I have to agree with mccormack944 I have personally had 3 of them crack before I quit. Being splayed I'm sure they aren't cheap and if your planning on over 500HP i would think twice. My 2 cents.

CHEVY SBC 400 ID

- Thread starter ssn696

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

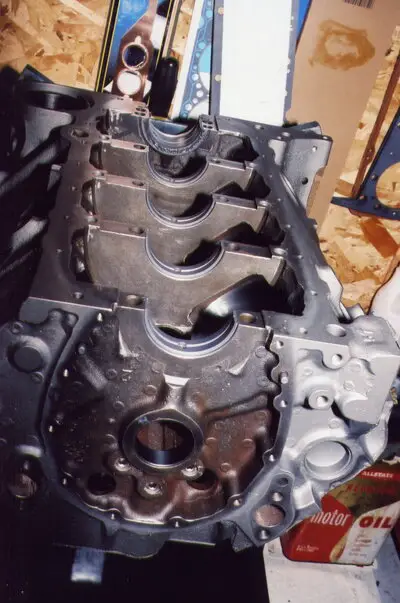

Yes the caps mimic the big block design of 2 bolt caps that the register is the same size as the 4 bolt cap.I have a late 72 400 block that has 3 freeze plugs per side and is a 2 bolt block. Most casual observers do not realize that the 2 bolt 400's have the 3 center main caps that are as wide as the 4 bolt caps. As such, the registers in the block are already the correct width. The smaller 2 bolt small blocks have narrow main caps on the center 3 mains which requires machining to fit 4 bolt caps.

There are two other concerns with 400 factory blocks. The first is that they can only be overbored a max of .030 safely. The cylinder sleeves are siamesed, meaning they touch each other internally from cylinder to cylinder which limits the amount of meat available for a re-bore. To compensate for the fact that coolant cannot circulate between the sleeves, GM went to steam holes to allow for coolant movement. The heads you use for a 400 build have to have these holes drilled in them or you will have overheating issues. Someone earlier suggested an 'M' block as the foundation for a serious horsepower 400, Concur.

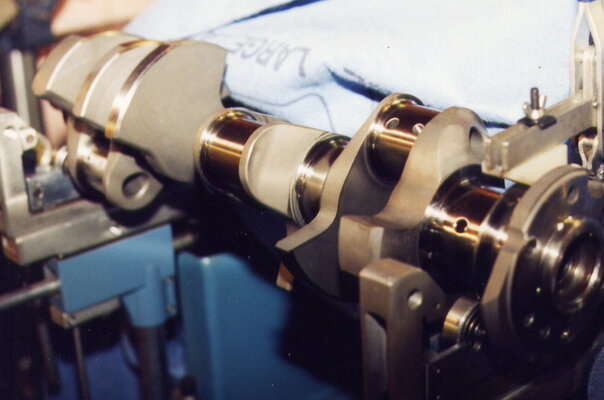

The other concern is that 400's came from the factory as being externally balanced. The front balancer was huge; 8"?. and with a stock crank, has to be there to keep the reciprocating assembly happy. You can go internal balance but that tends to require an aftermarket crank/rods/pistons/etc. I honestly don't know if an externally balanced crank can be converted to internal balance through a combination of drilling and Mallory metal slugs but the cost at a good machine shop would likely be expensive,. You can also destroke them to a smaller CID by using a shorter stroke crank but that can require main journal bearing spacers. Because I happen to have both a 400 4 bolt block and a 327 large journal forged crank I actually ran the math to see what I would get for size. Don't remember what it worked out to be but it was Small. The elephant in the shop was the heads; they are not plentiful around here as circle track racing back when pretty much ran the supply down to nothing. Afterrmarket = $$$.

Nick

The other concern is that 400's came from the factory as being externally balanced. The front balancer was huge; 8"?. and with a stock crank, has to be there to keep the reciprocating assembly happy. You can go internal balance but that tends to require an aftermarket crank/rods/pistons/etc. I honestly don't know if an externally balanced crank can be converted to internal balance through a combination of drilling and Mallory metal slugs but the cost at a good machine shop would likely be expensive,. You can also destroke them to a smaller CID by using a shorter stroke crank but that can require main journal bearing spacers. Because I happen to have both a 400 4 bolt block and a 327 large journal forged crank I actually ran the math to see what I would get for size. Don't remember what it worked out to be but it was Small. The elephant in the shop was the heads; they are not plentiful around here as circle track racing back when pretty much ran the supply down to nothing. Afterrmarket = $$$.

