BUILD THREAD “The Juggernaut”

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yeah Jack, it definitely helps with the 'ol inspiration factor!

But more importantly, it helps clarify what the car would look like finished. Paint materials are too damn expensive to be playing trial and error with. It's nice to see how the car would look in a finished state, and if the colours I have in mind would go well together.

Personally, I'm liking the potential results based on the rendering, what say you all??

Yay or nay?

Like two two tone or hate it?

Like the two colours together, or not so much?

Weigh in with your feedback here, and let me know what y'all think.

Thanks

Color combination looks killer Donovan. It will look even better when its all painted and detailed!

Keep the updates coming!

Chevy

Donovan

Opie Knievel

Rum Fueled Midnight Mechanic and Moderator

I love the grille, headlight and headlight bezel mods. The front end of the Juggernaut is poppin' now!! Its brilliant, gleaming, new chrome jumps out and grabs you. While at the same time, when you take a closer look, the changes seem so subtle. "Wait, didn't the Cutlass this year model have dual sealed beam headlights on each side?", "Wow, that grille looks REALLY GOOD.!!".

I haven't been on here as much as I usually am lately. When I saw that I was 5 pages behind on your updates, I was afraid that I was missing out on something really good and I was right! Great work as always Donovan. I can't wait to see what's next.

I haven't been on here as much as I usually am lately. When I saw that I was 5 pages behind on your updates, I was afraid that I was missing out on something really good and I was right! Great work as always Donovan. I can't wait to see what's next.

Looks good Donovan!

I was drooling looking at those grilles all taped up...

I used to do all that stuff at the resto shop, so I can sympathize how much time you have into them!

Unmasking them was my favorite part!!

I was drooling looking at those grilles all taped up...

I used to do all that stuff at the resto shop, so I can sympathize how much time you have into them!

Unmasking them was my favorite part!!

Hey guys, back again for another update, so get comfy!

As most of you that are familiar with me and the 'Naut probably already know, when I get quiet here on the forum, it usually means I'm hard at work on something. Well, you'd be absolutely right, and lately has been no different. As it's name implies, progress on the Juggernaut never truly stops! So here goes...

To be honest, I was actually a little apprehensive about writing and posting this update.

Quite recently I read a thread on here where the conversation gravitated towards talking about lowered G's and big wheels. Both of which I have, the car is on air ride, and the wheels are 18"ers.

In that thread, I was somewhat surprised and taken aback when several members started slamming lowered G bodies and the big wheel look. I wasn't at all prepared for the negative comments on the subject!

It wasn't directed towards my car mind you, but it still surprised me nonetheless. The Juggernaut isn't among the lowest of the low, nor does it have the 24 and 26" wheel look of certain "other" G's out there, but it struck a nerve anyways for some reason. Hence my hesitation and apprehension on posting this particular update, since it has to do directly with lowered suspension...

But, at the end of the day, it's my car and its what I want, so the haters can just suck it up and deal with it. No ones forcing you to read this or like the direction I've taken with the car, so if anyone doesn't like it, there's the door; you're name's on the knob!

Lol

Anyways, here's what's been happening in the "toybox" as of late.

While I've previously touched on and had the AccuAir air management system for a couple of years now, the system hasn't been fully installed and functioning up to this point. There's been several factors for this, primarily because considerable fabrication had to take place and be completed in the trunk and on the rear suspension to get to the point where I could start finalizing the air management and functionality end of things.

After the successful completion of the grilles and headlight bezels, I dove right into working towards rectifying that.

All the air lines under the car are stainless steel hardlines front to back with the exception of the front where there are short sections of high pressure flexible braided stainless hoses that attach directly to the front shockwaves for some forgiveness in movement. All this was completed some time ago, but where the current problem lay was where the hardlines needed to connect to the bulkhead connectors that come through the trunk floor.

The hardlines were purposely cut and left long while the body was still off the frame last. With the body back on, I now knew where the lines needed to be trimmed to, but there was a lack of room to spin the tube cutters to actually accomplish the task.

I overcame this hurdle by swapping my sharp stainless cutting wheel from my regular sized cutters over to a cheap "mini" cutter. It still took a bit of effort, but it was just the ticket. Once the lines were trimmed to the proper length, I was able to slide on the tube nuts and sleeves, and make the necessary 37 degree flares on the ends of the tubes.

