The EGR valve was replaced during repairs after the first failed test. The manifold passages were clear, and the engine does now falter at idle when the EGR is opened.Has anyone actually confirmed the operation of the EGR system? When the EGR valve is manually opened at idle, the engine should stall, or at least run roughly. You stated originally that there was no effect on the idle when the valve was opened manually. This would indicate that the passages in the intake manifold may be plugged.

1984 El Camino Conquista failing first smog check ever

- Thread starter MarcD

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Are you sure you found all the leaks? Vacuum leaks can be very hard to find and sometimes can have weird causes like an incorrect spec PCV valve or a underside intake manifold leak.

inside the CCC Qjet is a air/fuel mixture control solenoid. The solenoid has a dwell time that should average around 30 degrees on a dwell meter if everything is good. You connect the green lead of the meter to the green diagnosis plug in the computer harness near the carburetor. Always set the dwell meter to the 6 cylinder mode to read the solenoid dwell. When the solenoid is on it leans the mixture. When the solenoid is off it enrichens the mixture.

The T stant sets the floor temp, not the ceiling. A colder T-stant delays warmup and closed loop operation and increases wear rate. The ECM is programed to see a certain engine temp for proper operation. 195 is the stock T stant temp for these cars, normal engine coolant temp should be 210 degrees.

inside the CCC Qjet is a air/fuel mixture control solenoid. The solenoid has a dwell time that should average around 30 degrees on a dwell meter if everything is good. You connect the green lead of the meter to the green diagnosis plug in the computer harness near the carburetor. Always set the dwell meter to the 6 cylinder mode to read the solenoid dwell. When the solenoid is on it leans the mixture. When the solenoid is off it enrichens the mixture.

The T stant sets the floor temp, not the ceiling. A colder T-stant delays warmup and closed loop operation and increases wear rate. The ECM is programed to see a certain engine temp for proper operation. 195 is the stock T stant temp for these cars, normal engine coolant temp should be 210 degrees.

Thanks for the prompt and helpful info about connecting and reading the MCS dwell time…I’ve had a fair amount of experience working with Amal, Mikuni, Weber, SU, Carter and Holley carbs, but not as much with ‘60’s Quadrajets and certainly not the CCC units. I’d never figure out this stuff by looking at it!Are you sure you found all the leaks? Vacuum leaks can be very hard to find and sometimes can have weird causes like an incorrect spec PCV valve or a underside intake manifold leak.

inside the CCC Qjet is a air/fuel mixture control solenoid. The solenoid has a dwell time that should average around 30 degrees on a dwell meter if everything is good. You connect the green lead of the meter to the green diagnosis plug in the computer harness near the carburetor. Always set the dwell meter to the 6 cylinder mode to read the solenoid dwell. When the solenoid is on it leans the mixture. When the solenoid is off it enrichens the mixture.

The T stant sets the floor temp, not the ceiling. A colder T-stant delays warmup and closed loop operation and increases wear rate. The ECM is programed to see a certain engine temp for proper operation. 195 is the stock T stant temp for these cars, normal engine coolant temp should be 210 degrees.

Now that I know the dwell is measured, how is it adjusted to spec of 30? If adjustment leans the A/F in one direction and riches it in the other, which is which?

I’ve seen some forum discussions about turning the Idle Air Bypass screw to alter MCS dwell; if that’s the case, would adjusting an idle circuit bleed affect main circuit performance? Seems counter-intuitive, but I’ve already demonstrated my lack of experience these carbs.

May we agree that while the 180 degree thermostat is not optimal and delays full operation of the system, it should operate normally once normal operating temperatures are reached. The car is driven on the California coast and never sees freezing weather.

The vacuum system was inspected and repaired by a professional mechanic (not me!) and should be intact. Do you have a favorite location to connect a vacuum hand pump to verify?

Again, thanks for sharing your knowledge.

Marc

Thanks for the prompt and helpful info about connecting and reading the MCS dwell time…I’ve had a fair amount of experience working with Amal, Mikuni, Weber, SU, Carter and Holley carbs, but not as much with ‘60’s Quadrajets and certainly not the CCC units. I’d never figure out this stuff by looking at it!

Now that I know the dwell is measured, how is it adjusted to spec of 30? If adjustment leans the A/F in one direction and riches it in the other, which is which?

I’ve seen some forum discussions about turning the Idle Air Bypass screw to alter MCS dwell; if that’s the case, would adjusting an idle circuit bleed affect main circuit performance? Seems counter-intuitive, but I’ve already demonstrated my lack of experience these carbs.

May we agree that while the 180 degree thermostat is not optimal and delays full operation of the system, it should operate normally once normal operating temperatures are reached. The car is driven on the California coast and never sees freezing weather.

