You know in theory those bent studs would help keep the wheels. Atleast you're not asking how to fix this and then end up buying a set of over priced chrome lug nuts.

On the 'mildly' Cheap SS Monte Carlo chasing a 9.0____(oil pan woes)

- Thread starter 64nailhead

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Supercharged111 ’I’ll see your 10 bent studs with 4 bent and one broken stud’

You win hehe!!

I had every plan to change to 5/8 after January 8th. January 8th I have a dyno appointment. So now I’m in a bit of a conundrum. I’d like to send the axles out tomorrow (7 day turnaround from Quicks) to be drilled for 5/8, or should I put in another set 1/2” to get me to the dyno appointment without issue and then change after that?

I doubt I’ll bend a set on the dyno and now I need a new set anyway if I ever want to change back to 1/2” for wheel fitment.

I think I’ll have a beer and sleep on it.

You win hehe!!

Yup.1/2-20?

Been there, done that....

I had every plan to change to 5/8 after January 8th. January 8th I have a dyno appointment. So now I’m in a bit of a conundrum. I’d like to send the axles out tomorrow (7 day turnaround from Quicks) to be drilled for 5/8, or should I put in another set 1/2” to get me to the dyno appointment without issue and then change after that?

I doubt I’ll bend a set on the dyno and now I need a new set anyway if I ever want to change back to 1/2” for wheel fitment.

I think I’ll have a beer and sleep on it.

Grinding away.

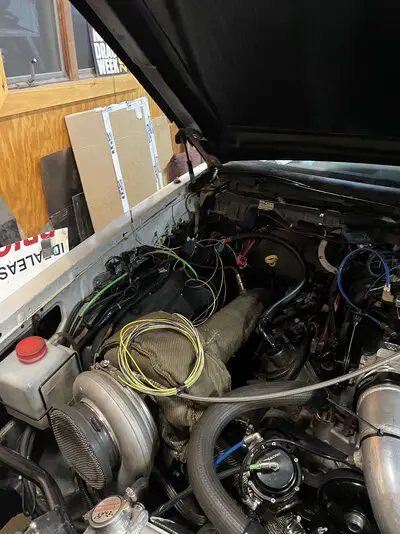

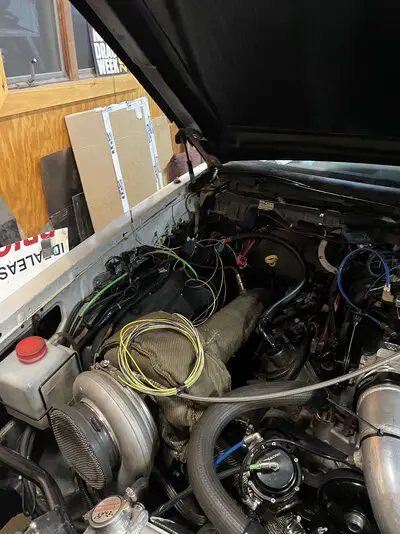

New master cylinder installed, brakes bled (wheel studs replaced), and wiring getting installed for exhaust pressure sensor, front wheel speed sensor (traction control in my future hopefully), line lock input for burnout box limiter.

Hopefully take it for a ride this weekend to seat the rings before I hit the dyno next weekend

New master cylinder installed, brakes bled (wheel studs replaced), and wiring getting installed for exhaust pressure sensor, front wheel speed sensor (traction control in my future hopefully), line lock input for burnout box limiter.

Hopefully take it for a ride this weekend to seat the rings before I hit the dyno next weekend

I've been out with it. The new sensors seem to be working well other than some fine tuning - I need to set the broadcast rate higher - 10 times per second isn't fast enough. But I'm getting some data that seems accurate.

I really wanted to make some hard pulls, but I've given up on that because I'm traction limited. The 255/60/15's just can't grab ahold of the road at 40-50 degree ambient temps. I tried at 10, 20, 40, 60mph and it just breaks them free on WG spring pressure. So 6500 rpm's is all I can get (spinning).

Shockingly, no leaks. One thing that is not what I expected (possibly concerning) is that my oil pressure is not getting much over 60 psi. I used to see it hit 65psi at 6500, but now I'm seeing high 50's. I'm not too concerned (other than I worry about everything). I was expecting to see another 10-12 psi at mid 6k rpm range. And it needs more fuel then it did before - like 10-15% reasons possibly being more compression, freshly cleaned and serviced injectors........I'm not sure. But I'm a big fan of giving it what it wants. I'm not concerned about the oil pressure until it gets to the low 40's at full rpm (7500).

Next weekend I'll have it on a dyno. I'm not shooting for any number or trying to beat anyone with dyno HP numbers. My goal is to make sure it will have a safe tune at 25ish psi before I head to Florida (Sick Week) in Feb. The only dyno time that I can find locally (sort of) is the Sloppy Mechanic guy (Matt Happel) in Allentown, PA. He is very well versed in what I'm running and I hope to learn something.