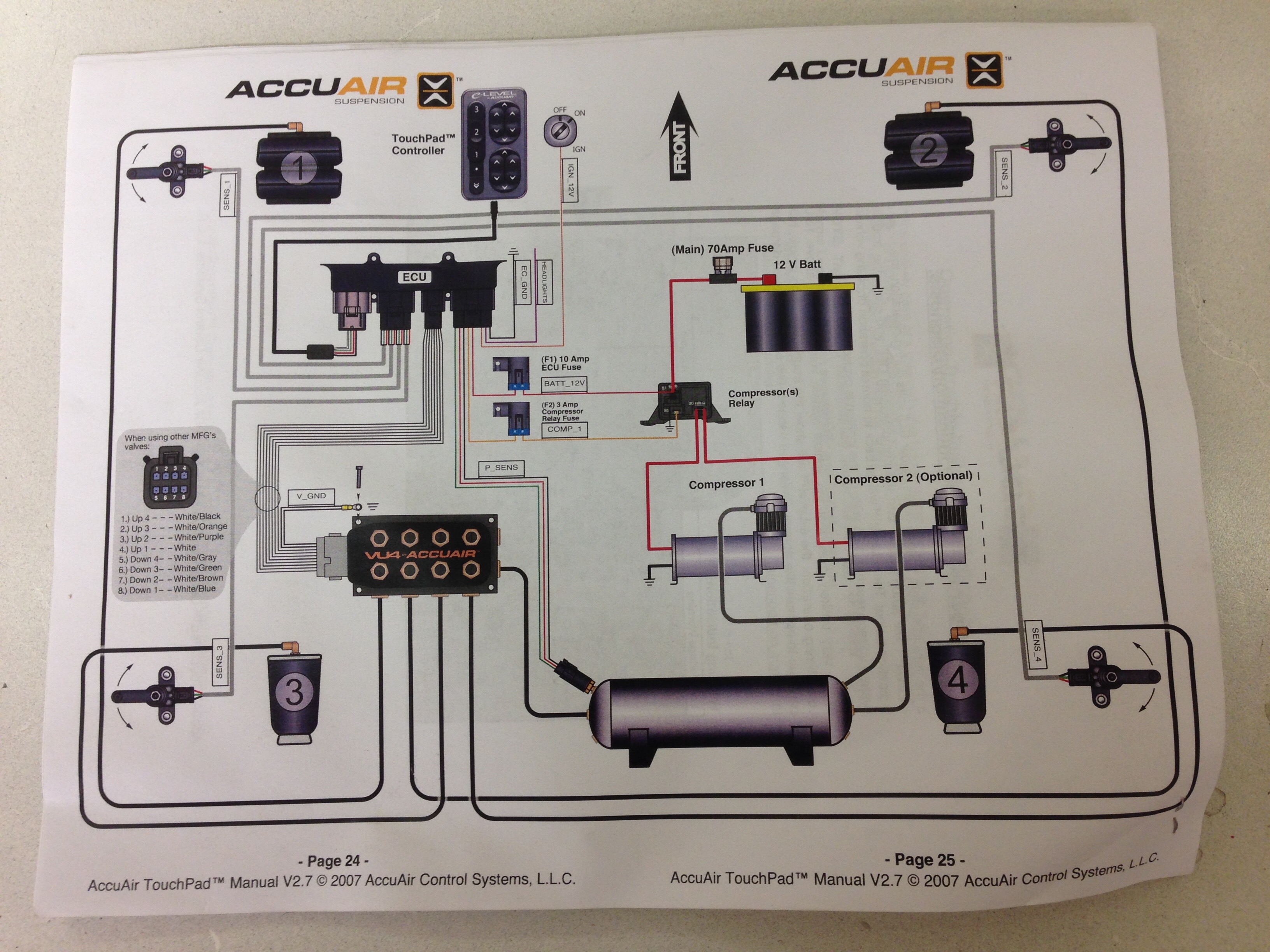

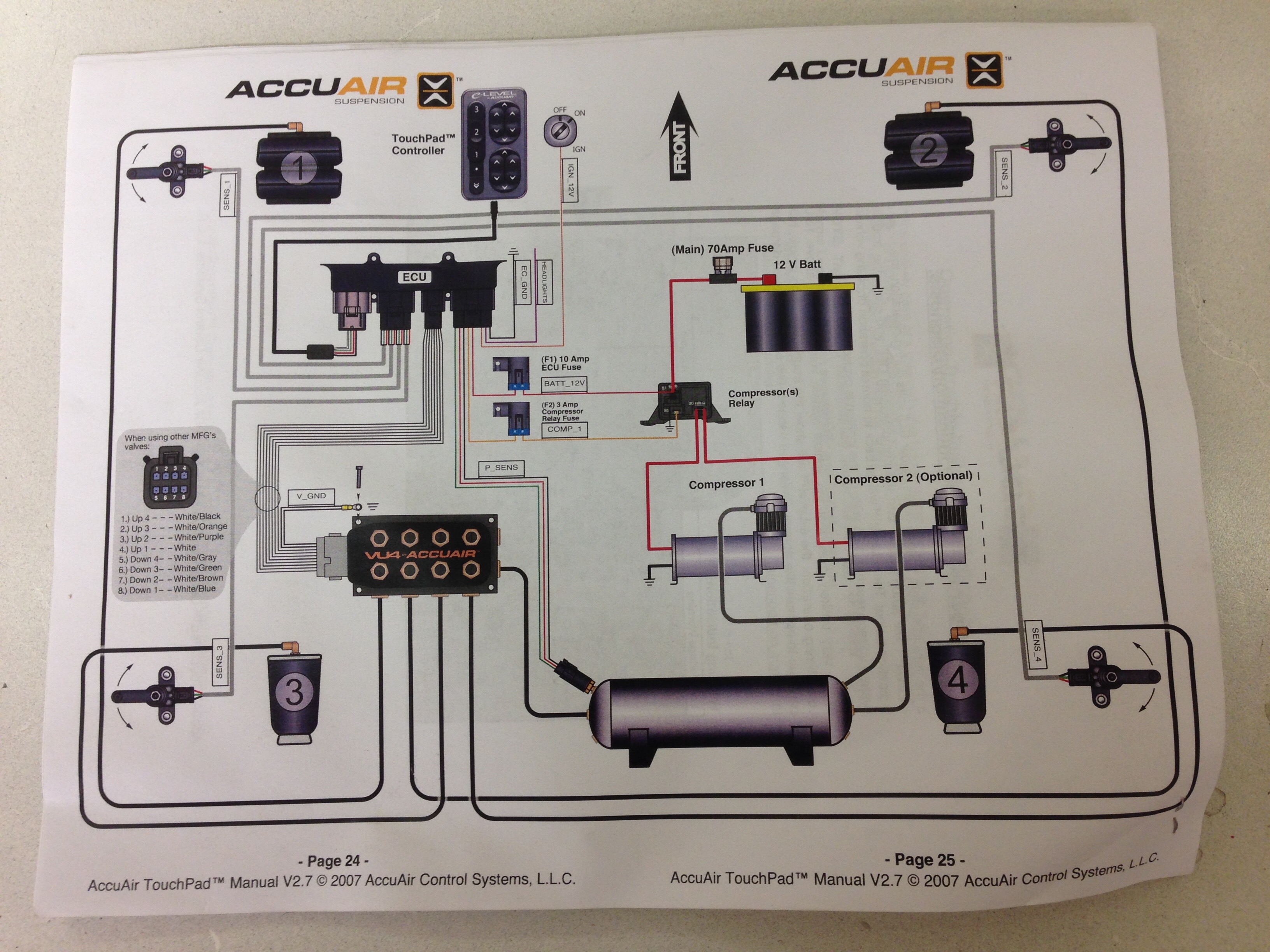

With the final work completed on the pneumatic side of things, I needed to get onto the electrical. While not difficult, the wiring needed to be just as carefully thought out and planned as the rest of the car. After some careful thinking and experimenting with different options, I decided to mount the compressor relay (which is central and primary for pretty much everything) to the back of my custom built rear firewall. Here's the schematic of what needed to happen:

I traced out the mounting flange of the relay onto some 1/8" flat plate and cut it out. I then drilled and tapped the holes to accept the stainless button head fasteners I'm using throughout the car. With this done, I plug welded the plate about 2" above the trunk floor to the backside of the firewall. It needed to be welded as any fasteners I used would show directly on the frontside of the firewall, unacceptable!

2" above the trunk floor was chosen to keep the relay hidden behind the tank and compressors, yet keep the wiring fairly close to the trunk floor. (Sorry, no pics!)

