Awesome work Donovan! Thanks again for staying up late and spending so much time on the update!

BUILD THREAD Project Olds Cool (Recognition!!)

- Thread starter Rktpwrd

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hi, Donovan,

Beautiful work. I've been wondering why there's been no noticeable grinding pattern on the roof where the paint has been removed up until now that you've hit it with the 8" 40 grit disc. Am I right to understand that you used an 80 grit on a D/A sander to produce that almost-smooth finish? How long has it been since the paint was removed? Were the spider-track rust spots visible then, or have they shown up in the interim?

I, too, look forward with great anticipation, and bated breath, your next installment! Don't keep us waiting!

Cheers - Gary

Beautiful work. I've been wondering why there's been no noticeable grinding pattern on the roof where the paint has been removed up until now that you've hit it with the 8" 40 grit disc. Am I right to understand that you used an 80 grit on a D/A sander to produce that almost-smooth finish? How long has it been since the paint was removed? Were the spider-track rust spots visible then, or have they shown up in the interim?

I, too, look forward with great anticipation, and bated breath, your next installment! Don't keep us waiting!

Cheers - Gary

I'm enjoying the repair work. You make me want to go buy a welder. As everyone else said..Great work!

I'm enjoying the repair work. You make me want to go buy a welder. As everyone else said..Great work! I see a lot of work where the guy will strip the car to metal and then shoot a couple coats of Epoxy Primer on the bare steel and then body work the panel. Will the All Metal not work with the epoxy under it?

Hutch

Again, great work Donovan!

lookin good! I'm actually hoping to benefit from this writeup, as I was working on "Chief Sh**tting Bull" today, and noticed rot out on the leading glue edge of what's left of the vynil top.... I may not be able to do the steps you're doing, but it's given me insight on what to expect, and at least an idea of a plan of attack.

Darin

Darin

Ive been working 80 hr weeks and I tell ya the best thing about being up at 2 in the morning is getting to read the new posts during my first 4 hours at work lol

Sounds like you're enjoying following along with the updates! Glad to hear it.

Continue to tune in occasionally, and follow along as I progress. Hopefully it'll continue to be (somewhat) entertaining and Gasp! even educational!

Lol

Thanks for the kind words.

Awesome b progress! It looks great Donovan.

I too prefer to sand, grind, or cut out rust.

Sent from my Z981 using Tapatalk

Thanks Jim.

Sometimes it's safer to stay with what you know. I know that if I physically grind it out, there's no chance of it returning. It's more piece of mind in my opinion over using a manufacturers chemical treatment product.

Fantastic work Donovan. I really enjoyed reading the update. I take it there was zero distortion from the welding?

Haha

I knew you were going to ask that!

Correct. As you predicted, there was virtually no distortion from the welding process. In fact, there was more distortion simply due to the fact of having that thin layer of panel bond in between the pieces and the Cleco clamps.

If anything, the entire repair is now slightly low, which I consider a good thing. I'd rather have it a bit low than high, it's easier to hammer and dolly and add more filler if needed than it would be to try and shrink the whole area to bring it back down.

Thanks for acknowledging the hours and effort that goes into composing these updates. I know you can relate with the threads you have on your dad's Galaxie, and Sean's Camaro.

Cheers my friend!

Excellent as always.

Thank you! Appreciate it!

Awesome work Donovan! Thanks again for staying up late and spending so much time on the update!

No problem Kevin, my pleasure.

If those that take the time to read through and follow along can gain tips, tricks, or even simply the confidence to tackle a seemingly daunting task like this, then I consider all my time and effort in posting the progress worthwhile.

After all, I have to do it anyways, why not share my knowledge and experiences with everyone along the way?

Hi, Donovan,

Beautiful work. I've been wondering why there's been no noticeable grinding pattern on the roof where the paint has been removed up until now that you've hit it with the 8" 40 grit disc. Am I right to understand that you used an 80 grit on a D/A sander to produce that almost-smooth finish? How long has it been since the paint was removed? Were the spider-track rust spots visible then, or have they shown up in the interim?