For those that aren't aware of the winter upgrades - I've rebuilt it with .030" over Summit rod/piston combo, new crank and cam bearings, properly sized head gaskets, Treadstone intercooler, Blazer front brake upgrade, ARP head studs and some new sensors - Exhaust Back Pressure (between exhaust manifold and turbo turbine) and a front wheel speed sensor. I hit 10psi on my pulls and the IAT temp has yet to hit 70 degrees. But current conditions aren't good for making any decisions about the IC efficiency because ambient temps aren't very warm. And regarding more fuel, it appears to only be making 10psi on WG - that's a section of the fuel table that I've never run in due to the previous setup.

I really wanted to make some hard pulls, but I've given up on that because I'm traction limited. The 255/60/15's just can't grab ahold of the road at 40-50 degree ambient temps. I tried at 10, 20, 40, 60mph and it just breaks them free on WG spring pressure. So 6500 rpm's is all I can get (spinning).

Shockingly, no leaks. One thing that is not what I expected (possibly concerning) is that my oil pressure is not getting much over 60 psi. I used to see it hit 65psi at 6500, but now I'm seeing high 50's. I'm not too concerned (other than I worry about everything). I was expecting to see another 10-12 psi at mid 6k rpm range. And it needs more fuel then it did before - like 10-15% reasons possibly being more compression, freshly cleaned and serviced injectors........I'm not sure. But I'm a big fan of giving it what it wants. I'm not concerned about the oil pressure until it gets to the low 40's at full rpm (7500).

Next weekend I'll have it on a dyno. I'm not shooting for any number or trying to beat anyone with dyno HP numbers. My goal is to make sure it will have a safe tune at 25ish psi before I head to Florida (Sick Week) in Feb. The only dyno time that I can find locally (sort of) is the Sloppy Mechanic guy (Matt Happel) in Allentown, PA. He is very well versed in what I'm running and I hope to learn something.

For those that aren't aware of the winter upgrades - I've rebuilt it with .030" over Summit rod/piston combo, new crank and cam bearings, properly sized head gaskets, Treadstone intercooler, Blazer front brake upgrade, ARP head studs and some new sensors - Exhaust Back Pressure (between exhaust manifold and turbo turbine) and a front wheel speed sensor. I hit 10psi on my pulls and the IAT temp has yet to hit 70 degrees. But current conditions aren't good for making any decisions about the IC efficiency because ambient temps aren't very warm. And regarding more fuel, it appears to only be making 10psi on WG - that's a section of the fuel table that I've never run in due to the previous setup.

Kickin' butt!

Glad to see it's back together in such short order.

What's the trailer plan for SW? Uhaul rental again?

Glad to see it's back together in such short order.

What's the trailer plan for SW? Uhaul rental again?

Already rented one. Picking it up 3 miles from the hotel on Saturday. $115 for the week.Kickin' butt!

Glad to see it's back together in such short order.

What's the trailer plan for SW? Uhaul rental again?

Only an extra 4-5 or so with the .030" overbore. It could be a bunch of things causing it, but I'm not to concerned abut needing more fuel - I have more than enough with the 3 pumps. Hopefully more than enough for 1200whp and perhaps 1400. I never expected to run out when I did (obviously!)More cubes require more fuel, no?

I have to admit though, it was nice to get in some seat time, even if it was only for 20 minutes or so.

I've been busy.

Last weekend took the car to the dyno operated by Matt Happel (sloppy mechanic guy). Determined that something was wrong. Never really cranked it up past mid 20's for boost. It was making heat and backpressure very early anywhere over 15psi. We believed it was a turbo issue as the fuel consumption and boost indicated alot more horsepower than what the dyno was reading. It put down low 700's, but made enough boost and consumed enough fuel for 900 whp. The popular consensus was I should try another turbo. The positive was that the freshly assembled motor performed flawlessly, but power was down. Happel operated the car on the dyno and didn't run it much over 6700 rpm's (???). He also left a couple of things very puzzling in my tune, but oh well - I'm moving on.

A friend, that went with me, made a couple of calls and found one of his friends had a new VS racing T6 85/102 with a race cover new in the box (70 miles from me). This is a more optimized setup than my 88/96 T6 with a standard cover. The race cover is advertised to make another 30-50hp. So I grabbed that and got it installed. Of course the race cover required some minor modifications to my cold side piping due to it's dimensionally larger than mine. But the turbine side is exactly the same for the exhaust mounting. I also installed a 2nd WG due to I was having a ton of boost creep. The boost creep isn't the end of world other than it is uncontrollable when trying to get it going before the 330'.

