Space City 1982 GP Build

- Thread starter Texas82GP

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Jared, the trunk looks great! I think the sticker looks like it belongs there.

Jared, I think you missed my question on where you got your driveshaft hoop. I like that it is formed to give clearance for the u joint which hits the stock floor brace when a T 5 is installed

You're making great progress Jared. The trunk looks really good, and its good to see you get the driveline in the proper place. Keep it up!

It's probably just the angle of the pic but the driveshaft loop looks like it hangs down pretty far

It doesn't feel that close to me but I feel great about the progress made thus far this fall/winter. I have about 2, maybe 2-1/2 months left before the blast so I don't think I'll be driving it this summer but I do think I'll get it on the road next winter. Thanks for the positive feedback on the trunk kit. After a lot of effort and swearing, I'm satisfied with it. I won't recommend it to anyone for the price they charge for it.Your so close man. That trunk kit is sweet

Thanks! I know it can seem silly to agonize over where the jacking decal is placed but the details are what make a car for me.Jared, the trunk looks great! I think the sticker looks like it belongs there.

Sorry Steve! I saw your question but somehow failed to remember to answer it. I bought it from JT Raceshop. His website seems to be inactive right now but I clicked on the link to his Facebook page from a Google search (I'm not on Facebook) and he looks to still be active. If you are in the market for a driveshaft loop, the quality on this one is exceptional. It's way overkill for what I need but I was looking for a bolt in solution when you previously warned me that the stock floor brace was going to interfere with the front U-Joint when I made the swap to the T5. I really could have just fabricated my own offset floor brace but I don't regret having this nice piece on my car.Jared, I think you missed my question on where you got your driveshaft hoop. I like that it is formed to give clearance for the u joint which hits the stock floor brace when a T 5 is installed

Thanks Jeff! I'm trying to stay after it.You're making great progress Jared. The trunk looks really good, and its good to see you get the driveline in the proper place. Keep it up!

It's not too bad. I certainly don't think it is any lower than the front crossmember or the center section on the rear end. If I remember, I'll measure from the floor to see what is the lowest point on the car. I don't think it is that hoop. I think UMI is offering a hoop now that is much tighter to the tunnel, but I don't recall if it is offset rearward or not, which is needed when you go to a T5 or a 700R4.It's probably just the angle of the pic but the driveshaft loop looks like it hangs down pretty far

Thanks Kevin!Coming right along...trunk looks great Jared!

Small update:

