So back when I posted about my header issues, which, by the way, are still issues. several of the respondents mentioned what they had done by way of modifying the motor mounts they had to gain needed clearance. Since I am waiting for parts, again!!, and had dedicated the afternoon to some mig driven rehab work, it occurred to me to see what I could do by way of creating a pair of suitably modified upper engine mounting clams, just in case my speed shop couldn't persuade the distributor to credit me for their mis-applied part number tubes. The pictures that accompany this post show what I came up with

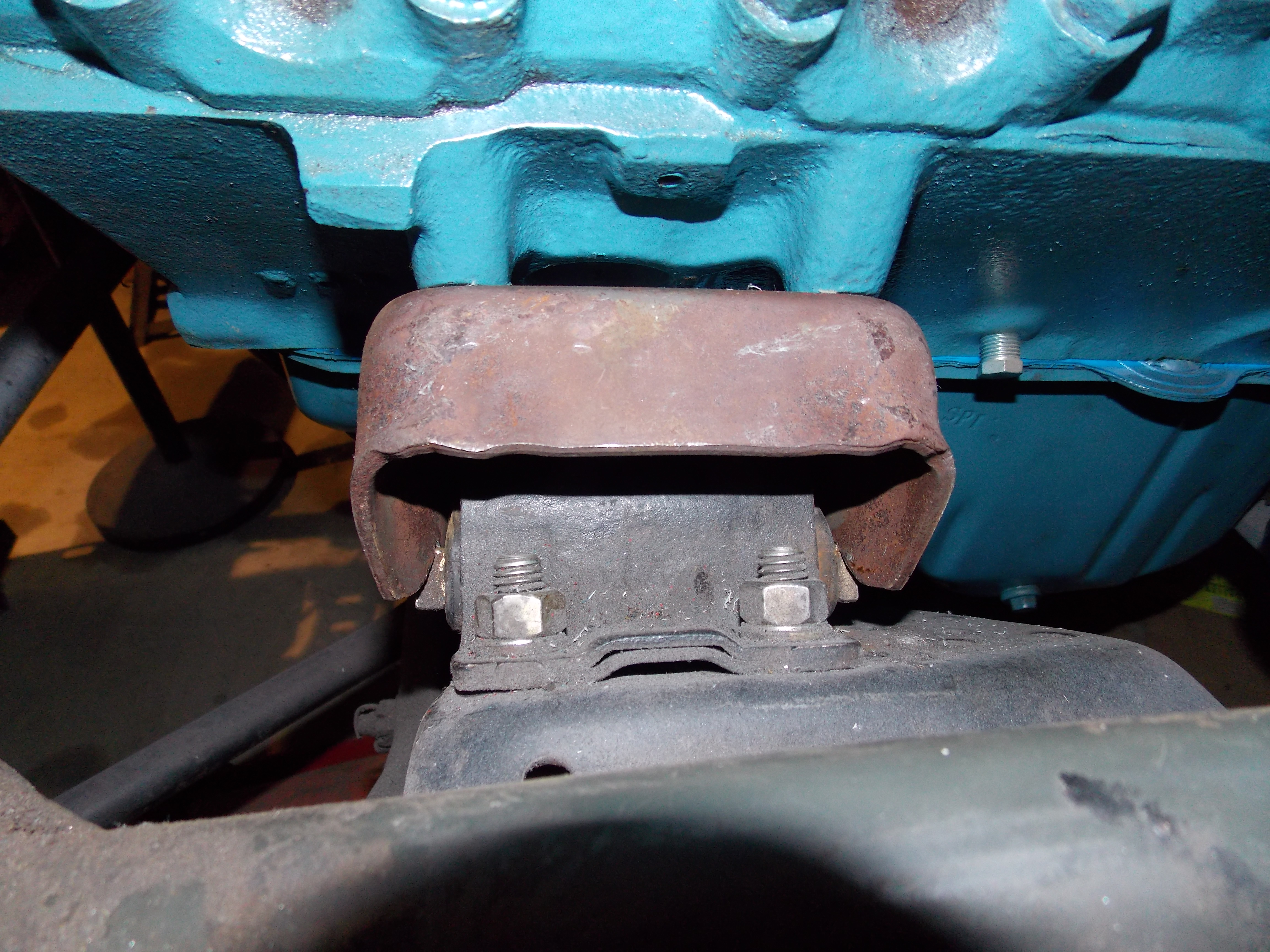

This first pic is of the upper mount that I ended up using after my first choice didn't want to drop cleanly onto the frame shell and urethane inner biscuit. This is one of a pair of clams that I used when I did the mockup of the clutch linkage and found that I had to reshape the ears through which went the cross bolt because originally they wouldn't drop into place either. With the 400 acting as my dummy block, an with the services of the engine crane, I could raise and lower the assembly to trial fit the upper clams and see what I had to add or remove to get a clam that would work.

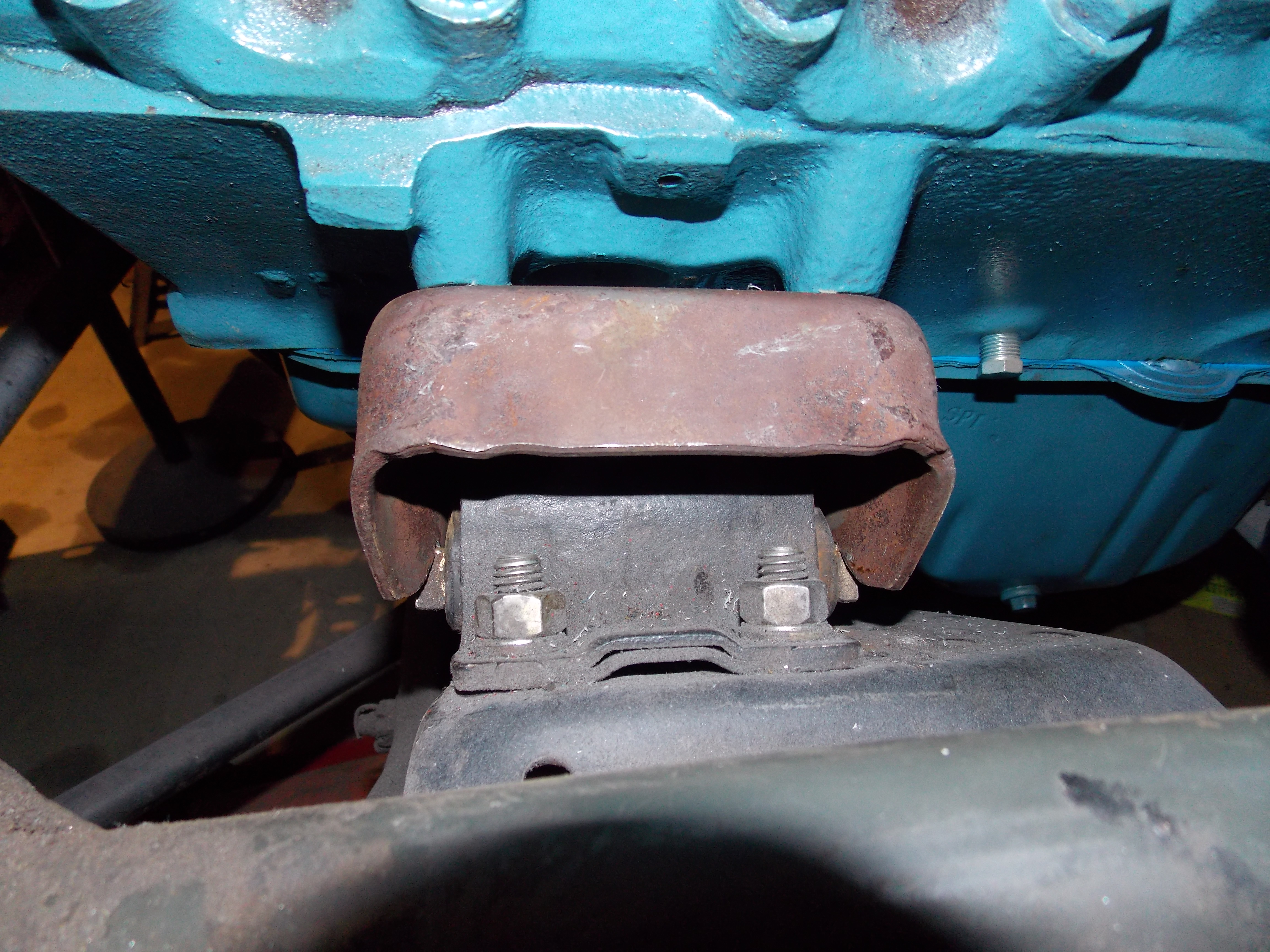

For contrast, here is a picture of one of the first pair of upper mounts that I originally attempted to use. Unlike the first version, this one has two reliefs or pockets in it that were put there by the factory as part of the stamping process. Apart from this difference everything else remains about the same, including the distance between the inner surface of both mounts and their respective outer edges, about 1.75". The matching clam to this one was the part that became my victim (Insert blood curdling screams and moans

And this was the result of my whittling efforts. The width of the material removed from the upper edge/face/surface worked out to about n inch, leaving me with about 5/8ths - 3/4 of an inch of shoulder.

And, finally, a comparison shot of the stock, unmodified upper mount sitting beside the one that has already been played with. This is not the actual final shape will end up being used, this is more of an "in progress" shot. After I took this, I revisited the concaved curve that I had created between the modified upper edge and the mounting ear and dished it in more deeply, removing some additional material from the upper edge of the bolt ear in the process. That is where the shape lies now, but it may still not be the final configuration as I am thinking of shaving an 1/8th or 3/16 of an inch more out of the curve to make it even rounder and deeper. At this point I have no firm idea as to exactly how much the amount of material might be that I need to remove in order to gain the clearance and room that I need. I also have no real plan to go ahead and use these variants unless the cannot score the set of headers that I have identified as a proper fit, If I end up stuck with the Flowmasters then it becomes a case of unbedding the motor and swapping the resident clams for the ones that I have modified and hoping that I got my sums right. All of the pictures presented as alternatives show mounts that have been radically trimmed back, including the store bought variant. Not thinking that radical, just looking for a result that both works and that, at first glance, will appear normal and baffle the looky-lous.

Nick

, here!!)

This first pic is of the upper mount that I ended up using after my first choice didn't want to drop cleanly onto the frame shell and urethane inner biscuit. This is one of a pair of clams that I used when I did the mockup of the clutch linkage and found that I had to reshape the ears through which went the cross bolt because originally they wouldn't drop into place either. With the 400 acting as my dummy block, an with the services of the engine crane, I could raise and lower the assembly to trial fit the upper clams and see what I had to add or remove to get a clam that would work.

For contrast, here is a picture of one of the first pair of upper mounts that I originally attempted to use. Unlike the first version, this one has two reliefs or pockets in it that were put there by the factory as part of the stamping process. Apart from this difference everything else remains about the same, including the distance between the inner surface of both mounts and their respective outer edges, about 1.75". The matching clam to this one was the part that became my victim (Insert blood curdling screams and moans

And this was the result of my whittling efforts. The width of the material removed from the upper edge/face/surface worked out to about n inch, leaving me with about 5/8ths - 3/4 of an inch of shoulder.

And, finally, a comparison shot of the stock, unmodified upper mount sitting beside the one that has already been played with. This is not the actual final shape will end up being used, this is more of an "in progress" shot. After I took this, I revisited the concaved curve that I had created between the modified upper edge and the mounting ear and dished it in more deeply, removing some additional material from the upper edge of the bolt ear in the process. That is where the shape lies now, but it may still not be the final configuration as I am thinking of shaving an 1/8th or 3/16 of an inch more out of the curve to make it even rounder and deeper. At this point I have no firm idea as to exactly how much the amount of material might be that I need to remove in order to gain the clearance and room that I need. I also have no real plan to go ahead and use these variants unless the cannot score the set of headers that I have identified as a proper fit, If I end up stuck with the Flowmasters then it becomes a case of unbedding the motor and swapping the resident clams for the ones that I have modified and hoping that I got my sums right. All of the pictures presented as alternatives show mounts that have been radically trimmed back, including the store bought variant. Not thinking that radical, just looking for a result that both works and that, at first glance, will appear normal and baffle the looky-lous.

Nick

, here!!)

Last edited: