Alright guys, I’ve got a TON of info and progress to share with you, an awful lot has happened in this last week. Unfortunately I’m a bit pressed for time tonight, and probably won’t get through everything I have to share.

So this just might be a two night update, seeing as how SOME of us have to work and can’t be lollygagging on the forum all day long.

😉

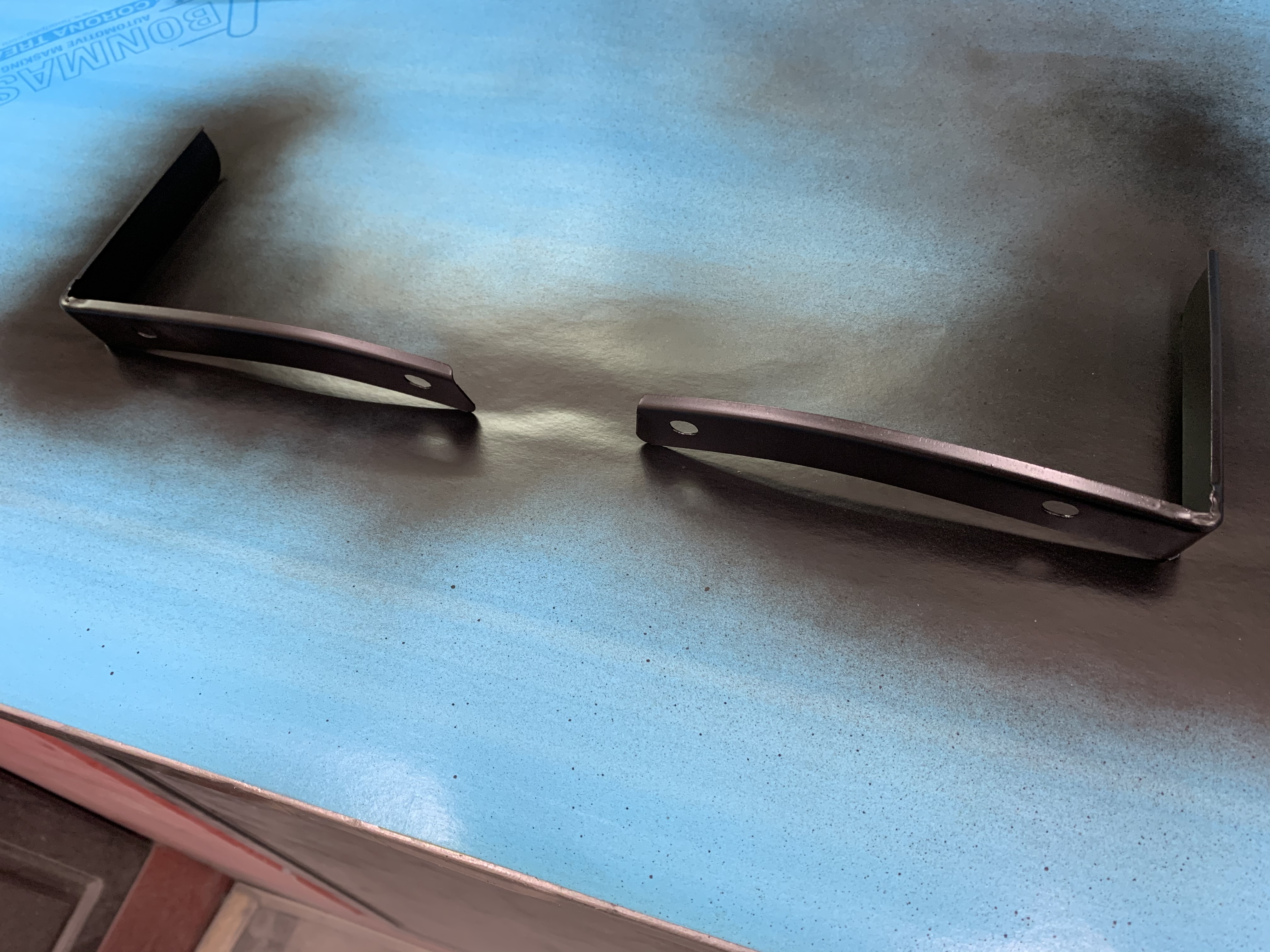

