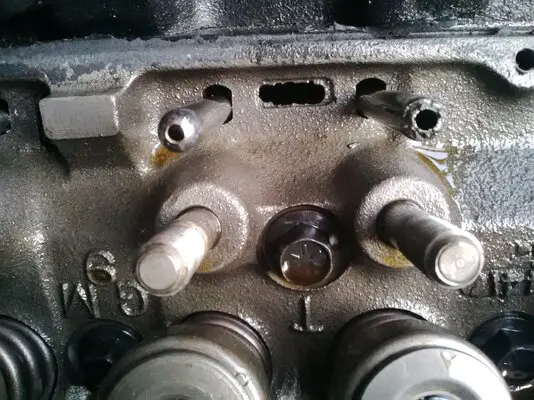

Soo, Ive done everything I was supposed to as far as break in,oil changes etc for my new engine. Had it out a few weeks back and the engine started to tick. got home and pulled the valve cover and noticed # 8 exhaust rocker loose. Went through all the rocker arms and re adjusted them. Was fine till probably tuesday, started ticking again. Now im concerned. My transmission shifts high Ive kicked it down a few times and whatnot but the engine is supposed to be built to the rpm i shift at as i gave all the info to the guy i bought the engine off and was told it wouldnt be a problem..... So my question is what could cause this ? Poor lubrication ? i have a high volume oil pump.... Over rev? or just plain cheap parts ? the bottom of the rocker arms where the pivot ball sits in them is slightly scored and metal is rough to the touch sharp pieces. And the biggie is most of the push rod ends re worn bad, along with the part they sit in on the underside of the rocker arm. Id say some have the end worn right off!! My other worry is internal damage due to the metal loss being sent through the engine oil system ! This is just one pic.

NEW 355 SBC Sick, need help, opinions !

- Thread starter horners85regal

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Are u running a solid or hydr cam? what's the lift? I see u don't have screw in studs are they pin in? What's ur springs set up for too?

I'm curious as to why the engine builder did not break in the cam and is there no warranty on the engine?

I think you should list a breakdown of what was done and what parts were installed in the engine, including cam specs.

You say you have a high volume oil pump but what was your oil pressure at idle and while driving?

It sounds like you are running stock stamped steel rocker arms and if the lift of the cam is too high you would need long slot rocker arms.

Typically rocker arms don't just come loose and based on what appear to be stock heads I would think the press in studs are pulling out since they don't appear to be pinned.

I am also curious as to what your rocker arm adjusted technique is? And I will guess that this is a hydraulic flat tappet cam?

And when you were re-adjusting the rocker arms did you do it while it was running and if so did oil come out of each pushrod hole?

Sorry only questions with no answers but my first guess would be either a binding issue in the valvetrain or a severe misadjustment of the rocker arms.

Add more pictures of the damage and I would pull the intake off and look at all the lifters and I would want to see the other end of those pushrods and keep everything

organized as to what position they were in to help trace the problem.

You say you have a high volume oil pump but what was your oil pressure at idle and while driving?

It sounds like you are running stock stamped steel rocker arms and if the lift of the cam is too high you would need long slot rocker arms.

Typically rocker arms don't just come loose and based on what appear to be stock heads I would think the press in studs are pulling out since they don't appear to be pinned.

I am also curious as to what your rocker arm adjusted technique is? And I will guess that this is a hydraulic flat tappet cam?

And when you were re-adjusting the rocker arms did you do it while it was running and if so did oil come out of each pushrod hole?

Sorry only questions with no answers but my first guess would be either a binding issue in the valvetrain or a severe misadjustment of the rocker arms.

Add more pictures of the damage and I would pull the intake off and look at all the lifters and I would want to see the other end of those pushrods and keep everything

organized as to what position they were in to help trace the problem.

well i am currently emailing the engine builder back and forth.

Dosnt sound too promising for me however.

Thsi is an email from him when i was shopping and questioning the engine,

This is newer emails.............after i sent pics and findings

I said...........

Well this is for sure shitty, in our first emails about an engine for my car I did tell you my WOT shift points, rear end ratio and what not. You told me this engine with a 750 carb would have no issues 6000 to 6500 shifts. Now you are saying after its all in and im having problems it is not built to really go past 5000 rpm? I would not have installed this engine knowing that as I spent a fair bit on having a 200r4 over hauled and fully built to shift hard and high when stepping into it. It never goes to the track and spends 95% of its time at 1800 to 2200 rpm. So I guess this engine wasn't what I needed after all.

i recieved back.......

he said 1 year or 20,000 km warrenty,

this is engine info.....

fully rebuilt 355 cu SB Chevy engine . All new and fresh . Although designed for street use it received all the same prep work as our all out race engines . The block is a early 2 bolt , bored and honed with a deck plate , alighnhone mains , decked square .

Fully balanced rotating assembly , Flat top pistons , Molly rings , HI Pres oil pump , pick up , steel collor drive , double roller chain .