I, too, look forward with great anticipation, and bated breath, your next installment! Don't keep us waiting!

Cheers - Gary

Hi Gary. Thanks for commenting on the thread. It's nice to have you.

I actually mentioned my reasons for sanding off the old paint first rather than grinding earlier on at the start of this undertaking. It's so that I can safely determine the extent of the damaged areas, and "sneak up" on the perimeters of the rusted areas. The paint all has to come off for the repair anyways, so this just makes sense to me.

The other reason for doing so, is that our cars are painted with a lacquer based paint. When you attempt to grind the paint off, I find it just smears with the heat and speed of the grinder. Sanding it off with 80 grit on the DA doesn't do this. It simply removes the paint, and reveals whatever is hiding beneath.

Which brings us to your next couple questions:

Yes, the smooth finish you saw in the pics was the resulting finish left by the 80 grit on the DA.

I've been posting these updates in as near "real-time" as I can, so the paint has only been removed for the last week or so.

The spider-tracking traces of rust actually weren't visible at first, before sanding. They revealed themselves as I sanded the top layers of paint and primer off. Another benefit to sanding the finish off, rather than going straight to grinding. They were the start of rust pitting in the metal underneath. They've since been dealt with, they are no more!

Excellent questions, hopefully I was able to answer them in a way that makes sense to you.

Thanks for contributing to the thread, you may have asked questions that others may have been wondering about.

Donovan

lookin good! I'm actually hoping to benefit from this writeup, as I was working on "Chief Sh**tting Bull" today, and noticed rot out on the leading glue edge of what's left of the vynil top.... I may not be able to do the steps you're doing, but it's given me insight on what to expect, and at least an idea of a plan of attack.

Darin

Thanks Darin.

Hopefully you don't find the same damage and to the same extent as I did, but like you say, at least you know what to possibly expect.

If you expect the worst, you'll either be validated, or pleasantly surprised!

Thanks for the kind words. I hope this documentation can indeed be of benefit to you!

Thanks everyone again, for all the great comments, likes, and support.

You guys are the best.

Donovan

Hutch gets his own response simply due to the complexity of his question, and the extended answer:

Thank you Hutch!

Go buy that welder man, and start playing! It's a pretty cool feeling to be able to melt steel with fire!

(Paraphrasing Tim Taylor from Home Improvement) ARR ARR ARR!!

Great question.

I too have seen the instances you mentioned, and all I can tell you is what I know, and my reasons for why I do it the way I do. It's. It isn't necessarily because the All Metal wouldn't stick to epoxy primer.

When I went to school for Automotive Refinishing, I was taught you NEVER apply repair products over existing finishes. The reasons for this are simple:

1) You don't know what the compatibly is between the finish your applying the product over, and the product itself.

Either the product, (whatever you're applying over top), or the substrate below could wrinkle, peel, or react to each other in unwanted ways.

and

2) You don't necessarily know if the finish (epoxy or otherwise) was applied properly, or how good it's adhesion to the panel is.

For example, I've seen epoxy coatings peel and flake off of panels. Whether due to improper prep, mixing ratio off, or maybe even old product. Who knows.

The point being, if you were to apply your filler, seam sealer, or what have you over over a flaking finish like that, all your hard work would come off with it too.

It's simply not worth the risk IMO.

Now before everyone jumps on my back, and tells me about how they've done it with no problems, etc etc, every situation is slightly different.

Guys on the coast that can't go more than a couple hours with their bare steel flash rusting on them, pretty much HAVE to epoxy prime right away.

Long term projects are another one where it would make sense to protect the metal with epoxy ahead of time.

For me and my particular situation, I don't plan on having the bare metal exposed for very long. Hopefully less than a month. If any flash rusting should happen in that time, I'm right there, and I can address it right away. The humidity in the air is usually fairly low here too, so that's another factor playing in my favour.

