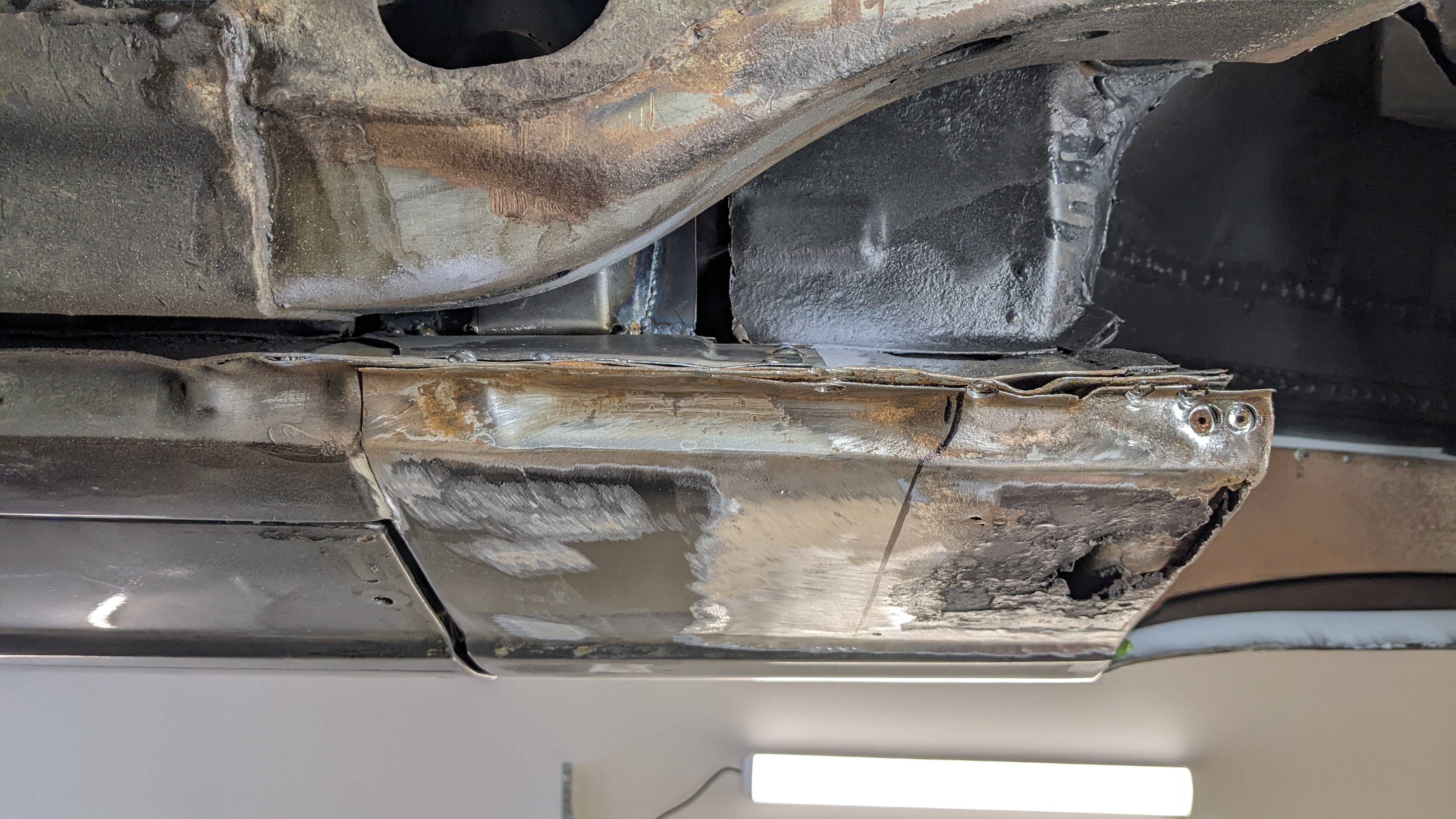

Nice repairs.

Thanks. 50% of something is better than 100% of nothing. Clearly there was nothing left.

Next: the disintegrating quarter panels.

After that: two pages of issues to mitigate.

Nice repairs.

And this is the nicer replacement body you are fixing! You guys have it rough. -30° and your cars disintegrate at an accelerated pace. I feel for you.Thanks. 50% of something is better than 100% of nothing. Clearly there was nothing left.

Next: the disintegrating quarter panels.

After that: two pages of issues to mitigate.

And this is the nicer replacement body you are fixing! You guys have it rough. -30° and your cars disintegrate at an accelerated pace. I feel for you.

So the time has come.

View attachment 189683

View attachment 189684

Five minutes later...

View attachment 189685 View attachment 189686

Out came Mr. Sandblaster. I regret nothing!

View attachment 189688 View attachment 189689

Now I get to build back better (too soon?)... from the inside out.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.