I've been busy so I haven't had a chance to post an update. Here goes:

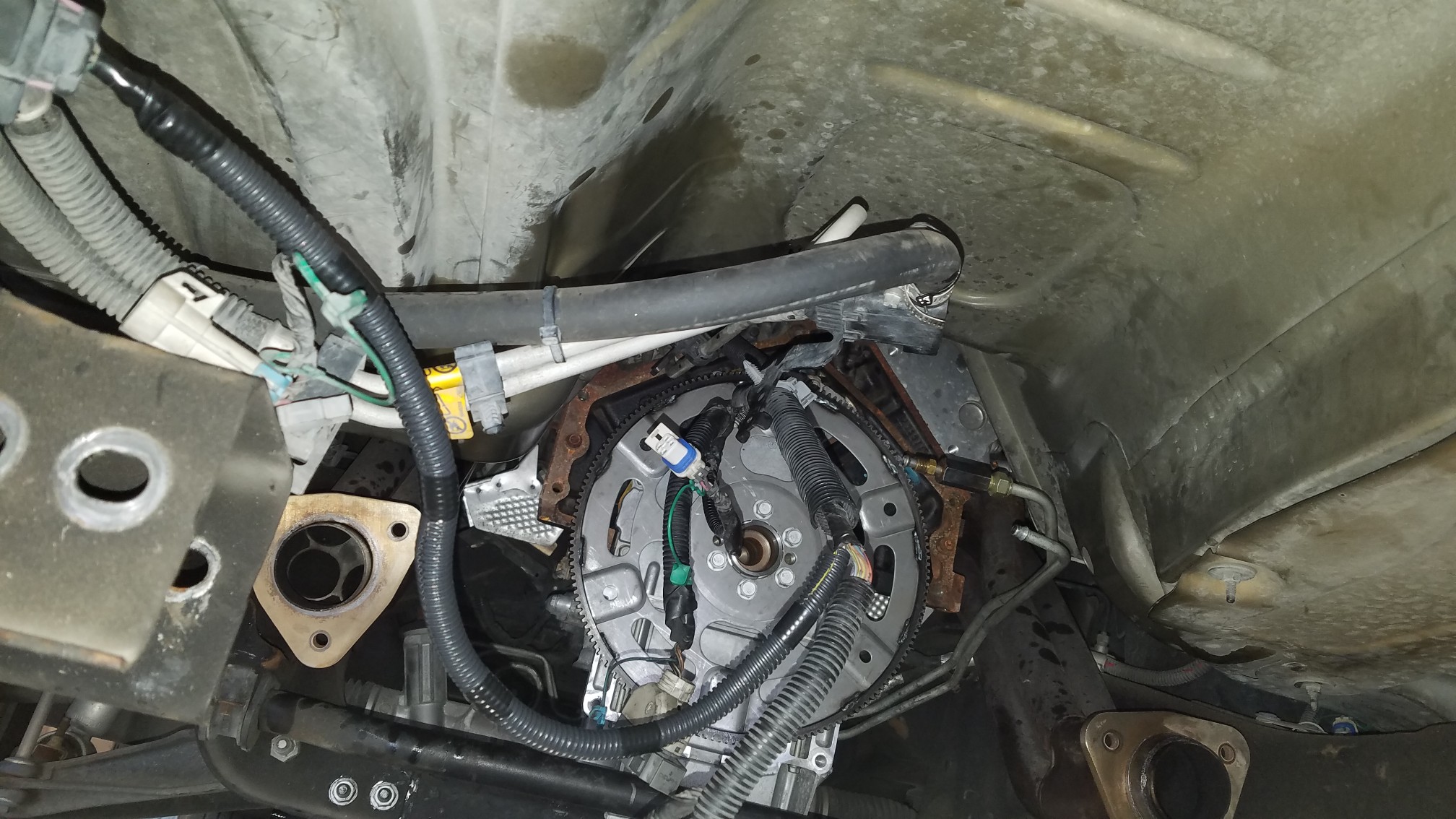

I went over to the storage on Saturday to pull the transmission back out. I did so without any drama (thankfully). Next, I decided I wanted to flush the transmission lines and cooler (one in the radiator and one auxiliary. I used an aerosol flush from ATP. You can see it on one of the shelves in this pic (I think I'm done buying stuff for this project)....