Nick

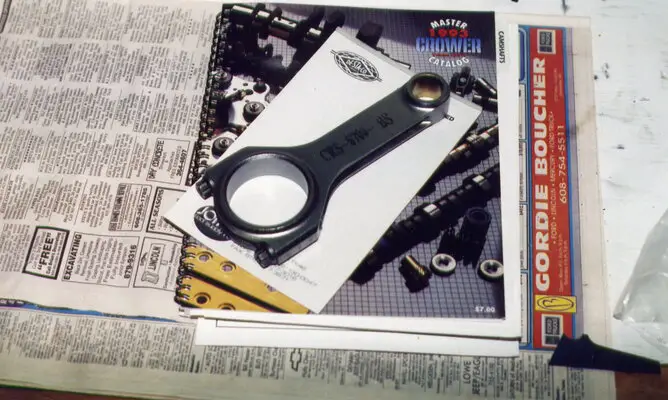

Greetings Guys; Ah 400's, built my first one in 1985, second one same block 28,000 miles & 9 years (94-95) later. Then in 2004 & 27,000 additional miles & it didn't seem right. I had put a Calies crank in back in 95 & that was a good thing. During disassembly (04) I found two cracked main caps! The only thing holding it all together was the Calies crank! Also had cracked decks around the steam holes, repaired & sold cheep. In most cases you can add enough Mallory metal to a stock crank to internally balance, but at over $100 per oz. it's much more cost effective to buy a new crank. Do NOT use the 5.5 rods, they are weak & create higher piston thrust loads & speeds (bad for higher Performance). So the third engine that so many of you guys have read about on my previous post is still runnin' Strong with new Care Taker. So this is what I learned, If ya want 400 or more cubes from a SBC & plan to stay under 550 HP (@ crank), stay under 10.5 compression. Put splayed caps on it, 5.7" or better yet 6" rods, after market crank & hardened cam & or main & rod bearings. Except around 30,000 miles of use max. If ya stay under 10.1 to 1 compression & 6000 RPM ya might see 40,000 - 50,000 miles?? before the decks start cracking? But they will crack sometime in the future, you can bet on it. The UP side is they make a bunch of Torque & HP for cheep. Ok well that last statement may be dated as the LS world has rearranged our reference points! Ole' Bob.

Attachments

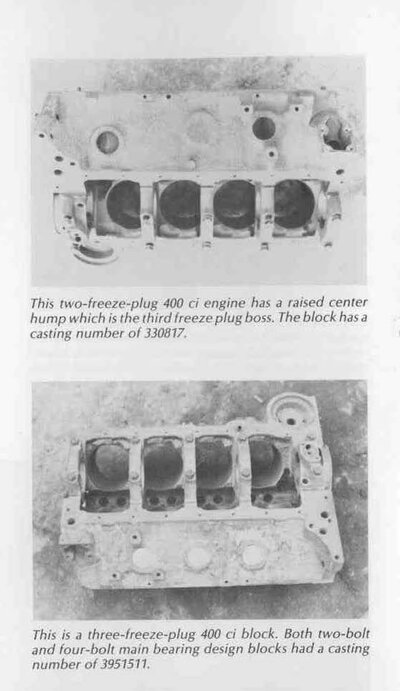

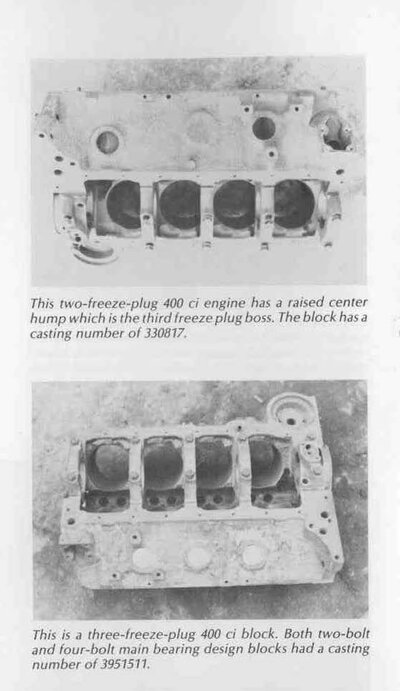

The 400 blocks are an unusual bunch. Some of the 511 blocks we machined with 2 & 4 bolt mains. The 509 blocks are supposedly only 2 bolt mains as referenced in a couple of my parts books. It also mentions that all 4 bolt main blocks will have 3 freeze plugs machined on both sides. Interestingly, some blocks were cast with the 3rd freeze plug bosses but not machined for plugs. And some of the later blocks (79-80) were not cast with these 3rd freeze plug bosses at all, so it's hard to tell them from any other block with the exception of the harmonic balancer and flex plate. The balancer will have a large groove machined into the back about half way around and the flex plate will have the counterweight spot welded to it. Just got done rebuilding a 509 block with 3 freeze plugs and also have a 76 SS El Camino parts car with a 509 block that only has 2 plugs. And I also found out the hard way that most 400 blocks are not machined with the dual starter bolt pattern and are not machined to accept the clutch fork pivot ball. So it seems many things on other small blocks are not necessarily available on these 400 blocks. They also have a tendency to run hotter than other blocks due to the siamesed cylinders as mention in one of the posts earlier. If they run too hot for too long you're almost guaranteed to blow a head gasket or crack the head. I went with Dart Iron Eagle heads on my build since they are a much heavier casting than the original heads. I just had to be sure the machine shop drilled the steam holes on the new heads otherwise there would be over-heating issues there as well. I also had to upgrade to a 4 core aluminum radiator for additional insurance since I'm in the Houston area and summers here are not nice to old school rides or any other vehicle for that matter. Overall, these engines are a great upgrade to the originals that came in our cars. Very happy with mine.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 320

- Replies

- 5

- Views

- 930

- Replies

- 11

- Views

- 1K

- Replies

- 8

- Views

- 854

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.