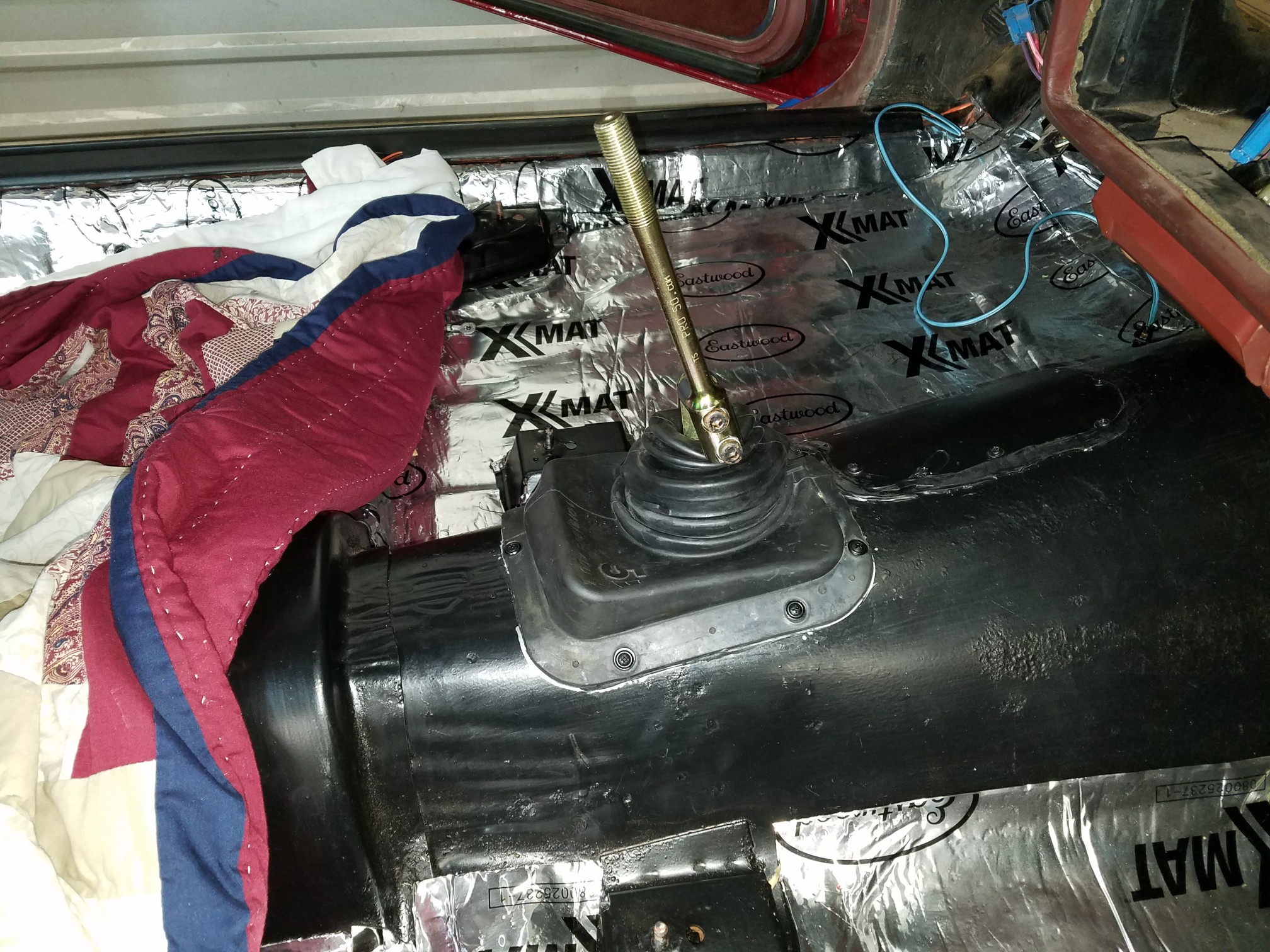

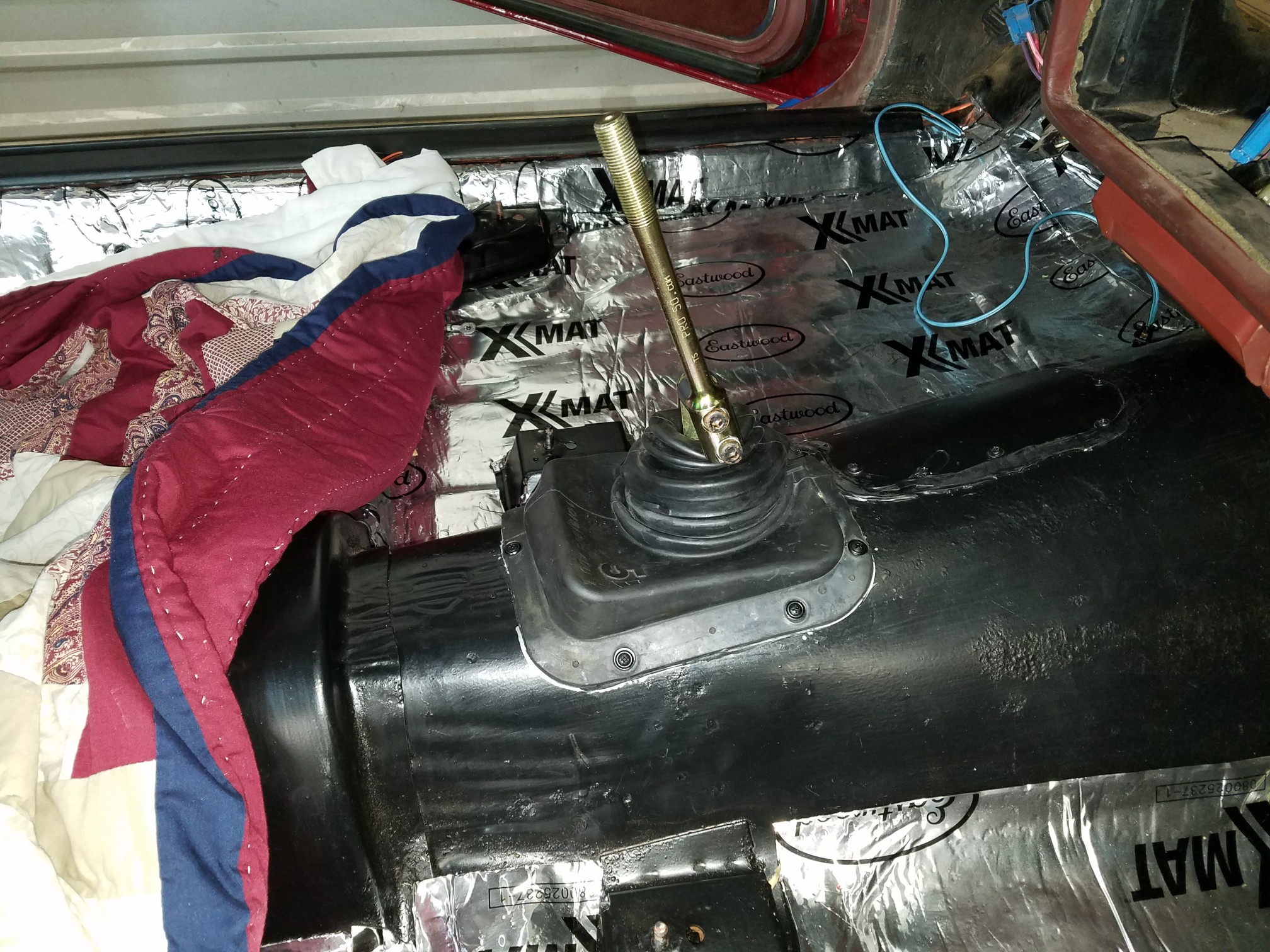

I got over to the storage last night and got the lower shifter boot secured to the tunnel and installed the dust boot on the shifter. I think the shifter handle itself is on for good at this point, at least until the car needs a clutch. You can see the spacers my buddy fabricated for me that space the handle over to the center of the tunnel. This should make it work well with the console. The shifter I'm using is a Pro 5.0 shifter for a 3rd gen Camaro with a T5. Pro 5.0 gained most of their fame with their shifters for T5 Fox Body Mustangs. The reason I went with a Pro 5.0 was that it was a more precise shifter than the stock Camaro shifter and it has stops built into it, which the stock shifter and other aftermarket offerings were lacking. The T5 doesn't have internal stops so having stops on the shifter is a good idea. Anyway, here are the pics...

I also started on re-routing the reverse light wiring. The previous owner had extended the wiring for the reverse lights and routed it through the grommet for the speedometer cable. He also had his extension in a length of clear vinyl tubing. I cut away his extension so I'm back to the remains of the factory wiring. I will extend it and route it down the tunnel and will likely put a grommet in the patch, ahead of the shifter. Once that is done, the console mounts are attached to the tunnel and Sean is able to finish up his X-mat install on the tunnel, the carpet can go in. I'm looking forward to that.

I won't make it over to the storage tonight. I need to service my truck tonight (change oil and rotate tires). Tomorrow night I'm going to work on securing the mount brackets to the console so Sean and I can mock it up and locate where the brackets need to mount to the tunnel on Saturday.

I'll update as progress warrants. Until then....

Best,

--Jared