With the relay mounted to the new plate, laying out of the wiring could begin. A 7/8" hole and a grommet were drilled and installed far under the package tray through the passenger's side upper inner wheelhouse flange for the 4 gauge power wire and 70 amp fuse to run through to the trunk mounted battery.

Another 7/8" hole was drilled in the trunk floor and grommet installed directly under the air tank for the ride height sensor wires to pass through to the underside of the car. With this done, all the wires were sleeved with some bulk "split braided sleeving" from a local electronics supply store, and terminal ends were crimped and soldered on.

The spilt braided sleeving:

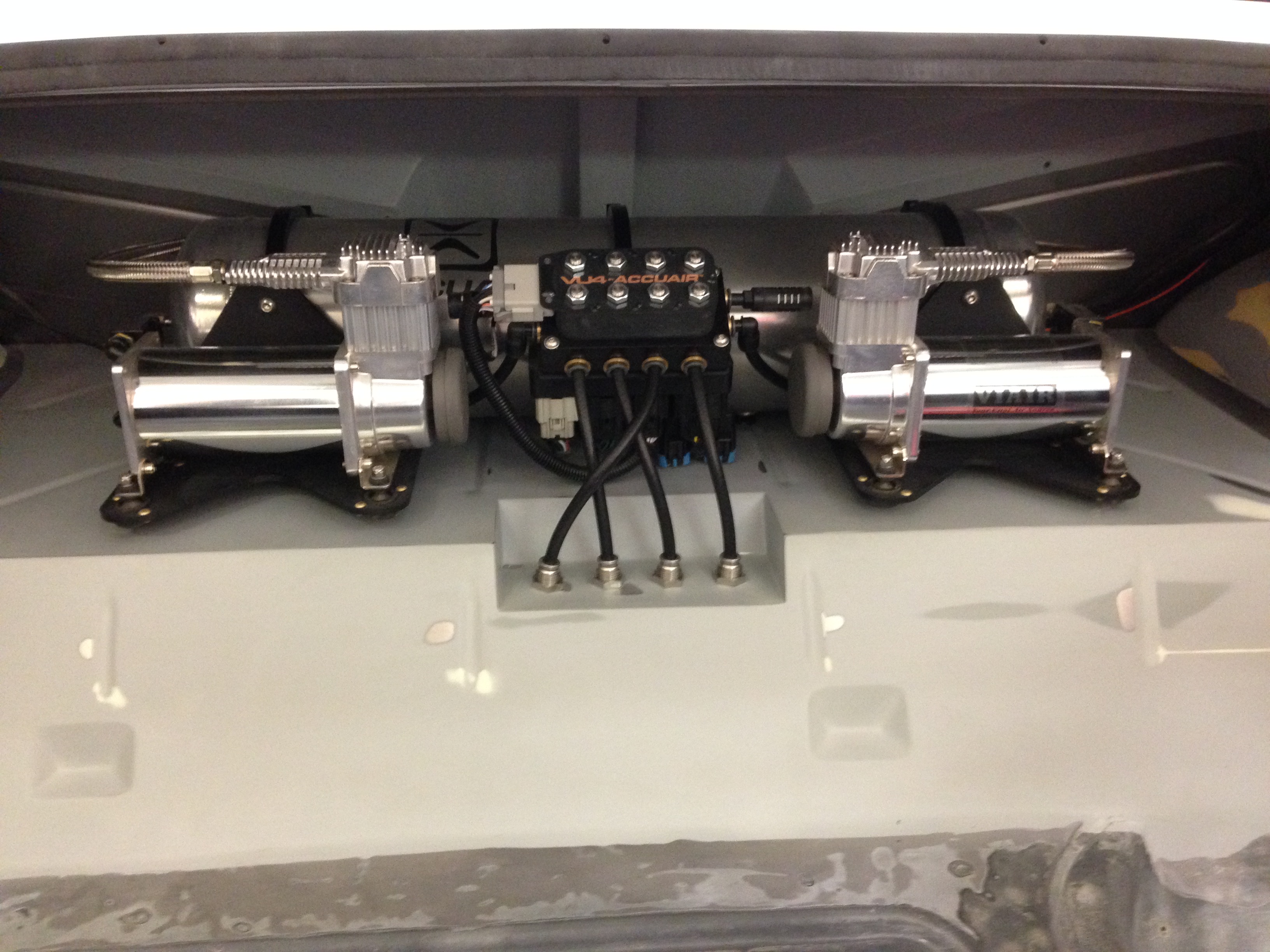

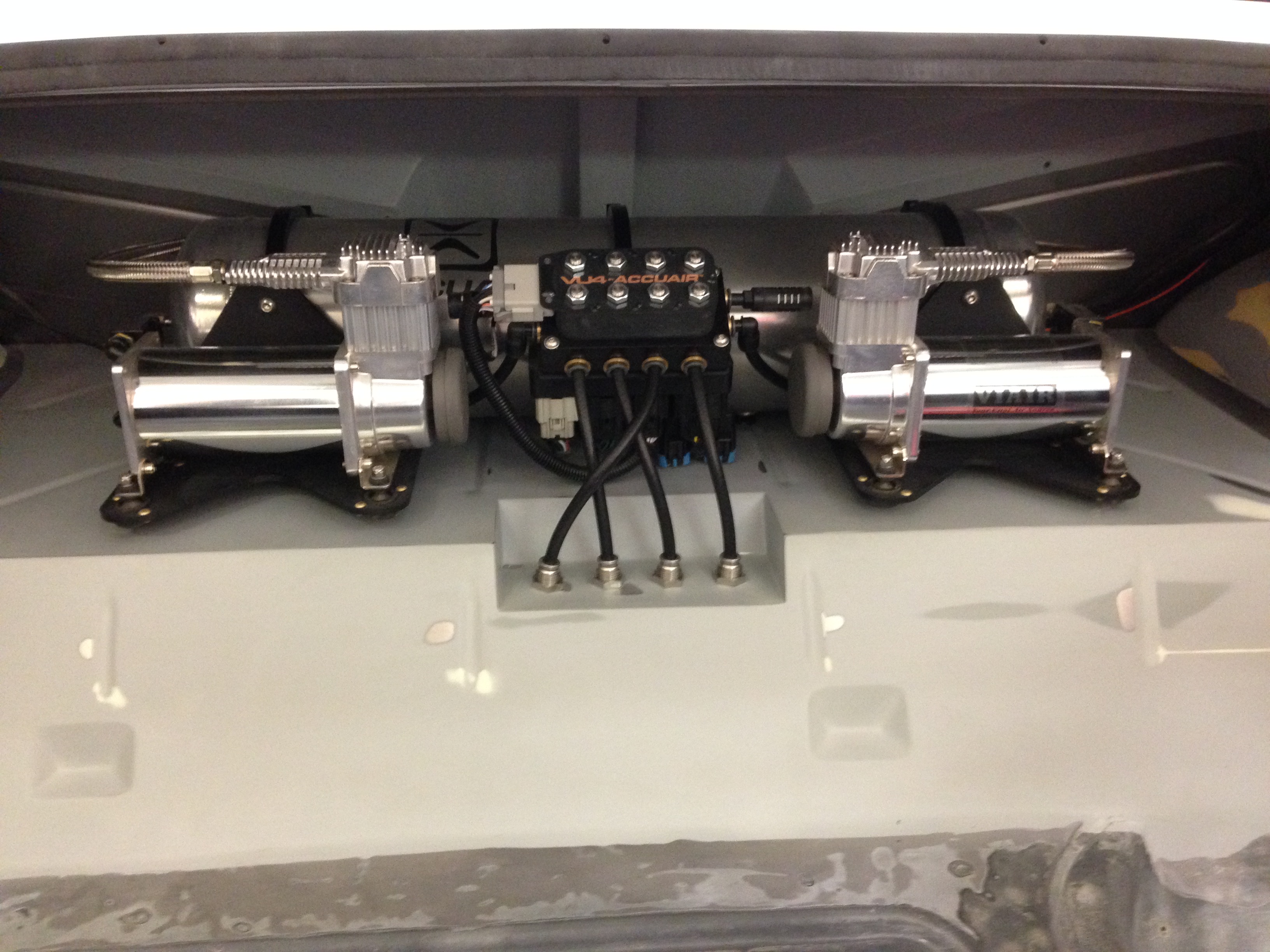

With this completed, the tank and compressors were reinstalled, and the wiring was plugged into the ECM. The power and ground wires from the compressors were connected to the relay, and the pneumatic lines were reconnected again as well. The Optima battery was dropped back into its mount in the spare tire well, and a temporary ground was run to the body.

