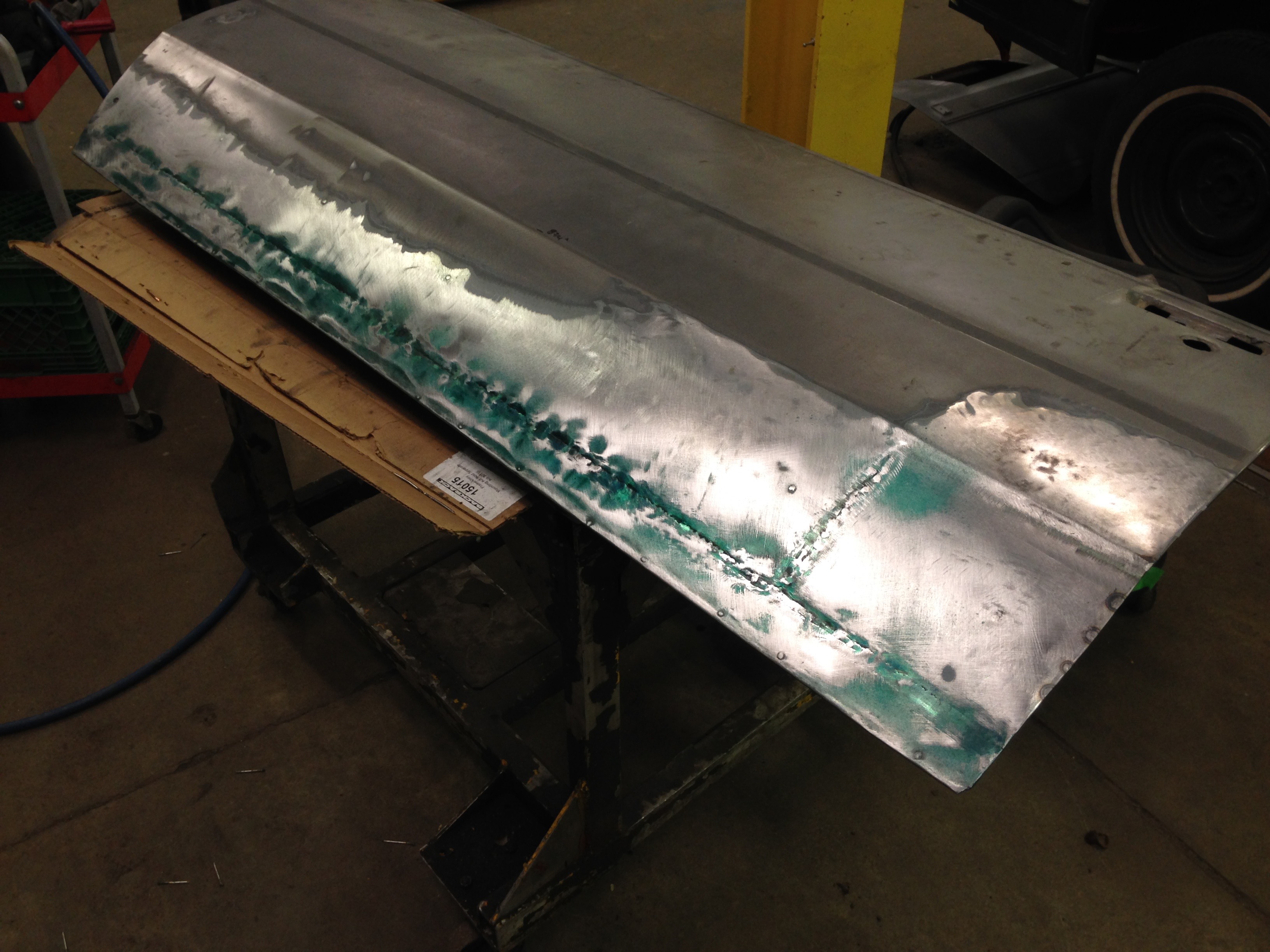

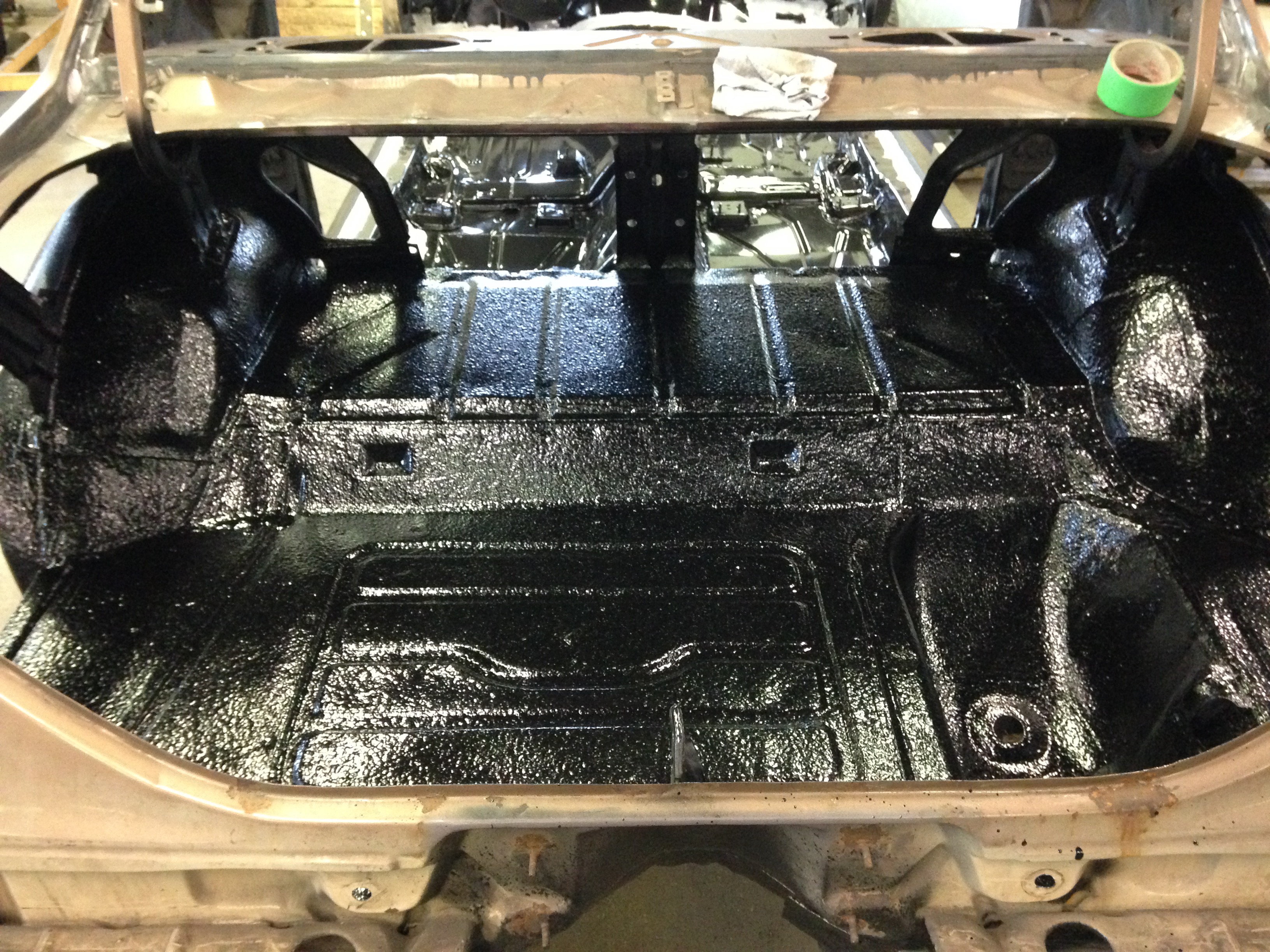

Glad you were able to sort it out, it's looking good great!

Glad you were able to sort it out, it's looking good great!

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.