Hopefully this gave you some food for thought, and some insight as to determine whether or not you'd do it first before repairs or not.

Great question, hope my reply was helpful.

Donovan

I'm enjoying the repair work. You make me want to go buy a welder. As everyone else said..Great work!

I see a lot of work where the guy will strip the car to metal and then shoot a couple coats of Epoxy Primer on the bare steel and then body work the panel. Will the All Metal not work with the epoxy under it?

Hutch

Again, great work Donovan!

Thank you Hutch!

Go buy that welder man, and start playing! It's a pretty cool feeling to be able to melt steel with fire!

(Paraphrasing Tim Taylor from Home Improvement) ARR ARR ARR!!

Great question.

I too have seen the instances you mentioned, and all I can tell you is what I know, and my reasons for why I do it the way I do. It's. It isn't necessarily because the All Metal wouldn't stick to epoxy primer.

When I went to school for Automotive Refinishing, I was taught you NEVER apply repair products over existing finishes. The reasons for this are simple:

1) You don't know what the compatibly is between the finish your applying the product over, and the product itself.

Either the product, (whatever you're applying over top), or the substrate below could wrinkle, peel, or react to each other in unwanted ways.

and

2) You don't necessarily know if the finish (epoxy or otherwise) was applied properly, or how good it's adhesion to the panel is.

For example, I've seen epoxy coatings peel and flake off of panels. Whether due to improper prep, mixing ratio off, or maybe even old product. Who knows.

The point being, if you were to apply your filler, seam sealer, or what have you over over a flaking finish like that, all your hard work would come off with it too.

It's simply not worth the risk IMO.

Now before everyone jumps on my back, and tells me about how they've done it with no problems, etc etc, every situation is slightly different.

Guys on the coast that can't go more than a couple hours with their bare steel flash rusting on them, pretty much HAVE to epoxy prime right away.

Long term projects are another one where it would make sense to protect the metal with epoxy ahead of time.

For me and my particular situation, I don't plan on having the bare metal exposed for very long. Hopefully less than a month. If any flash rusting should happen in that time, I'm right there, and I can address it right away. The humidity in the air is usually fairly low here too, so that's another factor playing in my favour.

Hopefully this gave you some food for thought, and some insight as to determine whether or not you'd do it first before repairs or not.

Great question, hope my reply was helpful.

Donovan

For tonight's update:

Although I worked for the better part of the day on the car, there's not really much to report or post in the way of pics.

It was mostly more cleanup of painted, rusted, pitted, and seam sealed areas on the driver's side.