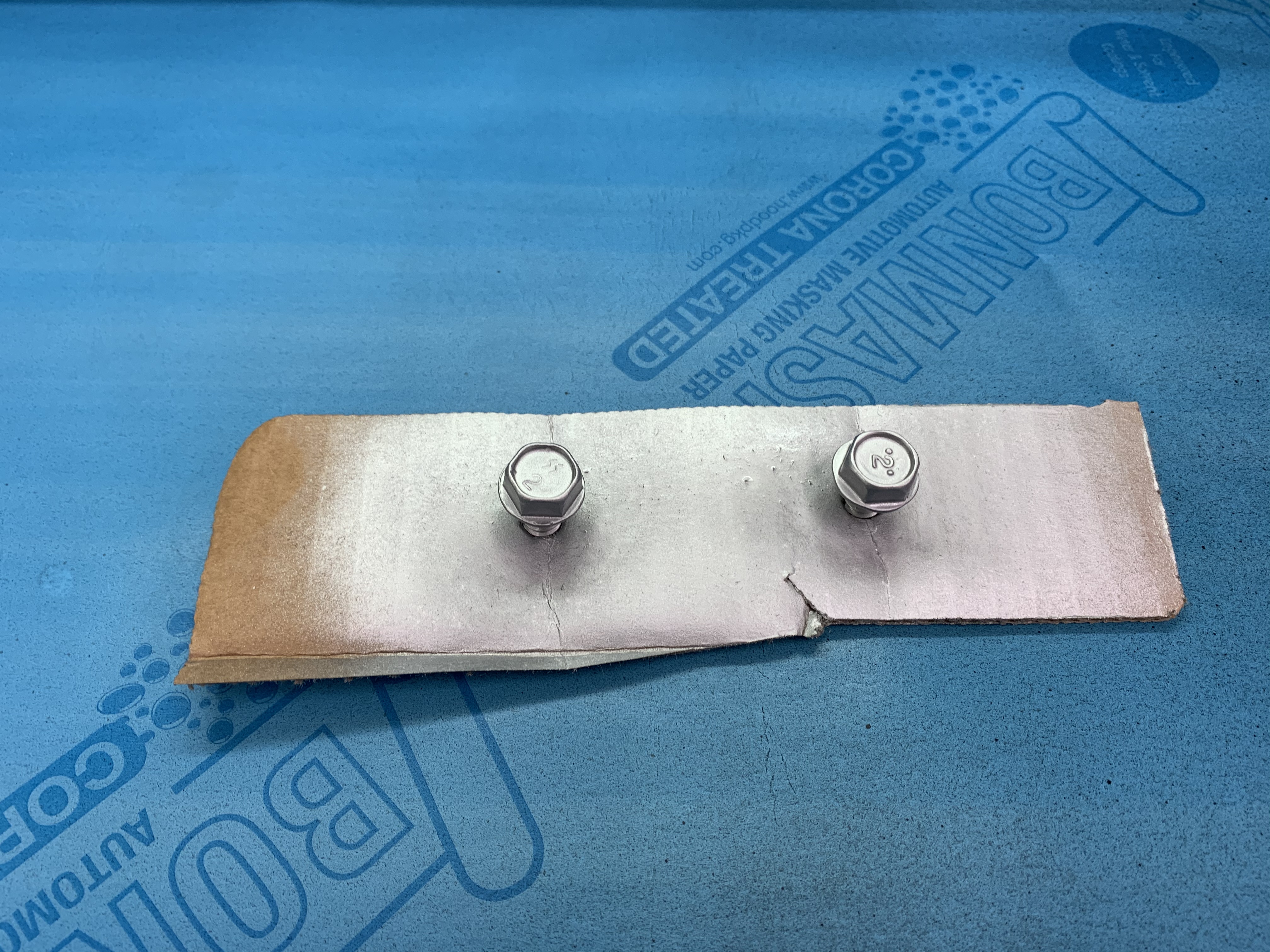

Anyhow, we’ll start with last Friday. After work I stayed behind for a half hour and did some sandblasting of small parts. Then stopped by one of the parts stores and grabbed a few items. The stuff I sandblasted was the 2 horns and brackets, their mounting hardware, and the two rubber front filler panel reinforcing brackets. Here they are along with some 1156 equivalent LED bulbs I grabbed.

