Hey, life happens. I started my build thread on my Malibu back in 2018 or 19. I thought it would be long done by now, meanwhile I’m knee deep in doing a car I bought 2 years ago. This is real life, not tv. Keep doing what you’re doing, we’re not going anywhere.I've been putting off this update because I was unsure how to word it without "Facebookin' up the place", which I despise. Though I'm guilty of it already, my personal drama is not to be aired on a car forum so I'll just give ya the bullet: the most important relationship in my life imploded and that devastated me. Combined with the weather it meant I had no interest in improving my car or even my situation, but after longer than promised I received a small lump sum of $$ so I got a dog and a bunch of tools. I've now moved out of the basement and have purchased enough furniture for an entire home so I can dump all of this broken trash. This house has been been turned upside down like it should have been years ago and we're about to shake out and clear up room in the garage so I can be productive and utilize the skills I claim to possess but haven't shown. Anyone else have 6 "damaged but salvageable" dining room tables and complete tax records for the last 25 years occupying valuable storage space? Yeah, we're probably alone on that one. If ya need mismatched chair sets we've got those too.

I feel as though I've broken promises to the forum and failed to deliver on more than one occasion, hurting my credibility when I had very little to begin with. I'll now refrain from putting a time schedule on planned modifications since I never seem to fulfill that goal, and I'll also work on completing a task before starting another. Sometimes I just can't help myself though.

The radiator situation has been figured and seam sealer was applied to the rear window/ trunk channels but that's it until I organize the garage. That's an area that I've made worse by accumulating more stuff but not being set up to use it. I actively made the problem worse and now I get to fix it, which really should entail gutting the garage but will at least include hanging the shelving I've owned for years and tossing some stuff into the neighbor's yard.

On a related note, if you're working on a project G Body with your offspring shoot me a DM, I might have something for you. I need to clear more space and I'll donate certain parts I have if they'll get you talking to your kids. Being present doesn't mean you're actually there, and working on cars can include life lessons on how to be a true, honest man who understands why things are done.

BUILD THREAD Sweet Johnny & Gina: A Love "Two Large" To Fail

- Thread starter Sweet_Johnny

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

don't beat yourself up too much Jon,onward and upward to a new beginning with a new pup!I've been putting off this update because I was unsure how to word it without "Facebookin' up the place", which I despise. Though I'm guilty of it already, my personal drama is not to be aired on a car forum so I'll just give ya the bullet: the most important relationship in my life imploded and that devastated me. Combined with the weather it meant I had no interest in improving my car or even my situation, but after longer than promised I received a small lump sum of $$ so I got a dog and a bunch of tools. I've now moved out of the basement and have purchased enough furniture for an entire home so I can dump all of this broken trash. This house has been been turned upside down like it should have been years ago and we're about to shake out and clear up room in the garage so I can be productive and utilize the skills I claim to possess but haven't shown. Anyone else have 6 "damaged but salvageable" dining room tables and complete tax records for the last 25 years occupying valuable storage space? Yeah, we're probably alone on that one. If ya need mismatched chair sets we've got those too.

I feel as though I've broken promises to the forum and failed to deliver on more than one occasion, hurting my credibility when I had very little to begin with. I'll now refrain from putting a time schedule on planned modifications since I never seem to fulfill that goal, and I'll also work on completing a task before starting another. Sometimes I just can't help myself though.

The radiator situation has been figured and seam sealer was applied to the rear window/ trunk channels but that's it until I organize the garage. That's an area that I've made worse by accumulating more stuff but not being set up to use it. I actively made the problem worse and now I get to fix it, which really should entail gutting the garage but will at least include hanging the shelving I've owned for years and tossing some stuff into the neighbor's yard.

On a related note, if you're working on a project G Body with your offspring shoot me a DM, I might have something for you. I need to clear more space and I'll donate certain parts I have if they'll get you talking to your kids. Being present doesn't mean you're actually there, and working on cars can include life lessons on how to be a true, honest man who understands why things are done.

delays are part of life and tend to disrupt the flow whenever and wherever possible, and promises don't necessarily come with a clock or deadline attached to them a lot of the time either.

Nick

Hey, life happens. This is real life, not tv. Keep doing what you’re doing, we’re not going anywhere.