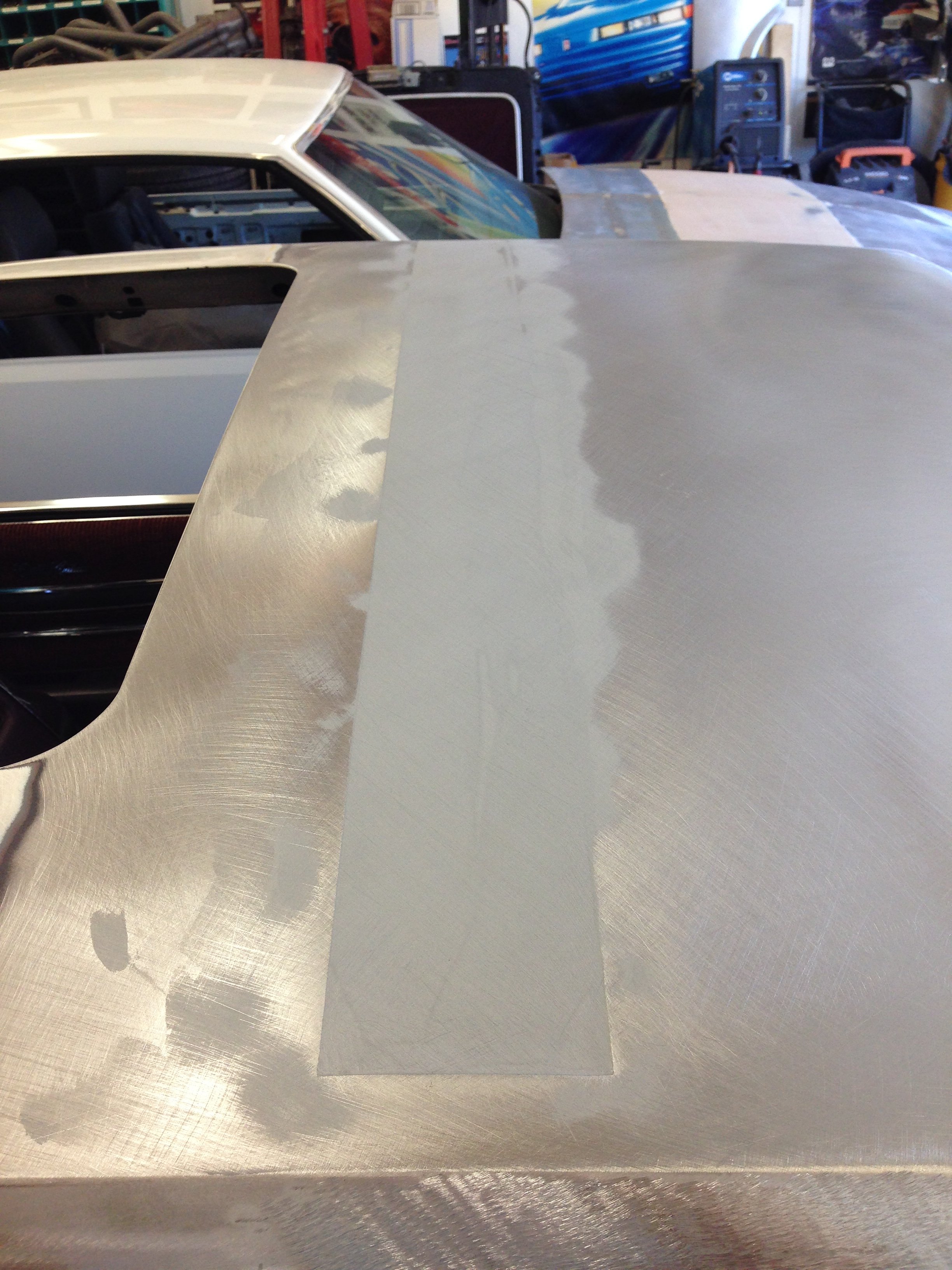

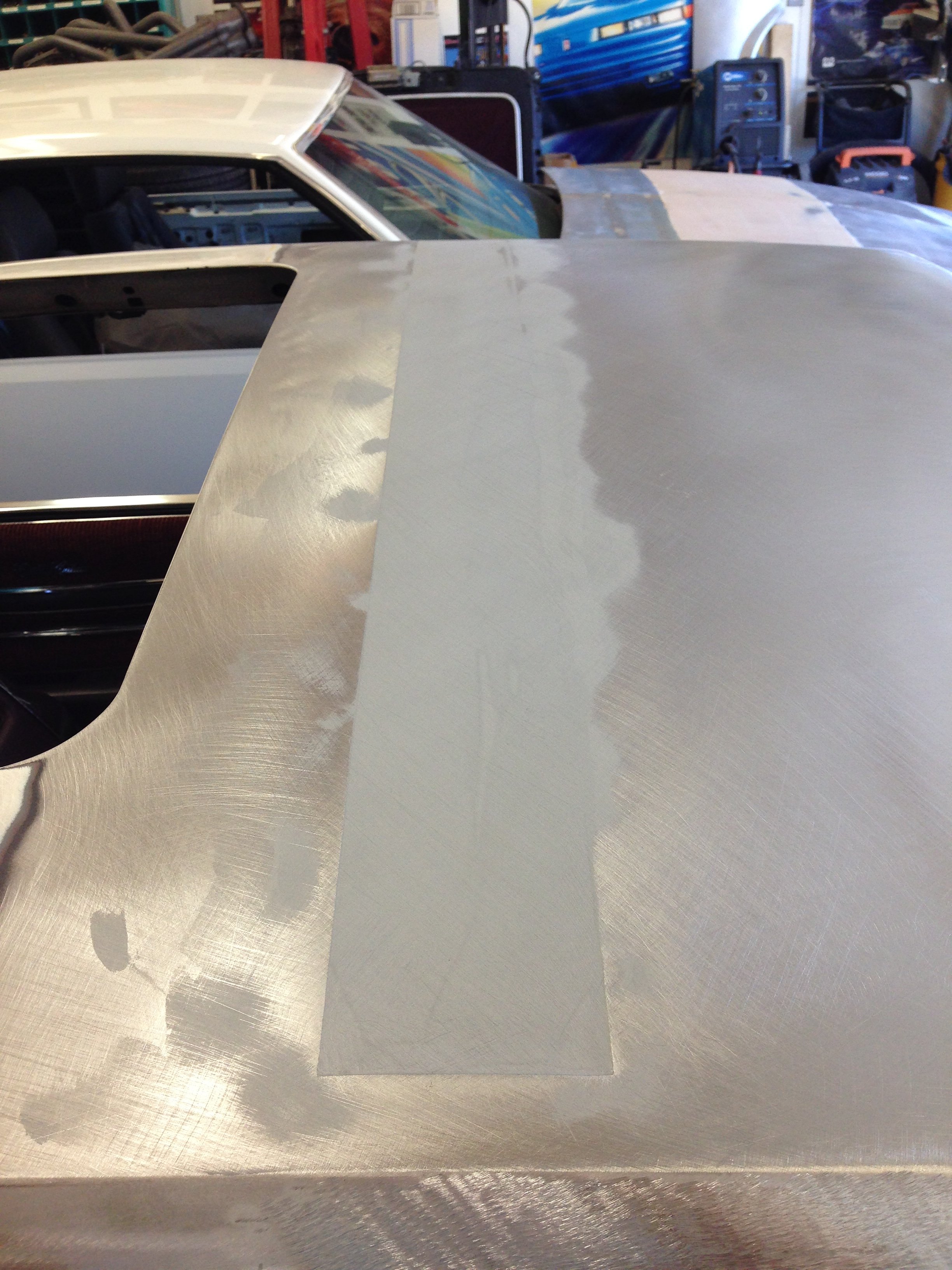

First off however, I started by tackling blocking out the All Metal I applied last night.

I purposely undercut the hell out of it, I wasn't even remotely concerned with trying to get the area straight yet. I only wanted the All Metal sanded smooth, and ready for the subsequent coats of body filler to follow.

Here it is, sanded out with the perimeter of the seams filled:

From there, the rest of the time was spent concentrating on cleaning up the aforementioned areas on the driver's side sail panel, "B" pillar, quarter window opening, and drip rails.

