Alrighty, let’s see... where were we?

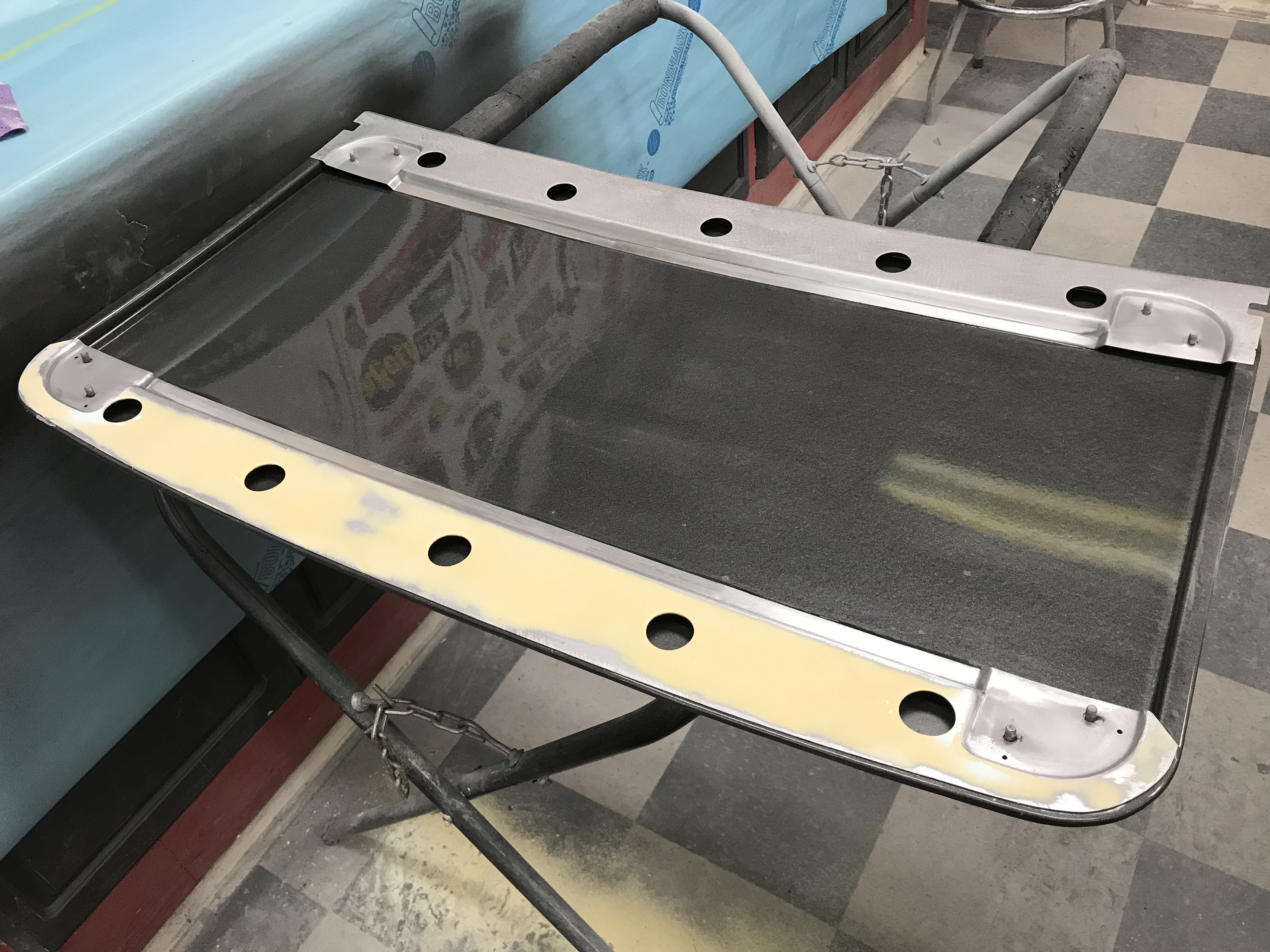

Right. At the end of the last update, I had the AstroRoof inner braces Panel Bonded to the insides of the pan, and everything clamped together. The next step after everything had cured was to start plug welding the outer edges up back to the pan itself.

