Keep reading, that's not the only stuff I got done.

Tired of freezing my chestnuts off I decided it was time to tackle the heater core replacement. I knew this would suck because I could see numerous cracks on the heater box top, and some no doubt came me leaning on it in the last year. However, it's painfully clear that the last "mechanic" absolutely butchered this thing- it was cracked everywhere and missing pieces when it was reinstalled. These two things combined for a tricky removal that actually resulted in moderate success: I added one small crack, broke off a 1" X 1" piece that nobody will miss, and got it into the house for cleaning after about an hour. I didn't miss any screws but prying this away from the firewall without making things worse was difficult thanks to the old butyl rubber rope caulk and some kind of sealer that has dried to be rock hard. I used Murphy's wood soap and Dawn dish soap to get things sparkling clean, and when the time came to hang it up to dry Mr. Butterfingers here dropped it. With catlike reflexes I lowered my shoulders and clamped my hands together, saving the box top from hitting the floor. And succeeded in smashing it into the freakin tub... I broke off a substantial portion of the top right corner, including a mounting bolt hole. Ugh. Super Glue!!!

Many of the screw holes were also stripped out, and those as well as all

visible cracks were repaired with Super Glue 5 minute epoxy until I ran out. It dries nice and hard and is exceptionally clear considering what it is. To knock the shine off I sprinkled a bit of baking soda on top before it fully cured, and this avoids having eye catching glossy spots that would need sanded or painted to match. It ain't gonna match. Adding the soda too soon results in an ugly, goopy mess that takes forever to dry and is weaker. It only takes a little, and I added it after the glue was half set up with darn good results. On the inside I added a layer of Super Glue Fix All for reinforcement, and this was also used for some cracks although they didn't turn out as good. The case below was completely split open from the blower motor hole to the outside perimeter, can you find the seam? That was epoxy and soda. The ones that get covered by the the cowl screen are the cracks with only Fix All.

The lower half needed a bit of glue too so I returned to the store for more 5 min epoxy. I then strung duct tape around my air cleaner to hold things in place.

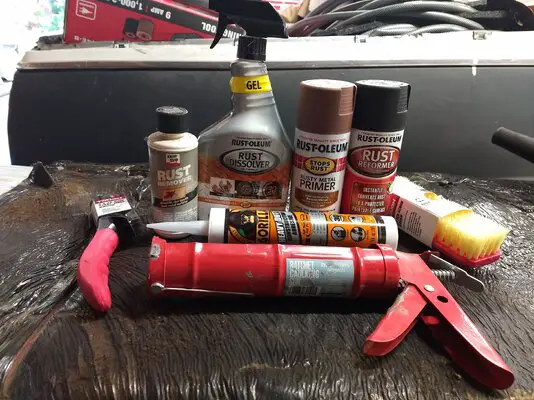

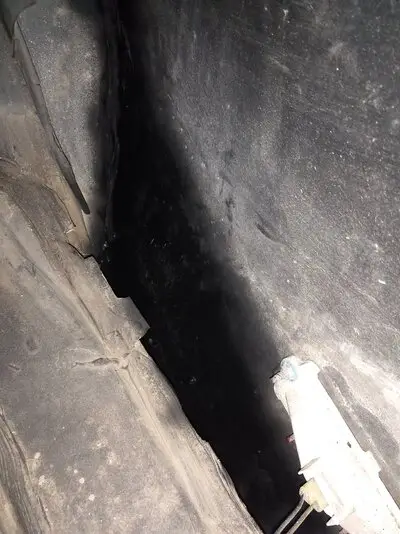

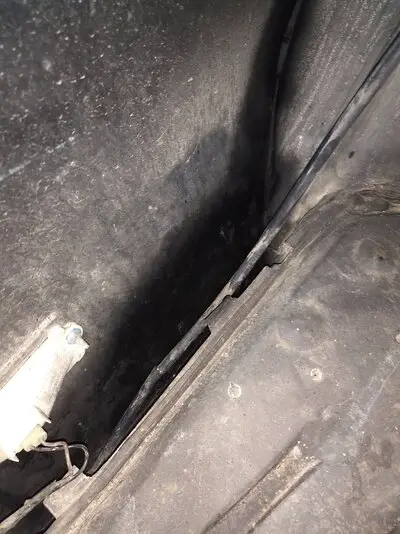

Behind the rubber firewall gasket was a ton of loose rust and debris.

So it was dealt with and covered with Rust-Oleum Rusty Metal Primer and Flat Black Primer just so everything was black. I was out of black rust converter as well as sealer primer so I used what I had. The car was on stands now and I couldn't leave.

While that dried I took to removing and replacing some seam sealer near the radio antenna and both ends of the windshield channel. The windshield will be replaced at some point and the sealer directly below the antenna was solid so it stayed in place. No masking was performed but an old t-shirt was slung onto and inched along the windshield for protection.

The same sealer was squeezed into the depths of the heater box to form a dam that prevents future toe-wetting.

After a short time the grey sealer formed a skin and started to dry, at which point it was covered with black primer.

The Spectra heater core arrived with bits of foam on the sides, but it was far from enough to seal things properly. I procured some single sided foam insulation tape and added a couple strips that covered the sides and bottom, with the 2nd piece being longer to trap the first. It required 2 layers to achieve a very solid fit that wouldn't leak all the airflow.

You may notice what appears to be JB Weld where the inlet/outlet attach to the tank, and that's exactly what it is. I saw no visible damage or pinholes but figured a little schmear couldn't hurt but could potentially help. It's a bit messy due to the Kwik Weld setting up as I used a toothpick to spread things around. You don't see it when things are put together.

I had a helluva time tracking down rope caulk locally. Living outside of town is cool but local to me is often still within 30 minutes of nowhere. Wal Mart doesn't carry it and whoever runs the Lowe's near me needs fired, but I found it at Ace Hardware: 90 feet of 1/8" cords for under $10. The box said "Grey" but I'm seeing "White"... You? I also added more foam tape to the top of the heater core and installed a new, larger ground strap. I still need to replace the other ground strap on the AC lines.

I said that JB Weld wouldn't show and I meant it. I snagged some foam from the trash can, glued it together, and drove a piece of 3/4" pipe through it after tracing the square shape I needed.

Fits good and tight. Snug as a rug full of smuggled drugs.

But this shot shows that the 3/4" heater line goes through that area at an angle. Thankfully the interior piece seems to be blocking what the outer would release. Go ahead, zoom in and check out my hole.

Not wanting to plug up a new heater core, I drained the coolant and cleaned my overflow tank. I didn't do a flush although it's recommended. I can never drain a radiator or engine without spilling at least some of it, and a big cup of fresh water poured all over helped to clean up.

I normally reach for Prestone or Peak coolant but couldn't find the green concentrate ANYWHERE for over a month. A month. I'm not buying 50/50, that's for suckers, and that other coolant has no place in my old engines regardless of how compatible it claims to be. I don't care. I eventually located the pure, unadulterated juice I craved at Atwoods (farm/ implement store). I've never used this coolant before but their condoms are top notch.

All systems are fully functional with no new leaks that I can find, but I do have an issue that I could use some help with. I've got the default setting of air only coming from the defrost and floor vents, surely caused by a vacuum leak at the selector behind the climate controls- it gets worse if I pinch or move the main piece. I seem to recall there being a disc or something in there that can dry out and leak- am I imagining things?

Edit: It's going to be this lil guy, isn't it?