Thanks for understanding guys, but there's just no hiding the fact that I've had a few quite public failures and struggled with things that should've been easy. I just may be at the edge of getting something real going here and to be quite honest I have a habit of self sabotage so you may be in for a dumpster fire, haha. I will say that many hours have been spent investigating LLC vs S Corp among other things, but no promises of "Sweet Johnny's Twisted Customs Garage" yet. For tax purposes it would not be the only company under the umbrella of "Justus Industries".don't beat yourself up too much Jon, onward and upward to a new beginning with a new pup!

I do still have high hopes and believe this year will be a great one unless I get in my own way. I now have a laser guided big boy drill press, a compound slide milling table, 8" bench grinder, anvil, 5" forged steel vice, and portable blaster. I got another air compressor, though it's not big enough to run much, and its intended job is to supply fresh breathing air for my space suit. I'm liking Puma for the real thing but it'll be a while before that gets added and it can power my solvent tank. I purchased every size of Bauer battery including the 12, and now have carts/boxes full of their tools. I'm in possession of nearly all the necessary goodies to finish reinstalling the interior. My entire sound system is here. I'm putting my battery in the trunk and adding a Delco remote solenoid- got everything just gotta do it. Double adjustable lower C/As need installed. I've got a new gear reduction starter and high output alternator. Lyle's in Ontario supplied me with 409 stainless tailpipes on the cheap. https://www.mandrelbending.ca/

There's a H.F. 10x17 "shed" that needs erected around my old '86 truck frame, and it'll house other assorted parts as well to free up shop space. The cab/doors will also be leaving the garage and joining the frame/bed. I'm considering adding a dog pen around all of that so my buddy can run around unsupervised. I've spoken with salvage about the nearly 2 dozen wheels/tires I need to dispose of, and they'll take 'em all at a flat rate of $5 each. The new dishwasher gets installed tomorrow, and the pup starts obedience training on Thursday.

Last edited:

Yeah as everyone has said we are always our biggest critic, things happen and we get side tracked. Also we all self sabotage to an extent, just most people don't accept it and try to put the blame on someone else. I can never caste any stones cause I am 4 years or more into the quick running of the Blazer before decide to go full tilt rather than test it first, we will see how that works out for me.Thanks for understanding guys, but there's just no hiding the fact that I've had a few quite public failures and struggled with things that should've been easy. I just may be at the edge of getting something real going here and to be quite honest I have a habit of self sabotage so you may be in for a dumpster fire, haha. I will say that many hours have been spent investigating LLC vs S Corp among other things, but no promises of "Sweet Johnny's Twisted Customs Garage" yet. For tax purposes it would not be the only company under the umbrella of "Justus Industries".

I do still have high hopes and believe this year will be a great one unless I get in my own way. I now have a laser guided big boy drill press, a compound slide milling table, 8" bench grinder, anvil, 5" forged steel vice, and portable blaster. I got another air compressor, though it's not big enough to run much, and its intended job is to supply fresh breathing air for my space suit. I'm liking Puma for the real thing but it'll be a while before that gets added and it can power my solvent tank. I purchased every size of Bauer battery including the 12, and now have carts/boxes full of their tools. I'm in possession of nearly all the necessary goodies to finish reinstalling the interior. My entire sound system is here. I'm putting my battery in the trunk and adding a Delco remote solenoid- got everything just gotta do it. Double adjustable lower C/As need installed. I've got a new gear reduction starter and high output alternator. Lyle's in Ontario supplied me with 409 stainless tailpipes on the cheap. https://www.mandrelbending.ca/

There's a H.F. 10x17 "shed" that needs erected around my old '86 truck frame, and it'll house other assorted parts as well to free up shop space. The cab/doors will also be leaving the garage and joining the frame/bed. I'm considering adding a dog pen around all of that so my buddy can run around unsupervised. I've spoken with salvage about the nearly 2 dozen wheels/tires I need to dispose of, and they'll take 'em all at a flat rate of $5 each. The new dishwasher gets installed tomorrow, and the pup starts obedience training on Thursday.

Thanks man, I appreciate it more than you guys know. I feel like I'm swingin' in the dark & occasionally punching myself here. With the settlement/ new furniture I actually feel like a real human being with a real home for the first time. Ever. I also feel better knowing so many people's projects have taken longer than expected.Yeah as everyone has said we are always our biggest critic, things happen and we get side tracked. Also we all self sabotage to an extent, just most people don't accept it and try to put the blame on someone else. I can never caste any stones cause I am 4 years or more into the quick running of the Blazer before decide to go full tilt rather than test it first, we will see how that works out for me.