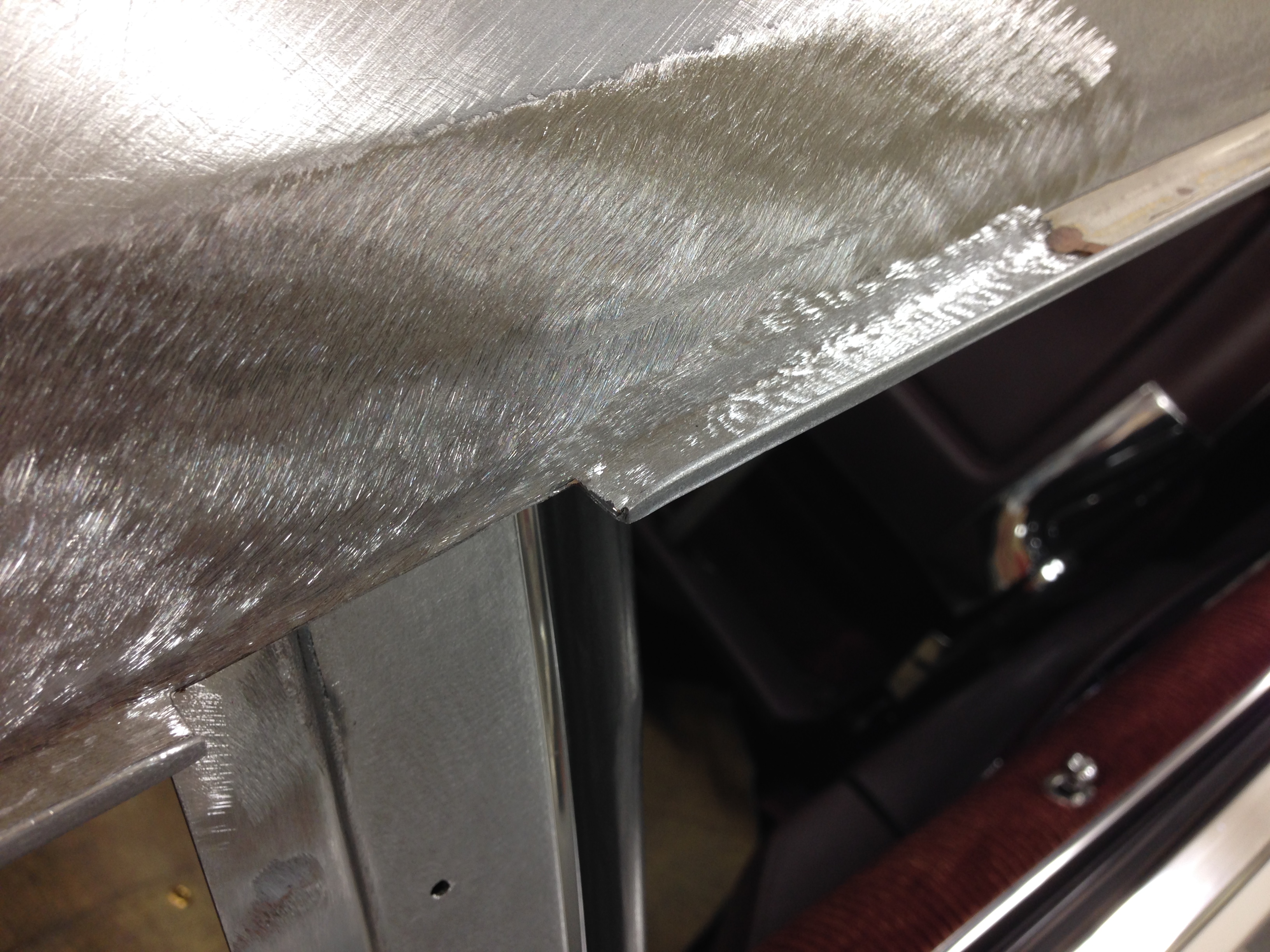

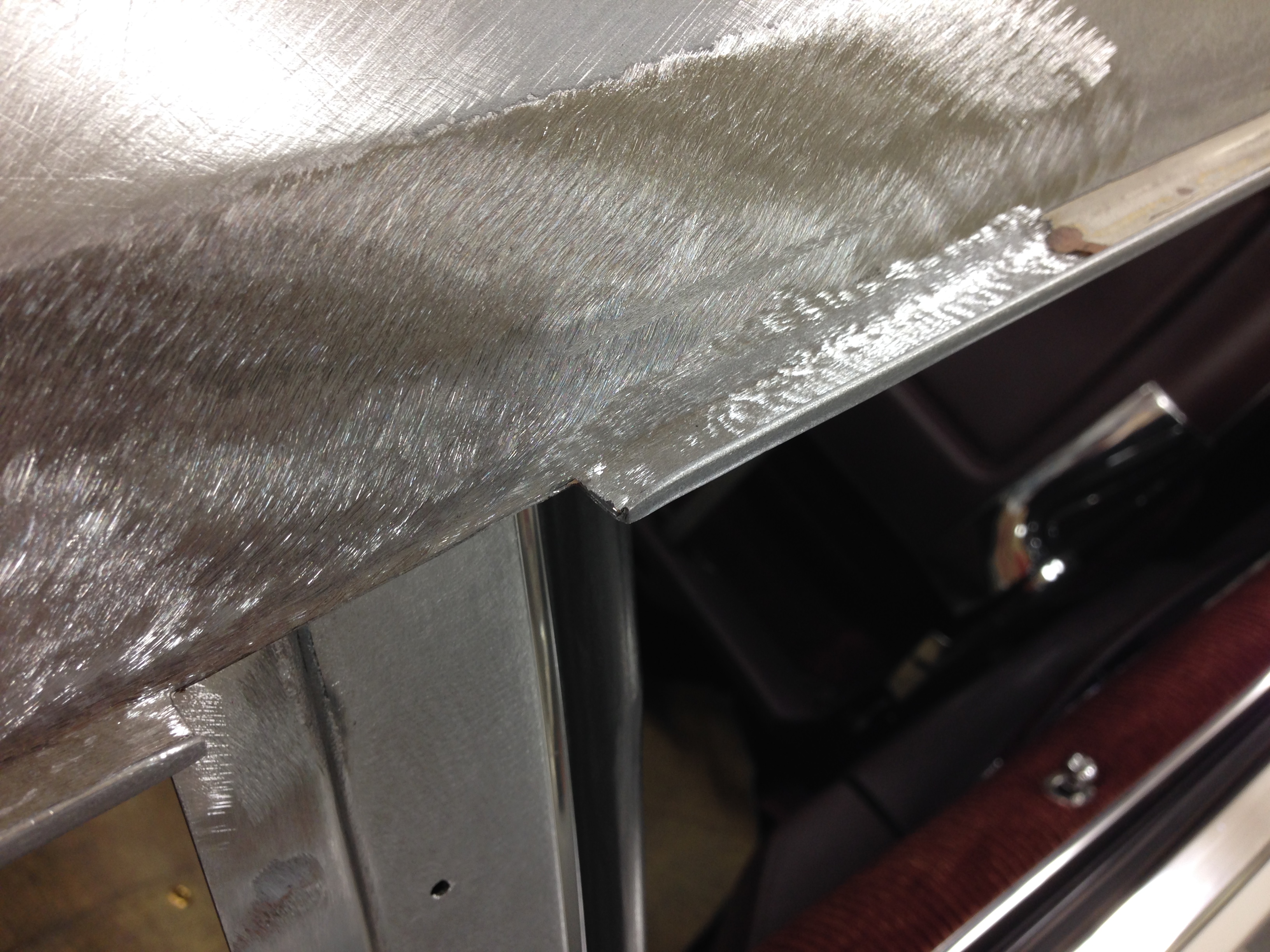

Here's the drip rail above the quarter window once the old seam sealer was scraped out:

A close up of the rusty area:

After cleaning out all the old paint, primer and rust:

Good as new!

The ledge below the quarter window after cleanup:

The "B" pillar stripped of its paint, rust and crud:

More work done to remove the last remnants of seam sealer and some of the brass brazing from the roof seam. (I'll touch a little more on the brass removal in future updates):

And finally, the first few inches of the drip rail forward of the "B" pillar:

I plan on welding a section in to make the two drip rails as one on each side. This requires both drip rail ends to be prepped to bare metal so I can weld in the sections.

There is a piece used on the factory hardtop cars that goes on the "B" pillar, but I'm not going to be using that.

The plan is to finish out the "B" pillars nicely, and paint them gloss black so they "disappear" with the tinted windows.