The vacuum system was inspected and repaired by a professional mechanic (not me!) and should be intact. Do you have a favorite location to connect a vacuum hand pump to verify?

Again, thanks for sharing your knowledge.

Marc

The mixture dwell can be adjusted by both the idle mixture screws and the idle air bleed valve. The mixture screws are the coarse adjustment which affects both curb idle and off idle mixtures. The idle air bleed valve is the fine adjustment that only affects the curb idle mixture. The dwell needs to be set with the engine fully warmed up into closed loop and trans in drive. When you adjust the idle air bleed valve, you need to close the aircleaner lid and let the computer settle down after each adjustment before taking the reading.

Another issue to look out for are upstream exhaust leaks. These can let oxygen in the exhaust system and give a false lean reading at the O2 sensor.

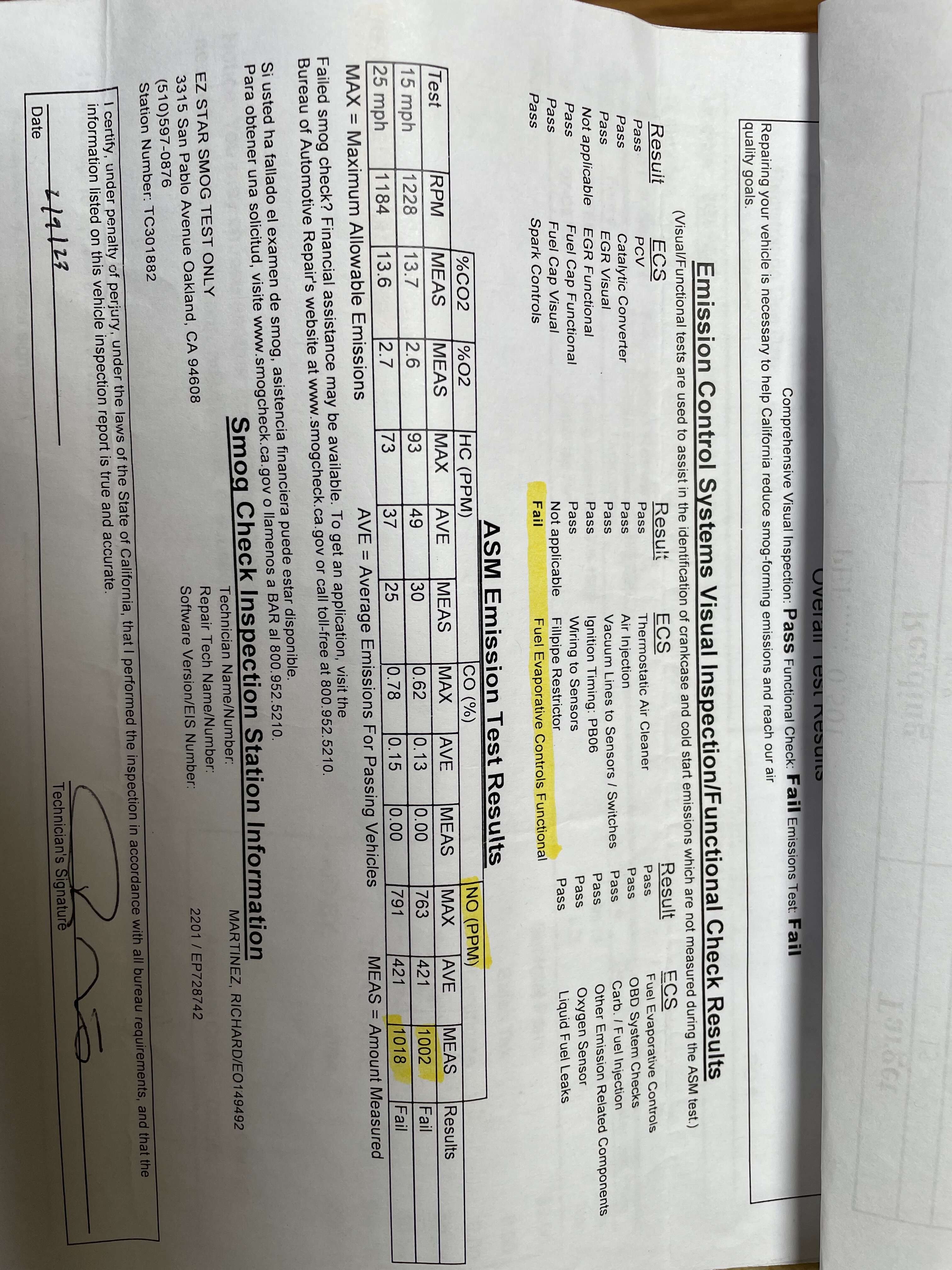

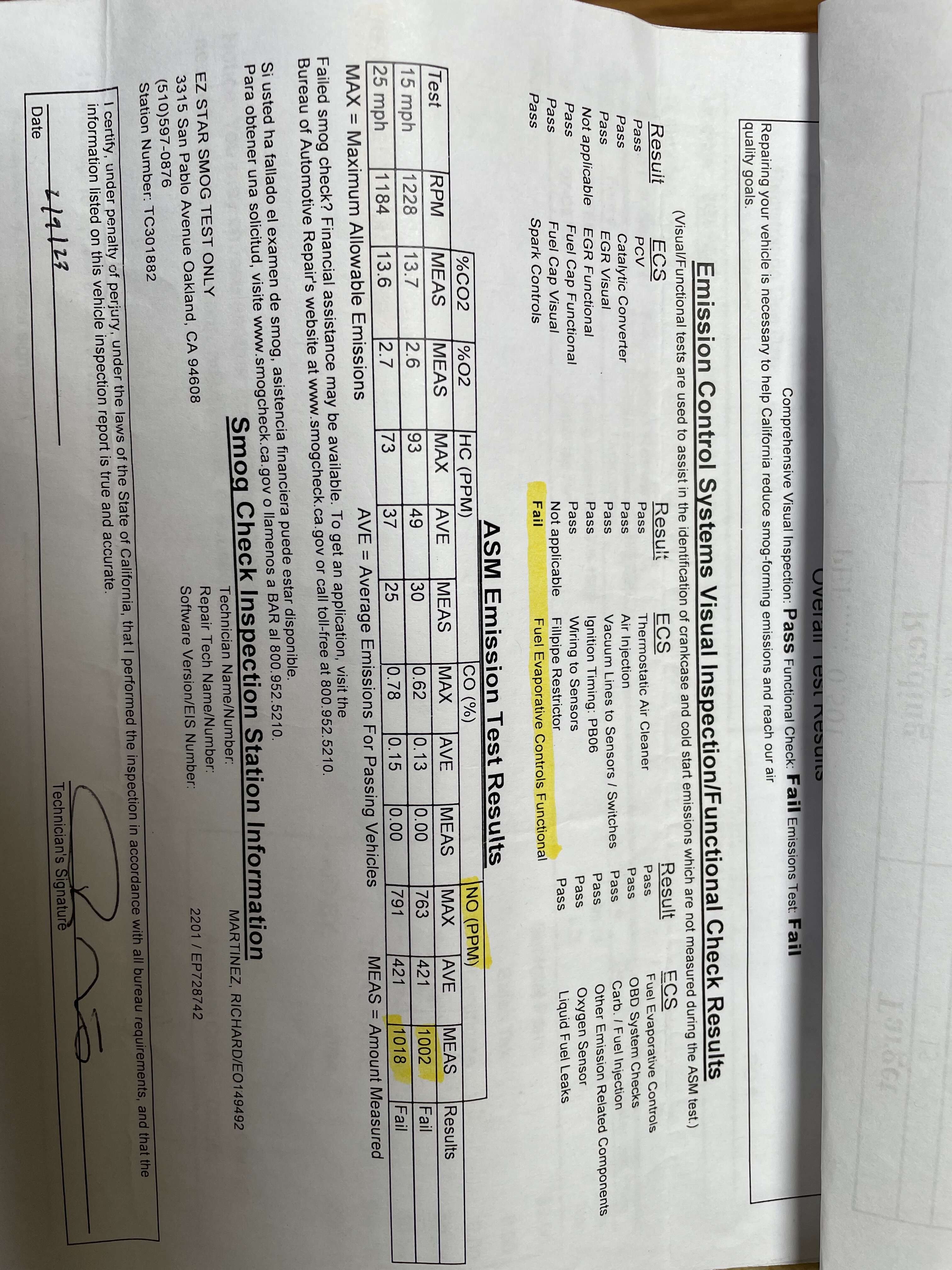

During perfect combustion, a 14:7 to 1 air fuel ratio generates about 13.5 % CO2. Since your emissions report does not provide a parameter for CO2 I'd assume the parameter is percentage. The same for the CO value, since you wouldn't use a decimal to report PPM.How is a high CO2 determined? The inspection printout has no parameters for that gas, and I could only find references to CO2 emissions in kg/mi, not in concentration percentage.

1000 PPM NOx is not all that high, since combustion always produces some NOx. If you look at the attached chart, you'll see that NOx moves up as the fuel mixture reaches stoichiometric (called "Target Range" in the chart). It goes up further as the mixture leans out, but drops down later, as an extremely lean mixture has less energy, reducing NOx formation.I thought a very low HC and CO, along with a high NOx indicates a lean condition and high combustion chamber temperature which would generate excessive NOx and prevent the catalytic converter from reducing it, since the cat requires a correct mixture to operate correctly.