This was a little bit of a frustrating process, as the paint and primer on the undersides of the braces contaminated the weld puddles (as I knew it would) causing a lot of sputtering and popping. But that was the price I was willing to pay for piece of mind that the added protection would provide. I just went slow and took my time, grinding and filling in any little voids as I went:

The 3M anti-spatter paper was intended to try and protect the painted surface, but I quickly realized that was a poor choice. It got switched out for the dedicated welding blanket not long after that pic was taken. Likewise, the tape over the holes was to keep the slag and grindings out of the insides of the braces.

The front brace had all new plug weld holes that I had punched in it, but the rear brace only had the factory ones that I had drilled out to separate it. When I took this pic, all the holes had been welded up and ground smooth, and I thought I was done.

Three become one once again...

This is just a quick shot of the rear brace, I was pretty happy with how smooth I had got it:

Because I’m a little odd and an anal retentive f**k, I wanted the front brace to look really clean and smooth even though no one else will ever see it. So I skimmed all the grinder marks and gave it a quick skim of filler and blocked it out:

Once it’s primed and painted, it should look good as new, and properly restored.

Here’s a look at the spots along the front edge where the plug welding took place. You can clearly see the blistered paint, I knew this was going to happen.

No big deal, I just feathered those spots all out back to bare metal and prepped the rest of the areas:

It was at this point that I had made an important discovery. Remember when I said I had just welded up the factory spot weld locations on the rear brace? This was insufficient. I should’ve gone with my gut instinct and added a few more plug weld holes along the perimeter of the rear brace. What I found was that there were some gaps between the pieces and that caused the rear brace to have some minor weird warping to it.

While I have no pics of this process, I had to go back and add an additional 9 or 10 plug weld holes evenly spaced between the factory ones and clamp and buzz them up. This immensely helped the gap and warping issues. A little hammer and dolly work afterwards got everything looking good again.

Once that was done, I wanted to incorporate an additional step that the factory never did, and that probably would’ve prolonged the life of this pan if they had’ve.

