I'll see if this works before pulling out power tools tomorrow! Thanks, bub!They sell box end extractors but ironically they mentioned that they work better on a good quality fastener i.e. grade 8 bolt I’ve seen this trick employed on a yt video but I’m sure it’ll be difficult to get a screwdriver in there but who says it has to be a screwdriver.View attachment 256071

How would you go about this, Fellas?

- Thread starter RustyKnight

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

you can try a stubby flathead, or .... shim some pennies/dimes in thereThey sell box end extractors but ironically they mentioned that they work better on a good quality fastener i.e. grade 8 bolt I’ve seen this trick employed on a yt video but I’m sure it’ll be difficult to get a screwdriver in there but who says it has to be a screwdriver.View attachment 256071

I've had this exact issue before and stubby Vice Grips are the answer unless you can utilize a hex key in the recessed Allen socket. Feel free to cut them down so they fit but if you really wrenched 'em on then removing them with the hex key is going to hurt your fingers. Twelve point bolts are MUCH easier to install & remove in the future, though these bolts do seem to work better in certain spots.

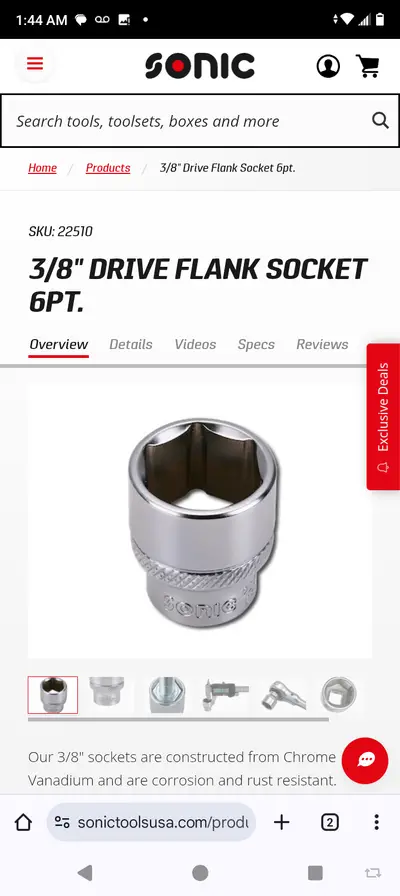

You need a flank drive socket. Heat the bolt, just the bolt, cherry with MAP, Oxygen/Acetylene or plain old Propane torch. Then let cool for an hour or so. Try a good quality proper size hex (Allen) wrench. Put short piece (12 - 18 inch) 1/4" pipe to use as leverage (cheater pipe) and work back and forth to break tension between bolt threads and any corrosion bonding between the bolt threads and the threaded hole drilled in the head. It should come loose.

If that doesn't work heat the flange (not the bolt) cherry red, and let cool. As the flange expands it will apply pressure to the bolt and its threads, and this should free up any threads that are bound up.

Re-assemble with better quality bolts, use the WHITE high temp Locktight (TM). Any thing I build, which any more is few..., all manifold and header bolts get the high temp Locktight.

A bolt is actually a spring, (spiral incline) which is why proper torque is needed when putting things together so less problems when taking apart. So the threads are in there under spring tension and after multiple heat cycles the "male" threads tend to bond to the "female" threads. So turn it to tighten and then to loosen and repeat, and the areas of bonding should break free.

Cherry Red is high enough temp to get most steels into a plastic state and torque applied too soon will just twist the bolt to separation failure. So you want the heat to expand (stretch) and then relax to original size after cooling. This should be enough to break the threads free and not damage the bolt.

If that doesn't work heat the flange (not the bolt) cherry red, and let cool. As the flange expands it will apply pressure to the bolt and its threads, and this should free up any threads that are bound up.

Re-assemble with better quality bolts, use the WHITE high temp Locktight (TM). Any thing I build, which any more is few..., all manifold and header bolts get the high temp Locktight.

A bolt is actually a spring, (spiral incline) which is why proper torque is needed when putting things together so less problems when taking apart. So the threads are in there under spring tension and after multiple heat cycles the "male" threads tend to bond to the "female" threads. So turn it to tighten and then to loosen and repeat, and the areas of bonding should break free.

Cherry Red is high enough temp to get most steels into a plastic state and torque applied too soon will just twist the bolt to separation failure. So you want the heat to expand (stretch) and then relax to original size after cooling. This should be enough to break the threads free and not damage the bolt.

Last edited:

Example of flank drive socket.

sonictoolsusa.com

sonictoolsusa.com

3/8" Drive Flank Socket 6pt. - Sonic Tools

3/8" Drive Flank Socket 6pt. Our 3/8" Drive 6-Point Flank Socket provides versatility for various applications. Crafted with durability and precision, it

Attachments

Considering I'm an American who loves women, I'm gonna stick with the headers, lol but thanks bub!1st thing i would do is make the decision to never go with headers again after this debacle is resolved cuz you only have to tighten those bolts once with cast iron. lol but your dremel sounds good as a 2nd step.

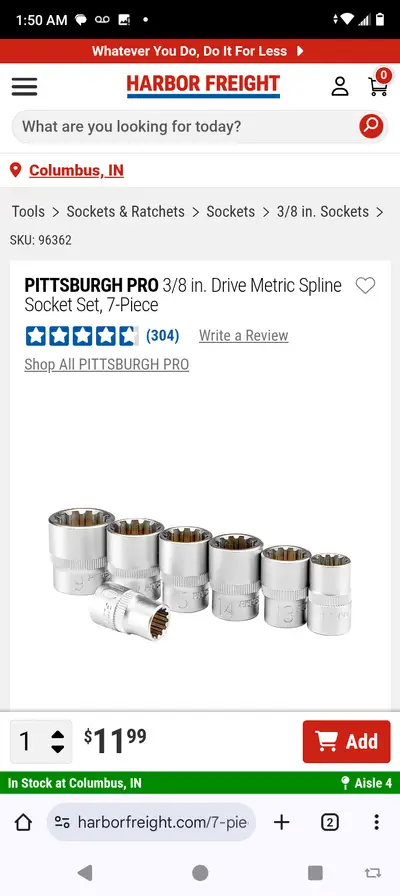

I have extractors that didn't fitExample of a spline drive, which is also a possibility.

Roll on with the headers but for everyone's sanity, always...and I mean ALWAYS...did I mention ALWAYS? Oh, maybe I didn't. ALWAYS use the highest quality bolts you can afford. This means if you ain't got $$, then wait and buy good ones when you do. ARP makes very nice quality stuff, and when doing headers, DO THAT. Buy once, cry once. Get the ones with safety wire holes pre-drilled and use that or those bolt lock washers that doesn't allow the bolt to budge once installed. I would hesitate to use loctite on header bolts.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.