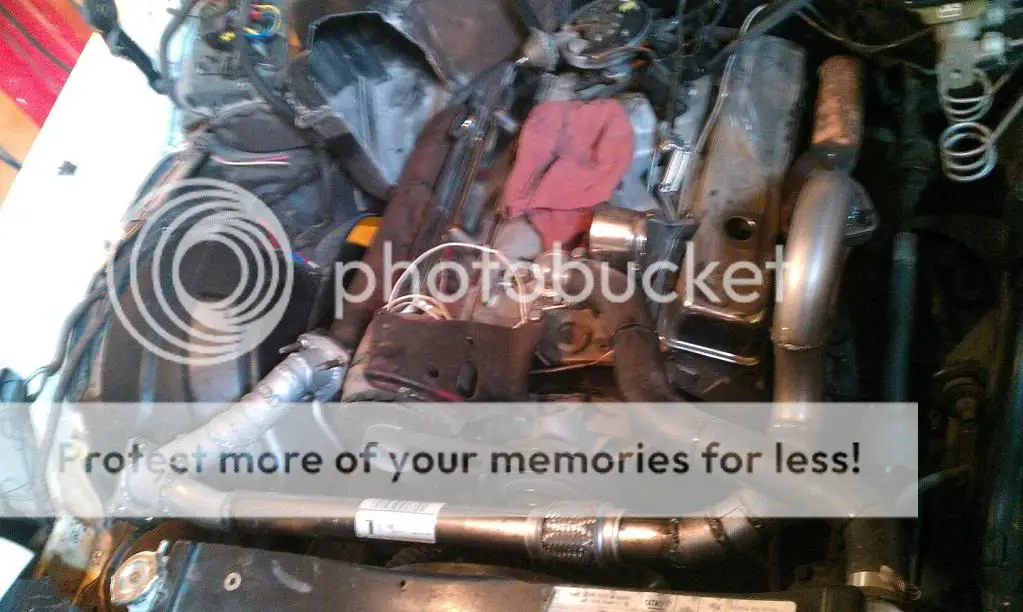

Ok guys, well if any of you remember me, I started a thread about 3 years ago on my 86 Monte SS. It was all original and I purchased an LT1 and started building it. Well, I got the LT1 all built and a guy came in and saw it and HAD to have it for his '94 Z28. He made me an offer I couldnt refuse, so I sold it for a decent little profit. I was a little burned out on the car anyways at that point, so I put her back in the corner all stripped down and didnt touch it for about 2 years.

Fast forward to 2012...