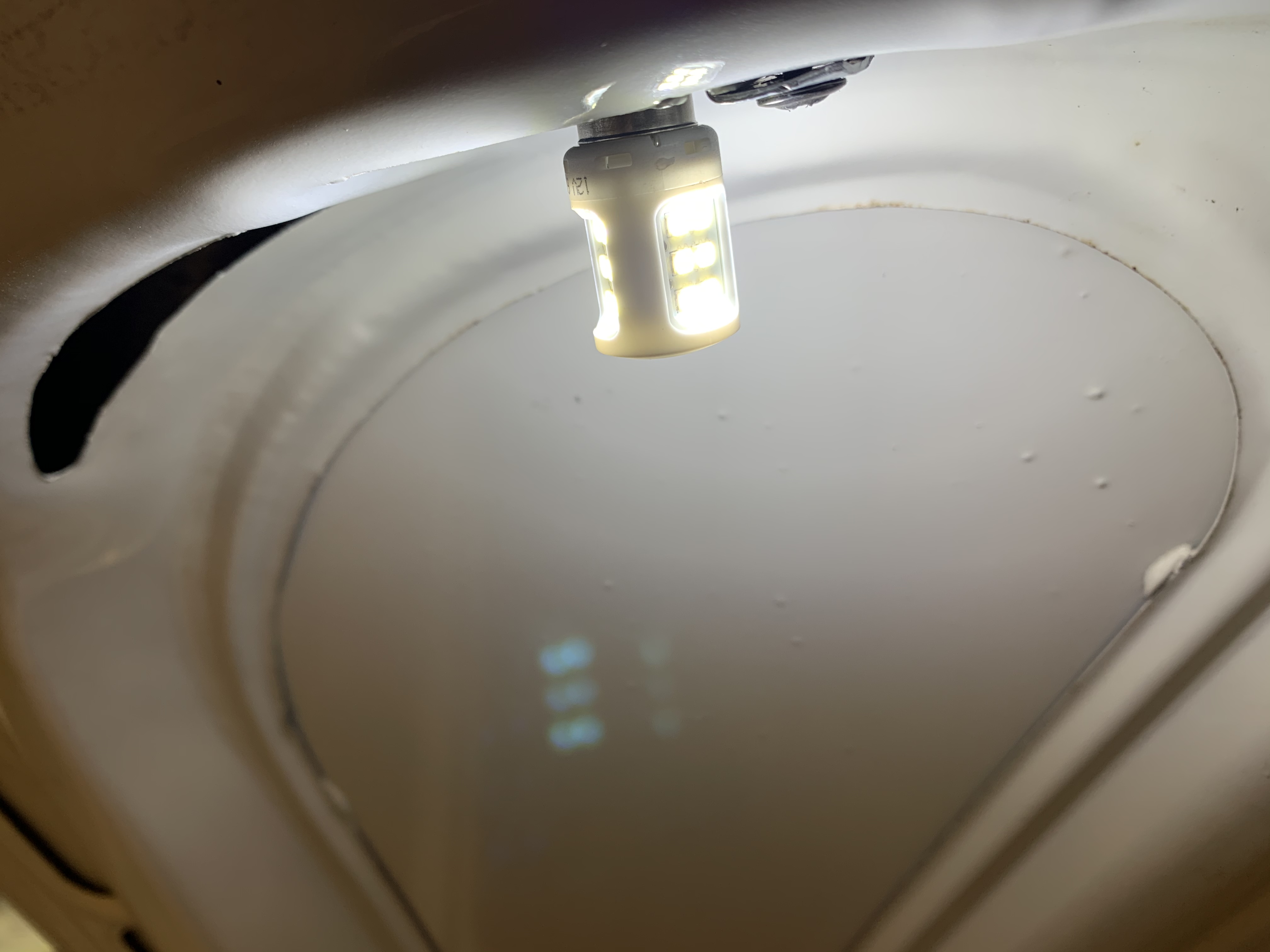

I started off Saturday by thinking I’d just pop the LED bulbs in the trunk and under hood lights real quick, then move on. However when I installed the LED bulb in the trunk light housing, I quickly realized I wasn’t happy with the lighting. It wasn’t that the bulb wasn’t bright enough, it was plenty bright, but it was that it sat recessed in the trunk structure too far. Because the ends of the LED bulbs I got are capped and don’t emit any light, the shrouding in the structure was prohibitive.

