Thanks for the comments and "likes" everyone. It's very much appreciated!

It's been a couple of days since the last update, and to be honest, not a lot has been completed but there is a few things I feel I should probably cover.

First of all, I would like to give a huge shout out and thank you to Jared (Texas82GP) and Blake ((Blake442). These two fine gentlemen came through in spades in educating my dumb *ss as to the existence of moulding trim rivets for use with my UniSpotter, as well as posting the necessary attatchments and how to use them.

It turns out I had all the necessary parts in my kit to use them all along, and didn't even realize it!

This is the end piece that makes it possible, the trim rivet simply sits in place here, you position it wherever you need it and weld it on:

As soon as I realized the possibilities with these, and the fact that I'd need them for the back window channel, I set about to locate some.

I had a minor panic attack when my body shop supplier said she had none available, but thankfully she was able to locate some for me the very next day.

$25 for 500 rivets, that's pretty reasonable. Plus, that's roughly 480 chances to screw up and re-do them!

I've yet to test them out on a scrap piece, but I'm looking forward to doing so and using them. I may even end up grinding off some or all of the existing ones in the windshield channel and replacing them with these just so that I can thoroughly clean out all the old paint and crud from underneath them first.

On a related note, I think I'm going to make another trip back to the 442 on the weekend, this time as a reconnaissance mission. I want to remove the rear window trim from it and document exactly where the trim rivets are placed. This will ensure my trim will be held in place with the clips exactly where the engineers intended it to be.

Yep, I'm anal retentive like that!