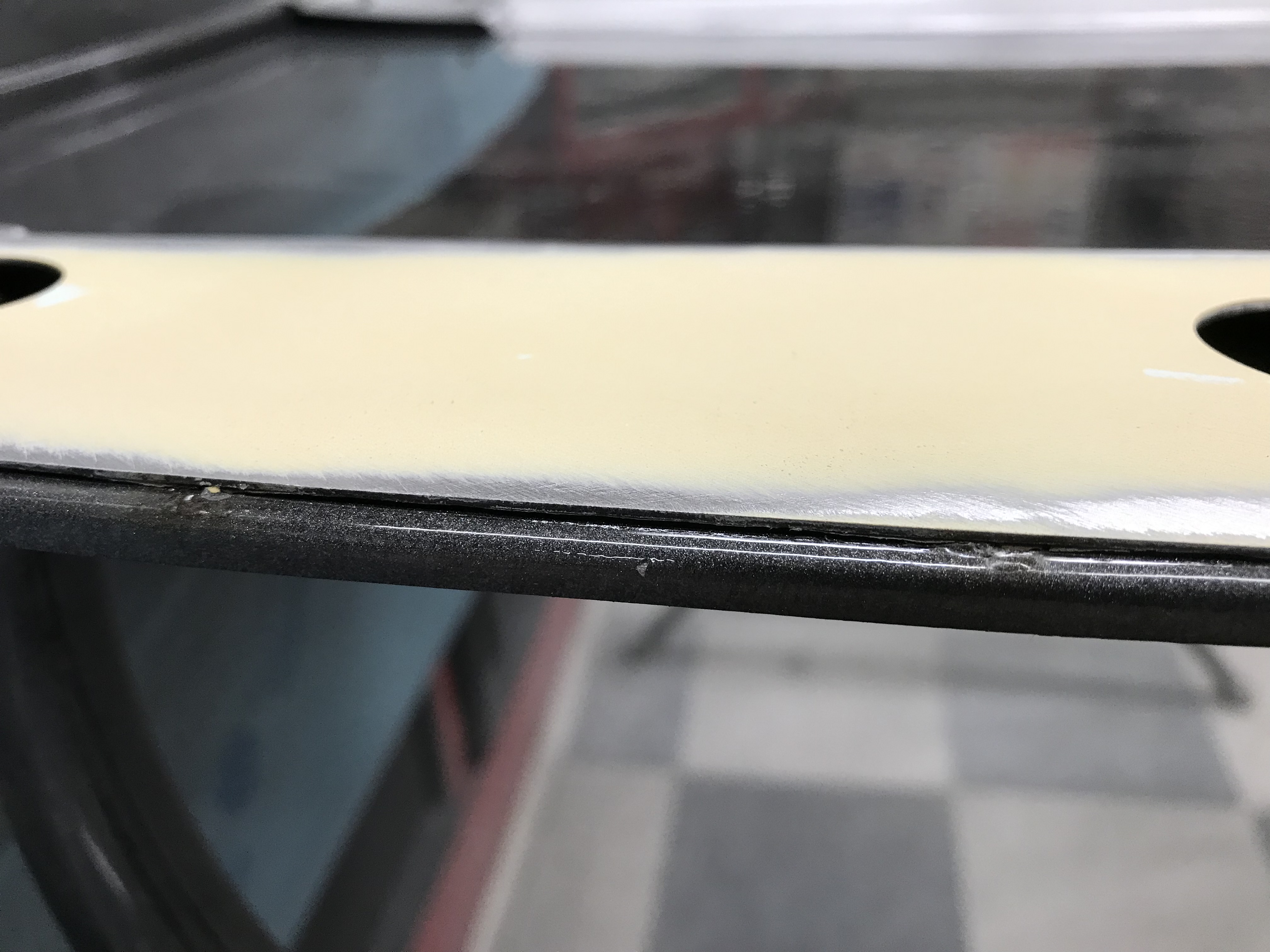

I mixed up some epoxy and brushed it in along the front and rear seams where the braces meet the pan...

...then once it cured, I sanded it and applied some heavy bodied seam sealer. To me, this should’ve been something that the factory had done. Generally speaking if you have a seam, you have to seal it up. Not so for The General apparently...

I picked up this little gizmo at Home Despot several years ago, it’s intended to ease in caulking bathtubs and counter tops etc. But it works pretty damn well for smoothing out seam sealer too!

All sealed up now, just a little rough around the edges. No worries, as this particular seam sealer is actually sandable.

After I had sanded and smoothed out all the seam sealer on both ends, I had a choice: I could either prime and paint the braces on the underside, or I could evaluate the condition of the outside sheet metal for straightness. Seeing as it was Sunday and Mike was over to help, I decided against poisoning his air supply with paint.

