Has anyone used the repop GNX rear seat brace on their car? I’m curious as to how it is supposed to be installed; and I’m weighing my options on straight up making one.

GNX rear seat brace

- Thread starter UC645

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I haven't used any, but those kind, IIRC, need to be welded in. They are an integral brace so I wouldn't bolt them in. The originals are spot welded into place.

If I were going to do it, I'd get the X bars in a kit like from Mike's Montes. Around $75.00. Just depends on how far you want to go. Or make your own.

If I were going to do it, I'd get the X bars in a kit like from Mike's Montes. Around $75.00. Just depends on how far you want to go. Or make your own.

Rear Seat Frame Brace Kit-082

www.mikesmontes.com

I cut one out of a Grand Prix and welded it in. The harbor freight spot weld remover tool works good. In my opinion the factory bracing looks so much better than aftermarket options. If you can’t weld you might consider panel bond

It's pretty easy to make your own.

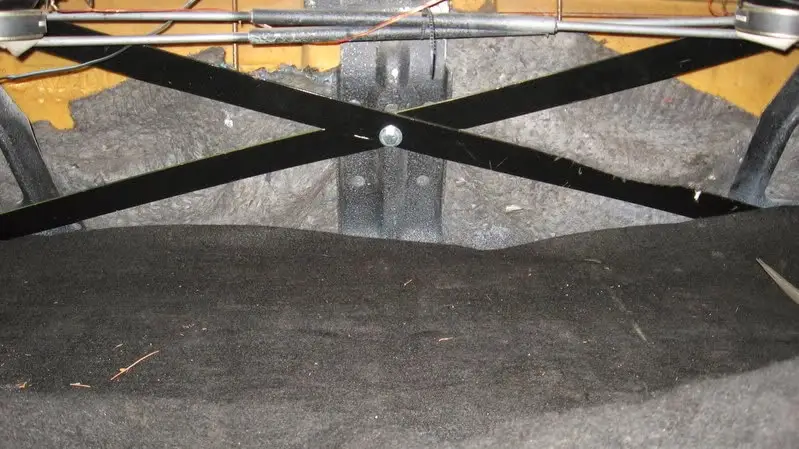

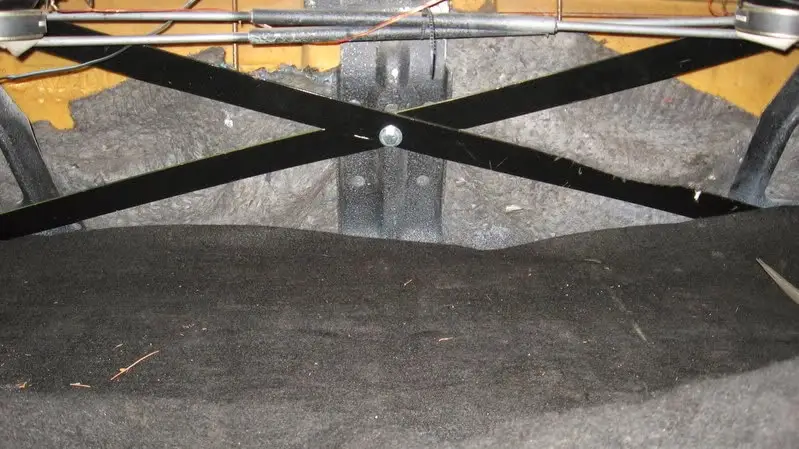

I used some aluminum flat bar and bolted them in place.

Guy

I used some aluminum flat bar and bolted them in place.

Guy

I haven't used any, but those kind, IIRC, need to be welded in. They are an integral brace so I wouldn't bolt them in. The originals are spot welded into place.

If I were going to do it, I'd get the X bars in a kit like from Mike's Montes. Around $75.00. Just depends on how far you want to go. Or make your own.

Rear Seat Frame Brace Kit-082

www.mikesmontes.com

I’ve got several GPs to rob the rear bracing out of, although I might end up making my own. I’d like the brace to pull double duty and serve as a frame for a rear firewall, and possibly hold shelves for amplifiers.I cut one out of a Grand Prix and welded it in. The harbor freight spot weld remover tool works good. In my opinion the factory bracing looks so much better than aftermarket options. If you can’t weld you might consider panel bond

That being said, would .083 wall 1x1 square be overkill for the main part of the brace?

Welding doesn’t really scare me, I need the experience

Best one on the market is the Tin Man brace that Kirban's sells. It is the closest to the factory style used on the GNX. https://www.kirbanperformance.com/product/416/GNX+REAR+SEAT+BRACE+#7169.html

I didn't write that to scare anyone out of tackling some welding. I was just pointing out that it would take more time and involve having to cut out and redo the spot welds, etc. More of a PITA than drilling a few holes and putting in what likely would be the same weight X rods. Which the X rods may get you closer to your goal of reducing flex. I do think if you welded the bracing in, it would be stronger than the X rods. But at least you have several options. It just depends on how far you want to go.

The Tinman brace is what I have in my Regal. I plug welded it in with MIG rather than bolting it in. The GNX braces are just riveted on while the GP are spot welded in.

The Tinman brace is designed to fit over the factory support brackets, no need to drill out factory spotwelds. You just drill it to either bolt into place or plug weld.

The Tinman brace is designed to fit over the factory support brackets, no need to drill out factory spotwelds. You just drill it to either bolt into place or plug weld.

I didn’t think you wrote that to scare anyone, I just meant welding won’t phase me because I really want to learn. My current welds on thin stuff look like trash.I didn't write that to scare anyone out of tackling some welding. I was just pointing out that it would take more time and involve having to cut out and redo the spot welds, etc. More of a PITA than drilling a few holes and putting in what likely would be the same weight X rods. Which the X rods may get you closer to your goal of reducing flex. I do think if you welded the bracing in, it would be stronger than the X rods. But at least you have several options. It just depends on how far you want to go.

As for how far, I think I might combine the X brace idea with the construction and placement of the GNX brace. Having a SRT of bars welded in should reduce flex far more if it’s welded in like the Tinman brace, while giving me ample area to fab plates for a firewall.

Do you have any pictures of how you installed it?The Tinman brace is what I have in my Regal. I plug welded it in with MIG rather than bolting it in. The GNX braces are just riveted on while the GP are spot welded in.

The Tinman brace is designed to fit over the factory support brackets, no need to drill out factory spotwelds. You just drill it to either bolt into place or plug weld.

I didn’t think you wrote that to scare anyone, I just meant welding won’t phase me because I really want to learn. My current welds on thin stuff look like trash.

As for how far, I think I might combine the X brace idea with the construction and placement of the GNX brace. Having a SRT of bars welded in should reduce flex far more if it’s welded in like the Tinman brace, while giving me ample area to fab plates for a firewall.

Do you have any pictures of how you installed it?

Sorry, I don't and its hidden behind the rear seat now. With plug welding, you drill a hole in the top panel, then weld it through to the back panel. It is pretty much one side spot welding.

- Status

- Not open for further replies.

Similar threads

- Replies

- 22

- Views

- 2K

- Replies

- 8

- Views

- 968

- Replies

- 28

- Views

- 4K

- Replies

- 0

- Views

- 1

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.