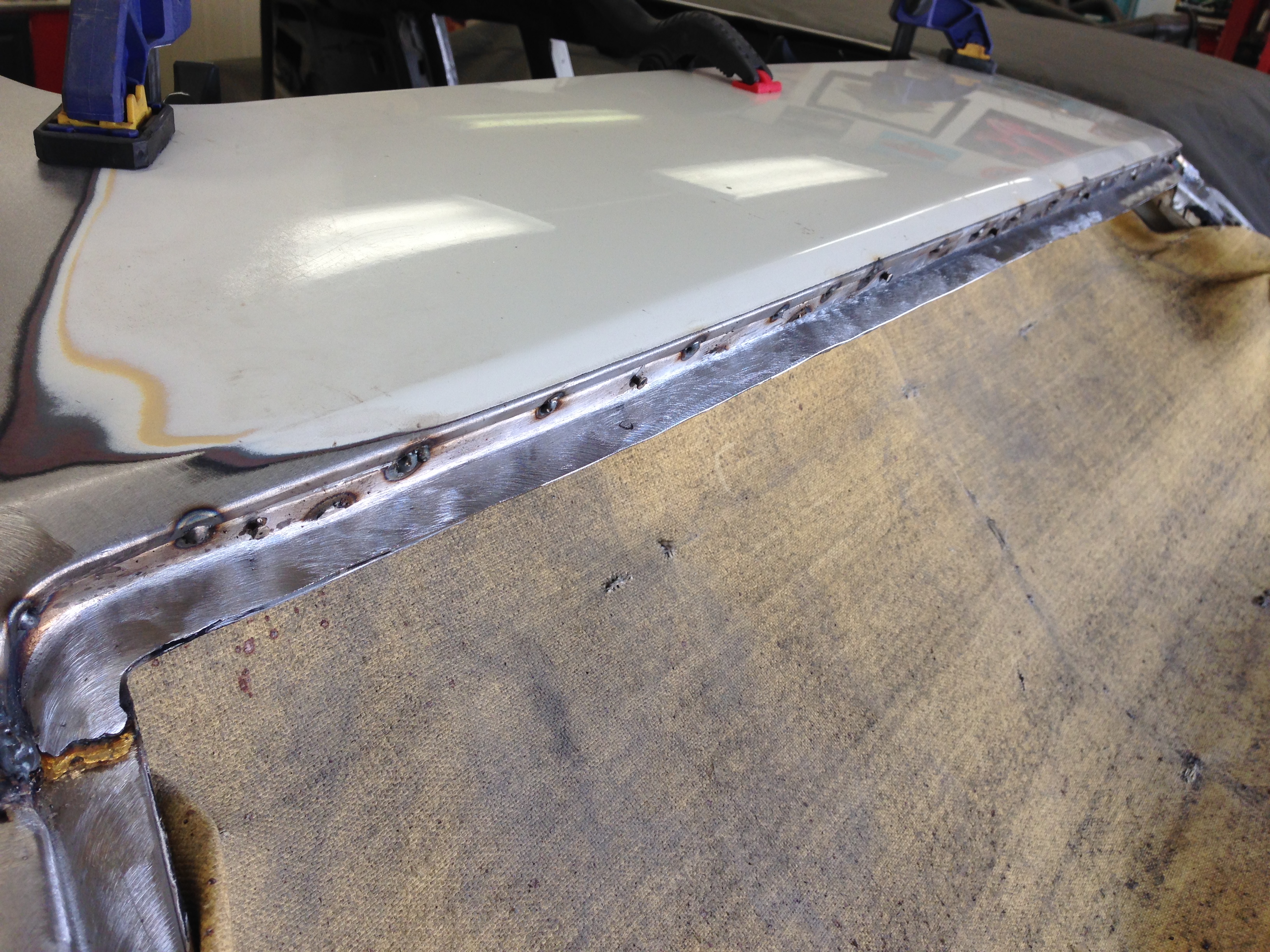

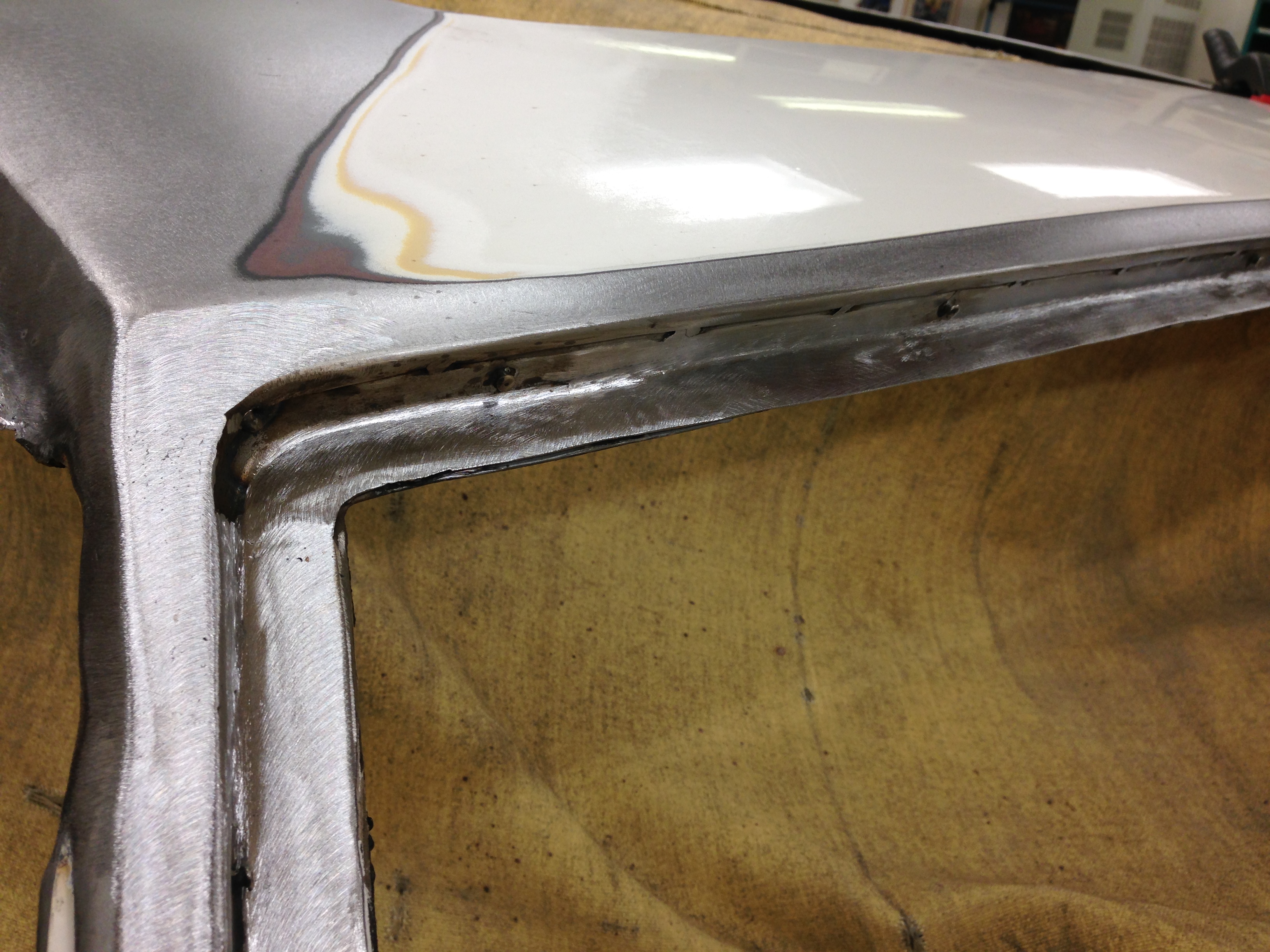

Getting back on the car, I got the passenger's side upper windshield corner finished as far as the metal work is concerned. Basically duplicating the same process as on the rear roof, I added weld material...

...ground it flush...

...and finished the shape to match the windshield moulding:

I still have to repeat this on the driver's side, as well as adding the same ton of weld to the previously leaded area, but at least one side is done now.