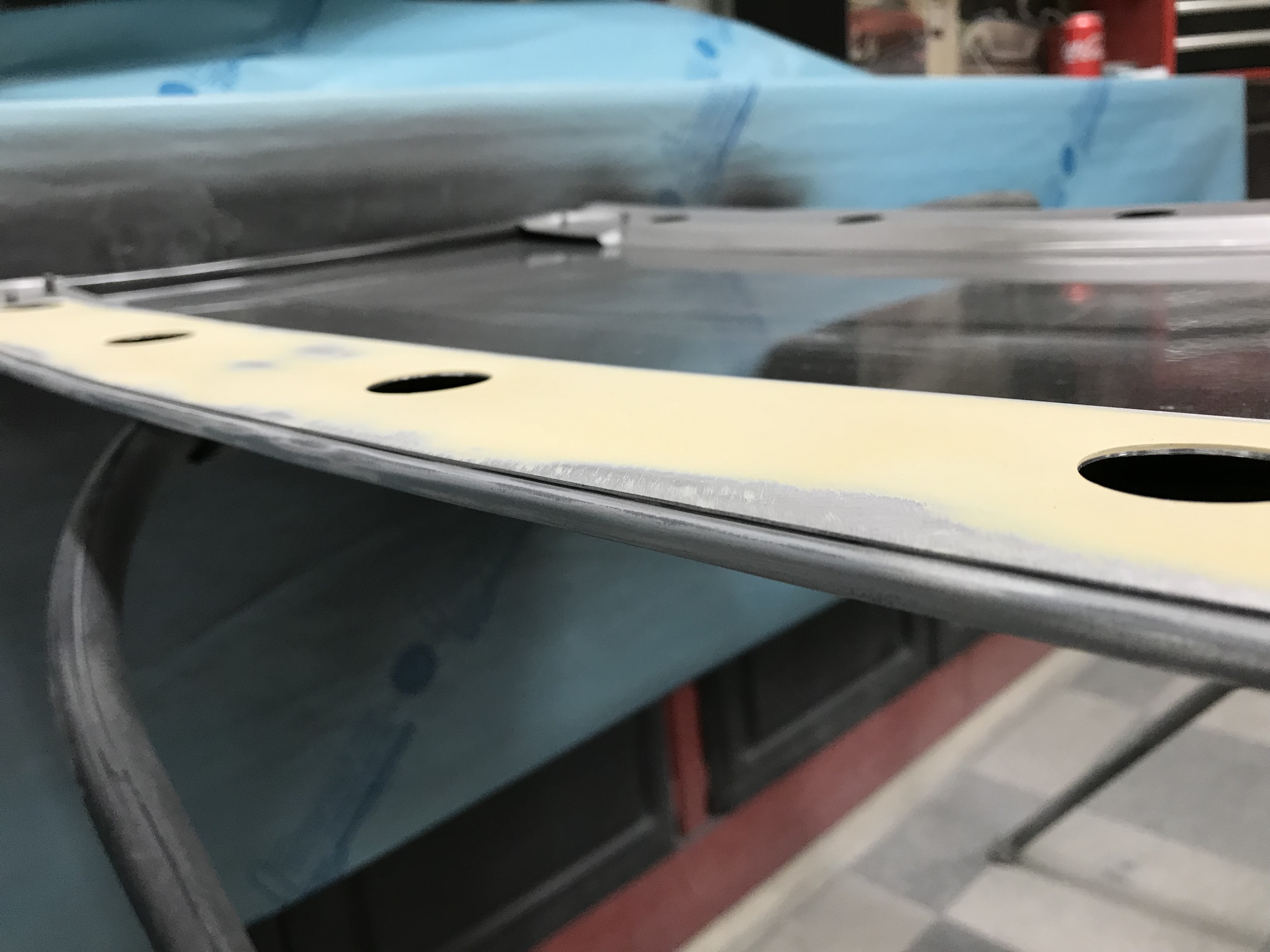

Evaluating the outer surface, I felt a couple little areas that I didn’t like, so the decision was made to profile and skim it.

First pass of filler going on:

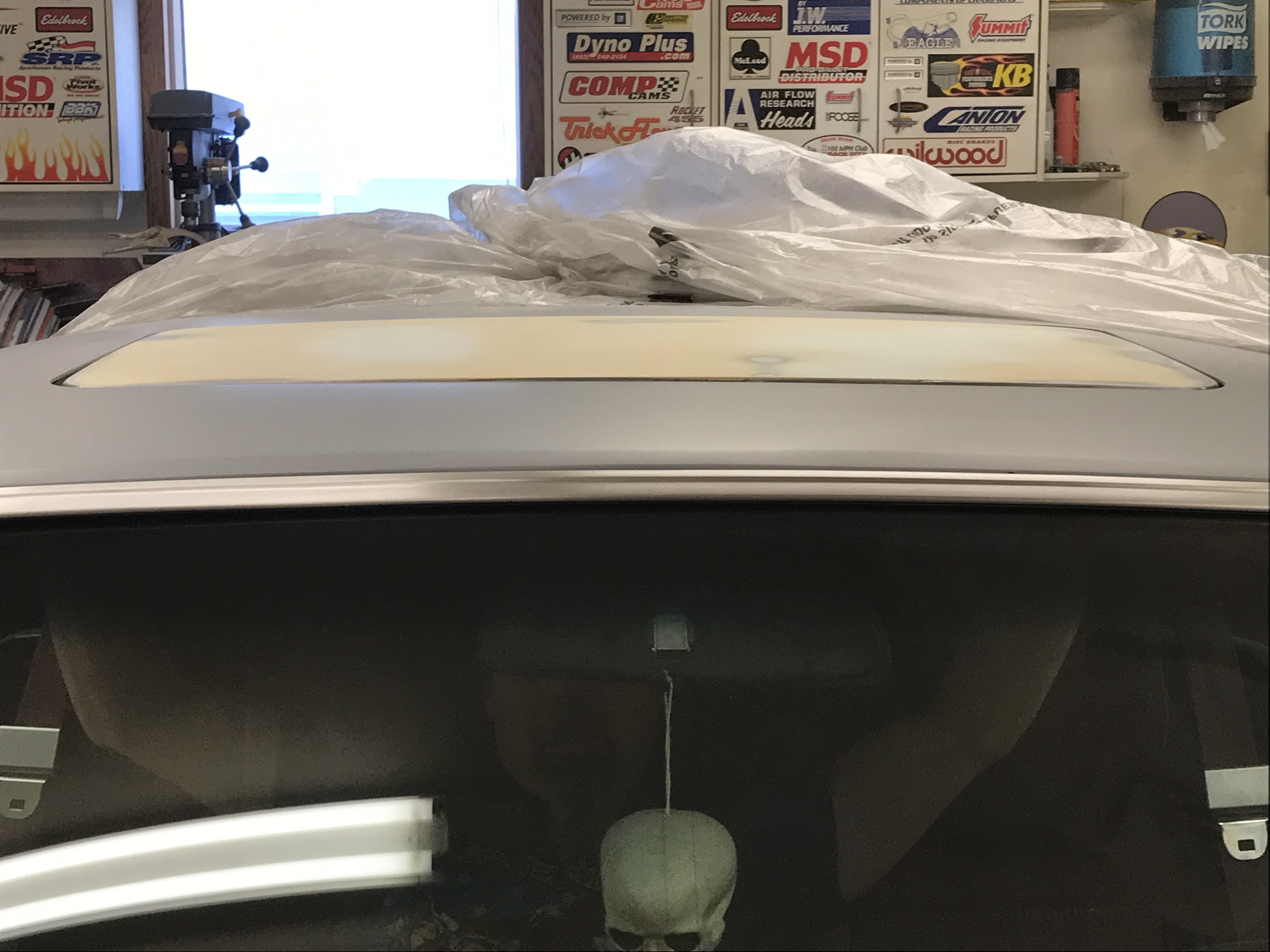

Once I was satisfied it was reasonably straight and smooth, I enlisted Mike’s help in doing the first real test fit since all the work on it began. He had to hold it up in place from the underside while I quickly snapped a couple pictures.

Looks like the fit and finish is going to be good, the slightly high appearance in the front middle is not accurate because it changes slightly as the angle front to back changes. It was just in how he was holding it up.

While I was body working the pan, Mike completely tore down the rest of the AstroRoof cartridge assembly, removing all the tracks, guides, motor and miscellaneous stuff. The corners of the cartridge had some rusted areas and some heavy pitting, so naturally we wanted to get that addressed.

No pics yet of his work, but he did an excellent job and got easily 95% of it removed and the rest of it converted with the same stuff I’ve used elsewhere on the car. I’ll cover this a little more in depth on another update.

Wednesday, I finally received my order from G body Parts. I had ordered a brand new AstroRoof outer pan seal, some power window guides to replace my broken ones, and some new door handle gaskets. And just for sh*ts and giggles, I also had them throw in a billet aluminum console shifter handle to replace my permanently sticky and mis-color matched one:

First thing I did was to inspect and test fit the seal. Being an aftermarket piece, I had some concerns and reservations about what the fit and finish was going to be like. I’m VERY pleased to report that the quality is exceptional, and the fit is excellent as well. I had to slightly stretch the seal over the edges, but once I did it pushed right down into the channel and fit beautifully.

This is of course, with no weatherstrip adhesive yet. It’ll seal and fit even better once I actually glue it in place.

Still playing with the new parts, I test fit the shifter handle. Looks ok...

... but with a little time and paint to get it color matched to my interior accents, I think I got it to look a whole lot better!

What do you guys think?

That’s all for now gents, as you can see this little AstroRoof pan project has turned out to be a whole lot more work than it initially looked like. I’m going to continue to work towards the end goal, and that’s to get it finished and primed like the rest of the body so that the whole thing can be permanently reinstalled and painted along with the rest of the car.

Till next time, keep the shiny side up!

Thanks for checking in on the progress.

D.