I got over to the storage last night and got the lower shifter boot secured to the tunnel and installed the dust boot on the shifter. I think the shifter handle itself is on for good at this point, at least until the car needs a clutch. You can see the spacers my buddy fabricated for me that space the handle over to the center of the tunnel. This should make it work well with the console. The shifter I'm using is a Pro 5.0 shifter for a 3rd gen Camaro with a T5. Pro 5.0 gained most of their fame with their shifters for T5 Fox Body Mustangs. The reason I went with a Pro 5.0 was that it was a more precise shifter than the stock Camaro shifter and it has stops built into it, which the stock shifter and other aftermarket offerings were lacking. The T5 doesn't have internal stops so having stops on the shifter is a good idea. Anyway, here are the pics...

I also started on re-routing the reverse light wiring. The previous owner had extended the wiring for the reverse lights and routed it through the grommet for the speedometer cable. He also had his extension in a length of clear vinyl tubing. I cut away his extension so I'm back to the remains of the factory wiring. I will extend it and route it down the tunnel and will likely put a grommet in the patch, ahead of the shifter. Once that is done, the console mounts are attached to the tunnel and Sean is able to finish up his X-mat install on the tunnel, the carpet can go in. I'm looking forward to that.

I won't make it over to the storage tonight. I need to service my truck tonight (change oil and rotate tires). Tomorrow night I'm going to work on securing the mount brackets to the console so Sean and I can mock it up and locate where the brackets need to mount to the tunnel on Saturday.

I'll update as progress warrants. Until then....

Best,

--Jared

Jared, you made a good choice not using the stock shifter, I have mentioned a few times in threads the stock shifter is known to be sloppy and can damage the transmission from over shifting. I have the Hurst shifter which has stops and it's a smoother acurate shift.