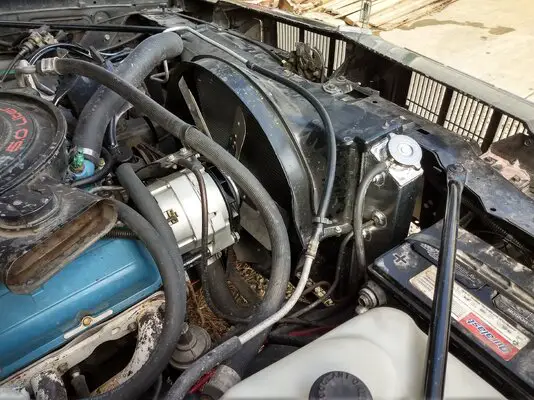

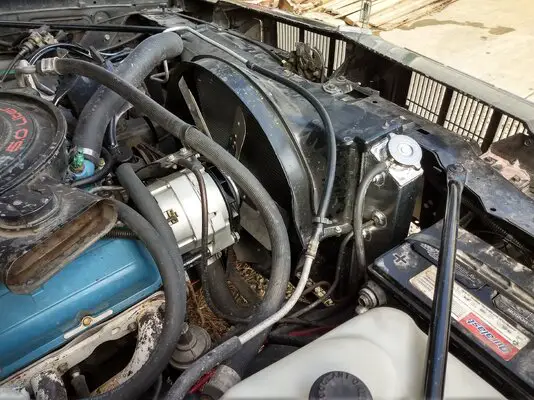

With that out of the way, let's talk radiator, shall we? The weather and my mind are both in better condition so I finally got to swap out my leaky Spectra unit for the Black Horse Racing all aluminum one. You may recall from the Radiator thread that my A Body hoses should fit perfectly, and they almost do- the upper is loose by a 1/16" and the lower seems to fit just slightly tighter. The transmission lines threaded in and seal just fine, and the whole thing sits perfectly in the factory rubber isolators, which I didn't even touch. I did use compressed air to blow out every orifice before setting it in place, and nothing came out: no shavings, no junk, nothing.

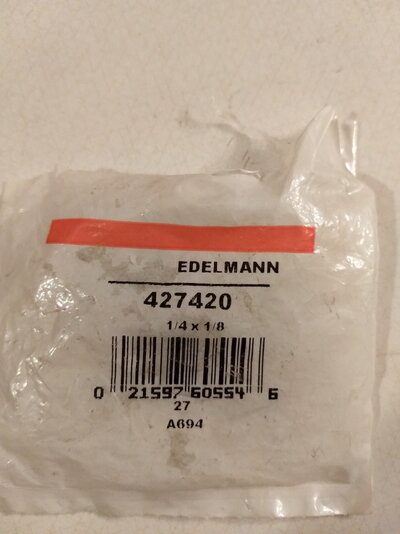

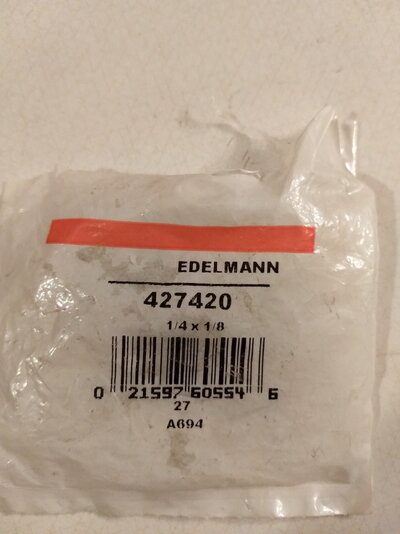

Now for the overflow nipple mod. The nipple has tapered threads that begin at 0.290", getting larger of course (5/16 - 18). You're not going to find another nipple that matches that and accepts 3/8" hose. I mean, YOU might, but I couldn't.

I'd considered just using a 5/16" hose or drilling the threaded hole and retapping for a larger fitting, but neither of those made me happy. I would have loved to drill it out but the kid that originally did it got it off center and closer to the cap so the fitting would hit if I did. I also considered pressing a larger nipple onto this one but don't have the proper tooling for a good fit: I'd crush them trying as I couldn't achieve tolerance. I Could drill the brass fitting to an I.D. of 0.3125 and press fit the aluminum one inside, but my closest bit is "N" (0.301"), making the press fit a difference of 0.0124, or 12 thousandths. Normally 1 or 2 is enough...