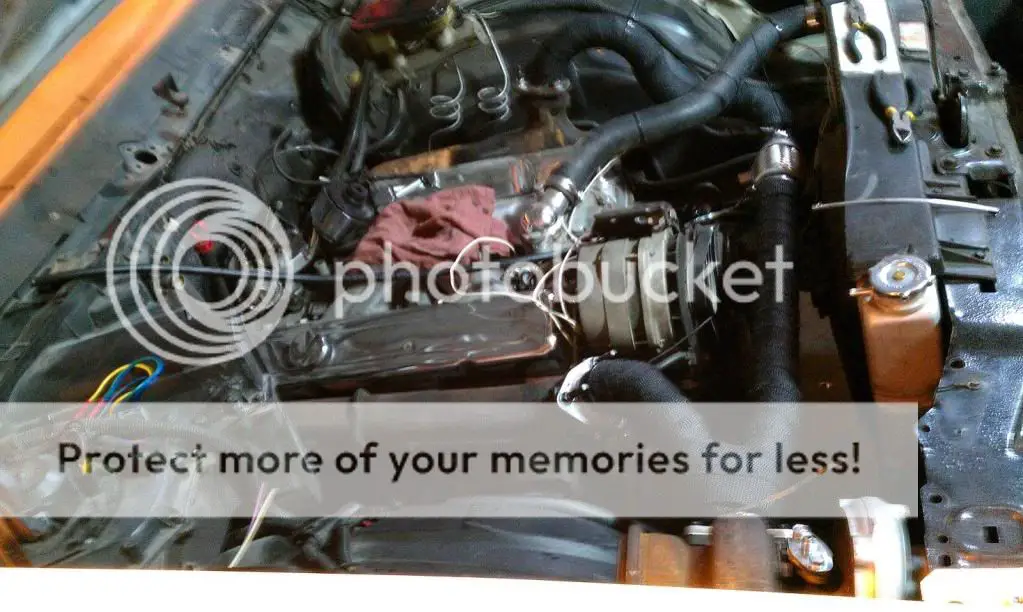

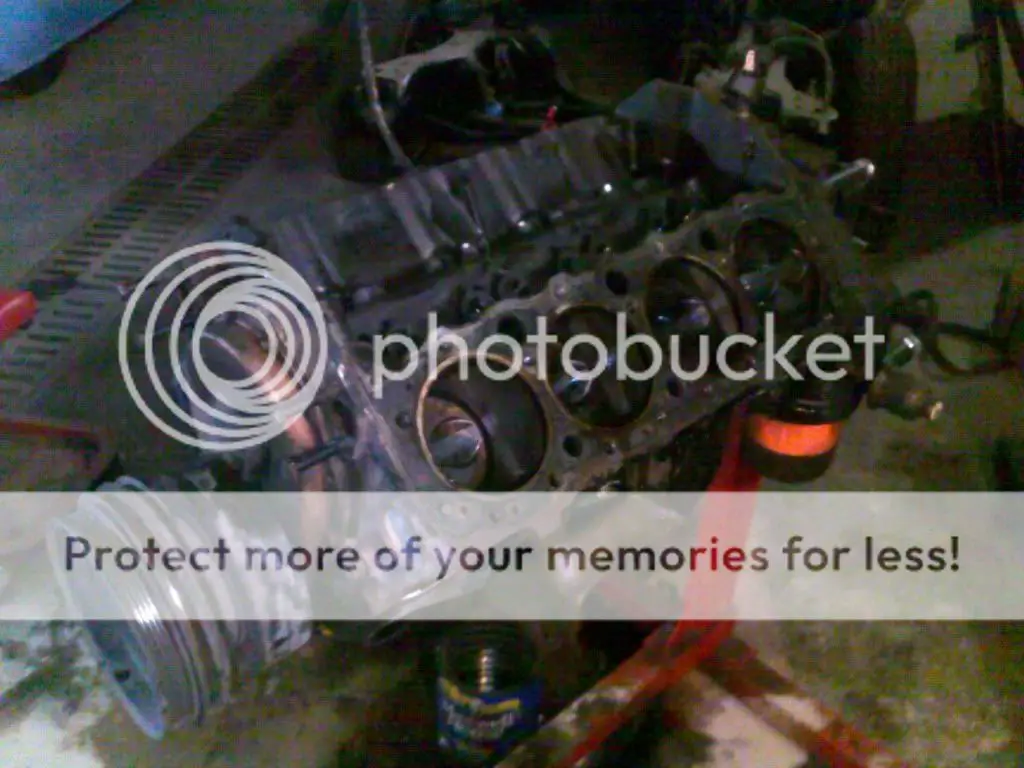

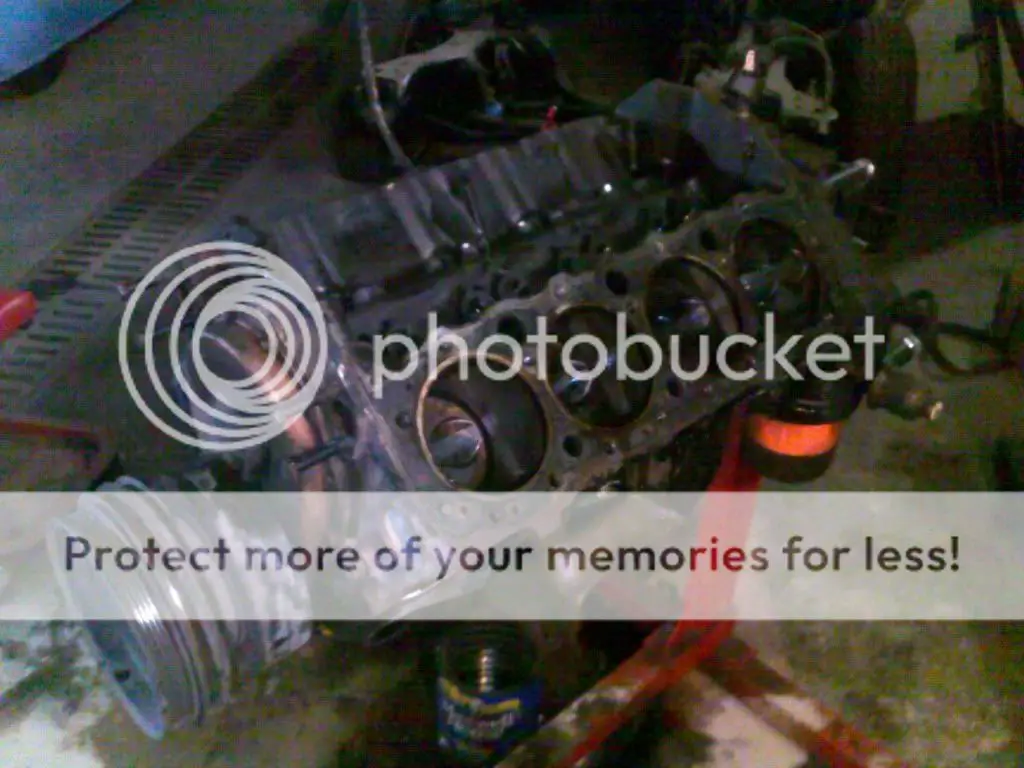

I decided that instead of sinking a bunch of money into the Monte, I'd do something different. Something that people would point and make fun of until they heard and saw it run. I decided to turbo the factory 305. I pulled it all apart, and the rings and bearings looked alright. So I cleaned it up, took all the BS smog sh*t off it. threw new MLS gaskets on it, threw a Summit 1103 cam in it, and put her pack together. Thats all thats done to the Motor.

Summit 1103 Cam and lifter kit

Edelbrock Torker Intake Manifold (not pictured yet)

Factory 305 H.O. heads and rockers

Factory HEI ignition

Now, I knew going to a TPI setup would be a lot easier and make more sense, but I had just picked up an Edelbrock 1405 600cfm carb with manual choke for the free. I've always hated Edelbrock. Have bought several new and tried to give them a chance. But they all sucked. Turned out i just didnt know what I was doing with them. The best advice I can give on this subject is: They arent a Holley, so dont tune them like a Holley