I made pretty good progress on the car this weekend. I've been waiting for weather good enough to paint the interior plastic trim for at least five weeks. It has been a fairly cold (not to you guys up north) and really wet winter for us. The weather was perfect for paint on Friday so I took a day of vacation. Sean had taken the Camaro to work that day so I hung plastic in the Camaro bay and got it set up for paint. Then I started cleaning parts. I wish I had done this previously but it worked out. I did a four step cleaning process:

I know, it doesn't look like very many parts but it took a long time to get the bay setup and to clean those parts. I stopped cleaning parts at about 3:00 PM (cleaning them with the first three stages mentioned above). I still had to setup the gun, get the parts hung and setup on their 'stands' and give them the final wipe down with the SEM prep spray before I could start with the adhesion promoter. The A-Pillar trim, side dash trim (between the A-pillar and kick panels), package shelf end trim, all four headliner trim pieces, the upper seatbelt at B-Pillar trim pieces, and the seatbelt trim pieces where the front belts attach to the inner rocker are in the view above.

Saturday morning I had to run and get another quart of Landau Black. I had misjudged how much material I needed. That slowed me down. I then had to carefully box up/load the pieces above in the back of my truck to clear out the bay. Then I had to clean the remaining pieces to get them ready to shoot. They included the kick panels, the upper and lower quarter panel trim pieces, the rear armrests, and the trim piece that goes along the front edge of the upper and lower quarter panel trim. Here is a pic Sean snapped as we were getting the second batch ready to spray....

And here is a picture of those pieces after paint. I should note that the arm rests were only cleaned with SEM soap and then SEM vinyl prep spray. There was a concerted effort to not get them too wet....

The paint turned out pretty nice. With all the prep work I hope the adhesion will be really good. Both of the upper quarter pieces ("opera window trim") had some minor sun damage. I elected to just clean them up and paint them as-is so they are not perfect. The trim piece for the driver's side, that goes along the leading edge of the upper and lower quarter panel trim had bad sun damage. I cleaned it up and sprayed it with the SEM texture coating and then put one coat of landau black on it and then stopped painting it. Its condition is unacceptable and I'm going to replace it. Here is a look at one of the painted lower quarter pieces with the armrest installed. I also have the speaker panel I got from Dixie in place...

I'm pretty happy with how everything turned out and this is sort of a watershed moment. A lot of the interior can go back together now that all these pieces are painted. I'm hoping to make some progress to that effect this week. I'll update when there is something to report. That's it for now. Thanks for following along guys. Until then...

Best,

--Jared

- Step One - I scrubbed each part with Dawn dish soap and a grey scuff pad

- Step Two - I scrubbed each part with a solution of 2 gallons of hot water with 1 cup of TSP with a grey scuff pad

- Step Three - I scrubbed each part with SEM Soap and a grey scuff pad

- Step Four, after the parts were hanging or on the table, ready for paint, I cleaned them with SEM leather and plastic prep spray and a brand new microfiber cloth

I know, it doesn't look like very many parts but it took a long time to get the bay setup and to clean those parts. I stopped cleaning parts at about 3:00 PM (cleaning them with the first three stages mentioned above). I still had to setup the gun, get the parts hung and setup on their 'stands' and give them the final wipe down with the SEM prep spray before I could start with the adhesion promoter. The A-Pillar trim, side dash trim (between the A-pillar and kick panels), package shelf end trim, all four headliner trim pieces, the upper seatbelt at B-Pillar trim pieces, and the seatbelt trim pieces where the front belts attach to the inner rocker are in the view above.

Saturday morning I had to run and get another quart of Landau Black. I had misjudged how much material I needed. That slowed me down. I then had to carefully box up/load the pieces above in the back of my truck to clear out the bay. Then I had to clean the remaining pieces to get them ready to shoot. They included the kick panels, the upper and lower quarter panel trim pieces, the rear armrests, and the trim piece that goes along the front edge of the upper and lower quarter panel trim. Here is a pic Sean snapped as we were getting the second batch ready to spray....

And here is a picture of those pieces after paint. I should note that the arm rests were only cleaned with SEM soap and then SEM vinyl prep spray. There was a concerted effort to not get them too wet....

The paint turned out pretty nice. With all the prep work I hope the adhesion will be really good. Both of the upper quarter pieces ("opera window trim") had some minor sun damage. I elected to just clean them up and paint them as-is so they are not perfect. The trim piece for the driver's side, that goes along the leading edge of the upper and lower quarter panel trim had bad sun damage. I cleaned it up and sprayed it with the SEM texture coating and then put one coat of landau black on it and then stopped painting it. Its condition is unacceptable and I'm going to replace it. Here is a look at one of the painted lower quarter pieces with the armrest installed. I also have the speaker panel I got from Dixie in place...

I'm pretty happy with how everything turned out and this is sort of a watershed moment. A lot of the interior can go back together now that all these pieces are painted. I'm hoping to make some progress to that effect this week. I'll update when there is something to report. That's it for now. Thanks for following along guys. Until then...

Best,

--Jared

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 791

- Replies

- 0

- Views

- 193

- Replies

- 4

- Views

- 1K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.