Onto today, was able to get it to another dyno a little closer (1.5 hrs vs 2.5hrs from home). And just like last weekend, had success and found another issue. The previous issues were resolved as far as I can tell. But either the converter, trans or combination of both has given up the ghost. At this moment I cannot confirm that the trans is not the issue, but the converter definitely is FUBAR. The 5th or 6th run, as we began turning it up, I made 820 at 25psi with crazy conservative timing of 11 degrees and 10.5 AFR - the wheel speed was 127 mpg at 6800rpm's (27" tire). As I began to dial in the timing and AFR the wheel speed began dropping. By the time I was done the converter slip increased to a little over 25% and the wheel speed was at 82 MPH at 7400rpm's, which of course related to less HP. For some reason the TQ # went up until the last couple of pulls, then it followed the wheel speed and HP onto the downward trajectory.

I have 27 days before Sick Week to get the converter re-worked and have the transmission checked. I had every intention to not having any of these type of 'down to the wire 'issues', but as always, here I am.

The EXTREMELY positive is that it made 820 before something went wrong between the engine and rear end on very conservative timing, AFR and boost. If I can get this trans/torque converter combo to work, then hold TF on when I put it between 30-35psi.

Notables - I spun it 7800 with no issues at least 5 times today and it spun 7500 more time than that (17 pulls in 3 hours). The Treadstone IC is crazy....and I mean crazy. I never seen a pull at 25-27psi have an intake temp of more than 72 degrees - the pre IC temps were at 200 consistently - I made all of these pulls with the meth injection turned off. I used to see 170+ IAT with the meth injection and 220 without at 27-28psi.

I'll try to get some videos posted on my YT channel so that I can link them here they are kinda boring after seeing one or two - plenty of noise and turbo whooshy sounds haha).

Last weekend took the car to the dyno operated by Matt Happel (sloppy mechanic guy). Determined that something was wrong. Never really cranked it up past mid 20's for boost. It was making heat and backpressure very early anywhere over 15psi. We believed it was a turbo issue as the fuel consumption and boost indicated alot more horsepower than what the dyno was reading. It put down low 700's, but made enough boost and consumed enough fuel for 900 whp. The popular consensus was I should try another turbo. The positive was that the freshly assembled motor performed flawlessly, but power was down. Happel operated the car on the dyno and didn't run it much over 6700 rpm's (???). He also left a couple of things very puzzling in my tune, but oh well - I'm moving on.

A friend, that went with me, made a couple of calls and found one of his friends had a new VS racing T6 85/102 with a race cover new in the box (70 miles from me). This is a more optimized setup than my 88/96 T6 with a standard cover. The race cover is advertised to make another 30-50hp. So I grabbed that and got it installed. Of course the race cover required some minor modifications to my cold side piping due to it's dimensionally larger than mine. But the turbine side is exactly the same for the exhaust mounting. I also installed a 2nd WG due to I was having a ton of boost creep. The boost creep isn't the end of world other than it is uncontrollable when trying to get it going before the 330'.

Onto today, was able to get it to another dyno a little closer (1.5 hrs vs 2.5hrs from home). And just like last weekend, had success and found another issue. The previous issues were resolved as far as I can tell. But either the converter, trans or combination of both has given up the ghost. At this moment I cannot confirm that the trans is not the issue, but the converter definitely is FUBAR. The 5th or 6th run, as we began turning it up, I made 820 at 25psi with crazy conservative timing of 11 degrees and 10.5 AFR - the wheel speed was 127 mpg at 6800rpm's (27" tire). As I began to dial in the timing and AFR the wheel speed began dropping. By the time I was done the converter slip increased to a little over 25% and the wheel speed was at 82 MPH at 7400rpm's, which of course related to less HP. For some reason the TQ # went up until the last couple of pulls, then it followed the wheel speed and HP onto the downward trajectory.

I have 27 days before Sick Week to get the converter re-worked and have the transmission checked. I had every intention to not having any of these type of 'down to the wire 'issues', but as always, here I am.

The EXTREMELY positive is that it made 820 before something went wrong between the engine and rear end on very conservative timing, AFR and boost. If I can get this trans/torque converter combo to work, then hold TF on when I put it between 30-35psi.

Notables - I spun it 7800 with no issues at least 5 times today and it spun 7500 more time than that (17 pulls in 3 hours). The Treadstone IC is crazy....and I mean crazy. I never seen a pull at 25-27psi have an intake temp of more than 72 degrees - the pre IC temps were at 200 consistently - I made all of these pulls with the meth injection turned off. I used to see 170+ IAT with the meth injection and 220 without at 27-28psi.

I'll try to get some videos posted on my YT channel so that I can link them here they are kinda boring after seeing one or two - plenty of noise and turbo whooshy sounds haha).

Similar threads

- Replies

- 21

- Views

- 3K

- Replies

- 5

- Views

- 644

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.