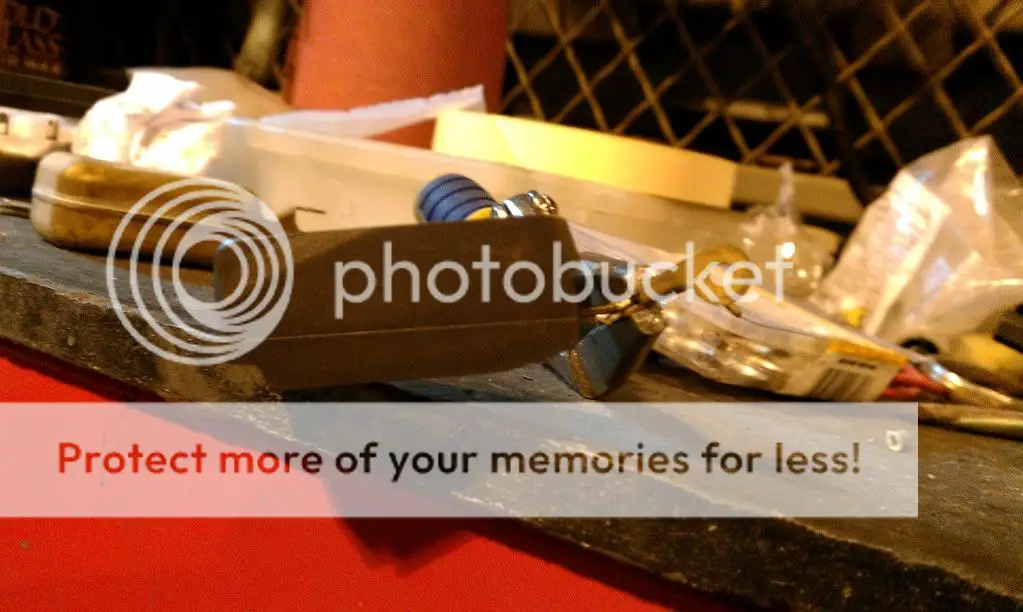

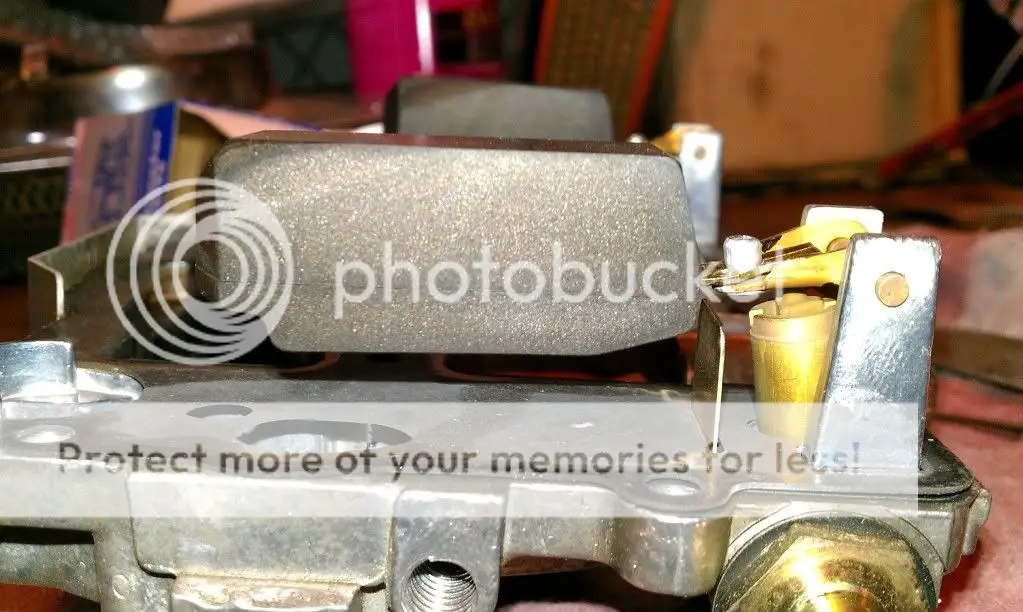

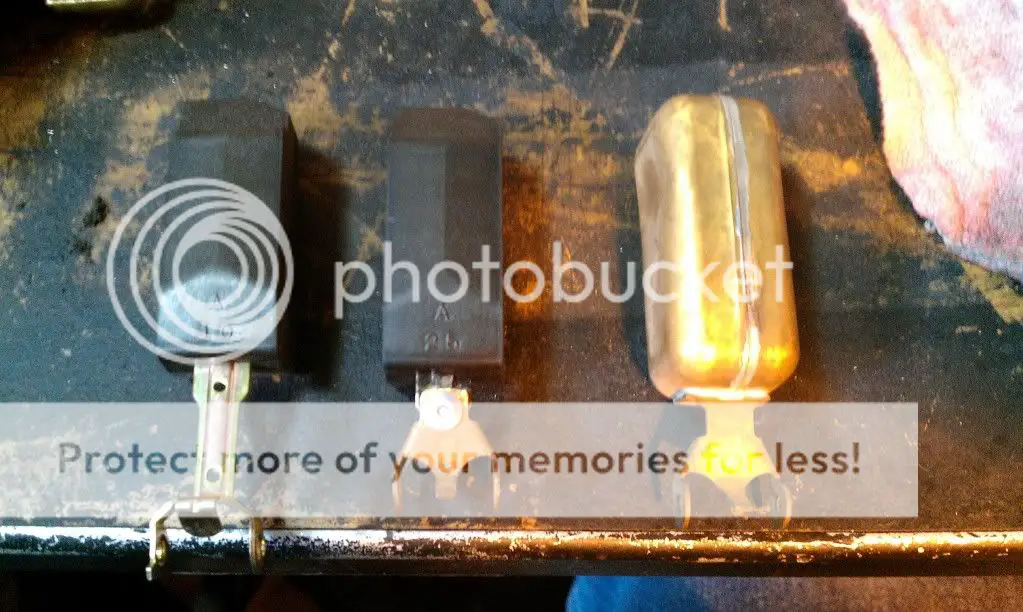

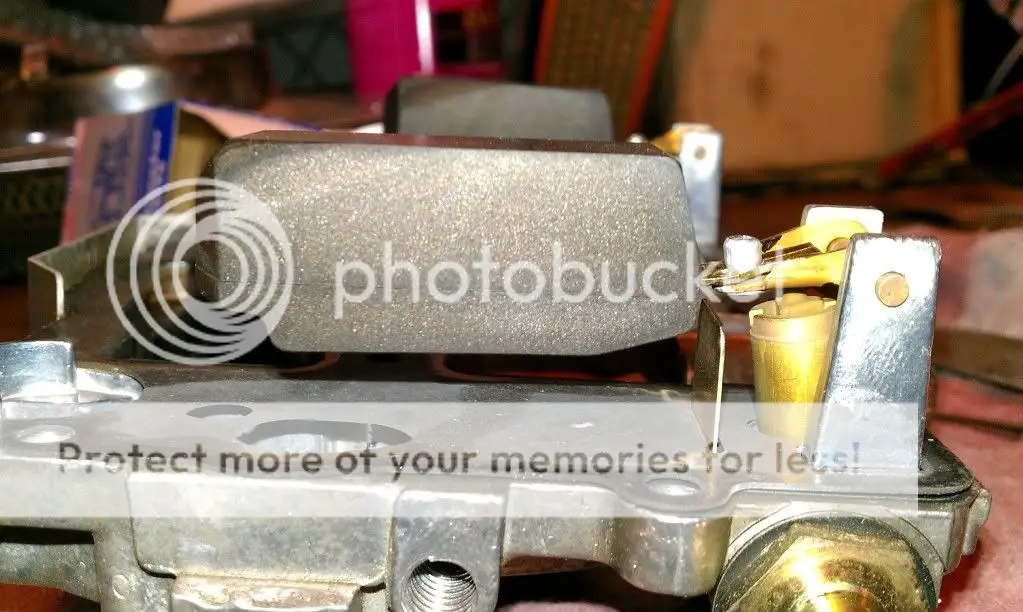

Nobody ever does Edelbrock carbs for Blow-thru, but i figured it couldnt be that difficult. Turns out the worst part is that nobody makes nitrophyl floats for them, and the brass floats crush under boost. Did a little (a lot) of internet research, and no biggy, I just modified a set of Chrysler Thermoquad Nitrofyl floats for it. Got them from my Carquest dealer. Part number is FL4. Desolder the float arms off your old floats, cut and trim up the FL4 arms so you can graft on the old arms, drill and rivet, then a dab of solder to keep it from moving. Only do 1 at a time so you can have a factory brass one to go off of. The angles of the arms to the floats HAVE to be the same.

After the floats, its all easy going from there. Drill/tap some brass vacuum barbs into the top of the carb plate above the fuel bowls for bowl vent extensions. Run a line from there into your intake charge pipe. I bent some brake line around and epoxied it into the charge pipe. This pressurizes the fuel bowls with a much better source than the factory bowl vents can. (If you'd like to know more details about this, message me about it or search for "bowl vent extensions" on theturboforums.com)

Install the big needle and seats from Edelbrock, and buy a bunch of Jets and metering rods for the massive amount of tuning you will soon be doing.

To be continued...

Fast forward to 2012...

I decided that instead of sinking a bunch of money into the Monte, I'd do something different. Something that people would point and make fun of until they heard and saw it run. I decided to turbo the factory 305. I pulled it all apart, and the rings and bearings looked alright. So I cleaned it up, took all the BS smog sh*t off it. threw new MLS gaskets on it, threw a Summit 1103 cam in it, and put her pack together. Thats all thats done to the Motor.