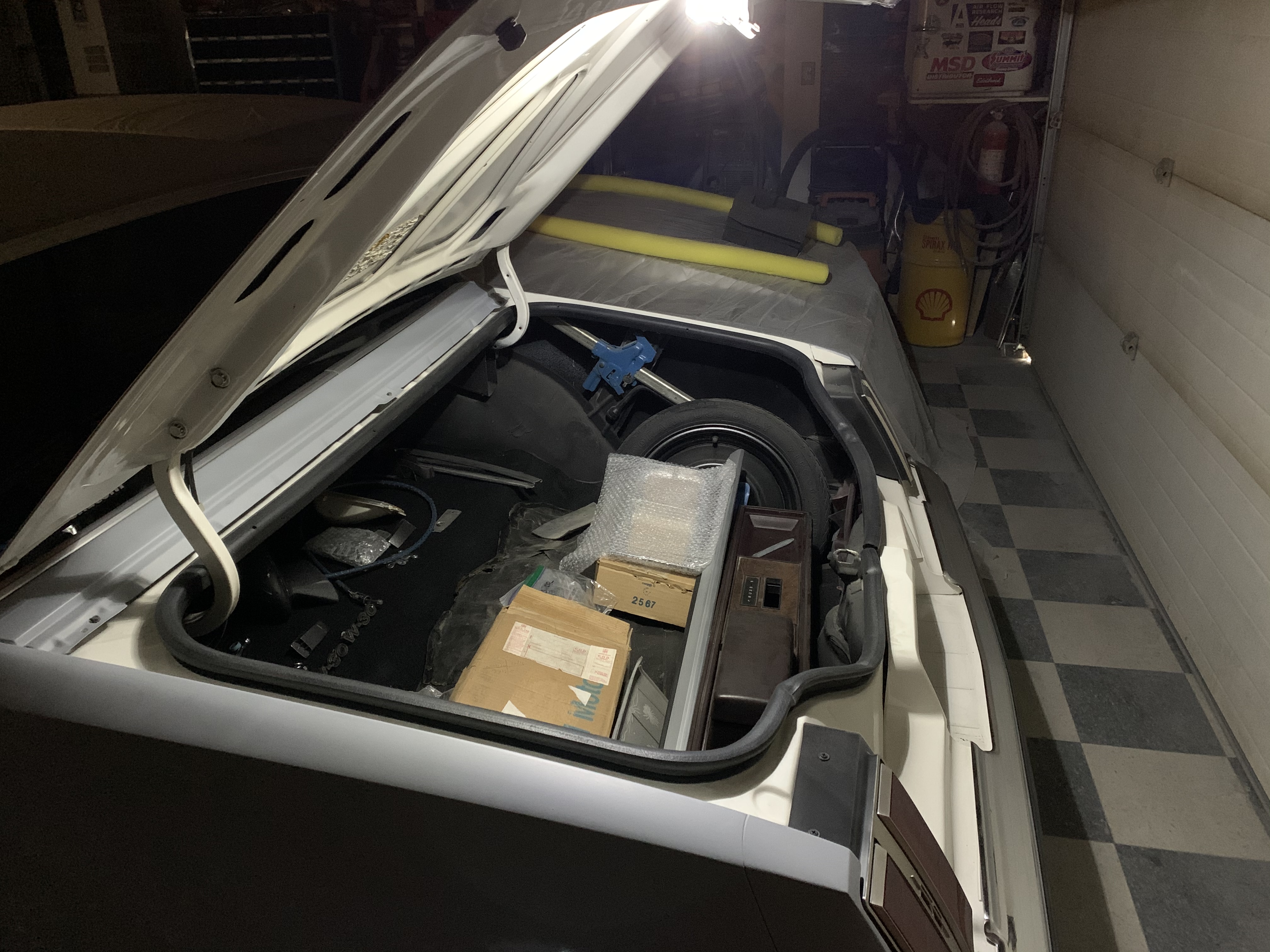

So I did an easy hack and modified the bracket slightly to make the bulb protrude a bit more but keep the wiring hidden inside. It worked like a charm. Here’s the trunk all lit up with the new LED bulb, I took these pictures with the lights in the shop turned off:

Don’t mind the mess in the trunk, it’s temporary storage for the time being.

As you can see, it has absolutely no problem lighting up the whole area!

The under hood light was much simpler, just a straight re and re:

Looks pretty good under there now though too.

With that behind me, I proceeded to shoot the blasted parts with a little VHT satin black and “cast aluminum” for the horn bolts:

I didn’t take any pictures before blasting, but trust me, they needed it. They were all a rusty scabby mess. Much better now.

While they were drying, I knew that moving on to the AstroRoof was gonna be the next project to tackle. To do this, I needed good clear access to both sides of the car. So out came the jack and the floor dollies and on and over she went.

Yikes! Been a while since I saw this part of the floor apparently!

After I swept up the dust bunny disaster, I proceeded with my plan of attack. Now, a quick little back story on the AstroRoof situation:

Last spring I went through and restored the whole thing from top to bottom and reinstalled the completed assembly with a reproduction outer weatherstrip seal from GbodyParts.com. It was disheartening to say the least, when, after all that work the new seal was found to be too stiff and wouldn’t allow the outer panel insert to compress it and sit flush with the rest of the roof.

In disgust, I walked away from it and moved on to the other panels that needed attention. For like 10 months. But during that entire time, I would often stop and analyze how it sat in the roof in the closed position. I eventually resigned myself to the fact that I likely had a secondary problem that was compounding the issue. When I pulled the outer pan for restoration, it was badly rusted and needed major repair. It was necessary at the time to separate the front and rear insert reinforcements and pretty much rebuild the entire thing.

However.

I had a sneaking suspicion that all that fabrication and welding had pulled the rear corners down slightly. I couldn’t confirm it with the insert in place, but if this was indeed the case, no amount of seal swapping or track adjusting was gonna fix it. For those with good memories, you’ll recall that I had to flatten out the front edge with a jig and some clamps (which worked great), but at the time I never thought to check the rear edge of the insert as well.

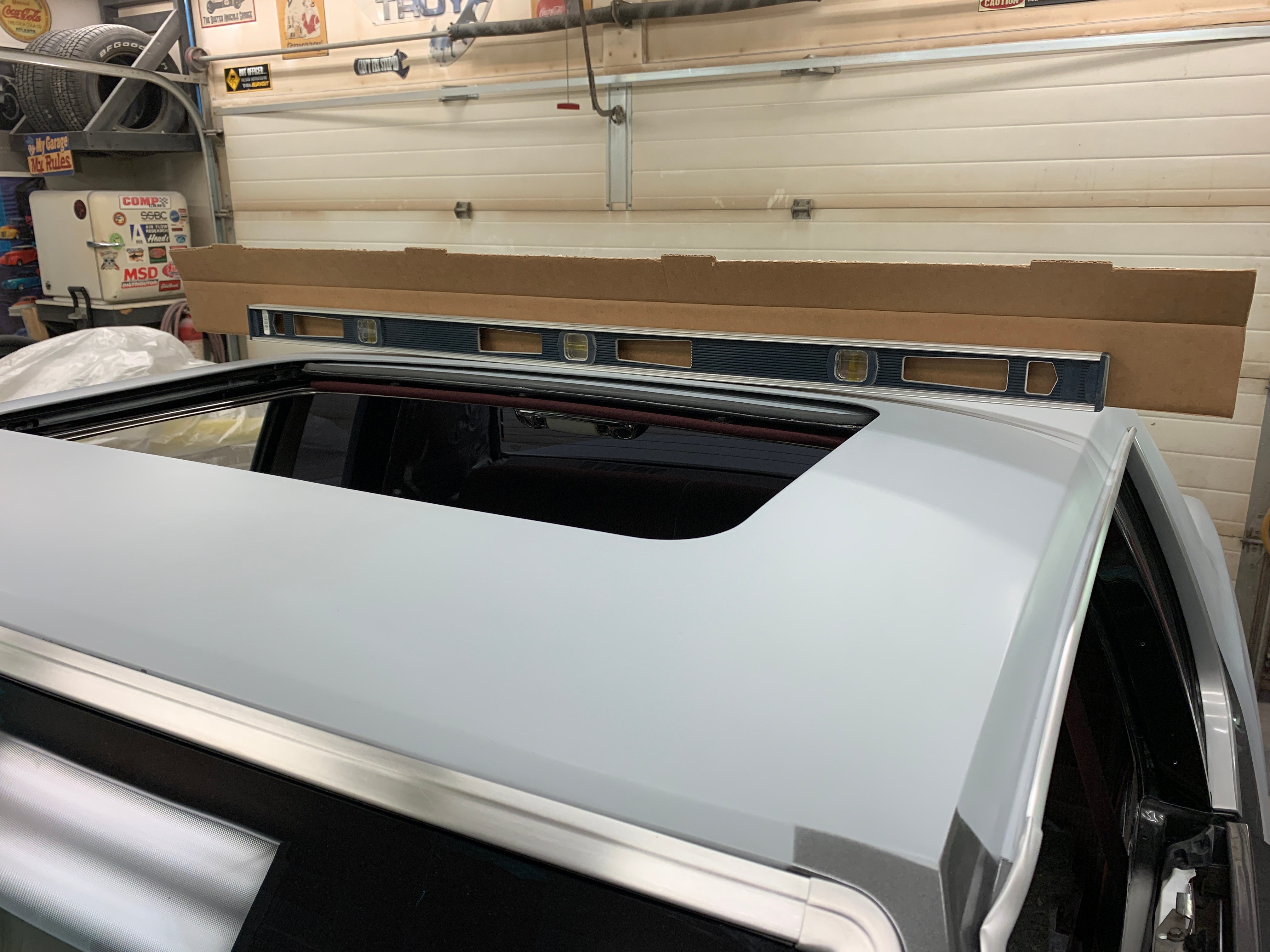

So, fast forward to last weekend, I had developed a plan to check the curvature of the insert against the curvature of the roof. I drug home some long cardboard from work, and cut 2 pieces the width of the roof. I needed to check the curvature of the insert in 2 places, along the front and rear edges.

So I started at the back...