Progress on the windshield channel has been painfully slow due to the difficulty of access to the area, and the fact that it's been just plain ignorant to work on. Windshield primer and urethane, seam sealer, paint and regular primer, and all the rest of the crap in there. Not to mention the rust.

To further complicate matters, I smashed my pinky finger pretty badly at work the other day (the nail is black and will probably fall off) and now even simple things like putting my gloves on is a painful procedure.

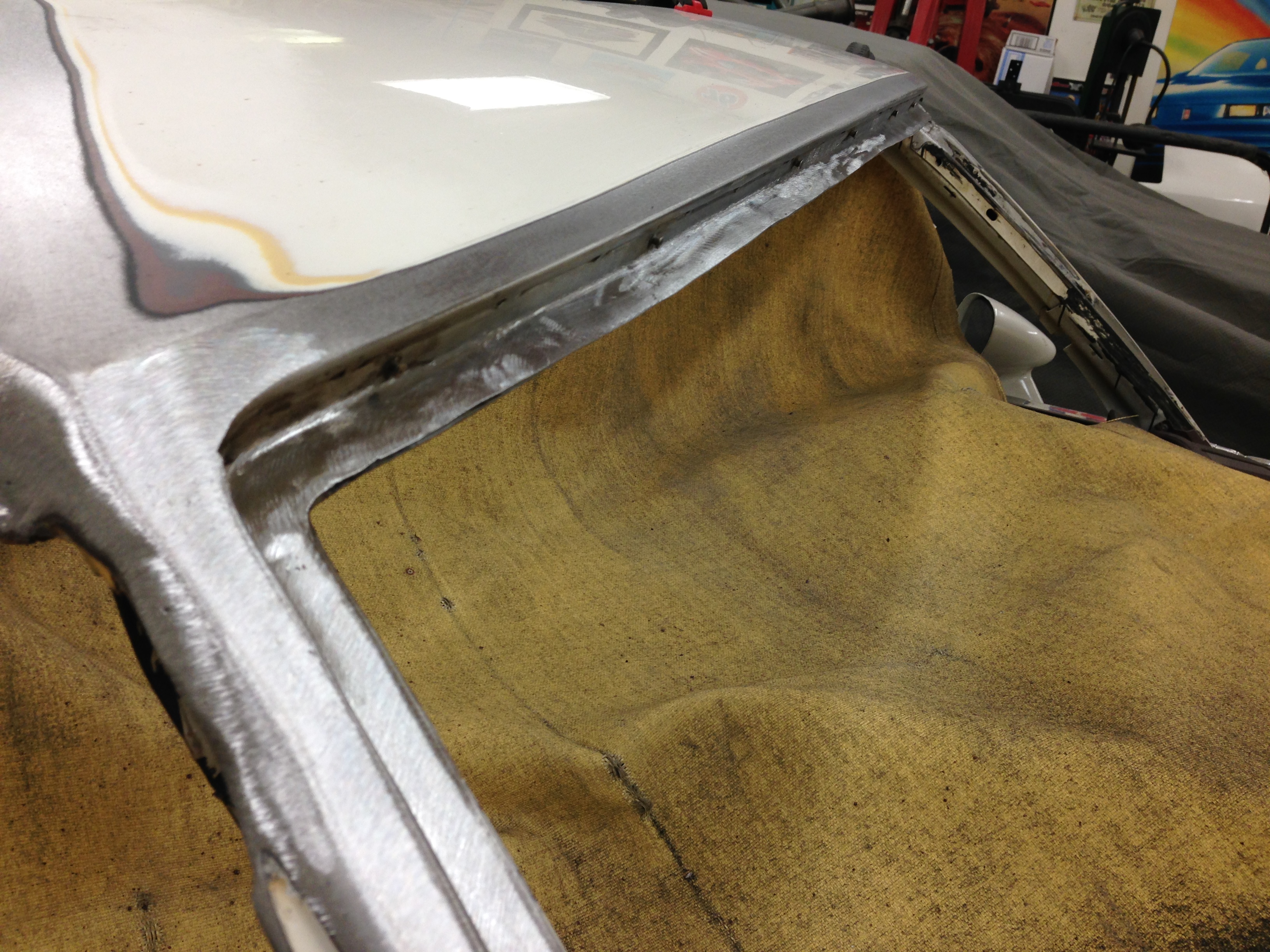

Despite my reduced capacity, I did get a little more done tonight. I got the last of the old crud and paint stripped from both "A" pillars, inside the channel and out:

The area that the base of the windshield sits on also got the same treatment:

Now I've finally got nice clean shiny virgin metal to work with!

If all goes well tonight, I should be able to make a decent dent in finishing off the driver's side "A" pillar and upper windshield corner.

That's all for now, as always thanks for following along. Your thoughts, comments and suggestions are always welcomed!

Donovan