Alright so I went out last night and measured my piston dome CC. The reason I had done this was because it was an unknown factor (unlike normal flat tops are usually -4 to -6cc due to valve relieves) as to how big the dome was in CC's which you need to know for figuring compression. As you can tell it's an important value.

Now there is a couple ways you could go about figuring the CC but this way is the best to do with the short block still assembled. You will need a few things. Something to measure distance. Preferably a dial indicator or caliper, vasoline, a burrette or something to measure liquid in CC (syringe works good.) a flat object with a hole in it to seal the top of the bore.

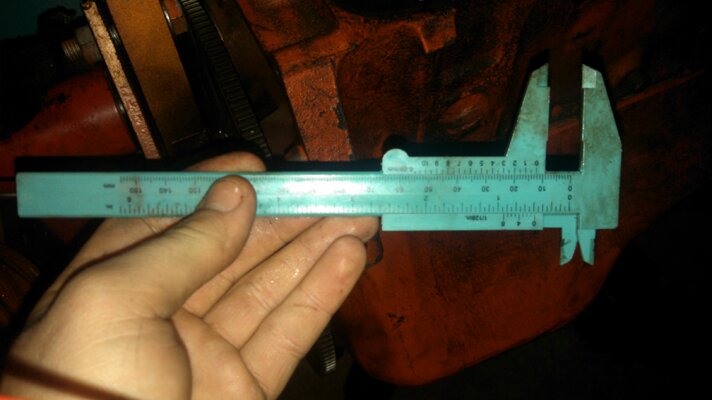

Your biggest factor here is going to be your know distance. You need rotate the engine to a predetiermand distance. I.E. .250, 1 inch, BDC, or like I did in my case for the sake of making my math easier I went to .500 or 1/2 inch which I measured with the dial caliper. You will now need to do a math formula to calculate the open area of the bore without the piston. You will need to know your bore diameter. This is where the caliper comes in handy again.

My engine is a 283 so the stock bore is 3.875 but, my block had been bored .030 taking it to 3.905. I still confirmed this with the caliper and it is indeed 3.905. So here is the formula that will give you the volume of the open area in CC's

Bore x bore x distance in the hole x .7854 x 16.39

So this is how my calculated.

3.905 x 3.905 x .500 x .7854 x 16.39

Which came out to 98.1481078.

Now you have the caluclated volume of the open area we will continue. Since your piston is at your predetermined distance you can now proceed to apply vasoline around the end of the piston to seal your bore to keep your liquid from leaking. After that is complete wipe the access off enough to where it still doesn't leak.

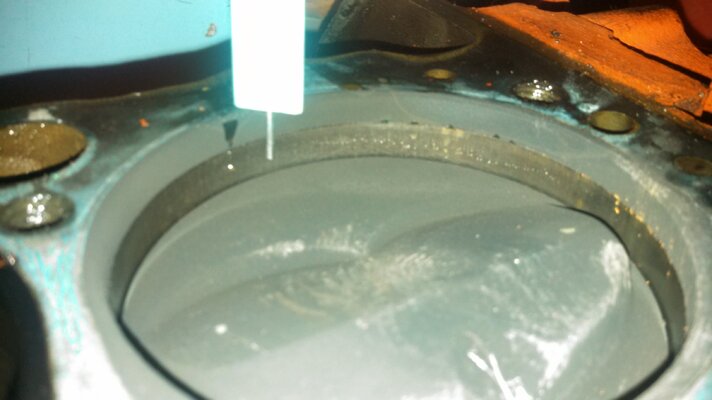

Now vasoline the outside of the top of the bore for your flat piece of material you will be using. I used an old cd. Once you vasolined it lighty touch your finger on the vasoline to make it look kinda of puffy is the best word I can think of you can see what I'm talking about in the picture. This will ensure that the material seals to the bore and doesn't leak.

Now have your liquid ready. I used a 60 mL syringe. 1 mL = 1CC the value is the same. So I filled up the bore with 60 mL of water and still had room. I then put 15 more in, then let it sit for about 30 seconds to see if would bubble any air out then I proceeded to add 3 more cc's of liquid. I got a total of 78 mL in.

Now that open area value comes in to effect now. You need to subtract your CC's from the liquid from the open area CC.

98.1481078 - 78 = 20.1481078

So now I know my dome volume. It is 20.1481078. I simply rounded it down to 20.1. Which is a really big dome! The whole CC process took about 5 minutes to do. It's pretty need to do all the little calaculations to make the best running engine possible!

Now while you have the dial caliper out might as well check your deck clearance! I checked my to see if the block had ever been decked or not and found out that I have 1 millimeter of clearance between the top of the piston and the deck. Which comes out to .03937. I rounded down to .039. Which means the deck is untouched. All small block chevy blocks come .025 to .040 from the factory and the reason for the vary is because of machineing tolerances and such.

Now that I know my deck height, bore size, stroke, dome volume, I can begin to start deciding on what thickiness of gasket I need. You need to know your deck clearance to help with figuring the quench or "squesh" of the combustion chamber. It comes down to how effiencant it makes the combustion and power making process go. The tighter the quench the more power you will make.

A little better explaining of the quench area to people who are familiar with it is when the piston comes to top dead center all the air and fuel is being compressed. Well anybody that had ever had a head off an engine will have noticed you have a flat area and the combustion chamber inside the bore. Well the flat area is your Quench. When TDC is reached it squeezes all the air and fuel in that area and forces it in to the combustion chamber in a hurricane effect.

