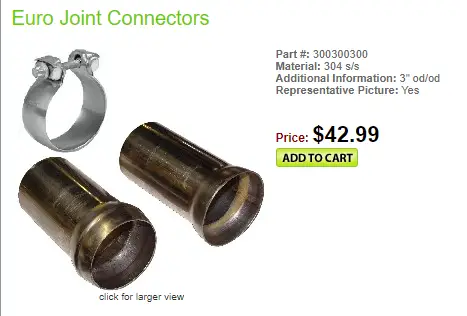

I intended to go to the salvage yard today, grab some 3" ball couplers at the exhaust shop on the way there and look at a 78 AMC spirit with a 401 today but I found out the yard was closed Christmas week (I've been burned with that before) and my plans flipped.

I intended to work a half day but that turned into almost a whole day and I didn't get into the garage until almost 5. Spent part of the afternoon trying to find a carbide burr to oval some holes and ended up going to 3 places before I found one.

Regardless I managed to get the bell housing modified and installed. It didn't sit fully into the block flat and I putzed around until I realized the pair of rear cover bolts were hitting the bell housing where it transitions into the cylindrical part. Those bolts have burned me before, when I bolted this 6.0 into the car originally 5 years ago with the 2004r.

Cut the slave cyl mount off too, ovaled out the last of the holes to mount the bell to the oil pan and cut some clearance around where the drivers side header goes. And took the burr after the bell to clear the rear cover bolts.

Not sure if modifying a $700 sfi bell retains it's rating or is something an intelligent person does but it's the game I play haha.

Cleaned up the trans too since no reason to put it in dirty. Almost put the trans in and caught myself and decided to finally put off what I've dreaded, cleaning the 30 year old oil and sand mix stuck to the trans tunnel. When I got the car the 2004r (that's now behind my turbo 4.1) had no joke 2" of oily sand goo on the sides. Same went for the trans tunnel in the car. The rear main on the 305 must have been shot and the car was a northern MN farm car so it got a nice coat of oil and sand every drive it made. I've slowly scrapped the goo off the floor over the past few years but never had the trans out long enough to actually address it. Burned a roll of blue shop towels and 2 cans of brake clean and part of my wax and geese remover gallon to get the floor clean but it's reasonably clean now. I don't get gravel in my eyes anytime I'm under the car now which will be nice.

Every one likes a clean transmission

Rear cover notches

Drilled 2 new holes for the Holley pan and ovaled a 3rd

Bell is on

You can see the moon shaped cut on the drivers side for the header and the lack of slave cyl bracket

Curse of the exon-valdez sbc rear main circa 1995

Too many towels later. Nobody will ever see it but it will keep crap out of my eyes so it's worth it.

Trans might finally go in tomorrow, depends on my motivation.

And my bad desire... The cash from selling the wagon roller really needs to go into a race car chassis but theres something about a 401 spirit....

I intended to work a half day but that turned into almost a whole day and I didn't get into the garage until almost 5. Spent part of the afternoon trying to find a carbide burr to oval some holes and ended up going to 3 places before I found one.

Regardless I managed to get the bell housing modified and installed. It didn't sit fully into the block flat and I putzed around until I realized the pair of rear cover bolts were hitting the bell housing where it transitions into the cylindrical part. Those bolts have burned me before, when I bolted this 6.0 into the car originally 5 years ago with the 2004r.

Cut the slave cyl mount off too, ovaled out the last of the holes to mount the bell to the oil pan and cut some clearance around where the drivers side header goes. And took the burr after the bell to clear the rear cover bolts.

Not sure if modifying a $700 sfi bell retains it's rating or is something an intelligent person does but it's the game I play haha.

Cleaned up the trans too since no reason to put it in dirty. Almost put the trans in and caught myself and decided to finally put off what I've dreaded, cleaning the 30 year old oil and sand mix stuck to the trans tunnel. When I got the car the 2004r (that's now behind my turbo 4.1) had no joke 2" of oily sand goo on the sides. Same went for the trans tunnel in the car. The rear main on the 305 must have been shot and the car was a northern MN farm car so it got a nice coat of oil and sand every drive it made. I've slowly scrapped the goo off the floor over the past few years but never had the trans out long enough to actually address it. Burned a roll of blue shop towels and 2 cans of brake clean and part of my wax and geese remover gallon to get the floor clean but it's reasonably clean now. I don't get gravel in my eyes anytime I'm under the car now which will be nice.

Every one likes a clean transmission

Rear cover notches

Drilled 2 new holes for the Holley pan and ovaled a 3rd

Bell is on

You can see the moon shaped cut on the drivers side for the header and the lack of slave cyl bracket

Curse of the exon-valdez sbc rear main circa 1995

Too many towels later. Nobody will ever see it but it will keep crap out of my eyes so it's worth it.

Trans might finally go in tomorrow, depends on my motivation.

And my bad desire... The cash from selling the wagon roller really needs to go into a race car chassis but theres something about a 401 spirit....

Last edited: