Unfortunately no. That's part of the problem. Each one I make is custom made.

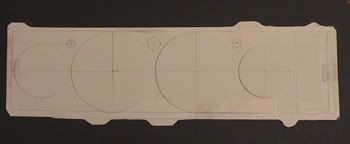

However what I typically do is just trace the outline of the stamped metal piece that covers the gauges and then cut out a piece of metal to that shape. From there I cut out my gauge holes using a hole saw. I then cut the majority of the stock stamped metal piece face out, leaving just an 1/8" lip all the way around.

Then the new metal faceplate can either be riveted or tack welded to the old stamped metal piece. That way the new gauges basically bolt in using the stock hardware.

However what I typically do is just trace the outline of the stamped metal piece that covers the gauges and then cut out a piece of metal to that shape. From there I cut out my gauge holes using a hole saw. I then cut the majority of the stock stamped metal piece face out, leaving just an 1/8" lip all the way around.

Then the new metal faceplate can either be riveted or tack welded to the old stamped metal piece. That way the new gauges basically bolt in using the stock hardware.