After careful measurements and a bit of math I discovered that I could simply cut two fittings and thread them together, and I chose the Dorman above since it's compact and takes a smaller wrench than others. The 5/16" aluminum barb has 5/16 - 18 threads into the radiator, and I chose to go with -24 for this side of it. A vice and H.F. tap/ die set got us in business. The O.D. actually measured at 0.3125, which is necessary if you want 5/16 - 24 threads to catch on anything, but the flared end was removed with a band saw.

This left me with a brass 3/8 fitting that needed an ID of 0.272 to be threaded for 5/16- 24, and it measures 0.273. Perfect! I held it in a vice by the flats and tapped it after cutting the threaded end off. Once the 3/8 brass fitting is tapped then the walls outside the threads will be 1/32" thick, the same as brake line. If you do this be careful and get that tap straight! Also, there's no sense in creating more threads than necessary.

Now I could thread them together using Dap Tank Bond as sealant because it was $1.25, and I added an o-ring just to make it pretty. (The die can't get threads all the way to the base so the two had a slight gap.) I also removed the brass flats by sanding it round so I won't be tempted to accidentally unscrew these two.

The drain petcock is a plug type so I wanted the usual kind but for nearly $20 ended up with this instead:

Remove the plug from the adapter in the rad and it fits in its place.

A bit of 1/4" NiCopp gets you this, and it just clears the sway bar:

But I made it stick out too far and it hits the frame. I'll need to shorten it if I want a downspout so it's currently naked, and the valve sits flat up against the core support if turned that direction, but goes either way:

And a final view:

Upcoming mods include custom preformed heater hoses that are nearly finished.

Now for the overflow nipple mod. The nipple has tapered threads that begin at 0.290", getting larger of course (5/16 - 18). You're not going to find another nipple that matches that and accepts 3/8" hose. I mean, YOU might, but I couldn't.

I'd considered just using a 5/16" hose or drilling the threaded hole and retapping for a larger fitting, but neither of those made me happy. I would have loved to drill it out but the kid that originally did it got it off center and closer to the cap so the fitting would hit if I did. I also considered pressing a larger nipple onto this one but don't have the proper tooling for a good fit: I'd crush them trying as I couldn't achieve tolerance. I Could drill the brass fitting to an I.D. of 0.3125 and press fit the aluminum one inside, but my closest bit is "N" (0.301"), making the press fit a difference of 0.0124, or 12 thousandths. Normally 1 or 2 is enough...

After careful measurements and a bit of math I discovered that I could simply cut two fittings and thread them together, and I chose the Dorman above since it's compact and takes a smaller wrench than others. The 5/16" aluminum barb has 5/16 - 18 threads into the radiator, and I chose to go with -24 for this side of it. A vice and H.F. tap/ die set got us in business. The O.D. actually measured at 0.3125, which is necessary if you want 5/16 - 24 threads to catch on anything, but the flared end was removed with a band saw.

This left me with a brass 3/8 fitting that needed an ID of 0.272 to be threaded for 5/16- 24, and it measures 0.273. Perfect! I held it in a vice by the flats and tapped it after cutting the threaded end off. Once the 3/8 brass fitting is tapped then the walls outside the threads will be 1/32" thick, the same as brake line. If you do this be careful and get that tap straight! Also, there's no sense in creating more threads than necessary.

Now I could thread them together using Dap Tank Bond as sealant because it was $1.25, and I added an o-ring just to make it pretty. (The die can't get threads all the way to the base so the two had a slight gap.) I also removed the brass flats by sanding it round so I won't be tempted to accidentally unscrew these two.

The drain petcock is a plug type so I wanted the usual kind but for nearly $20 ended up with this instead:

Remove the plug from the adapter in the rad and it fits in its place.

A bit of 1/4" NiCopp gets you this, and it just clears the sway bar:

But I made it stick out too far and it hits the frame. I'll need to shorten it if I want a downspout so it's currently naked, and the valve sits flat up against the core support if turned that direction, but goes either way:

And a final view:

Upcoming mods include custom preformed heater hoses that are nearly finished.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.