Texas82GP, Yeah, there is probably a Fuel Cut Off or similar setting located somewhere in the fuel delivery mapping that might trigger the equivalent response to what a choke would do.

Thing here is, Because of the initial twin issues of the recalcitrant, reluctant, obstinant pita Tip in, and the unadjusted idle stop, most of the fuel default settings had been turned down to zero to try and work around the tendency for the motor to bog and stall out because of the Tip in being so brutal. Basically what would happen is the vehicle would come to a light or sign, stop, and then cut out during the pull away. The pivot point for the accelerator was just too close to the physical center of throttle shaft and anything less than a heavy input by the foot on the gas pedal was totally unable to defeat the tension generated by the throttle shaft return springs. There is an option to access those springs and physically remove one; the throttle lever is secured by a nut, instead of being peaned or riveted solid. Only thing is that the throttle body almost has to be removed from the manifold to gain the necessary working room to snatch that spring.

Once the light bulb went off, and with a little assistance from the Boob Tube, I was able to shift the pivot point outward linearly from the throttle shaft physical centre and this virtually eliminated all the resistance to tip in that I had had to deal with previously. Very soft pedal and easy tip in now.

That issue rectified, I could turn to the idle stop screw and reset it back to the default position. it had been "bumped" to advance the throttle blades off the idle circuit in an attempt to overcome that miserable tip in issue; didn't work. Now it could be reset to bring the blades back to the fully closed position so that, at idle, the idle circuit could function correctly again. Getting back to that sweet spot has taken a couple of tries, mostly because it takes very little twist on the screw to get change so the adjustments have been along the line of one TPH of a turn at a time and then run it.

Most of the remaining changes are likely going to be in the tuning values in the computer/ECU. It is tuneable directly so no need for a laptop.

I also have a call in for a completely new HEI Distributor, my choices being a Davis DUI unit, Moroso, or MSD. My existing timer is 40 years old and has never been pulled for overhaul so it is probably pretty loose internally. I just picked up a 454 version HEI at the recent swap meet and after a little love and cleaning it spins cleanly. At some point it must have sat without a cap on it because the reluctor tips were all contaminated with that fine metal dust you get from a grinder or cut off wheel. Doesn't take much more than one miniscule grain of tha stuff to bind the shaft up solid.

Anyway, most of what is going on now is tune on the fly. Tweak it, run it and see if things get better or worse. Also thinking it may be about time for another set of plugs. The current ones are the last set that I put in just before I benched the Holley and went FI so they could be all carboned up from the Holley being so psychotic. Think that carb ran right about 5 days of the month and it had to be 75 degrees or higher with no humidity. Any kind of moisture or dampness and it just would not run. Barf, fart, wheeze and stall, but not idle. Think i about wore it out anyway; was on its second base plate, converted to cathedral bowls, had been fitted with the brass floats but think I put it over to the new nitrophyll ones that tolerate low e gas. At least one of the old brass ones was showing signs of lead/solder issues so..............

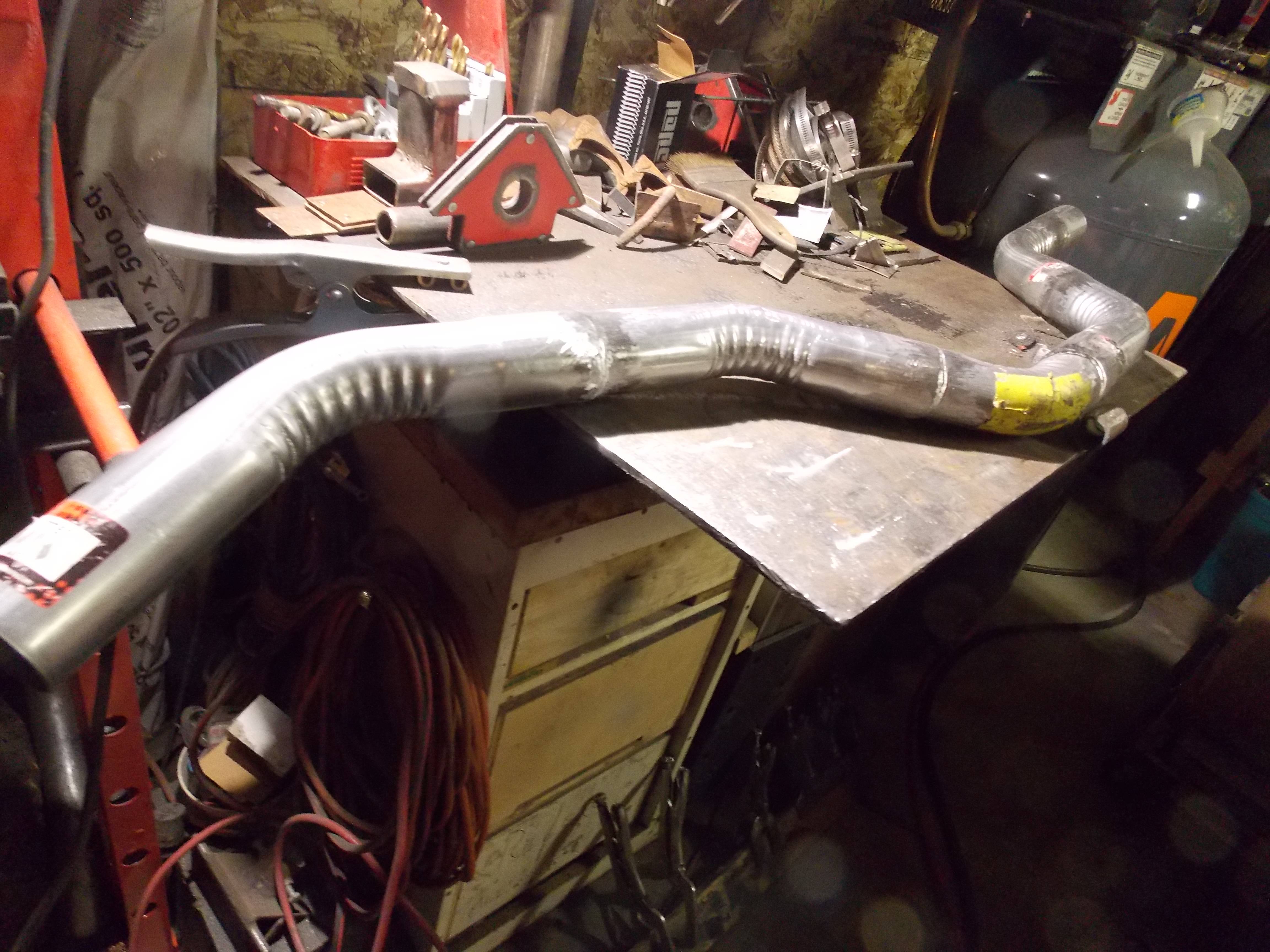

Right now it is run what I have time as I have to concentrate on the S-10 and getting the past years damage to its systems seen to. There are pictures of what is left of the passenger side post muffler exhaust pipe posted on the Non G site. BEyond salvage, I'll use it as a template for the new one because new one it must be, or be made.

Nick