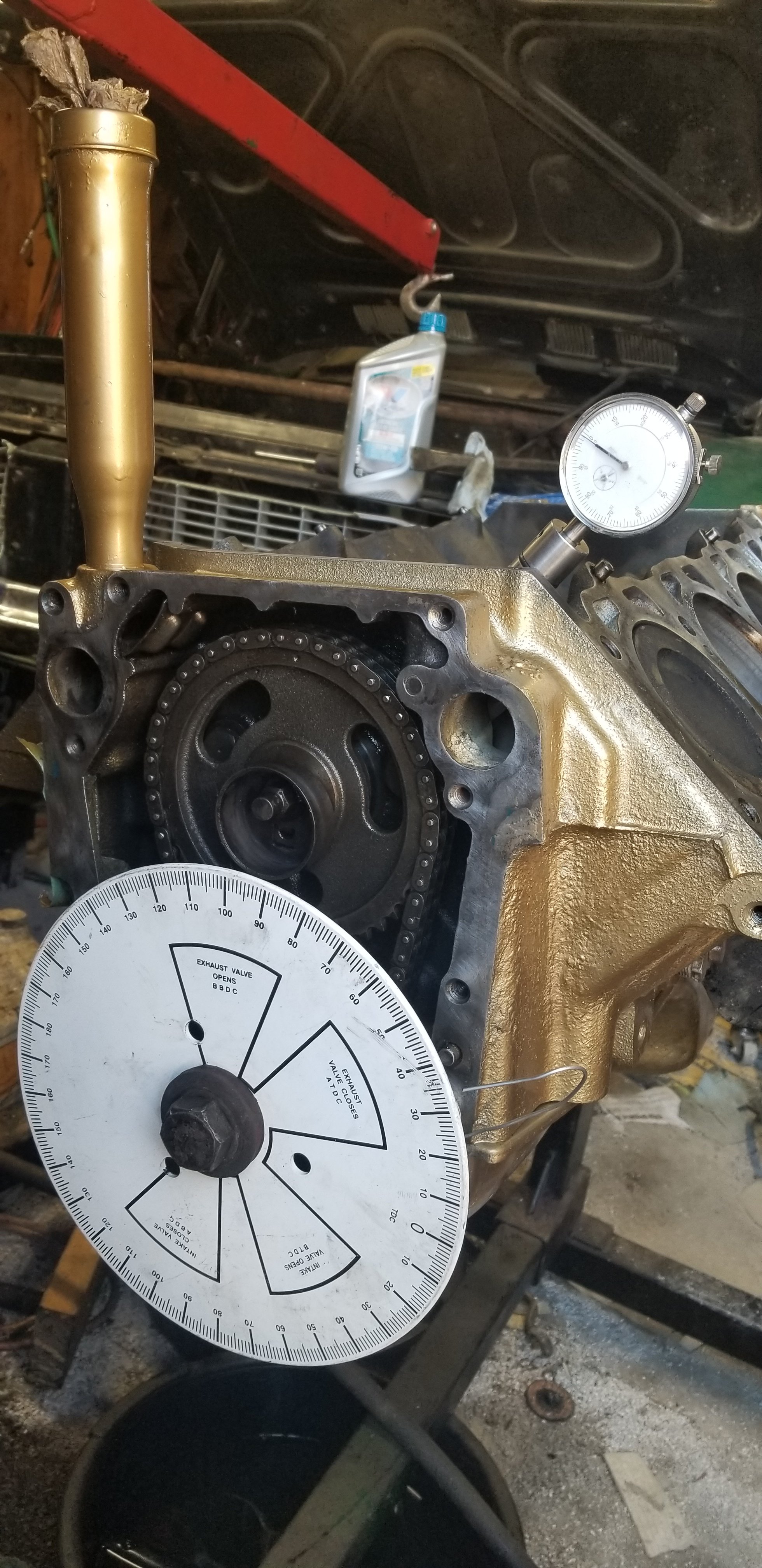

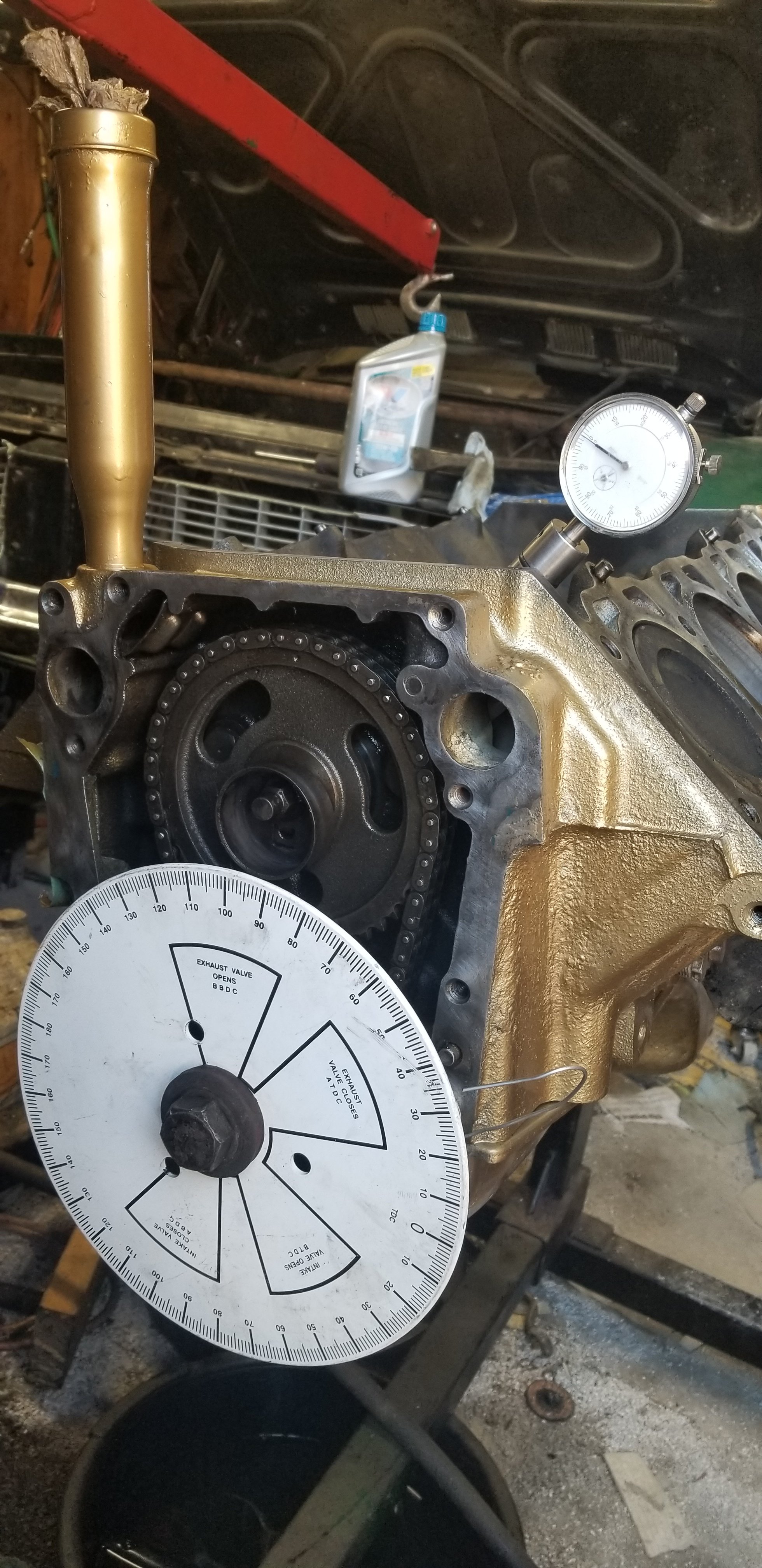

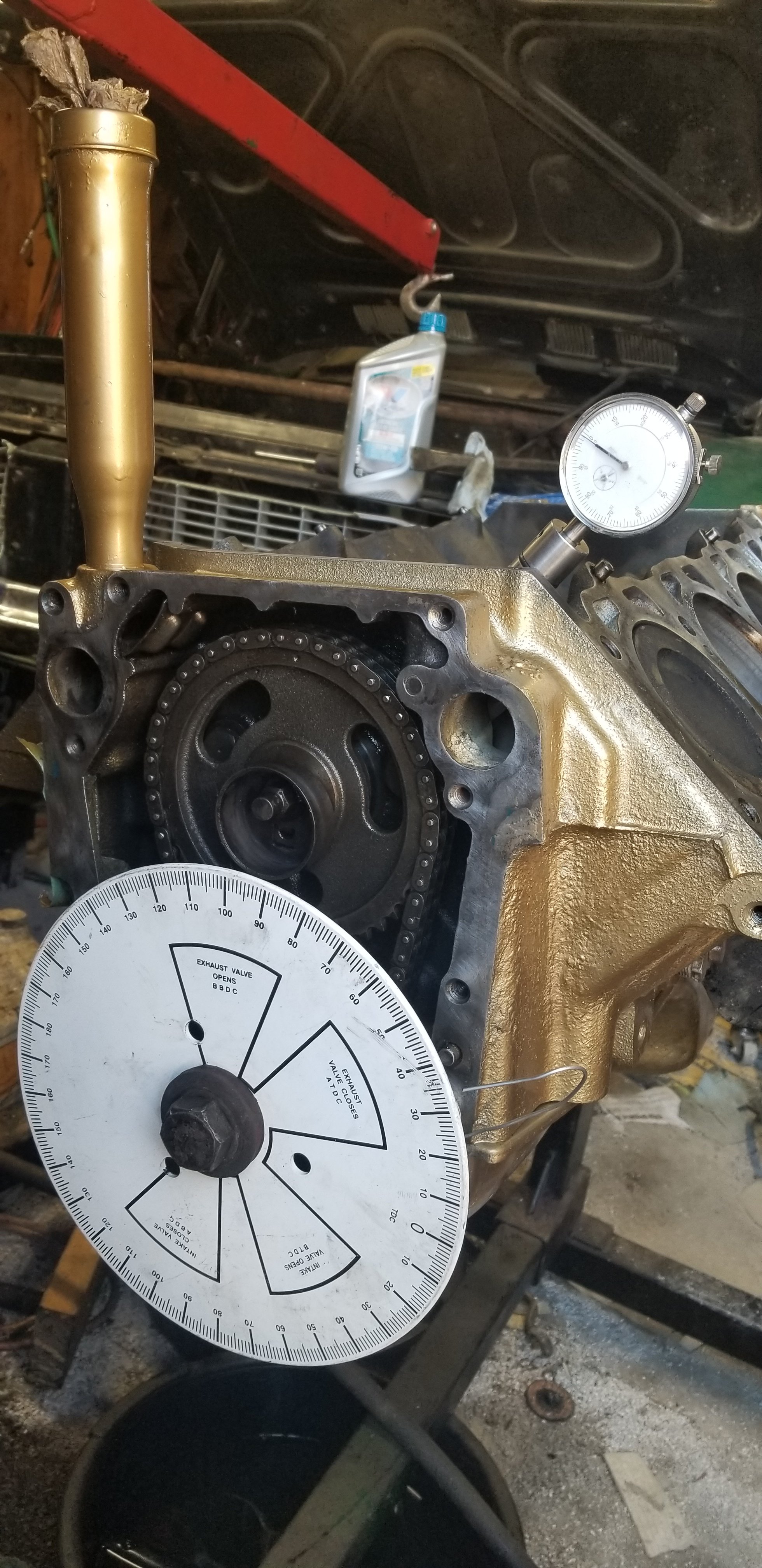

I am a bit rusty at this. Did the actual find TDC with a stopper. I am getting around 15 ATDC at .050" vs the 4 ATDC on the cam card. Here is my set up.

Are you describing two marks on the wheel and splitting the difference, then set the pointer, then adjust the wheel to the pointer?I brought it to what percieved as actual TDC with the piston stop and set that as 0.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.