Here's the install with everything connected. (Note, the trunk floor still isn't painted or finished, there's more work to be done there before I can get to that point. This exercise is just to get the air hooked up and working on its own).

Hopefully you'll note the absence of much visible wiring at the compressors, that's kind've been my signature trademark for many years. It's pretty tough to make wiring look good and/or clean, so I try to hide it altogether whenever possible.

With the wiring and pneumatics all connected, it was time for the moment of truth! I plugged in the controller, connected the main power cable and switched 12 volt wire and presto! Running compressors!

I nervously watched and monitored the compressors, and as intended, they cut out automatically once they hit pressure (determined by an in-tank pressure sensor).

Time to start playing...

I should mention here, that this is just the initial test run of the equipment; just to make sure that the wiring, ECM, and pneumatics all function as they're intended. My particular AccuAir air management system incorporates what AccuAir calls "E Level". This means the system uses ride height sensors (basically fancy potentiometers) mounted at each corner that read ride height and relay the info back to the ECM for adjustments to the ride height (within a 1/16 of an inch at each corner!) These sensors and their related components are still to be installed.

This means, as you add fuel, luggage, cargo, or your "hefty" friend into the car, the ECM will automatically compensate for it, and re-level the car. AccuAir calls this a "semi-real time" application. Adjustments to ride height to level are only automatically made after 45 seconds, so that it doesn't happen while driving which could lead to unexpected and dangerous changes to handling characteristics.

Anyways, I rarely take videos of stuff, but I figured if there was ever a time to do it, it was now! Unfortunately for me however, the site here won't let me upload the vid, it's too big apparently.

I'm not about to go through the rigmarole of signing up with YouTube and jumping through their hoops just to post a short crude video of me playing around with the air, so you're all going to have to make due with some pics I guess. Sorry guys.

Anyways, here they are. First time the car has EVER been up and supported on its own accord!

It's a shame that I can't upload the video, I even tried taking a super short one about 8 seconds long, but the site always says the files are too big. There's nothing quite like seeing it do it's thing in person!

In case the pics don't quite convey it, the car sits VERY low for a G body when aired down completely. For comparison, the famed Ford GT40 from the sixties got its name from its 40" roof height. The roof height of The Juggernaut is between 50 and 51" (difficult to tell due to the roof curvature) when aired out!

It's not "laying frame" or rocker panel like the trucks do, but that's plenty low for a G body and pretty respectable I'd say.

Overall, there's about 5" of travel at the rear, and 6" at the front. More than enough to make a dramatic statement and altitude/attitude change!

Anyways, that's about it for now. Once the novelty of being able to play around with the compressors and ride height wears off a bit, I'll put the car up on stands and remove the wheels to begin the ride height sensor installation.

That'll be a whole 'nother update all on its own.

Thanks for checking in on the progress as usual everyone!

D.

P.S. - I have a couple more pics, some with a tape measure for reference and idea of heights that I didn't post here. Let me know if you guys want to see those, or of any different angles etc. I'd be happy to accommodate if there's interest.

As most of you that are familiar with me and the 'Naut probably already know, when I get quiet here on the forum, it usually means I'm hard at work on something. Well, you'd be absolutely right, and lately has been no different. As it's name implies, progress on the Juggernaut never truly stops! So here goes...

To be honest, I was actually a little apprehensive about writing and posting this update.

Quite recently I read a thread on here where the conversation gravitated towards talking about lowered G's and big wheels. Both of which I have, the car is on air ride, and the wheels are 18"ers.

In that thread, I was somewhat surprised and taken aback when several members started slamming lowered G bodies and the big wheel look. I wasn't at all prepared for the negative comments on the subject!

It wasn't directed towards my car mind you, but it still surprised me nonetheless. The Juggernaut isn't among the lowest of the low, nor does it have the 24 and 26" wheel look of certain "other" G's out there, but it struck a nerve anyways for some reason. Hence my hesitation and apprehension on posting this particular update, since it has to do directly with lowered suspension...

But, at the end of the day, it's my car and its what I want, so the haters can just suck it up and deal with it. No ones forcing you to read this or like the direction I've taken with the car, so if anyone doesn't like it, there's the door; you're name's on the knob!

Lol

Anyways, here's what's been happening in the "toybox" as of late.

