a.k.a. HOW NOT TO BUILD A REGAL

this thread has been a long time coming, and admittedly won't be as flashy or as technical as some of the nicer looking builds (yeah, I don't possess alot of the skills to build a nicer build... :wink: ), but this car has taken a place in my family, and like 85 cutlass brougham stated in his lengthy thread, this is kinda more for reference, and for some people who just want to get a good laugh (if you can't laugh at yourself, you take life waaaay to seriously.... LIGHTEN UP!

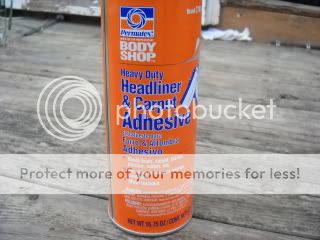

this build has been going for a few years now, since I don't have a garage to work in, I have to depend on nice weather/part readiness/correct tool availability/pure laziness on my part to get anything done. I also started this build thinking of when hot rodding first started, and you used what you had,was given, raided from the junkyard, bought cheap, etc..., . It has kind of taken on a life of it's own, and I have noticed that some of the skills I had very little of, has started to get better (i.e. this first part- floorboard repair/replacement and welding... 😢 )

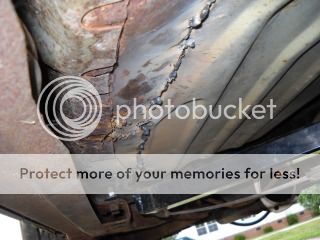

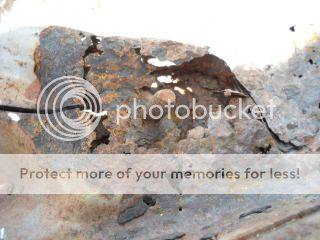

first off, lets start off where I first knew I was in trouble...:

I always knew that I had a little rust in the driver's side floorboard, but never knew exactly how much, so I got a wild hair up my rear, and decided to finally bite the bullet, and start the interior phase of the build.... that was last year.....

this thread has been a long time coming, and admittedly won't be as flashy or as technical as some of the nicer looking builds (yeah, I don't possess alot of the skills to build a nicer build... :wink: ), but this car has taken a place in my family, and like 85 cutlass brougham stated in his lengthy thread, this is kinda more for reference, and for some people who just want to get a good laugh (if you can't laugh at yourself, you take life waaaay to seriously.... LIGHTEN UP!

this build has been going for a few years now, since I don't have a garage to work in, I have to depend on nice weather/part readiness/correct tool availability/pure laziness on my part to get anything done. I also started this build thinking of when hot rodding first started, and you used what you had,was given, raided from the junkyard, bought cheap, etc..., . It has kind of taken on a life of it's own, and I have noticed that some of the skills I had very little of, has started to get better (i.e. this first part- floorboard repair/replacement and welding... 😢 )

first off, lets start off where I first knew I was in trouble...:

I always knew that I had a little rust in the driver's side floorboard, but never knew exactly how much, so I got a wild hair up my rear, and decided to finally bite the bullet, and start the interior phase of the build.... that was last year.....

. (after just setting these in and making a few adjustments, I could "hop" on the floor and didn't get the slightest movement from it)

. (after just setting these in and making a few adjustments, I could "hop" on the floor and didn't get the slightest movement from it)