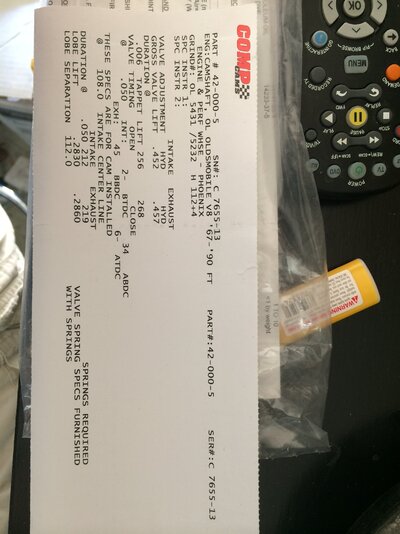

Hey guys, put a 403 in my HO and can't get it to run on the computer. Finally got rid of all the codes but it will not run right and is backfiring. There are a couple of things that are weird. Mild cam and high compression pistons (9.50 or so) using Edelbrock performer, AR headers, DUI distributor and SMI carb built for cam and compression etc. See attachment for cam specs.

1. Replaced MC solenoid as it was dead, however it reads 30 ohms and I read it should be 20

2. Installed heated O2 sensor however I don't appear to be getting to closed loop. It ran around 30 with 6 cyl dwell meter for a while and then dropped to 6 after it warmed up. It was not cycling up and down by 5 like it should.

3. set timing to 20ish when running with CCC disconnected, 35 to 40 when it is plugged in at 700 rpm

4. TPS set to .48 volts

Help!!!!

1. Replaced MC solenoid as it was dead, however it reads 30 ohms and I read it should be 20

2. Installed heated O2 sensor however I don't appear to be getting to closed loop. It ran around 30 with 6 cyl dwell meter for a while and then dropped to 6 after it warmed up. It was not cycling up and down by 5 like it should.

3. set timing to 20ish when running with CCC disconnected, 35 to 40 when it is plugged in at 700 rpm

4. TPS set to .48 volts

Help!!!!