I had the adapter that is the GM quick connect on one end and a 5/16 inverted flare fitting on the other end so hooking up the can was a snap....

By the way, for anyone working with those stupid quick connect fittings, this little inexpensive tool makes working with them easier....

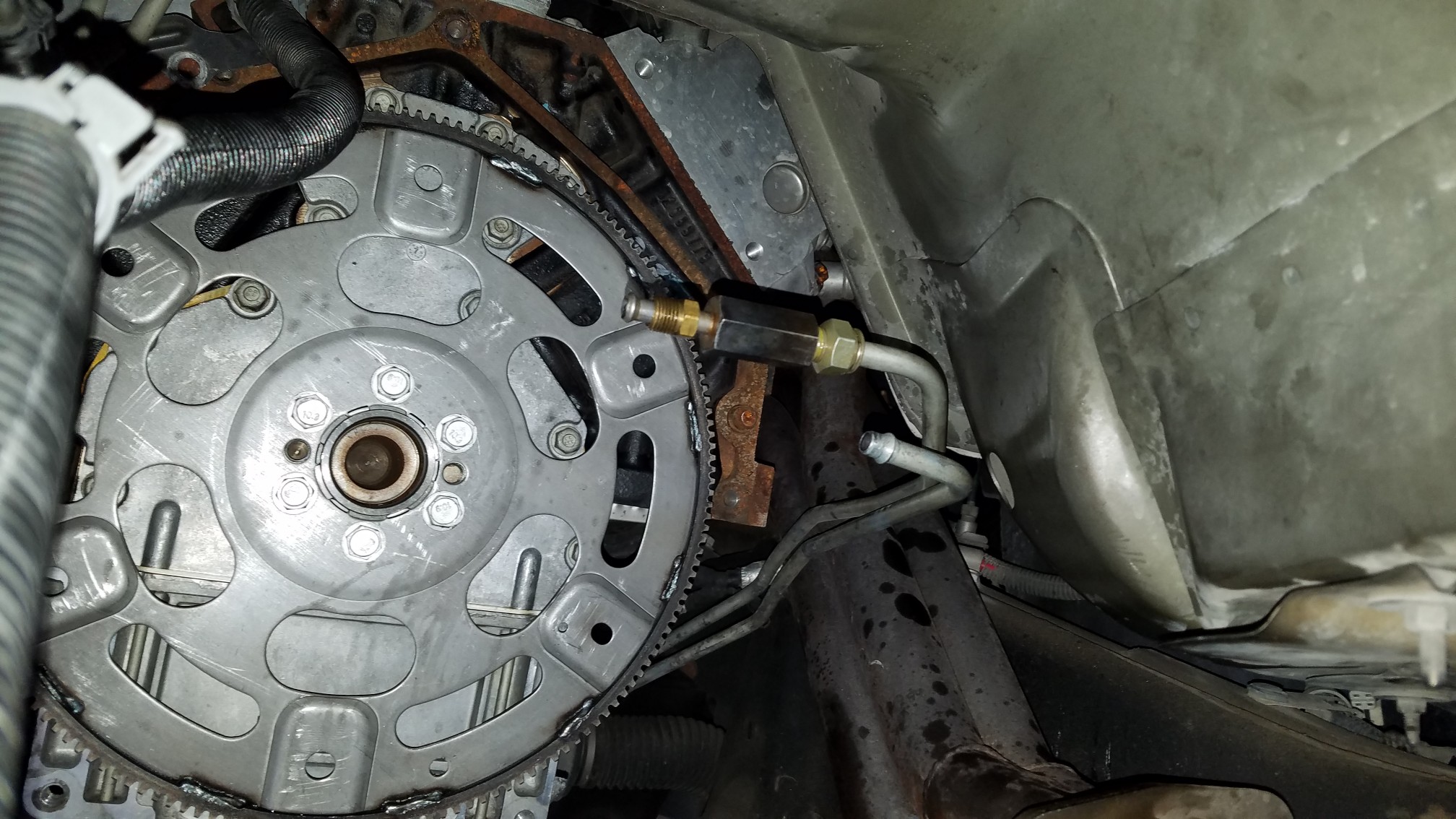

Here's a shot of the adapter on the transmission line....

Notice the splotches all over the passenger side header? Yeah, I managed to make a huge mess doing this. Poor preparation. I didn't start out with near big enough a catch container, and suffered the consequences. I back flushed the lines/coolers. I didn't like how what came out looked....

I ran two cans of flush through the system. The second can looked a lot better. Then I ran quite a bit of compressed air through the lines. I was still getting some black/grey residue on the paper towel when blowing out the lines so I ordered two more cans of that flush. I'd rather overkill this than regret not doing so.

Next, I decided to tackle the wiring. I started with replacing some cooked convoluted tubing on a section of the harness. Some of you may have noticed the uncovered wires in some of the pictures in previous posts. Around 20% of the convoluted tubing on this truck has gotten very crispy and just disintegrates when you touch it. It must be bad materials. Here's a pic showing the new tubing...

By the way, I may have mentioned it in my Grand Prix thread, but this electrical tape is awesome stuff. It's the only kind I will buy going forward....

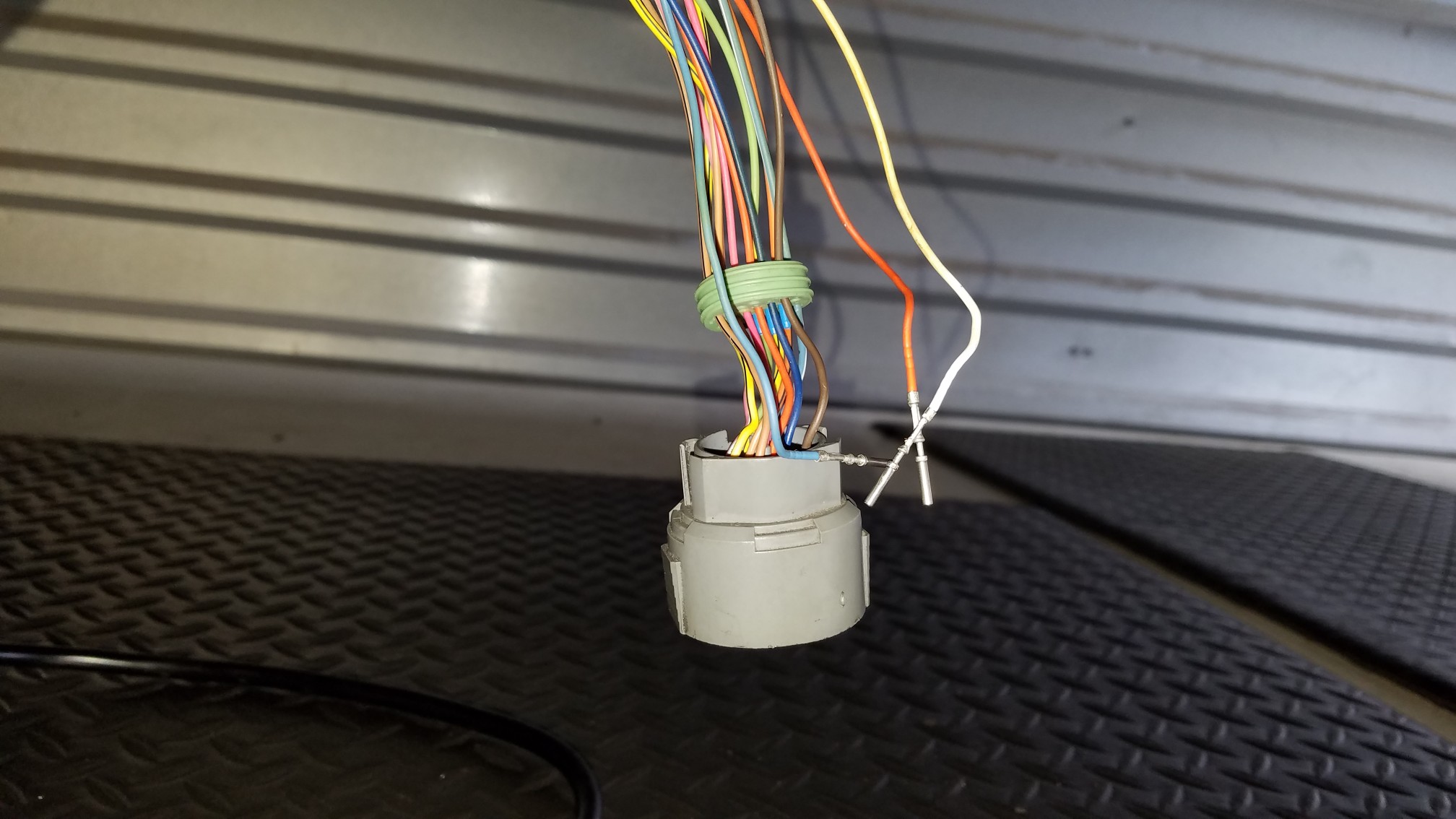

Next, following the Sloppy Mechanics guide I previously linked in this thread, I tackled repining the main transmission connector....

Basically, you pull the white wire, and it is no longer used. The brown wire moves from its original location to where the white wire was. The light blue and orange wires become the leads for the front speed sensor (the 4L80E has two speed sensors, where the 4L60E only has one). I sourced a pigtail for the front speed sensor online. It is the same for a 60E, 80E and even a T56, maybe others....

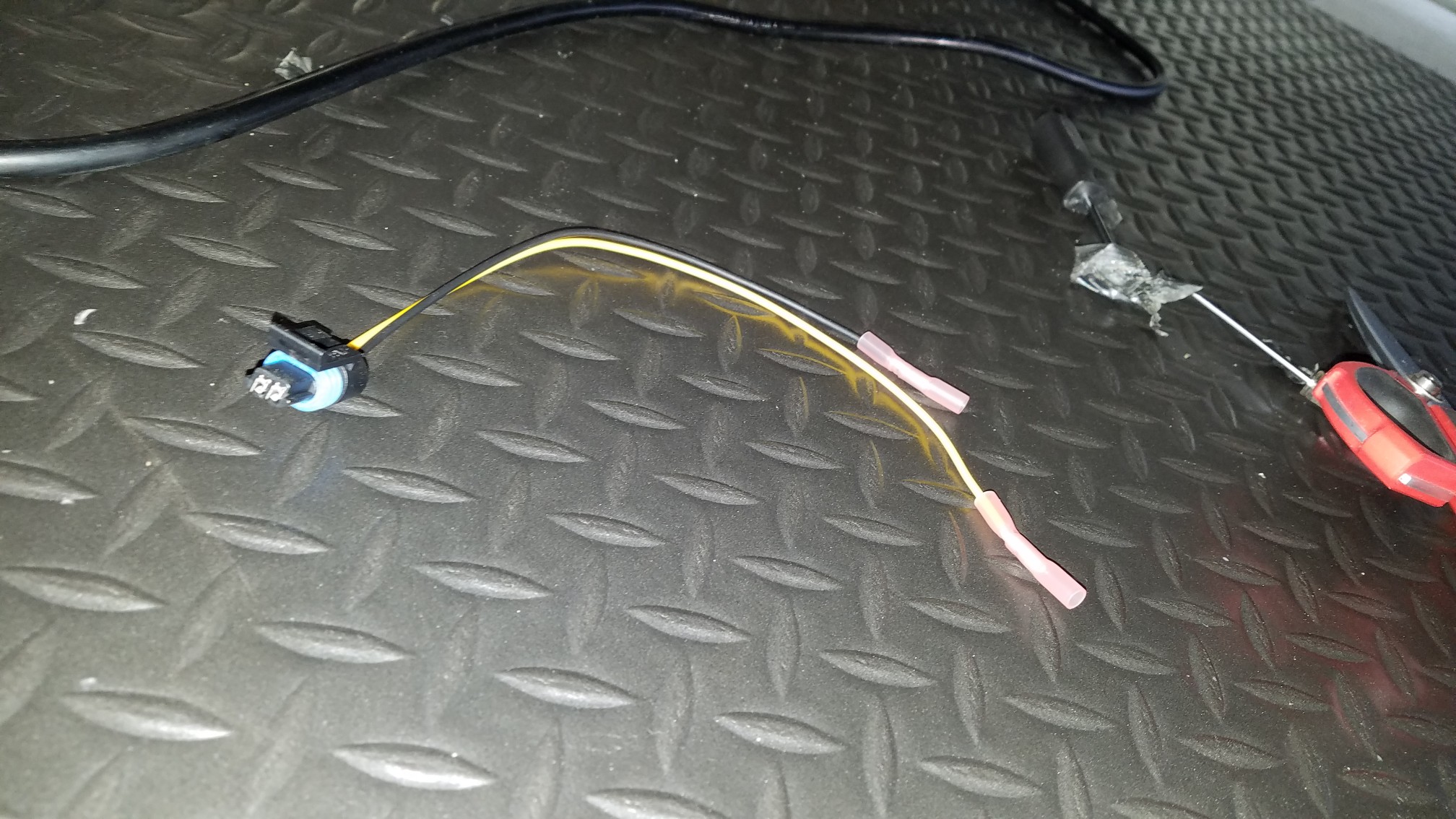

I have an assortment of those heat shrink solderless connectors and I really like them. They might be 3M brand, if my memory is correct. Here, I've got the main connector all back together and the new pigtail spliced in....

And here, everything is buttoned up, ready to go....

I forgot to mention that before I pulled the transmission, I cleaned up the stock pan and swapped it back on. It is much shorter so it is much better for getting the transmission out from under the truck on the jack. I pulled the filter while I was in there and took it home with me. Sunday I worked on chores around the house and a few small projects on my brother's truck. I also got started on painting the new cast aluminum transmission pan and the cast aluminum lower bellhousing. That's not finished to my satisfaction so no pics on that yet. I also pried that filter open for a look inside. I didn't like what I found....

I decided to have the transmission overhauled. I've spent around $120 on fluid. Add that to the cost of a new filter and having my torque converter cleaned out or replaced and I decided I didn't want to gamble. Its obvious to me that the salvage yard cleaned out the pan and the magnet while they had it down to drain the fluid for shipping. I took both transmissions (the 65E and the 85E) to a builder my friend recommended yesterday. He said the black material on the filter was clutch material. He said the metal is likely Babbitt bearing (bushing) material. He said the orange material is from the Teflon sealing rings. He didn't think it looked terrible but he thought it warranted going in and having a look. I traded the 65E core for a big chunk of his labor building my transmission. My buddy is cutting me a break on the parts so I should be able to pull this off for less than $1000 cash. At this point, I want to do this once and do it right. I'd like to get the truck back on the road and work on my Grand Prix, some day.

The builder was a little shocked that I went with such a "high" stall speed for my converter. I went with 3600-3700. Circle D's reaction was "this converter should work great". For grins I emailed FTI for their recommendation. They followed up with a few questions, which I've answered, but I haven't heard back from them yet. Since I bought the converter from Circle D, I feel pretty good using their recommendation. Still, this guy (the builder) clearly knew what he was talking about (as far as building transmissions) so I didn't totally discount his concern. Anybody else think I screwed the pooch?

I talked to the builder about transmission temperature. I had seen low 200's when in traffic on a hot day with the 65E running the Circle D converter, the cooler in the stock radiator and the stock external cooler that would come from a truck with the tow package (I added it when I put in the first Circle D converter). His feedback was this was fine. It was ten degrees or so less than engine operating temp so it was good. I should be fine with the bigger auxiliary cooler I'm putting in for sure.

That's it for now guys. Thanks for following along. I'll update when there is more progress to report.

Until then, Best,

Jared