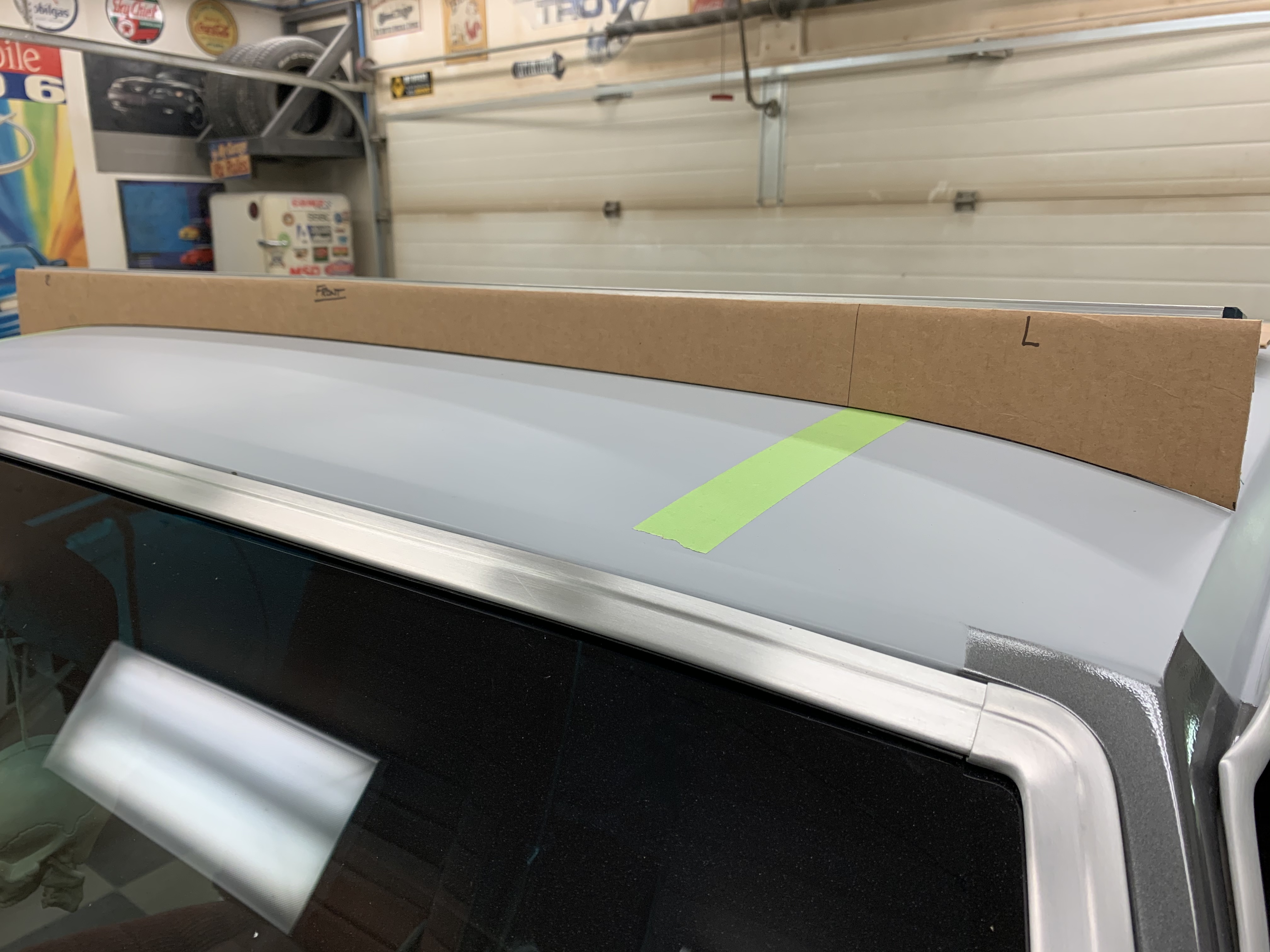

...and after laying out some masking tape lines to extend the sides of the insert for reference, I gradually traced and cut the cardboard down until it matched the curvature of the roof:

Perfect. One down, one to go.

Repeated the procedure to create the front template...

...until I had the exact curvature of the roof along the front edge of the insert:

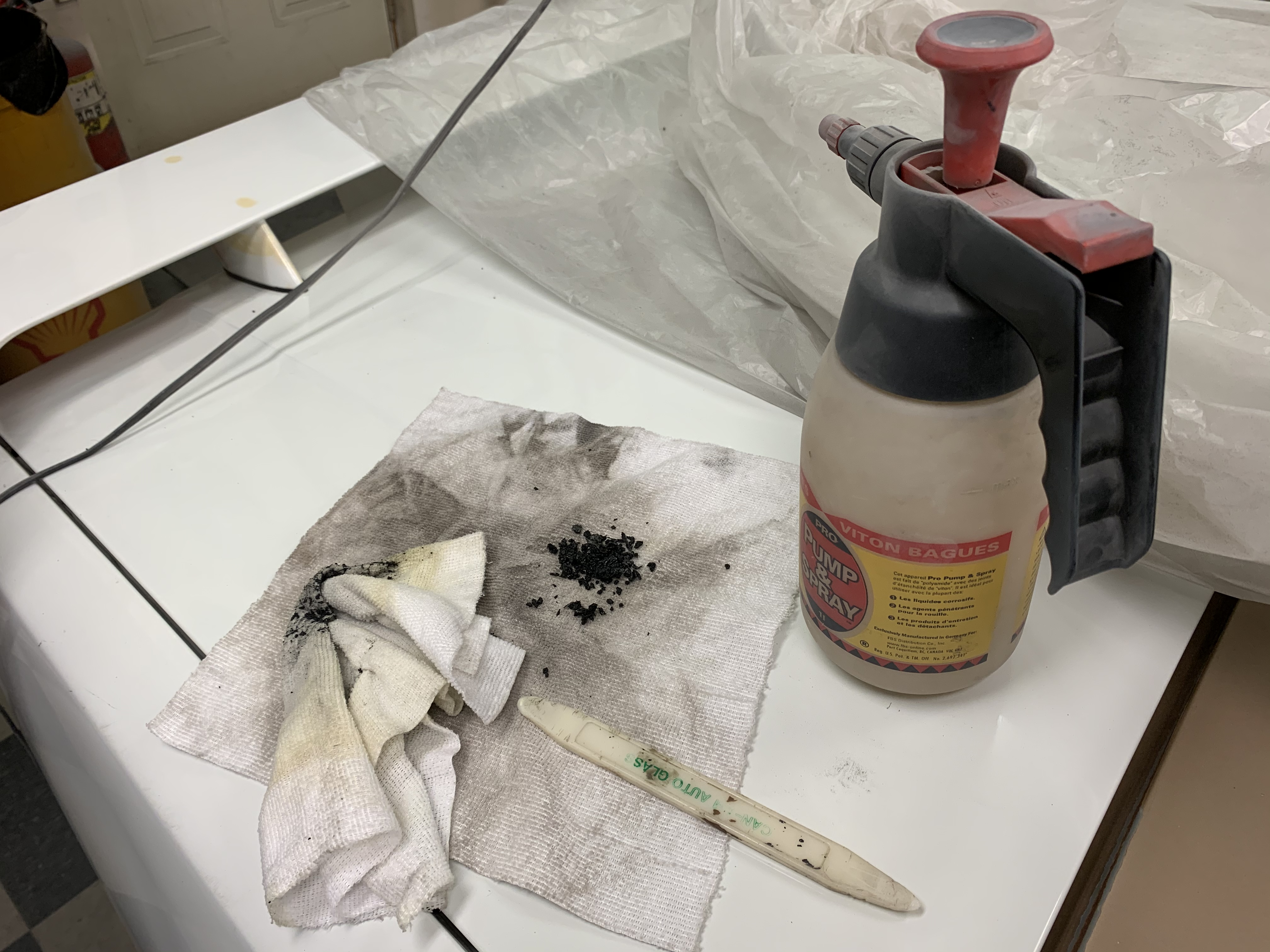

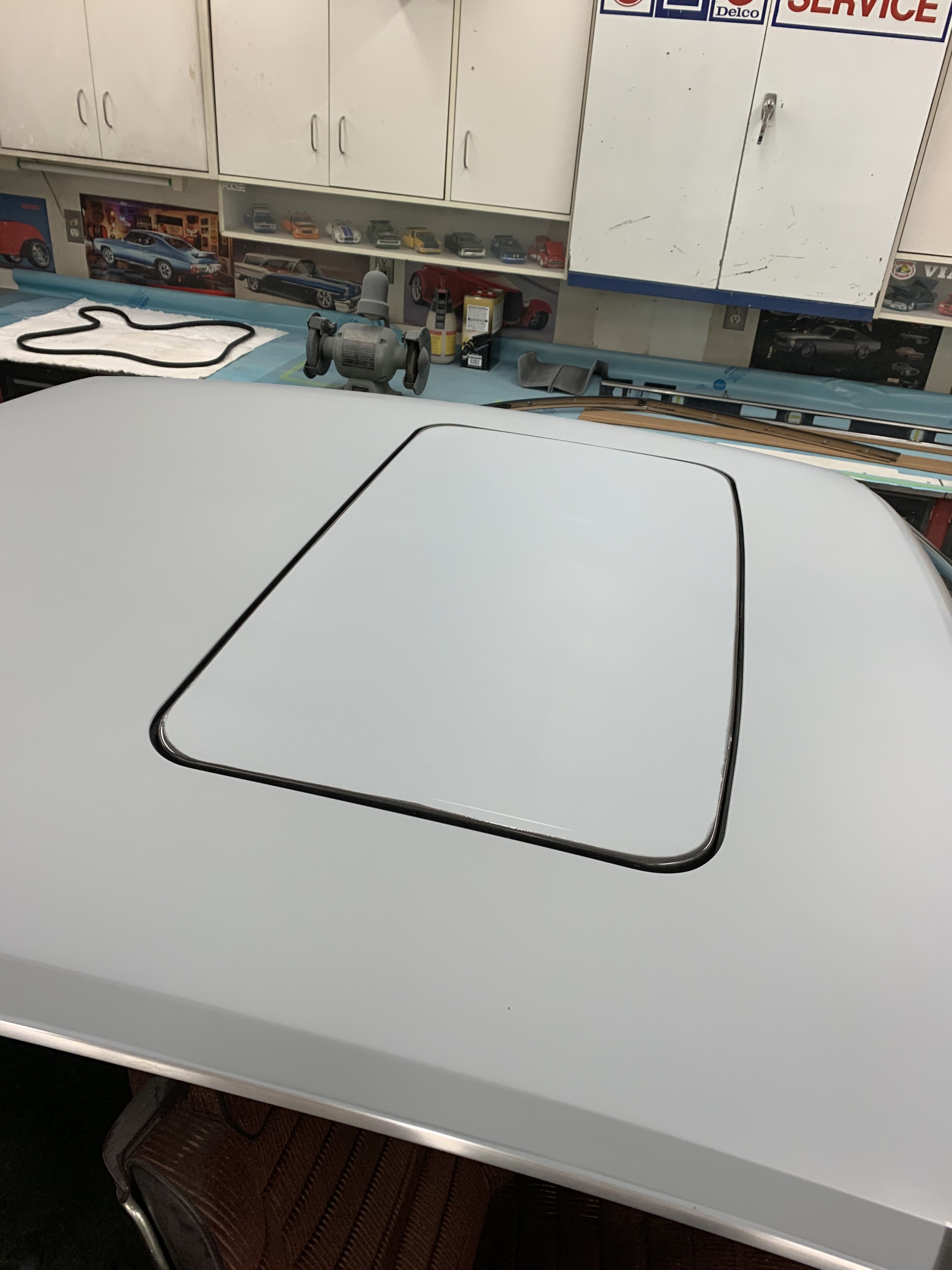

Now I had 2 great templates from which to work from. Next was to get the insert itself out, and remove the problematic weather stripping.