It does make sense, and this indicates proper O2 sensor operation at a stoichiometric fuel mixture.I connected a meter set at mV to ground and a wire inserted into the connector from the purple wire and the O2 sensor. I got readings the seemed to cycle from 680mV to zero in a rapid sequence. Does this make any sense?

Illuminating at ignition on and turning off at start up indicates normal operation. On these early technology PCMs, failing to illuminate with an open circuit is not unusual. You may have to drive the car for a day or two to turn it on.The “check engine” light does come on with the ignition turned to “on”, the goes out with engine started. Disconnecting the O2 sensor does not illuminate the light…this seems odd, and I’m wondering if the ECM is malfunctioning.

I was going to repeat the suggestion you check the EGR passages for a blockage, but I see you've already checked and confirmed EGR operation. The more checks you make, the more I'm convinced a new cat is the correct repair.

Attachments

Updates:

Bought the tool to adjust the mixture screws. The plugs had already been knocked off, and I found one screw at one turn out, and the other at three turns.

Since I’m trying for a richer mixture to bring the NOx down from over 1000 (max permissible is 783/791..see below ), I set the screws at 4 turns each and set the MCS dwell at 30.

Failed again with nearly the same results.

The tech suggested I take another look at the EGR system, including driving with a vacuum gauge connected to the EGR solenoid output port via a long vacuum hose.

Voila, no vacuum signal. Checked the hose from the carb to the EGR solenoid and got up to 14 vacuum at part throttle.

So the EGR solenoid appears to be at issue. Can someone please explain how the solenoid is supposed to work?

Logic tells me the ECM would tell the solenoid to close when the engine is cold, then allow vacuum to pass when at operating temperature. If that’s so, when would voltage be sent to the solenoid?

I’m tempted to bypass the solenoid and connect the EGR directly to the carb ported vacuum and test it that way to see if a functioning EGR lowers the NOx. It wouldn’t pass visual inspection, but at least I’d know whether I need to spend $800 on a cat or start searching for the unobtainable solenoid.

TIE and Dave, thanks for hanging in there on this!

Bought the tool to adjust the mixture screws. The plugs had already been knocked off, and I found one screw at one turn out, and the other at three turns.

Since I’m trying for a richer mixture to bring the NOx down from over 1000 (max permissible is 783/791..see below ), I set the screws at 4 turns each and set the MCS dwell at 30.

Failed again with nearly the same results.

The tech suggested I take another look at the EGR system, including driving with a vacuum gauge connected to the EGR solenoid output port via a long vacuum hose.

Voila, no vacuum signal. Checked the hose from the carb to the EGR solenoid and got up to 14 vacuum at part throttle.

So the EGR solenoid appears to be at issue. Can someone please explain how the solenoid is supposed to work?

Logic tells me the ECM would tell the solenoid to close when the engine is cold, then allow vacuum to pass when at operating temperature. If that’s so, when would voltage be sent to the solenoid?

I’m tempted to bypass the solenoid and connect the EGR directly to the carb ported vacuum and test it that way to see if a functioning EGR lowers the NOx. It wouldn’t pass visual inspection, but at least I’d know whether I need to spend $800 on a cat or start searching for the unobtainable solenoid.

TIE and Dave, thanks for hanging in there on this!

Not to be overly dense, but does that mean the solenoid requires 12v to allow vacuum to pass from the carb to the EGR under those circumstances, or does voltage cause it to block vacuum?From service manual.

The EGR solenoid is energized based on the following inputs.

-Engine running above idle but below WOT.

- Engine coolant above 108 degrees F.

- Transmission in gear.

My solenoid seems to be erratic on the bench, and I can’t tell what it’s supposed to do.

"Logic tells me the ECM would tell the solenoid to close when the engine is cold, then allow vacuum to pass when at operating temperature. If that’s so, when would voltage be sent to the solenoid?"

Also, the EGR valve should never open at idle- if it does, it will cause a stumble, and may stall the engine.

The +12 V feed should be pink with a black wire, and the computer control line should be grey.The solenoid is constantly connected to +12V the computer uses pulses (PWM) to control the ground to complete the circuit so it opens the valve and allow vacuum to pass to operate the EGR valve.

Also, the EGR valve should never open at idle- if it does, it will cause a stumble, and may stall the engine.

- Status

- Not open for further replies.

Similar threads

- Replies

- 1

- Views

- 78

- Replies

- 2

- Views

- 237

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.