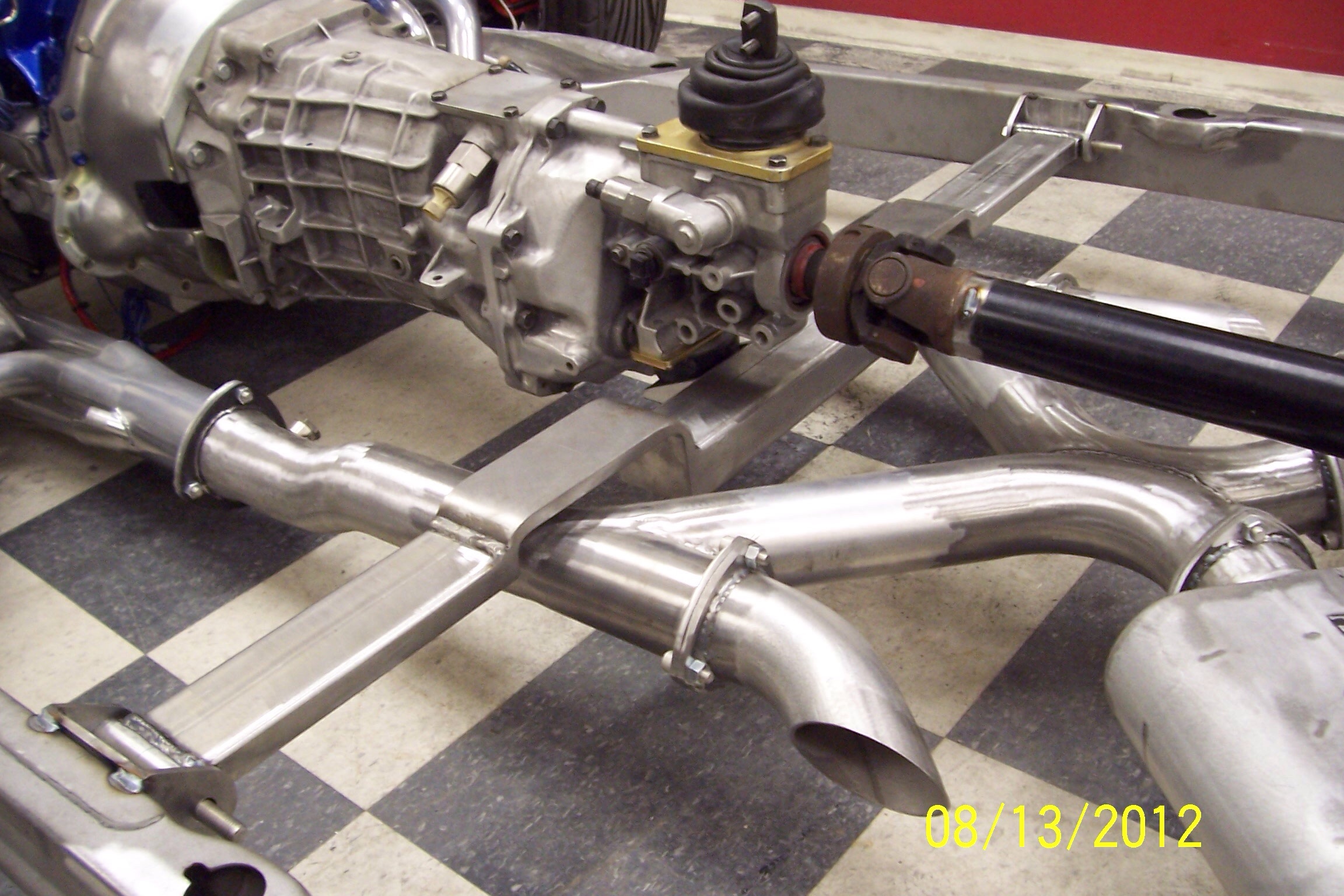

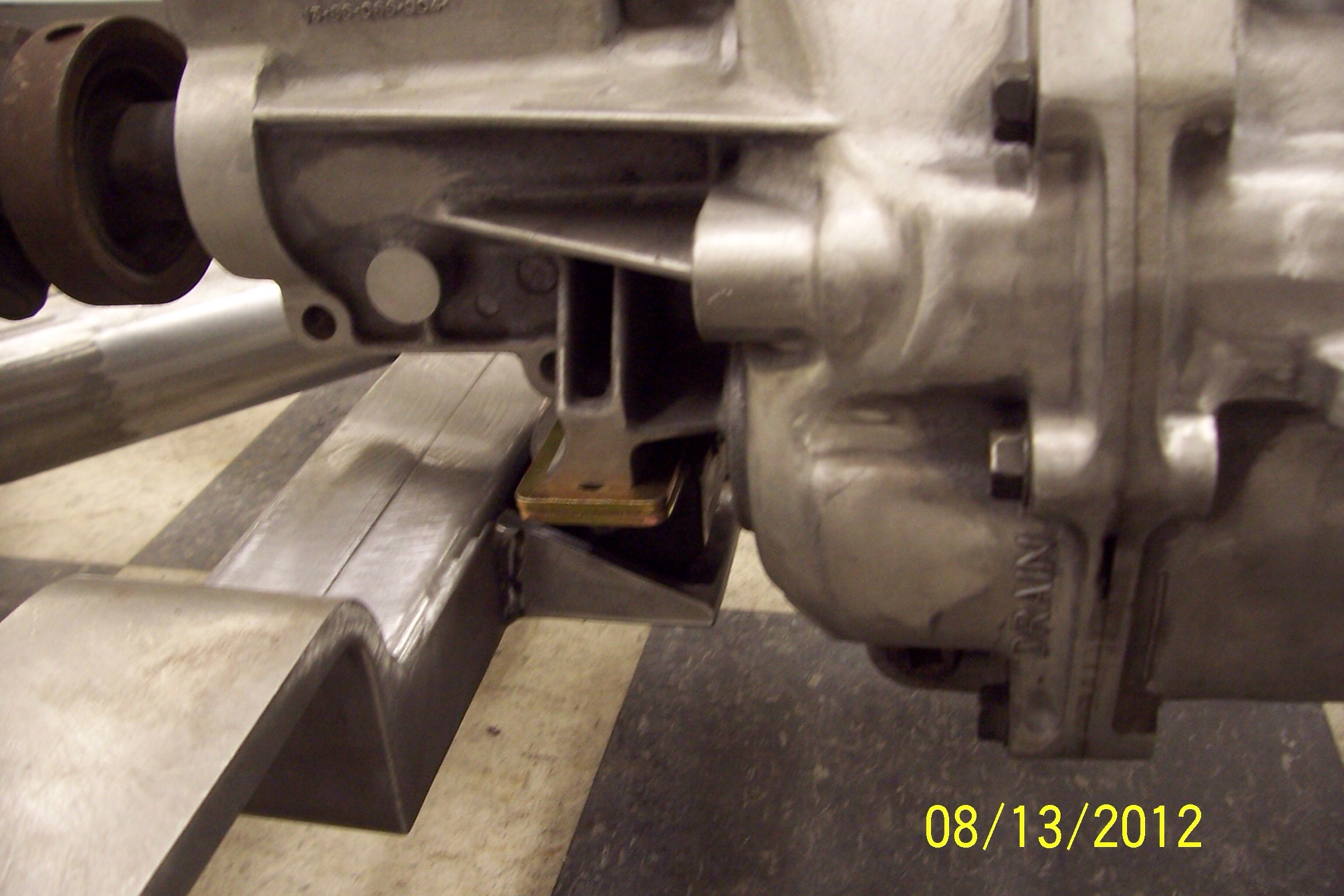

Jeg's product line has not withstood the test of time. It's made of 1-1/2" by 2" tube. The 700-R4 crossmember I bought from them 8 years ago was 1-1/2" x 2-1/2". The 200-4R crossmember cannot be bolted into my Malibu. No, it's not that I am missing the the frame extension. The arch on the driver's side for the exhaust is so badly designed/executed, plus the straight segment is welded on crooked. It almost looks like the assembler swapped the arches driver/passenger. No amount of dimpling will let this POC clear the floorpan. My bushings are factory, but not an inch and half low. The 700-R4 crossmember bolted right in, no issues.

Looking at Summit's 770303, for twice the price. With luck, Jeg's will take this back. Return shipping will suck.

Anyone have good/bad luck with the Summit part?

Looking at Summit's 770303, for twice the price. With luck, Jeg's will take this back. Return shipping will suck.

Anyone have good/bad luck with the Summit part?