Moment of truth:

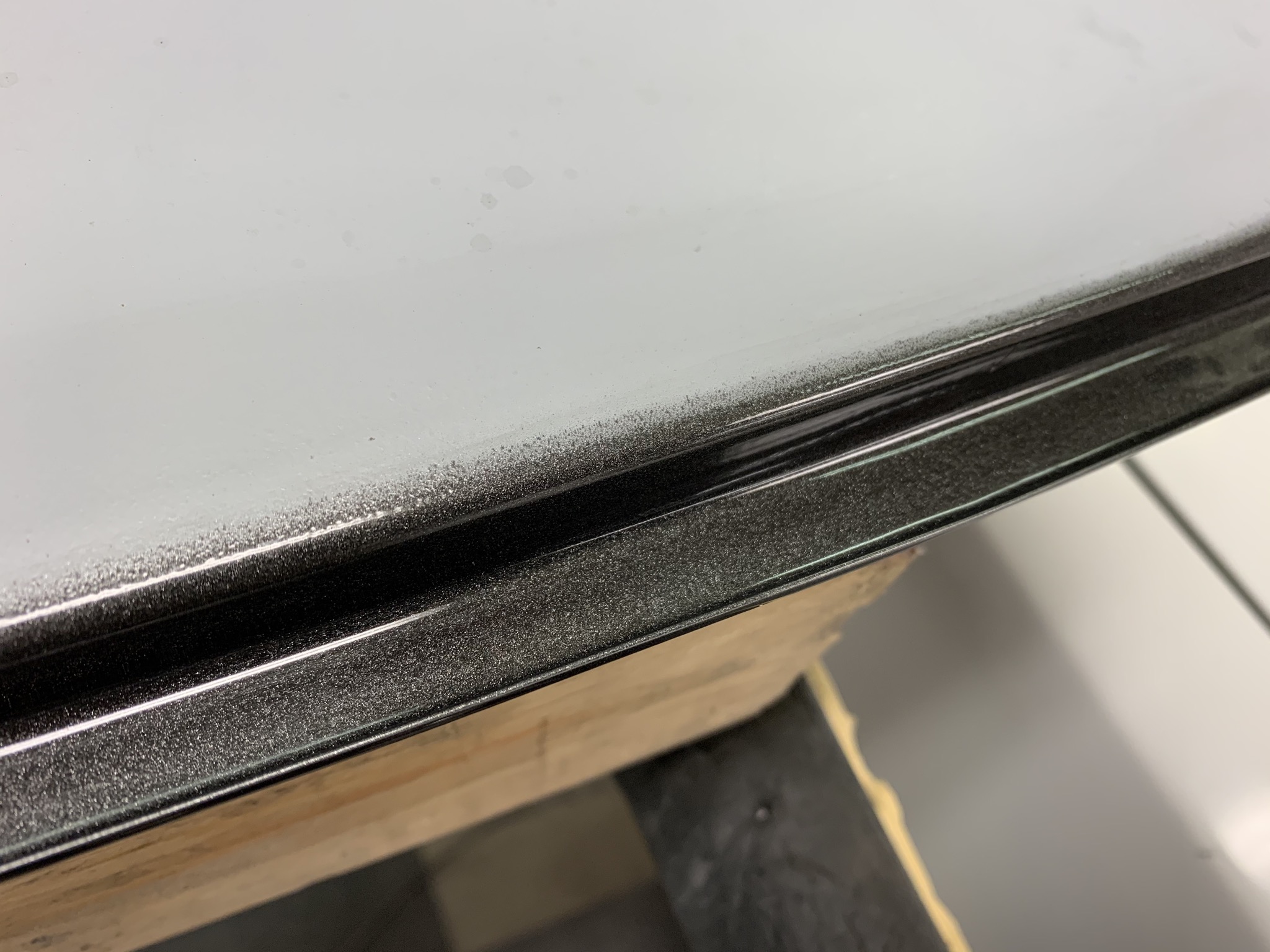

Laying the front template across the front of the insert, it matched pretty much exactly. Great news, I wouldn’t have to do anything there. The rear edge is what I was most worried about anyways. And wouldn’t you know it, my fears were confirmed as soon as I laid the rear template across it.

It was either down in the rear corners an 1/8”, up in the middle an 1/8”, or possibly a combination of the two:

The blue that you can see between the template and insert is the gap. And it most definitely should not be there.

Middle, no gap which is good. Maybe.

But same 1/8” gap on the other side:

Since it worked fairly well to flatten out the front edge of the insert last year, I figured I’d

give it a shot again on the rear this time. A couple of 2x4’s set up on the stand and 3 strategically placed clamps got it going.

I was gonna have to leave it clamped this way for a couple days, so that’s where I’m gonna leave y’all for now. I’ll continue on with part II of this update tomorrow night, but for now I’ve gotta hit the rack. Long day with a road trip for work tomorrow, so some shut-eye is probably a good idea.

Thanks for tuning in for part I of this update, until tomorrow gents.

D.