What I did was look at the old data. The 454 In the 70 Corvette was 9 psi and between 28 to 32 GPH (Gallons Per Hour) so the TPI or TBI electric FP (Fuel Pump) would suffice. I would be more inclined with the TPI Pump. Has a little more Capacity.

The regulator needed is Holley 12-803BP. I attached info from Jegs. You can get it for less if you look around. Don't get the cheaper ones available eBay and Amazon. Quality is not there. They work ok, but I've had good and bad experience with these.

There's a kit on Amazon about $44, has line and fittings and regulator. The Kit is ok for the fittings saves you some money there, but go with high quality line and use the Holley Regulator. You will be happier in the long run.

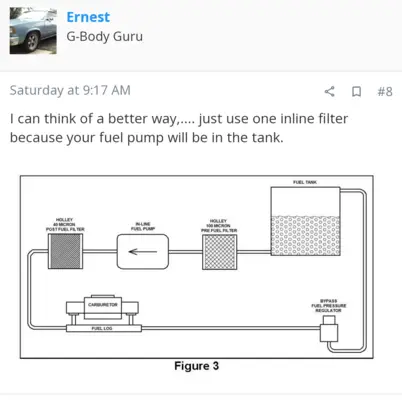

Someone else posted the diagram using the fuel log... Yes use that. That is the way to go.

From there you just need to work out pressure you need. Will be trial/error. Stopwatch runs or chassis dyno.

The regulator needed is Holley 12-803BP. I attached info from Jegs. You can get it for less if you look around. Don't get the cheaper ones available eBay and Amazon. Quality is not there. They work ok, but I've had good and bad experience with these.

There's a kit on Amazon about $44, has line and fittings and regulator. The Kit is ok for the fittings saves you some money there, but go with high quality line and use the Holley Regulator. You will be happier in the long run.

Someone else posted the diagram using the fuel log... Yes use that. That is the way to go.

From there you just need to work out pressure you need. Will be trial/error. Stopwatch runs or chassis dyno.