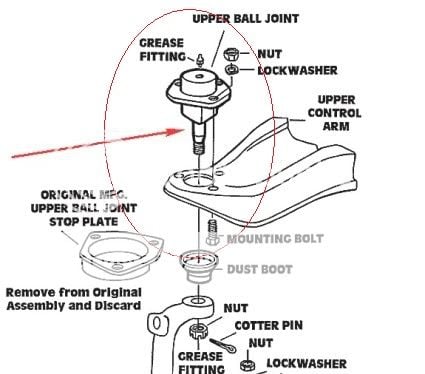

I finally got to replacing the shocks and springs in the Cutlass. In doing that, the upper ball joints were still the originals! The left side had some play, but the right was still good! I'm changing them both out while I'm there so dove into my spare parts bin, and found an ACDelco upper ball joint I still had...part number 45D0016. Great quality part, but I only had one. So I went to the local parts store and got the Moog replacement. I've had some issues with the Moog part, and I figure I'd post my experience, hoping it helps someone else out. Here's a pic of them side by side...

The ACDelco is on the left with the Moog on the right. I'm taking the Moog part back...here's why...

1. The boot on the Moog will be more prone to bursting/splitting because of its "balloon" design. The accordion design of the ACDelco part will hold up to the compression better.

2. A heavier crown nut is used on the ACDelco.

3. With the grease fitting at a 90deg, its easier to attach the grease gun.

4. Because the Moog part uses a sleeve to keep the boot on, when the sleeve presses against the body of the joint, the boot wants to slip off.

5. The Moog part does not fit! The sleeve adds too much to the diameter of the ball joint to fit the hole. I've never had to press in an upper ball joint.

So its back to the parts store to return it, and go to another parts store that carries ACDelco parts.

The ACDelco is on the left with the Moog on the right. I'm taking the Moog part back...here's why...

1. The boot on the Moog will be more prone to bursting/splitting because of its "balloon" design. The accordion design of the ACDelco part will hold up to the compression better.

2. A heavier crown nut is used on the ACDelco.

3. With the grease fitting at a 90deg, its easier to attach the grease gun.

4. Because the Moog part uses a sleeve to keep the boot on, when the sleeve presses against the body of the joint, the boot wants to slip off.

5. The Moog part does not fit! The sleeve adds too much to the diameter of the ball joint to fit the hole. I've never had to press in an upper ball joint.

So its back to the parts store to return it, and go to another parts store that carries ACDelco parts.

(Insert crass joke here...)

(Insert crass joke here...)