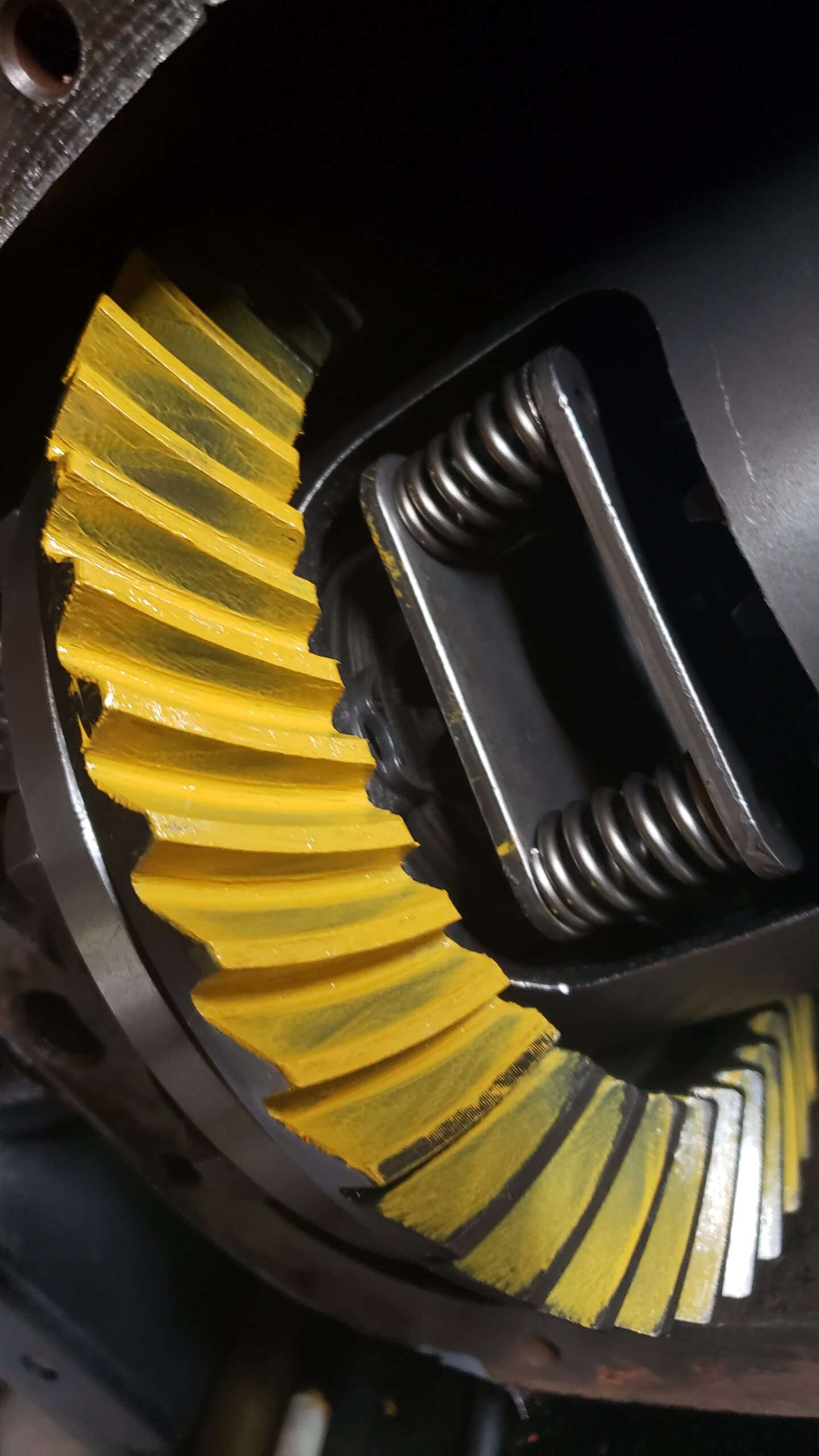

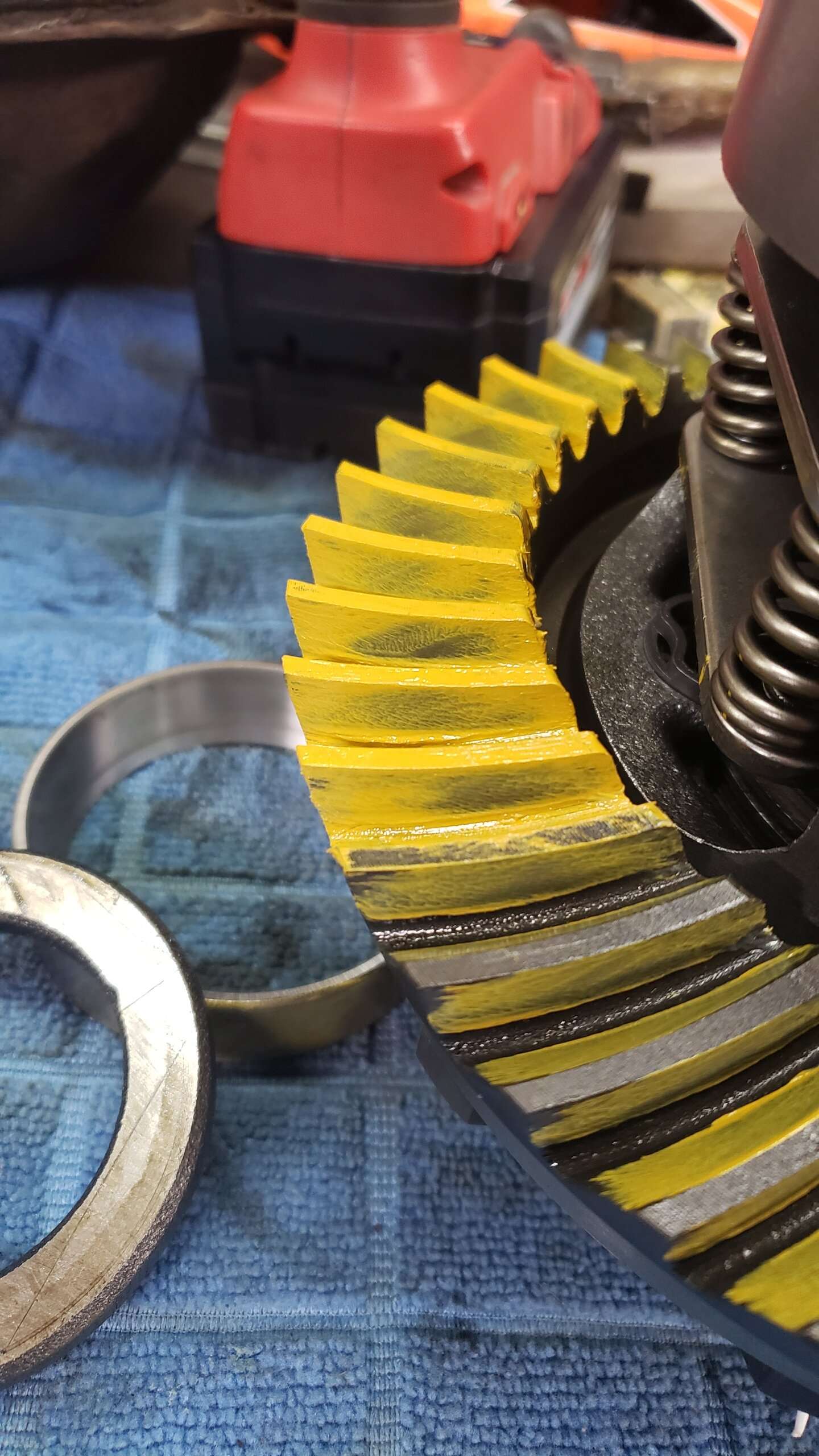

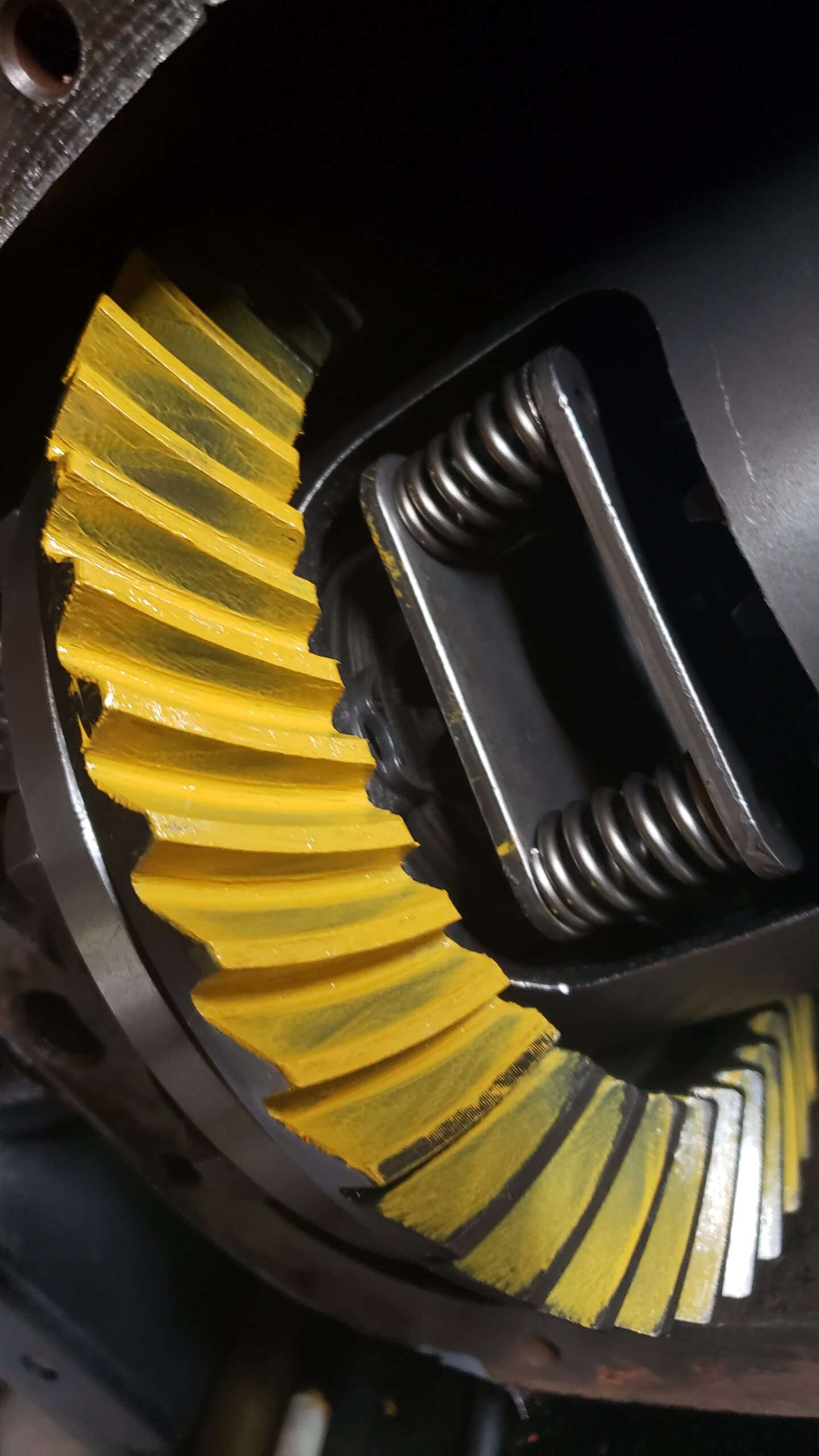

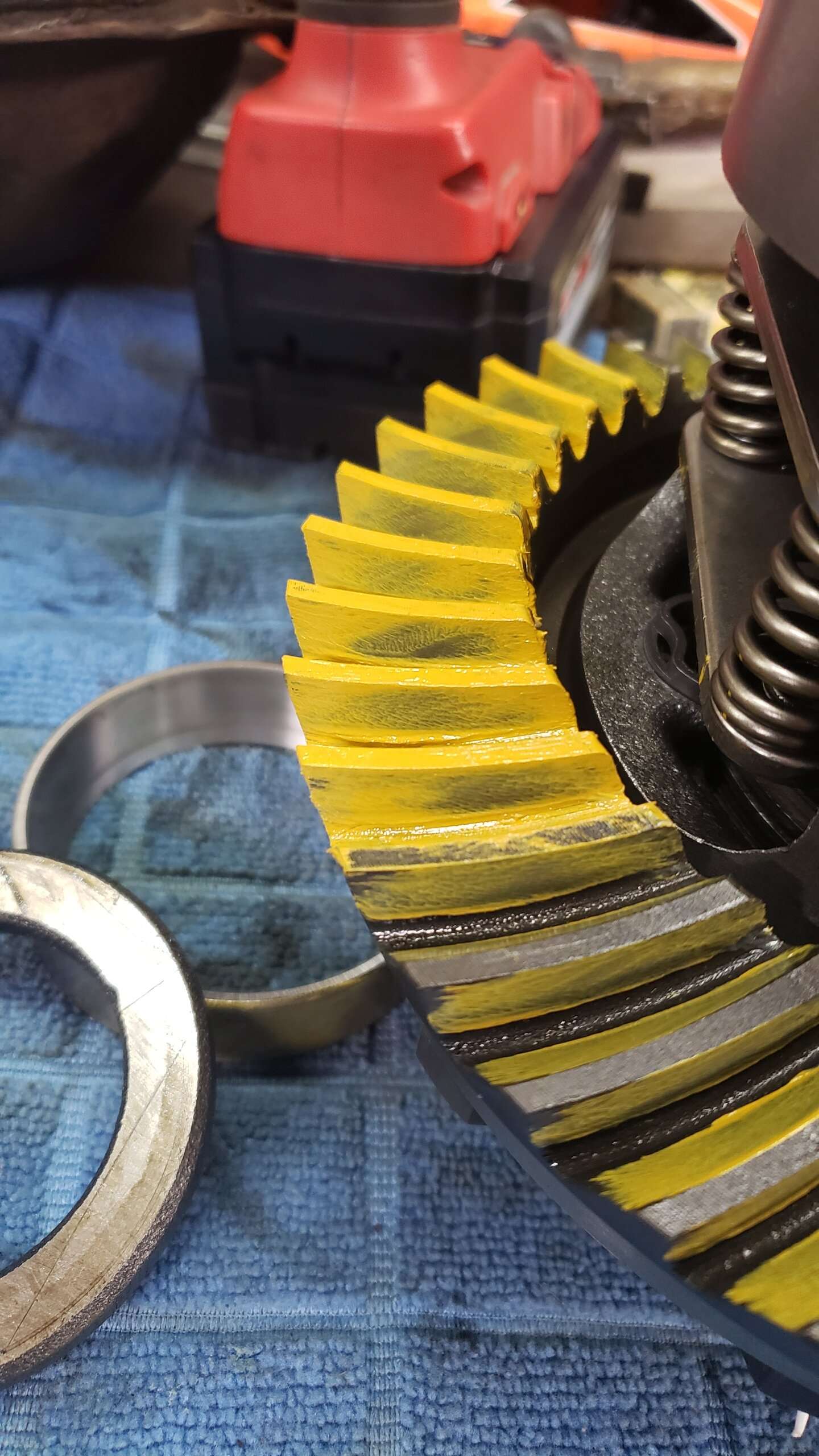

JMO- I'd lighten up a bit on the gear paint. There's a sweet spot in the amount of that stuff that gives you a solid reading without squishing the stuff everywhere. You're mainly looking for paint transfer to give a clear pattern and you only need to do a small handful of teeth to get your pattern. From what I see in your pics, the pattern looks ok. It looks like it's right in the middle between the heel and crown, and going a hair deeper into the gear would give you a textbook pattern, but you're certainly fine where you are. You could maybe run the rear with the .005 but that's pretty tight. Is that an average or worst case? I'm assuming you checked backlash at least a few points around the ring gear, right? It MIGHT change a tad. I've never seen a perfect set of gears with the same backlash all around the ring, but I've also not rebuilt hundreds of them either. They may be out there.

If you use the .010/.007 rule, where for every .010 of carrier movement you change backlash by .007, You could go + .005 on the passenger side and -.005 on the driver side. This would be a .005 shift to the left to widen the gap where you SHOULD see about a .003-.004 increase in backlash all around. So you should end up with around .008-.009 backlash, which is certainly a consideration. However, with that in mind, there's no rule of thumb that I'm aware of for pinion shims so it's possible you may need to add a thin shim to the pinion, although not sure, as you would have to recheck engagement pattern to determine that.

These are simply my opinions and mean nothing. I'm trying to do math without finishing my first cup of coffee so I could be off by 30 thousandths or more.

It's just a matter of shifting the carrier and pinion for the right mesh at this point. You're so close to the finish line, though. But this part is the most important and tedious thing. Good luck.