I did this same procedure with The Juggernaut, and I really like it. It kinda makes the "B" pillar disappear, and looks more like the true old school hardtops. Once it's framed by the drip rail trim and the quarter window moulding, it looks really good:

So that's it for tonight guys.

Thanks once again for checking in, and stay tuned!

D.

Although I worked for the better part of the day on the car, there's not really much to report or post in the way of pics.

It was mostly more cleanup of painted, rusted, pitted, and seam sealed areas on the driver's side.

First off however, I started by tackling blocking out the All Metal I applied last night.

I purposely undercut the hell out of it, I wasn't even remotely concerned with trying to get the area straight yet. I only wanted the All Metal sanded smooth, and ready for the subsequent coats of body filler to follow.

Here it is, sanded out with the perimeter of the seams filled:

From there, the rest of the time was spent concentrating on cleaning up the aforementioned areas on the driver's side sail panel, "B" pillar, quarter window opening, and drip rails.

Here's the drip rail above the quarter window once the old seam sealer was scraped out:

A close up of the rusty area:

After cleaning out all the old paint, primer and rust:

Good as new!

The ledge below the quarter window after cleanup:

The "B" pillar stripped of its paint, rust and crud:

More work done to remove the last remnants of seam sealer and some of the brass brazing from the roof seam. (I'll touch a little more on the brass removal in future updates):

And finally, the first few inches of the drip rail forward of the "B" pillar:

I plan on welding a section in to make the two drip rails as one on each side. This requires both drip rail ends to be prepped to bare metal so I can weld in the sections.

There is a piece used on the factory hardtop cars that goes on the "B" pillar, but I'm not going to be using that.

The plan is to finish out the "B" pillars nicely, and paint them gloss black so they "disappear" with the tinted windows.

I did this same procedure with The Juggernaut, and I really like it. It kinda makes the "B" pillar disappear, and looks more like the true old school hardtops. Once it's framed by the drip rail trim and the quarter window moulding, it looks really good:

So that's it for tonight guys.

Thanks once again for checking in, and stay tuned!

D.

Donovan, I really like the idea of painting the B pillar black. A very slick and steathly body mod. When you're done with both of your cutlasses I will be sending my 78 cutlass to you .LOL. As always great work!

Last edited:

Donovan,

You're almost too generous with your answers and advice. Don't hesitate to let us know when we get to be tiresome. Here's my new contribution.

What is it about All Metal that you like for this use at this point in the process?

BTW, I employed a similar flanged-and-epoxied approach to bodywork some 20 years ago, without the welding, substituting pop rivets, with success beyond any reasonable hope, on a 65 VW microbus. My epoxy of choice was PC-7, which I still consider a miracle adhesive, but I haven't tested my luck on any comparable project since then. I may have some hard copy evidence of my experiment but with any luck I won't be able to find anything incriminating.

Best - Gary

You're almost too generous with your answers and advice. Don't hesitate to let us know when we get to be tiresome. Here's my new contribution.

What is it about All Metal that you like for this use at this point in the process?

BTW, I employed a similar flanged-and-epoxied approach to bodywork some 20 years ago, without the welding, substituting pop rivets, with success beyond any reasonable hope, on a 65 VW microbus. My epoxy of choice was PC-7, which I still consider a miracle adhesive, but I haven't tested my luck on any comparable project since then. I may have some hard copy evidence of my experiment but with any luck I won't be able to find anything incriminating.

Best - Gary

Hi D,

As always, I'm totally impressed with your work. I know I must sound like a broken record, but I'm astonished with your level of craftsmanship and work ethic...I enjoy seeing your work in progress. Thank you again for showing us how it's done and being an all out great guy to boot.

As always, I'm totally impressed with your work. I know I must sound like a broken record, but I'm astonished with your level of craftsmanship and work ethic...I enjoy seeing your work in progress. Thank you again for showing us how it's done and being an all out great guy to boot.

Similar threads

- Replies

- 25

- Views

- 2K

- Replies

- 15

- Views

- 1K

- Replies

- 1

- Views

- 377

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.