I'm just not happy with the routing of my harness. It's very tight behind my engine and firewall. Anyone have a solution that I'm not seeing?

Wiring harness questions

- Thread starter Tony1968

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I am working on the same issue. I just finished fabbing up a new engine harness and now I am trying to figure out the routing of the new harness.

First issue: how to route harness from firewall connection. Essentially, choices from firewall origin are: i. Over the power brake booster; ii. Under power brake booster; and iii. Over the face of brake booster (similar to stock routing of speedo cable and CC harness).

Let me know what your thoughts are on routing from firewall connection.

First issue: how to route harness from firewall connection. Essentially, choices from firewall origin are: i. Over the power brake booster; ii. Under power brake booster; and iii. Over the face of brake booster (similar to stock routing of speedo cable and CC harness).

Let me know what your thoughts are on routing from firewall connection.

Last edited:

Injectedcutty hid his pretty well; maybe he'll play nice and share.

Under the booster is most hidden. I used the cruise control grommet hole for my DBW harness.

Under the booster is most hidden. I used the cruise control grommet hole for my DBW harness.

Once I get my 2hr drive done I'll explain. To be continued...Injectedcutty hid his pretty well; maybe he'll play nice and share.

Under the booster is most hidden. I used the cruise control grommet hole for my DBW harness.

Definitely watching this thread.

One thing I’m curious to try is sort of “flat packing” the wires, using a wire wrap that is molded into a flat shape and using some sort of plastic holder to keep the harness in that shape. Could it be tucked under the cowl more if the harness is molded like that?

One thing I’m curious to try is sort of “flat packing” the wires, using a wire wrap that is molded into a flat shape and using some sort of plastic holder to keep the harness in that shape. Could it be tucked under the cowl more if the harness is molded like that?

Ok, lemme give this a go here. In an effort to tuck and hide as much wiring as possible I did the following.

The factory harness block on the firewall was removed, hole welded closed and smoothed. The fuse block is mounted under the dash, with the main starter wiring entering the engine bay right behind the intake along with the engine harness.

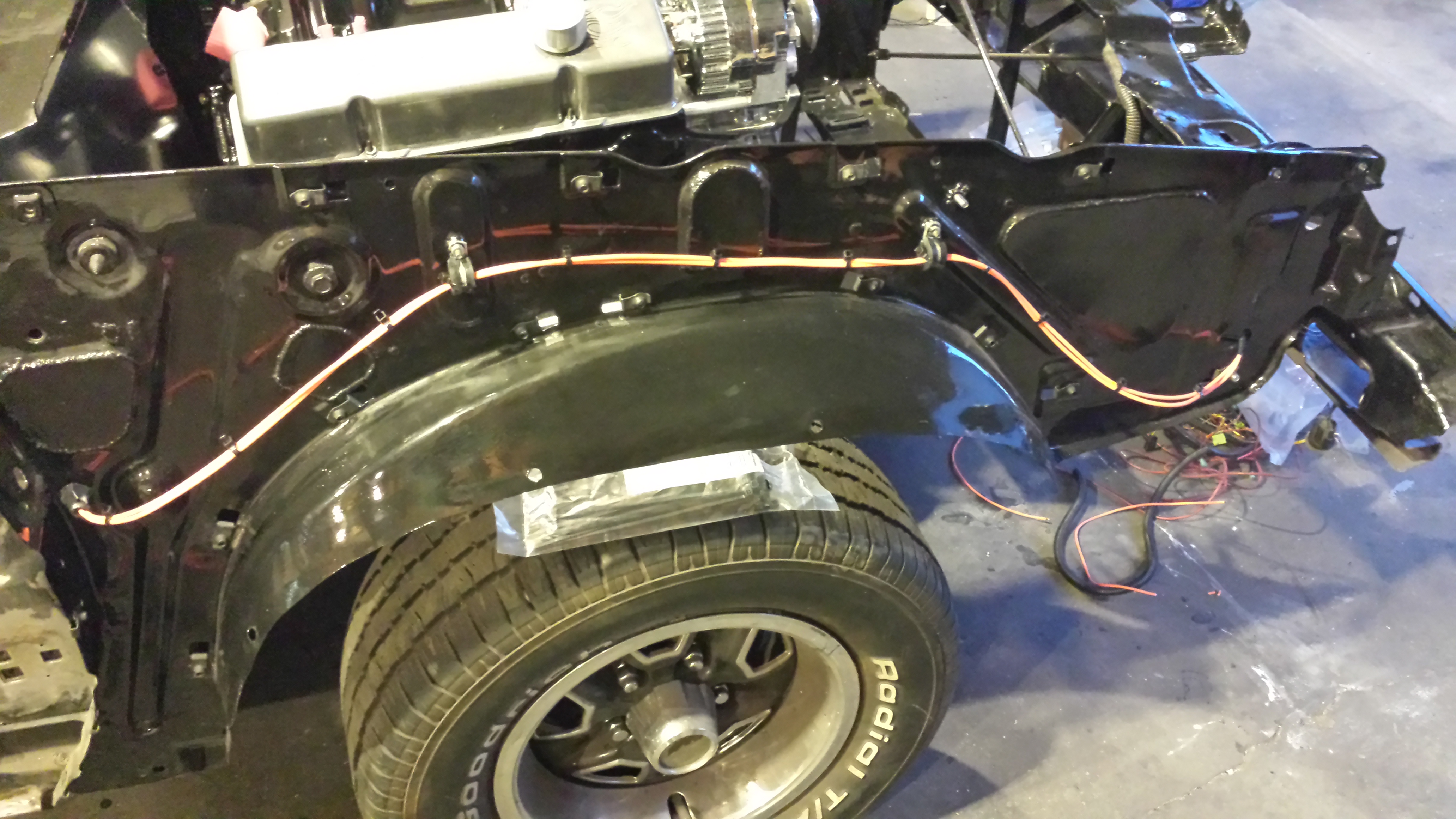

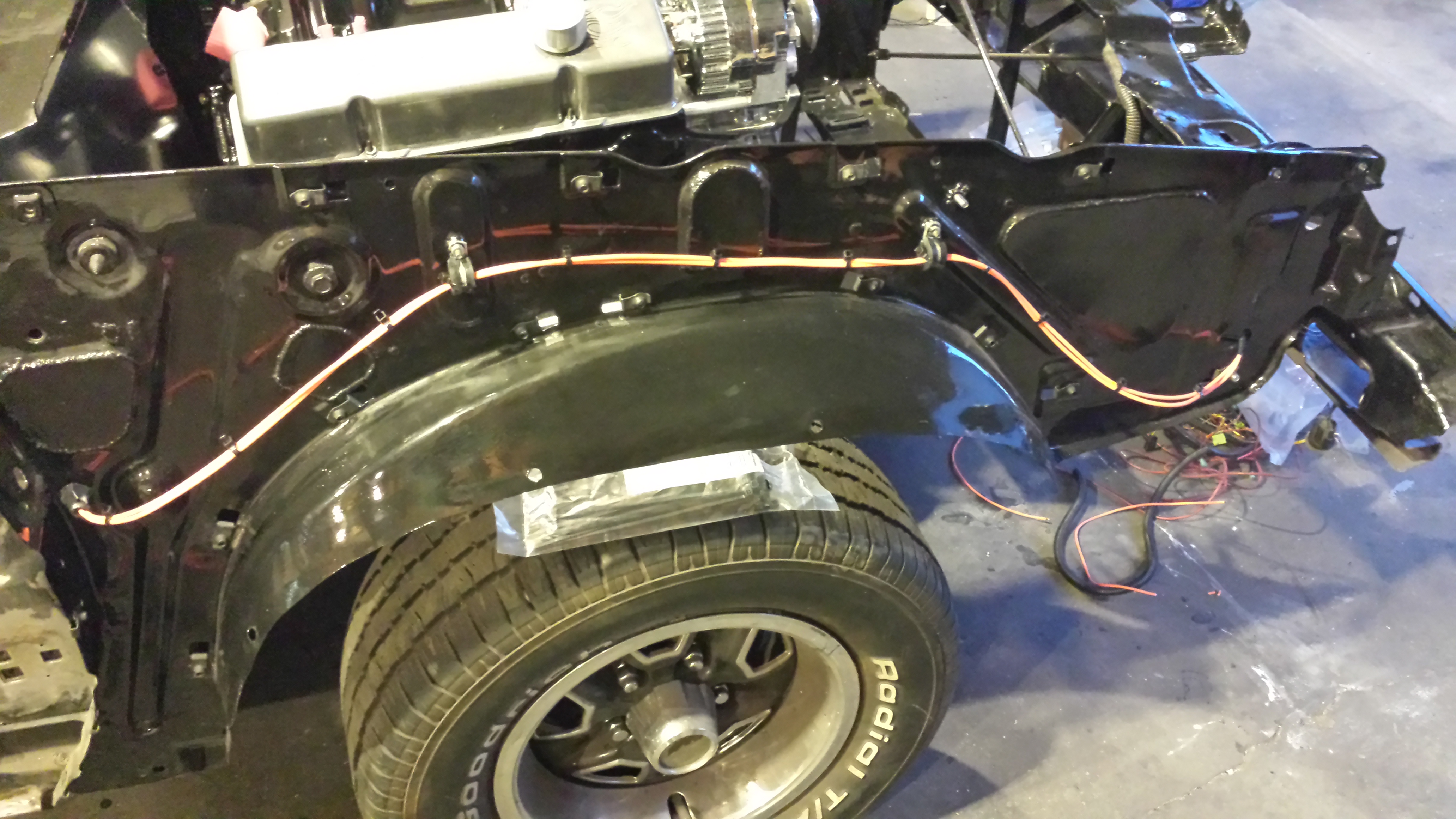

The headlight wiring was routed through the driver side fender and protected, then travels between the inner and outer fender. I welded studs to the inner fender to mount insulated clamps holding the wires, then ground the heads down to make em disappear. The wiring appears into the core support, and is wrapped in braided loom. I did the same for the electric fan wiring which runs along the pass side fenders, and enter the cabin via a hole and grommet by the old antenna hole. Here are pics of that.....

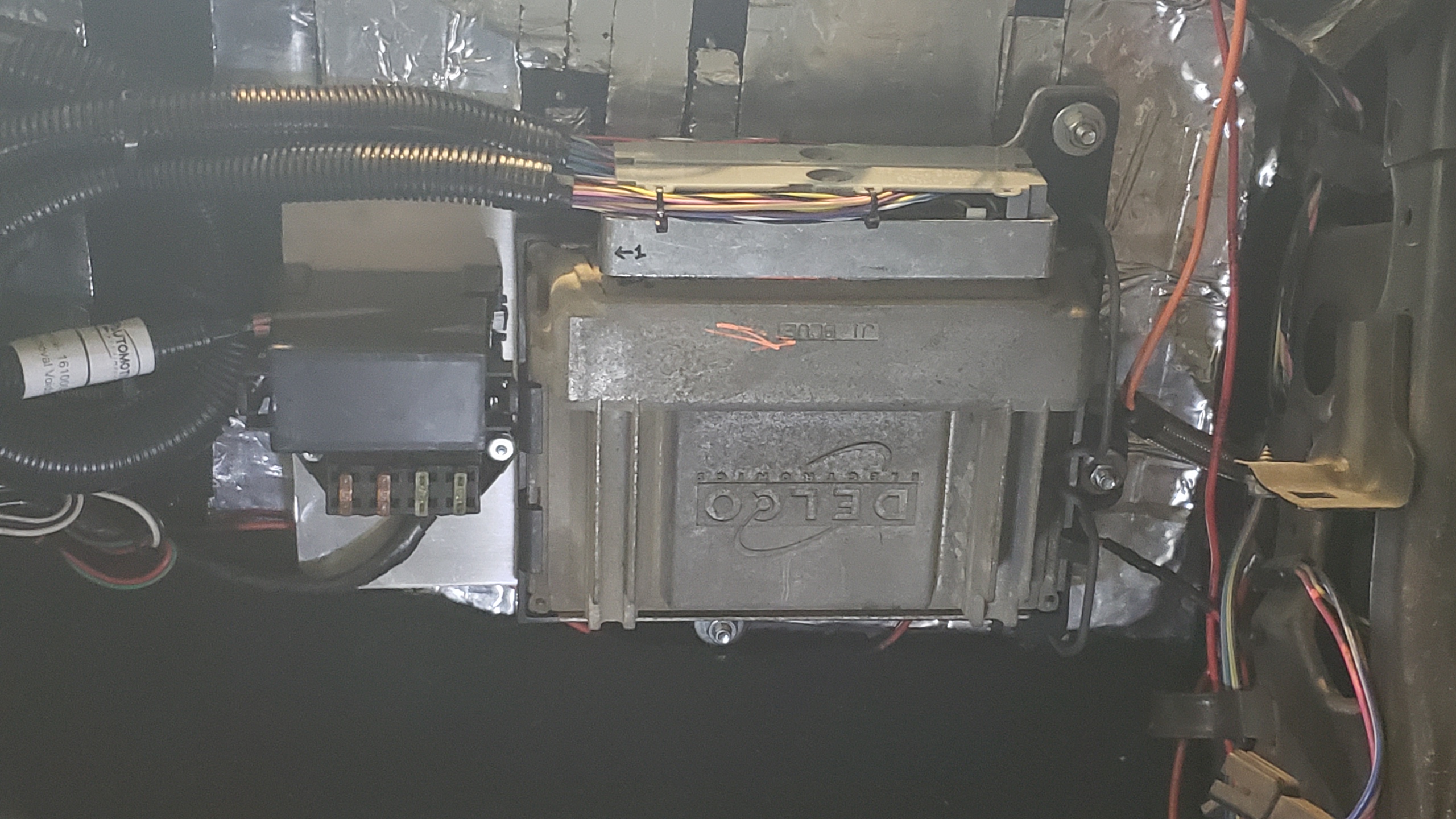

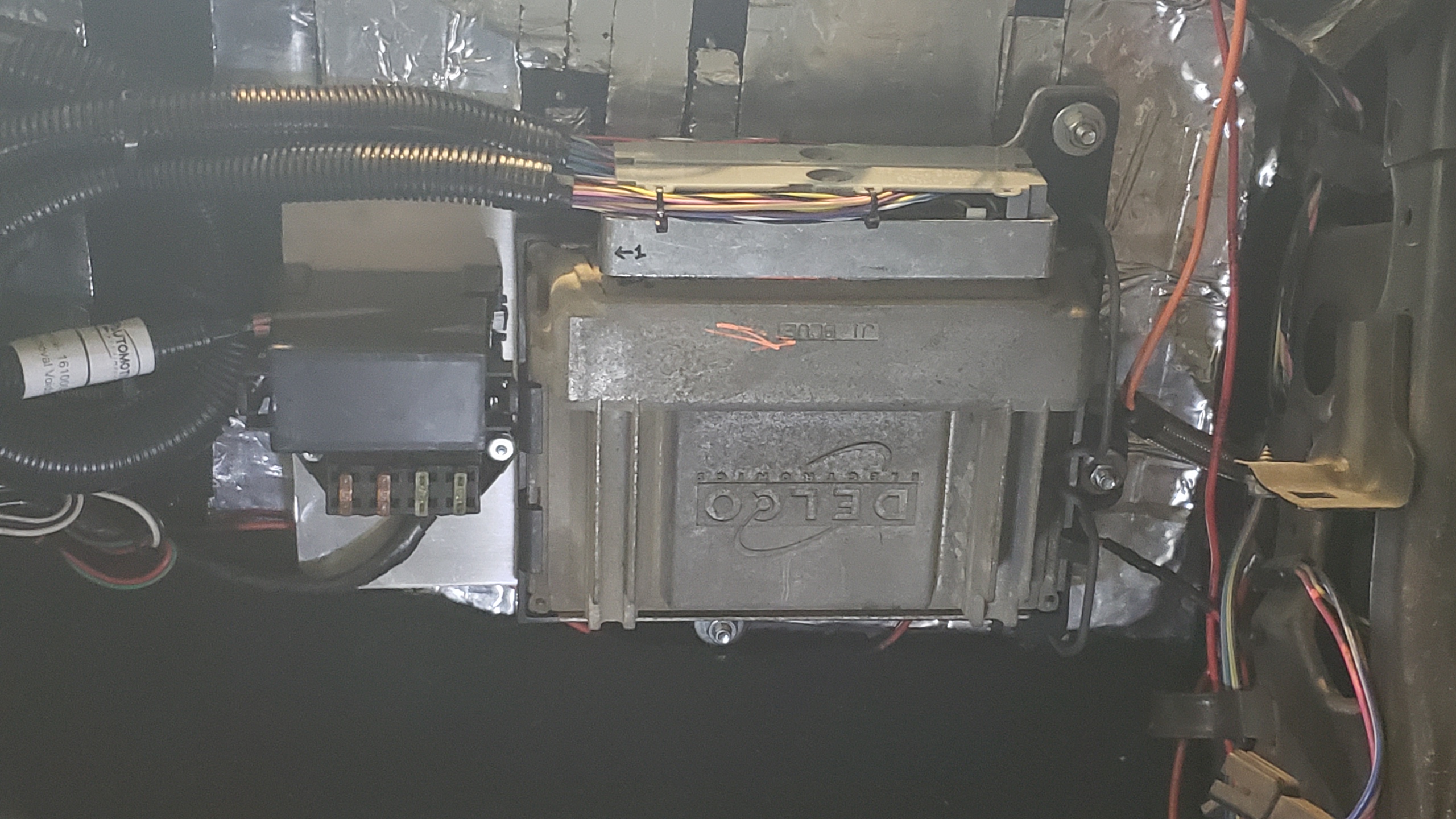

For my LS harness I went with a standalone unit that was custom built for me to keep the ECU under the dash. This dramatically cleans up the engine bay, and allowed me to drill one hold directly behind the intake. The harness enters the engine bay and splits to each side respectively according to the sensors, injectors, and such. I'm not gonna sugarcoat it, trying to tuck wiring is super time consuming, tedious, and hurts my hands, but the end results are so worth it. I still have some more to do over winter, but I'm pleased with the current state of progress.

The factory harness block on the firewall was removed, hole welded closed and smoothed. The fuse block is mounted under the dash, with the main starter wiring entering the engine bay right behind the intake along with the engine harness.

The headlight wiring was routed through the driver side fender and protected, then travels between the inner and outer fender. I welded studs to the inner fender to mount insulated clamps holding the wires, then ground the heads down to make em disappear. The wiring appears into the core support, and is wrapped in braided loom. I did the same for the electric fan wiring which runs along the pass side fenders, and enter the cabin via a hole and grommet by the old antenna hole. Here are pics of that.....

For my LS harness I went with a standalone unit that was custom built for me to keep the ECU under the dash. This dramatically cleans up the engine bay, and allowed me to drill one hold directly behind the intake. The harness enters the engine bay and splits to each side respectively according to the sensors, injectors, and such. I'm not gonna sugarcoat it, trying to tuck wiring is super time consuming, tedious, and hurts my hands, but the end results are so worth it. I still have some more to do over winter, but I'm pleased with the current state of progress.

Last edited:

Those are goals right there ^^^^

One day I wish to have a clean engine bay like that

One day I wish to have a clean engine bay like that

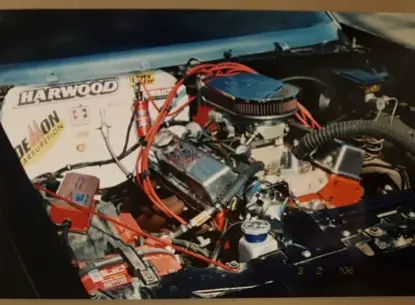

Thank you sir! It took me many years to change my way of thinking to get it to this point. When I was younger it didn't matter really, as long as everything worked, that's evident in this pic from when I was running a carbed 355...Those are goals right there ^^^^

One day I wish to have a clean engine bay like that

Some guys prefer function over form and that's fine, but I've tailored my design more towards functional form. Make it appear the engine doesn't run by tucking wiring as much as possible, yet still operate like anything else. In the event of an issue, all needed connections, fuses, relays, etc are still easily accessible. In the end, it's all about what your goals are and/or what lengths your willing to go to for achieving said goals.

Thats the plan I have in mind but for now I'm just trying to get it running right first and fix the butchered harness. Maybe I'll engine swap maybe not but thats later on down the road. One thing is for sure I've always liked rides with clean smooth bays or at least less stuff visible.

Man oh man. I guess I'm going to pull my dash out sooner than I expected 😌Ok, lemme give this a go here. In an effort to tuck and hide as much wiring as possible I did the following.

The factory harness block on the firewall was removed, hole welded closed and smoothed. The fuse block is mounted under the dash, with the main starter wiring entering the engine bay right behind the intake along with the engine harness.

The headlight wiring was routed through the driver side fender and protected, then travels between the inner and outer fender. I welded studs to the inner fender to mount insulated clamps holding the wires, then ground the heads down to make em disappear. The wiring appears into the core support, and is wrapped in braided loom. I did the same for the electric fan wiring which runs along the pass side fenders, and enter the cabin via a hole and grommet by the old antenna hole. Here are pics of that..... View attachment 158369 View attachment 158370

For my LS harness I went with a standalone unit that was custom built for me to keep the ECU under the dash. This dramatically cleans up the engine bay, and allowed me to drill one hold directly behind the intake. The harness enters the engine bay and splits to each side respectively according to the sensors, injectors, and such. I'm not gonna sugarcoat it, trying to tuck wiring is super time consuming, tedious, and hurts my hands, but the end results are so worth it. I still have some more to do over winter, but I'm pleased with the current state of progress. View attachment 158374 View attachment 158372 View attachment 158373

No other way to get that hole in the right spot behind the intake manifold. It's got to be done for whatever under dash hvac system i choose anyway. I wish I would have done it before I had engine installed but live and learn.

Thanks Scott!

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 13

- Views

- 2K

- Replies

- 21

- Views

- 1K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.