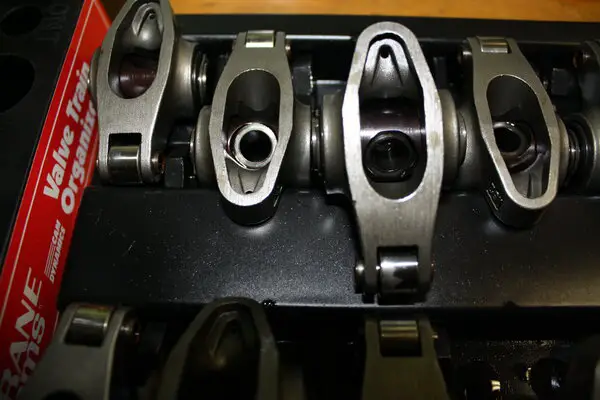

Just wondering what you guys think of these wear patterns. All the valves are similar to these two.

Motor is a 383, hydraulic flat tappet with roller rockers and guide plates.

Also wondering if there are any tricks to setting up guide plates correctly so the roller tip is centered on the valve stem. There are a few that were off centered.

*Side note, I'm hoping this is just the assembly grease in the oil? I Did the break in, changed the oil, then ran the motor for another 30 mins or so.

Motor is a 383, hydraulic flat tappet with roller rockers and guide plates.

Also wondering if there are any tricks to setting up guide plates correctly so the roller tip is centered on the valve stem. There are a few that were off centered.

*Side note, I'm hoping this is just the assembly grease in the oil? I Did the break in, changed the oil, then ran the motor for another 30 mins or so.