Summit 1103 Cam and lifter kit

Edelbrock Torker Intake Manifold (not pictured yet)

Factory 305 H.O. heads and rockers

Factory HEI ignition

Now, I knew going to a TPI setup would be a lot easier and make more sense, but I had just picked up an Edelbrock 1405 600cfm carb with manual choke for the free. I've always hated Edelbrock. Have bought several new and tried to give them a chance. But they all sucked. Turned out i just didnt know what I was doing with them. The best advice I can give on this subject is: They arent a Holley, so dont tune them like a Holley

Nobody ever does Edelbrock carbs for Blow-thru, but i figured it couldnt be that difficult. Turns out the worst part is that nobody makes nitrophyl floats for them, and the brass floats crush under boost. Did a little (a lot) of internet research, and no biggy, I just modified a set of Chrysler Thermoquad Nitrofyl floats for it. Got them from my Carquest dealer. Part number is FL4. Desolder the float arms off your old floats, cut and trim up the FL4 arms so you can graft on the old arms, drill and rivet, then a dab of solder to keep it from moving. Only do 1 at a time so you can have a factory brass one to go off of. The angles of the arms to the floats HAVE to be the same.

After the floats, its all easy going from there. Drill/tap some brass vacuum barbs into the top of the carb plate above the fuel bowls for bowl vent extensions. Run a line from there into your intake charge pipe. I bent some brake line around and epoxied it into the charge pipe. This pressurizes the fuel bowls with a much better source than the factory bowl vents can. (If you'd like to know more details about this, message me about it or search for "bowl vent extensions" on theturboforums.com)

Install the big needle and seats from Edelbrock, and buy a bunch of Jets and metering rods for the massive amount of tuning you will soon be doing.

To be continued...