Yeah I'm probably going with the Honeywell. The one Mike shared is good but I already wired in a GT150 Delphi connector and the Honeywell is a direct swap. I'm lazy lol.

I have like 3/4 tank of fuel I need to use up before I drop the tank and add the second pump but I'm the mean time I thought I'd get started on my fittings.

I need to add a second -6 exit into the pump hanger and add a passthrough for some heavier gauge wire.

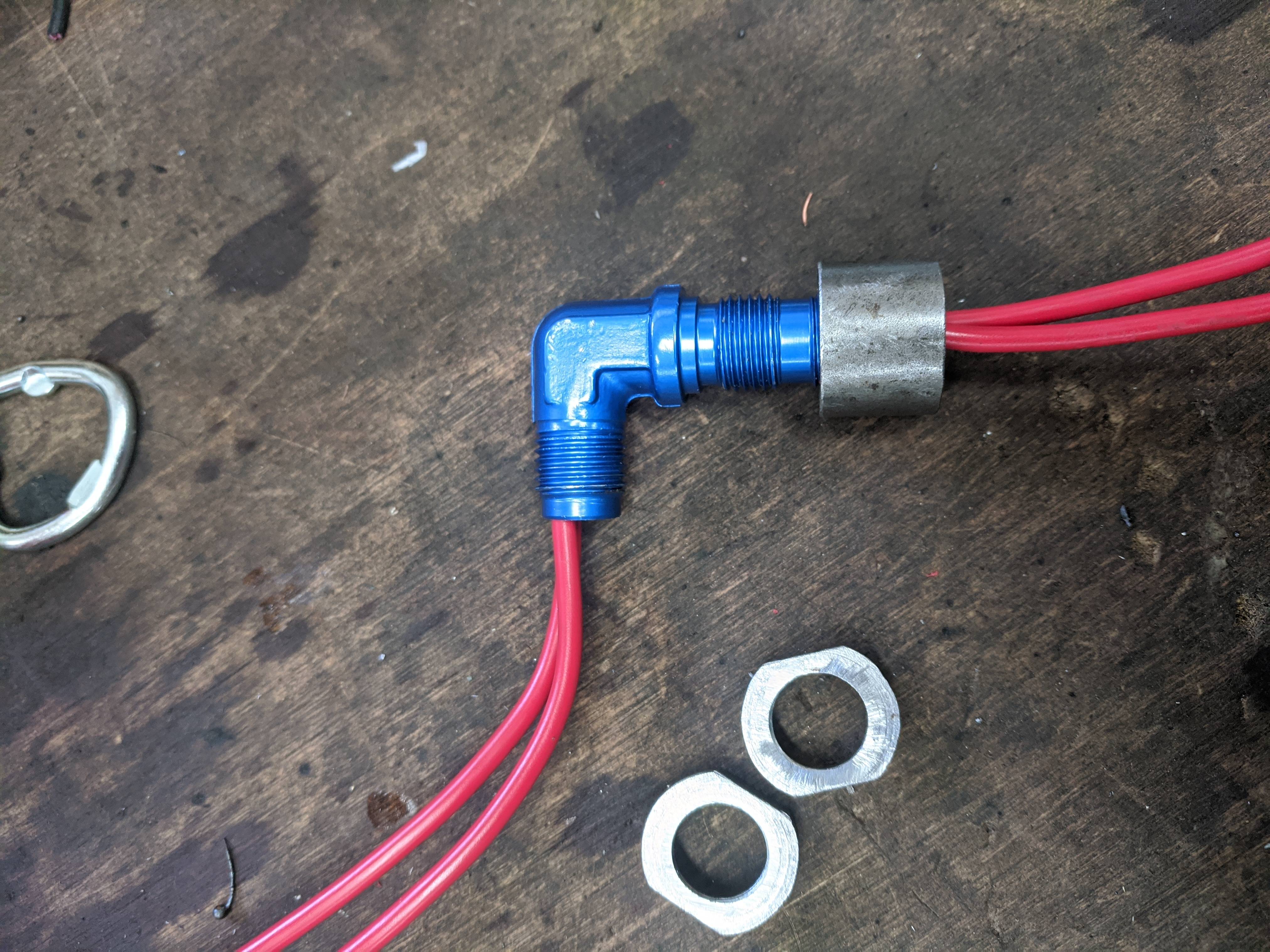

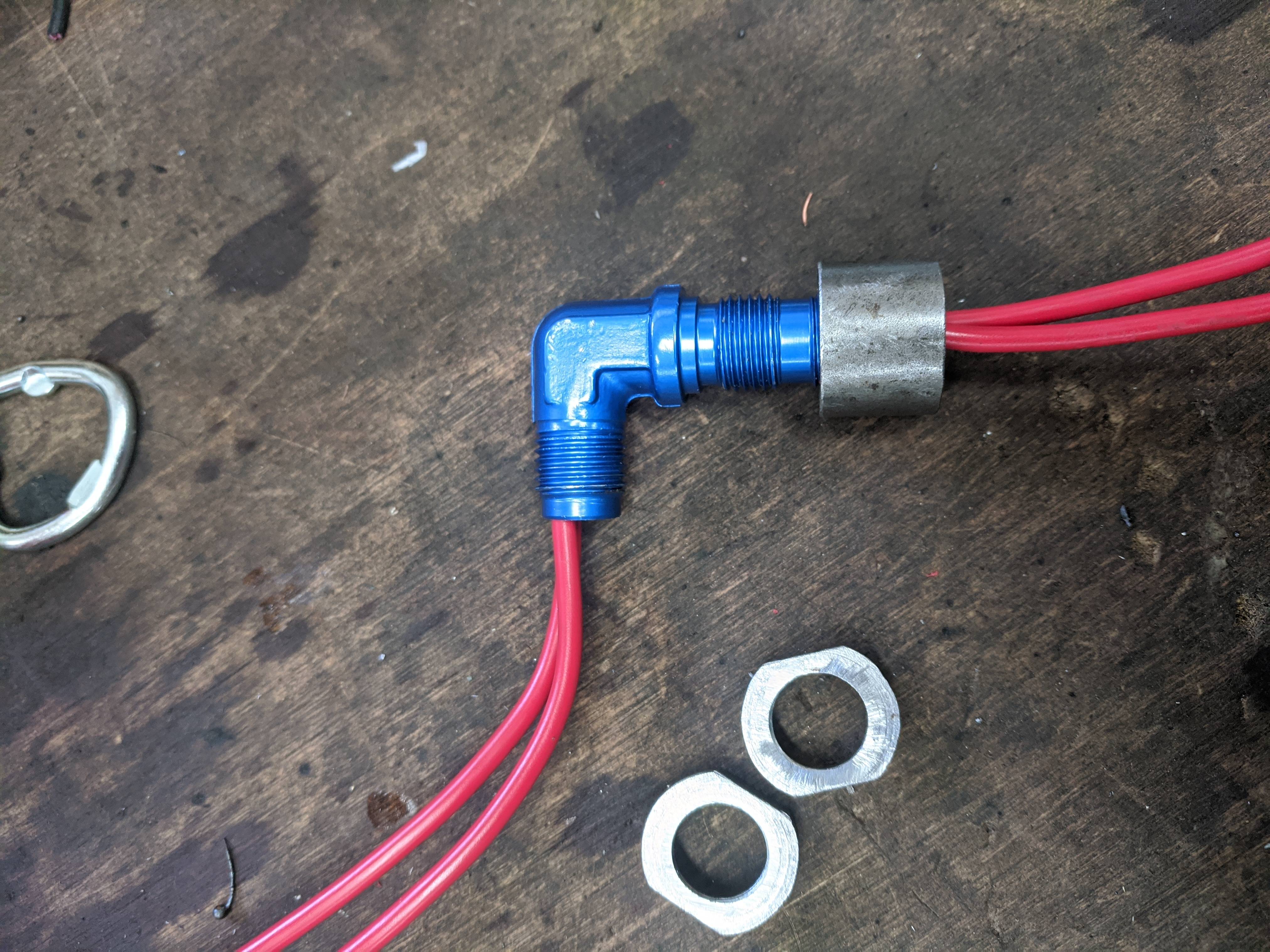

Fired up the lathe and made some orb nuts. Essentially I just drill a 9/16 hole in the fuel pump hanger and drop the bulkhead 90 in. Slide an o oring in and tighten the nut. The nut has the female orb port machined in and the o ring seals to the hanger and the fitting so it should be leak free.

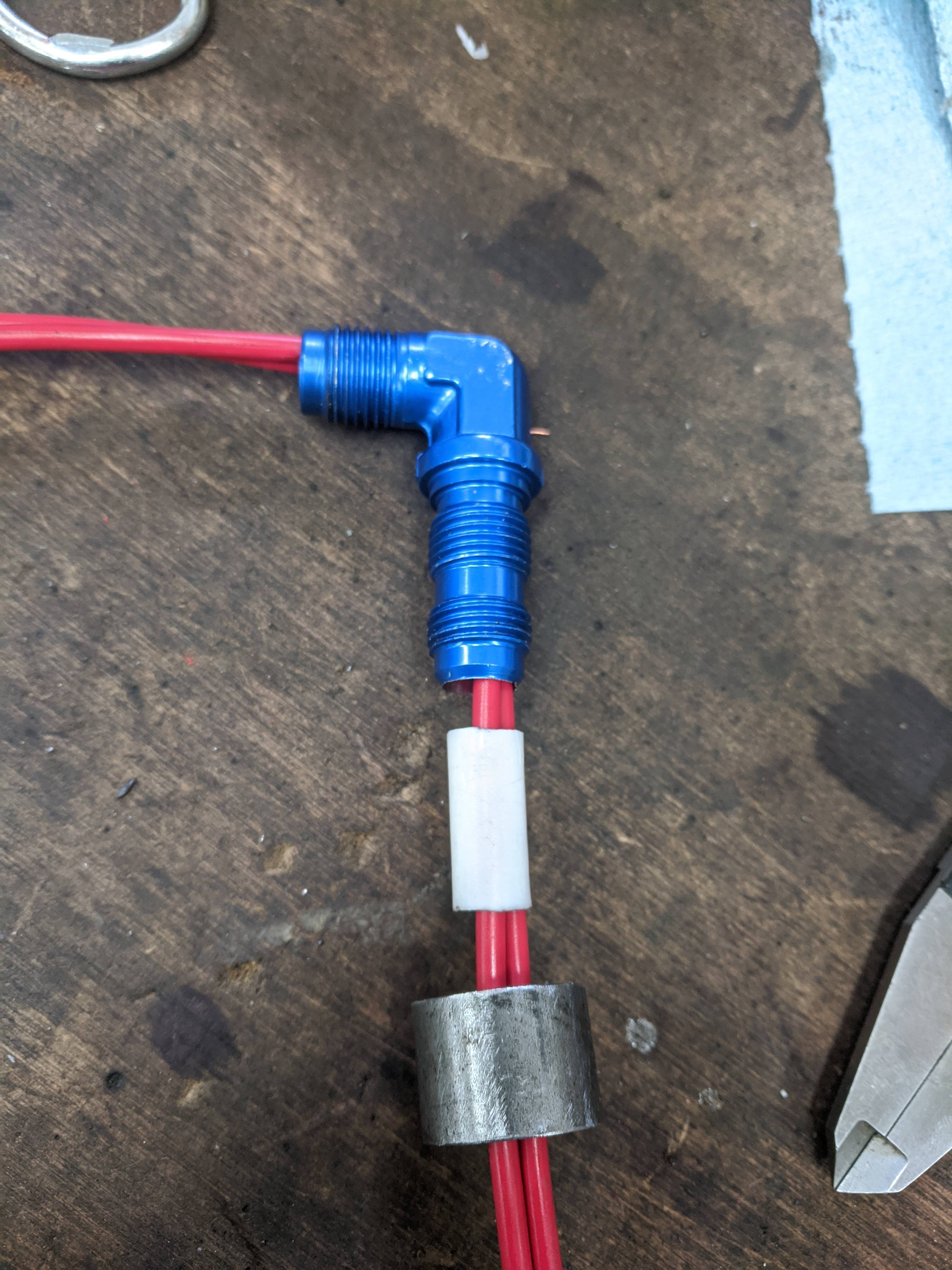

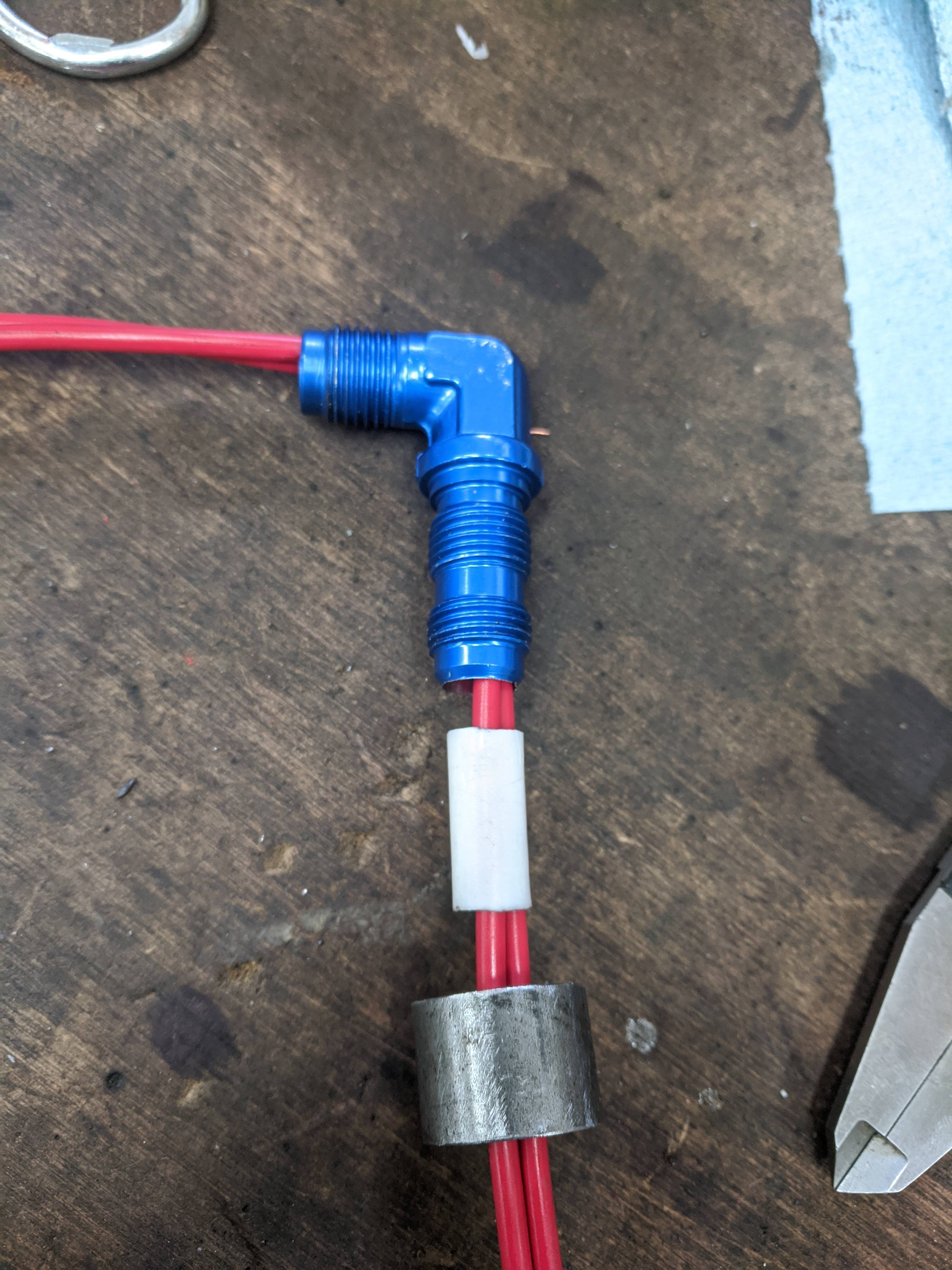

And I started on the wiring. I was going to buy one but again Mike convinced me otherwise and that I have a 'GD lathe' and to make one. I just drilled the bulkhead 90 out to 3/8 and made a slug out of Teflon I had sitting around and made a nut to retain the slug. A dab of epoxy and it should be a good 3 wire passthrough.

I need to buy a roll of 12 gage black wire, I'm out, and then I can drop the tank and work on the second pump installation.

I have like 3/4 tank of fuel I need to use up before I drop the tank and add the second pump but I'm the mean time I thought I'd get started on my fittings.

I need to add a second -6 exit into the pump hanger and add a passthrough for some heavier gauge wire.

Fired up the lathe and made some orb nuts. Essentially I just drill a 9/16 hole in the fuel pump hanger and drop the bulkhead 90 in. Slide an o oring in and tighten the nut. The nut has the female orb port machined in and the o ring seals to the hanger and the fitting so it should be leak free.

And I started on the wiring. I was going to buy one but again Mike convinced me otherwise and that I have a 'GD lathe' and to make one. I just drilled the bulkhead 90 out to 3/8 and made a slug out of Teflon I had sitting around and made a nut to retain the slug. A dab of epoxy and it should be a good 3 wire passthrough.

I need to buy a roll of 12 gage black wire, I'm out, and then I can drop the tank and work on the second pump installation.