While I've previously touched on and had the AccuAir air management system for a couple of years now, the system hasn't been fully installed and functioning up to this point. There's been several factors for this, primarily because considerable fabrication had to take place and be completed in the trunk and on the rear suspension to get to the point where I could start finalizing the air management and functionality end of things.

After the successful completion of the grilles and headlight bezels, I dove right into working towards rectifying that.

All the air lines under the car are stainless steel hardlines front to back with the exception of the front where there are short sections of high pressure flexible braided stainless hoses that attach directly to the front shockwaves for some forgiveness in movement. All this was completed some time ago, but where the current problem lay was where the hardlines needed to connect to the bulkhead connectors that come through the trunk floor.

The hardlines were purposely cut and left long while the body was still off the frame last. With the body back on, I now knew where the lines needed to be trimmed to, but there was a lack of room to spin the tube cutters to actually accomplish the task.

I overcame this hurdle by swapping my sharp stainless cutting wheel from my regular sized cutters over to a cheap "mini" cutter. It still took a bit of effort, but it was just the ticket. Once the lines were trimmed to the proper length, I was able to slide on the tube nuts and sleeves, and make the necessary 37 degree flares on the ends of the tubes.

With the final work completed on the pneumatic side of things, I needed to get onto the electrical. While not difficult, the wiring needed to be just as carefully thought out and planned as the rest of the car. After some careful thinking and experimenting with different options, I decided to mount the compressor relay (which is central and primary for pretty much everything) to the back of my custom built rear firewall. Here's the schematic of what needed to happen:

I traced out the mounting flange of the relay onto some 1/8" flat plate and cut it out. I then drilled and tapped the holes to accept the stainless button head fasteners I'm using throughout the car. With this done, I plug welded the plate about 2" above the trunk floor to the backside of the firewall. It needed to be welded as any fasteners I used would show directly on the frontside of the firewall, unacceptable!

2" above the trunk floor was chosen to keep the relay hidden behind the tank and compressors, yet keep the wiring fairly close to the trunk floor. (Sorry, no pics!)

With the relay mounted to the new plate, laying out of the wiring could begin. A 7/8" hole and a grommet were drilled and installed far under the package tray through the passenger's side upper inner wheelhouse flange for the 4 gauge power wire and 70 amp fuse to run through to the trunk mounted battery.

Another 7/8" hole was drilled in the trunk floor and grommet installed directly under the air tank for the ride height sensor wires to pass through to the underside of the car. With this done, all the wires were sleeved with some bulk "split braided sleeving" from a local electronics supply store, and terminal ends were crimped and soldered on.

The spilt braided sleeving:

With this completed, the tank and compressors were reinstalled, and the wiring was plugged into the ECM. The power and ground wires from the compressors were connected to the relay, and the pneumatic lines were reconnected again as well. The Optima battery was dropped back into its mount in the spare tire well, and a temporary ground was run to the body.

Here's the install with everything connected. (Note, the trunk floor still isn't painted or finished, there's more work to be done there before I can get to that point. This exercise is just to get the air hooked up and working on its own).

Hopefully you'll note the absence of much visible wiring at the compressors, that's kind've been my signature trademark for many years. It's pretty tough to make wiring look good and/or clean, so I try to hide it altogether whenever possible.

With the wiring and pneumatics all connected, it was time for the moment of truth! I plugged in the controller, connected the main power cable and switched 12 volt wire and presto! Running compressors!

I nervously watched and monitored the compressors, and as intended, they cut out automatically once they hit pressure (determined by an in-tank pressure sensor).

Time to start playing...

I should mention here, that this is just the initial test run of the equipment; just to make sure that the wiring, ECM, and pneumatics all function as they're intended. My particular AccuAir air management system incorporates what AccuAir calls "E Level". This means the system uses ride height sensors (basically fancy potentiometers) mounted at each corner that read ride height and relay the info back to the ECM for adjustments to the ride height (within a 1/16 of an inch at each corner!) These sensors and their related components are still to be installed.

This means, as you add fuel, luggage, cargo, or your "hefty" friend into the car, the ECM will automatically compensate for it, and re-level the car. AccuAir calls this a "semi-real time" application. Adjustments to ride height to level are only automatically made after 45 seconds, so that it doesn't happen while driving which could lead to unexpected and dangerous changes to handling characteristics.

Anyways, I rarely take videos of stuff, but I figured if there was ever a time to do it, it was now! Unfortunately for me however, the site here won't let me upload the vid, it's too big apparently.

I'm not about to go through the rigmarole of signing up with YouTube and jumping through their hoops just to post a short crude video of me playing around with the air, so you're all going to have to make due with some pics I guess. Sorry guys.

Anyways, here they are. First time the car has EVER been up and supported on its own accord!

It's a shame that I can't upload the video, I even tried taking a super short one about 8 seconds long, but the site always says the files are too big. There's nothing quite like seeing it do it's thing in person!

In case the pics don't quite convey it, the car sits VERY low for a G body when aired down completely. For comparison, the famed Ford GT40 from the sixties got its name from its 40" roof height. The roof height of The Juggernaut is between 50 and 51" (difficult to tell due to the roof curvature) when aired out!

It's not "laying frame" or rocker panel like the trucks do, but that's plenty low for a G body and pretty respectable I'd say.

Overall, there's about 5" of travel at the rear, and 6" at the front. More than enough to make a dramatic statement and altitude/attitude change!

Anyways, that's about it for now. Once the novelty of being able to play around with the compressors and ride height wears off a bit, I'll put the car up on stands and remove the wheels to begin the ride height sensor installation.

That'll be a whole 'nother update all on its own.

Thanks for checking in on the progress as usual everyone!

D.

P.S. - I have a couple more pics, some with a tape measure for reference and idea of heights that I didn't post here. Let me know if you guys want to see those, or of any different angles etc. I'd be happy to accommodate if there's interest.

Donovan. Thanks for the update. It's always a treat. You are as meticulous with your updates as you are with your work. I wish I had half the talent or creativity you have. Amazing work as always. Your build is really high end like the show cars in the magazines but you are doing it all in a two car garage. It's truly inspirational. Looking forward to the next installment.

Donovan. Thanks for the update. It's always a treat. You are as meticulous with your updates as you are with your work. I wish I had half the talent or creativity you have. Amazing work as always. Your build is really high end like the show cars in the magazines but you are doing it all in a two car garage. It's truly inspirational. Looking forward to the next installment.

Thank you Jared, I'm truly flattered.

I don't consider myself any more talented than anyone else on here, but I definitely enjoy the challenges that come up along the way.

I guess the meticulousness is just my nature, I constantly strive for as close to perfection as I can achieve, and am always looking to further enhance my skill set.

I just have these mental images of how I think something should look, and continue down that path until it matches what I envision. The fact that you appreciate the effort that goes into it makes it all the more rewarding at the end of the day.

Thanks again my friend.

Donovan, as Jared already said, the Juggernaut is truly magazine cover worthy! I understand the amount of time it takes to execute a clean, "wiring free" install of components...makes my fingers hurt thinking about it lol!

The layout of the air mechanicals can make or break the install, but you executed it perfectly. Not to mention, the trick little notch made into the trunk ledge to accomodate the airline connections, well done sir!

I've never been a fan of wheels bigger than a 20" on our cars, to each their own, but I've always loved an average size wheel with a lowered stance, or bagged out as i think it looks WAY more aggressive and more "muscle car-ish".

Truly loving it buddy, keep it coming!

Losing my mind here lol! I've always been a sound effects person, and usually am making silly sounds with my kids just to see them giggle! Doing car sounds, jet noises, the sound of boost coming in and blow off valves, etc.

That being said, I'm sitting here on my couch looking at the pics of the Naut airing up and down going "psssssssss" as it's airing out and tucking the tires lol!

That being said, I'm sitting here on my couch looking at the pics of the Naut airing up and down going "psssssssss" as it's airing out and tucking the tires lol!

Losing my mind here lol! I've always been a sound effects person, and usually am making silly sounds with my kids just to see them giggle! Doing car sounds, jet noises, the sound of boost coming in and blow off valves, etc.

That being said, I'm sitting here on my couch looking at the pics of the Naut airing up and down going "psssssssss" as it's airing out and tucking the tires lol!

You're not far off my friend! It makes all those wonderful sounds for sure! One more reason I'm so pissed I can't upload a vid or two!

I used 3/8" lines on the chassis so it's a nice compromise between the slow action you get with 1/4" and the "quick dump" the truck guys love with 1/2" lines.

I did choose to use mufflers on the dump valves tho, as I don't necessarily need to attract any more attention when I air it down.

PSSSSSSHHHHHHHTTTTT!!!!

Nah, I'm good thanks!

Lol

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.