Brand new pan and timing cover . Comp Cams CS 279 H-107 Thumper series cam shaft , 441 casting 2.02/ 1.60 valve cyl. heads . Has all new bronze guides , Comp valve springs , HT locks and stainless roller tip rockers .

It is assembled with all new head bolts and hardware and premium graphite gaskets.

Dosnt sound too promising for me however.

Thsi is an email from him when i was shopping and questioning the engine,

Now i ended up buying performer rpm intake and carb was rebuilt by carbrebuilders after i bought the engine, i sent build sheets and specs.With the right optimum carb and intake 325 hp and very close to 400 + tourque . Keep in mind this is real world not burger king HP . Also it is a premium street thumper worry free pump gas build . It is designed to provide power and tourque in street and mild bracket applications . It is not a race motor . Your intake is a compromize , but a nessesity for egr . The carb I think will work but I think will limit hp and rpm to around 5500 to 6000 . Engine it self will have no issues going 6 to 65 with a Holley style 750 .and worth 25 hp . The carb can be changed any time . Not sure if it helps but I would give the same deal if you wanted to put it on a credit card.

This is newer emails.............after i sent pics and findings

yep . You do not have a valve train to substane 6000 rpm. the valves start to float and everything crashes .

You ccan go to a chrome molly heat treated push rod and roller tip rockers .

Still the valve spring is your limit 5000 to 5200 rpm area . That,s what the engine is designed for .

The rockers and push rods are just under $400.00

I said...........

Well this is for sure shitty, in our first emails about an engine for my car I did tell you my WOT shift points, rear end ratio and what not. You told me this engine with a 750 carb would have no issues 6000 to 6500 shifts. Now you are saying after its all in and im having problems it is not built to really go past 5000 rpm? I would not have installed this engine knowing that as I spent a fair bit on having a 200r4 over hauled and fully built to shift hard and high when stepping into it. It never goes to the track and spends 95% of its time at 1800 to 2200 rpm. So I guess this engine wasn't what I needed after all.

i recieved back.......

Dave the engine does not make power there , why take it that high ?????

You had buget and the diference between a 5500 rpm engine going to 6 ocasionly and a designated 6500 rpm engine is about $2000.00 diference .

Do not make me feel I miss led you .

he said 1 year or 20,000 km warrenty,

this is engine info.....

fully rebuilt 355 cu SB Chevy engine . All new and fresh . Although designed for street use it received all the same prep work as our all out race engines . The block is a early 2 bolt , bored and honed with a deck plate , alighnhone mains , decked square .

Fully balanced rotating assembly , Flat top pistons , Molly rings , HI Pres oil pump , pick up , steel collor drive , double roller chain .

Brand new pan and timing cover . Comp Cams CS 279 H-107 Thumper series cam shaft , 441 casting 2.02/ 1.60 valve cyl. heads . Has all new bronze guides , Comp valve springs , HT locks and stainless roller tip rockers .

It is assembled with all new head bolts and hardware and premium graphite gaskets.

oil pressure is approx 45 psi @ 1800rpm, approx 25 @ idle hot.

And rockers are not comming loose, it was the push rod wearing that caused the clearence, causing the ticking

and adjusted engine off but warm, zero lash, quarter turn, i only have roller tip rockers, so i followed this, (And this is after. it came assembled and ready to go, less intake and carb)

Intake Valve Adjustment: ENGINE OFF!

with #1 cylinder Intake Valve at full valve lift .... Adjust #6 Intake Valve

with #8 cylinder Intake Valve at full valve lift .... Adjust #5 Intake Valve

with #4 cylinder Intake Valve at full valve lift .... Adjust #7 Intake Valve

with #3 cylinder Intake Valve at full valve lift .... Adjust #2 Intake Valve

with #6 cylinder Intake Valve at full valve lift .... Adjust #1 Intake Valve

with #5 cylinder Intake Valve at full valve lift .... Adjust #8 Intake Valve

with #7 cylinder Intake Valve at full valve lift .... Adjust #4 Intake Valve

with #2 cylinder Intake Valve at full valve lift .... Adjust #3 Intake Valve

Exhaust Valve Adjustment: ENGINE OFF!

You will notice that this is the same procedure and sequence as the intake valves listed above. Only now you are adjusting ONLY the exhaust valves the same way.

with #1 cylinder Exhaust Valve at full valve lift .... Adjust #6 Exhaust Valve

with #8 cylinder Exhaust Valve at full valve lift .... Adjust #5 Exhaust Valve

with #4 cylinder Exhaust Valve at full valve lift .... Adjust #7 Exhaust Valve

with #3 cylinder Exhaust Valve at full valve lift .... Adjust #2 Exhaust Valve

with #6 cylinder Exhaust Valve at full valve lift .... Adjust #1 Exhaust Valve

with #5 cylinder Exhaust Valve at full valve lift .... Adjust #8 Exhaust Valve

with #7 cylinder Exhaust Valve at full valve lift .... Adjust #4 Exhaust Valve

with #2 cylinder Exhaust Valve at full valve lift .... Adjust #3 Exhaust Valve

Engine "OFF" Hydraulic Lifter Adjustment:

If the engine is complete and installed in the vehicle you will need to warm up the engine by running it until it gets to operating temperature (15-minutes or so). Have all your tools ready and then quickly remove the valve cover(s) and start the adjustment procedure by using the chart above. With the #1 Intake valve at FULL LIFT. This means that you turn the engine by hand until the intake valve on the #1 cylinder is fully open (watch the rocker arm push down on the top of the valve stem, compressing the valve spring until it stops moving downward). You can now adjust the intake valve on "opposite in firing order" cylinder (see the above chart).

Remember, the opposite is engine firing order dependent. In this article I am using the small and big block Chevy engines as the example, so this would be the #6 cylinder. Loosen the rocker (if using roller rockers there is typically a Jam Nut that you must first loosen with an Allen Wrench). Now, with two fingers spinning the pushrod between them to feel for resistance you carefully snug the adjustment nut. When you feel resistance in the pushrod as it applies pressure to the socket in the rocker arm and lifter - STOP, now you will adjust the nut down "Only" 1/8-1/2 turn further. If you operate your engine a consistent high RPM, use the slightly lighter setting of (1/8 turn).

And rockers are not comming loose, it was the push rod wearing that caused the clearence, causing the ticking

and adjusted engine off but warm, zero lash, quarter turn, i only have roller tip rockers, so i followed this, (And this is after. it came assembled and ready to go, less intake and carb)

Intake Valve Adjustment: ENGINE OFF!

with #1 cylinder Intake Valve at full valve lift .... Adjust #6 Intake Valve

with #8 cylinder Intake Valve at full valve lift .... Adjust #5 Intake Valve

with #4 cylinder Intake Valve at full valve lift .... Adjust #7 Intake Valve

with #3 cylinder Intake Valve at full valve lift .... Adjust #2 Intake Valve

with #6 cylinder Intake Valve at full valve lift .... Adjust #1 Intake Valve

with #5 cylinder Intake Valve at full valve lift .... Adjust #8 Intake Valve

with #7 cylinder Intake Valve at full valve lift .... Adjust #4 Intake Valve

with #2 cylinder Intake Valve at full valve lift .... Adjust #3 Intake Valve

Exhaust Valve Adjustment: ENGINE OFF!

You will notice that this is the same procedure and sequence as the intake valves listed above. Only now you are adjusting ONLY the exhaust valves the same way.

with #1 cylinder Exhaust Valve at full valve lift .... Adjust #6 Exhaust Valve

with #8 cylinder Exhaust Valve at full valve lift .... Adjust #5 Exhaust Valve

with #4 cylinder Exhaust Valve at full valve lift .... Adjust #7 Exhaust Valve

with #3 cylinder Exhaust Valve at full valve lift .... Adjust #2 Exhaust Valve

with #6 cylinder Exhaust Valve at full valve lift .... Adjust #1 Exhaust Valve

with #5 cylinder Exhaust Valve at full valve lift .... Adjust #8 Exhaust Valve

with #7 cylinder Exhaust Valve at full valve lift .... Adjust #4 Exhaust Valve

with #2 cylinder Exhaust Valve at full valve lift .... Adjust #3 Exhaust Valve

Engine "OFF" Hydraulic Lifter Adjustment:

If the engine is complete and installed in the vehicle you will need to warm up the engine by running it until it gets to operating temperature (15-minutes or so). Have all your tools ready and then quickly remove the valve cover(s) and start the adjustment procedure by using the chart above. With the #1 Intake valve at FULL LIFT. This means that you turn the engine by hand until the intake valve on the #1 cylinder is fully open (watch the rocker arm push down on the top of the valve stem, compressing the valve spring until it stops moving downward). You can now adjust the intake valve on "opposite in firing order" cylinder (see the above chart).

Remember, the opposite is engine firing order dependent. In this article I am using the small and big block Chevy engines as the example, so this would be the #6 cylinder. Loosen the rocker (if using roller rockers there is typically a Jam Nut that you must first loosen with an Allen Wrench). Now, with two fingers spinning the pushrod between them to feel for resistance you carefully snug the adjustment nut. When you feel resistance in the pushrod as it applies pressure to the socket in the rocker arm and lifter - STOP, now you will adjust the nut down "Only" 1/8-1/2 turn further. If you operate your engine a consistent high RPM, use the slightly lighter setting of (1/8 turn).

Looks like spring bind and too much preload, maybe. Better drain the oil and get the metal shaving out before starting her up again.

how is that so ? and the engine shop had them pre set ( no adjustment needed ) when i received the engine.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 338

- Replies

- 5

- Views

- 997

- Replies

- 11

- Views

- 1K

- Replies

- 8

- Views

- 870

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.