You can see now why you want a tighter quench. The tighter the better. Now there is a limit to how tight you can go. You don't want your piston to come flying up and nailing your head ruining it. I've seen people run crazy tight quenchs and very loose. If you really feel brave you could run smaller then .040 quench. But I wouldn't.

Most high performance engine builders whether they are Pro or just a really good bracket racer run .050 quench as the smallest. .040 can be done but you really need to know what your doing.

Now I'm not going to get this engine deck since it doesn't need it and I don't want to put much money into this engine since it will be getting me through till my 355 is finshed. So I've got .039 deck clearance, now I want that .050 quench but unless I deck the block it's not gonna happen. So I'm going to go with a .018 steel shim gasket. Which will put me at .057. Pretty close!

Now with that tight of a quench and the fact I'm running domes Piston to Valve clearance is going to be really important as well as cam selection. I may have to fly cut my pistons or go with a lower lift cam. So to get 10.5 to 1 compression with all these paremeters I will need to go with a 70cc chamber.

I'm ready to see if we can get this 283 to fly! 8)

Now there is a couple ways you could go about figuring the CC but this way is the best to do with the short block still assembled. You will need a few things. Something to measure distance. Preferably a dial indicator or caliper, vasoline, a burrette or something to measure liquid in CC (syringe works good.) a flat object with a hole in it to seal the top of the bore.

Your biggest factor here is going to be your know distance. You need rotate the engine to a predetiermand distance. I.E. .250, 1 inch, BDC, or like I did in my case for the sake of making my math easier I went to .500 or 1/2 inch which I measured with the dial caliper. You will now need to do a math formula to calculate the open area of the bore without the piston. You will need to know your bore diameter. This is where the caliper comes in handy again.

My engine is a 283 so the stock bore is 3.875 but, my block had been bored .030 taking it to 3.905. I still confirmed this with the caliper and it is indeed 3.905. So here is the formula that will give you the volume of the open area in CC's

Bore x bore x distance in the hole x .7854 x 16.39

So this is how my calculated.

3.905 x 3.905 x .500 x .7854 x 16.39

Which came out to 98.1481078.

Now you have the caluclated volume of the open area we will continue. Since your piston is at your predetermined distance you can now proceed to apply vasoline around the end of the piston to seal your bore to keep your liquid from leaking. After that is complete wipe the access off enough to where it still doesn't leak.

Now vasoline the outside of the top of the bore for your flat piece of material you will be using. I used an old cd. Once you vasolined it lighty touch your finger on the vasoline to make it look kinda of puffy is the best word I can think of you can see what I'm talking about in the picture. This will ensure that the material seals to the bore and doesn't leak.

Now have your liquid ready. I used a 60 mL syringe. 1 mL = 1CC the value is the same. So I filled up the bore with 60 mL of water and still had room. I then put 15 more in, then let it sit for about 30 seconds to see if would bubble any air out then I proceeded to add 3 more cc's of liquid. I got a total of 78 mL in.

Now that open area value comes in to effect now. You need to subtract your CC's from the liquid from the open area CC.

98.1481078 - 78 = 20.1481078

So now I know my dome volume. It is 20.1481078. I simply rounded it down to 20.1. Which is a really big dome! The whole CC process took about 5 minutes to do. It's pretty need to do all the little calaculations to make the best running engine possible!

Now while you have the dial caliper out might as well check your deck clearance! I checked my to see if the block had ever been decked or not and found out that I have 1 millimeter of clearance between the top of the piston and the deck. Which comes out to .03937. I rounded down to .039. Which means the deck is untouched. All small block chevy blocks come .025 to .040 from the factory and the reason for the vary is because of machineing tolerances and such.

Now that I know my deck height, bore size, stroke, dome volume, I can begin to start deciding on what thickiness of gasket I need. You need to know your deck clearance to help with figuring the quench or "squesh" of the combustion chamber. It comes down to how effiencant it makes the combustion and power making process go. The tighter the quench the more power you will make.

A little better explaining of the quench area to people who are familiar with it is when the piston comes to top dead center all the air and fuel is being compressed. Well anybody that had ever had a head off an engine will have noticed you have a flat area and the combustion chamber inside the bore. Well the flat area is your Quench. When TDC is reached it squeezes all the air and fuel in that area and forces it in to the combustion chamber in a hurricane effect.

You can see now why you want a tighter quench. The tighter the better. Now there is a limit to how tight you can go. You don't want your piston to come flying up and nailing your head ruining it. I've seen people run crazy tight quenchs and very loose. If you really feel brave you could run smaller then .040 quench. But I wouldn't.

Most high performance engine builders whether they are Pro or just a really good bracket racer run .050 quench as the smallest. .040 can be done but you really need to know what your doing.

Now I'm not going to get this engine deck since it doesn't need it and I don't want to put much money into this engine since it will be getting me through till my 355 is finshed. So I've got .039 deck clearance, now I want that .050 quench but unless I deck the block it's not gonna happen. So I'm going to go with a .018 steel shim gasket. Which will put me at .057. Pretty close!

Now with that tight of a quench and the fact I'm running domes Piston to Valve clearance is going to be really important as well as cam selection. I may have to fly cut my pistons or go with a lower lift cam. So to get 10.5 to 1 compression with all these paremeters I will need to go with a 70cc chamber.

I'm ready to see if we can get this 283 to fly! 8)