This is a step by step-by-step account of how to install ATS Brembo brakes on your Monte SS or G-body. I call this the Brembo “Medium” Brake Kit because it will fit behind a 17 inch wheel, where as the CTS-V/Camaro SS/C7 Z51 Brembos will use the same mounting bracket but require a 14 inch rotor from the C7 Z51 Vette, which will not fit behind 17’s. I’m going to brake this install up into several posts. This is a re-post of my work on MonteCarloSS.com, but it applies to all G-bodies.

Disclaimer: As with any install guide, you proceed at your own risk. Neither the author or montecarloss.com is responsible for any damage, injury or death that occurs because you did or did not follow this guide. This guide is offered for reference only and makes no claims about warranty, safety, performance, or serviceability. Take care when modifying safety critical systems like brake systems, Use common sense and work with safety in mind. Changing brake components may drastically change the stopping and handling behavior of your car in unforeseen ways. Test your work in a safe controlled environment before going onto the open road or track.

First, you will need the following items:

C7 conversion hubs from BigBrakeUpgrade.com - http://bigbrakeupgrade.com/product/camaro-ss-cts-v-conversion-hub/

Brembo converson brackets + hardware - http://bigbrakeupgrade.com/product/s-10-g-body-brembo-conversion-brackets/

ATS Caliper Front Left - PN 1722777 - https://www.rockauto.com/en/moreinfo.php?pk=9313828&cc=3307659

ATS Caliper Front Right - PN 1722587 - https://www.rockauto.com/en/moreinfo.php?pk=8327508&cc=3307659

2 Base C7 Corvette Front Rotors, such as Centric C-tec 12162146 -https://www.rockauto.com/en/moreinfo.php?pk=7464212&cc=3308852

2 new M10x1 banjo bolts (DO NOT REUSE YOUR STOCK BANJO BOLTS YOU WILL STRIP YOUR CALIPERS THEY ARE THE WRONG THREAD PITCH!)

A set of pads for the BASE C7 Corvette Corvette Stingray / 2010-2018 Camaro SS / Cadillac ATS with Brembo Brakes

Raybestos PN H5878A hardware kit for ATS/CTS/XTS calipers

ARP Long Wheel Studs - PN 100-7713 or Opt for the Long Stud upgrade with your hubs. (Scott at BBU.com does not recommend pressing out the 12.8mm knurl Dorman studs and replacing them with .509 knurl studs because the hub may crack. Do so at your own risk)

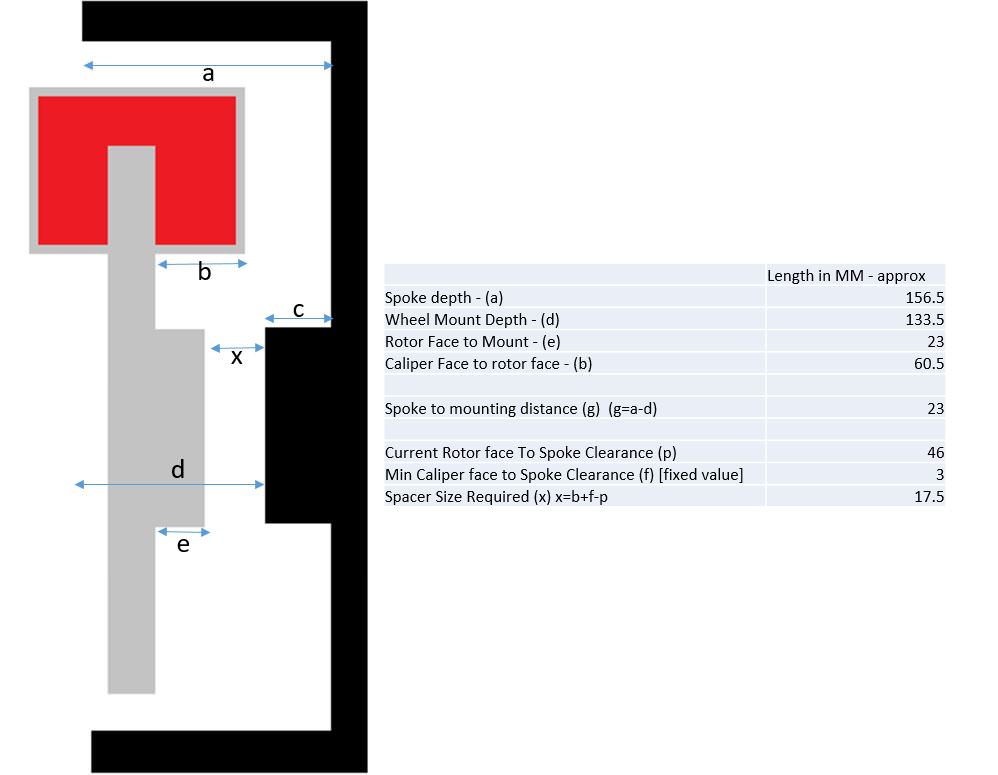

A wheel spacer that will provide the correct amount of clearance with your wheel/caliper - I'll show you how to measure in a bit. An 18mm spacer worked for me.

You will need at MINIMUM a 17 inch wheel to clear this installation. (Though it may work with JL9 brakes on 16 inch GTA wheels with a very large wheel spacer.)

Optional Items

Belltech 2 inch drop spindles - PN 2100

New Bearings + Seals

Russel Stainless brake lines - PN 692100

Specialty Tools

M12x1.75 Tap

10.5mm or 13/32 drill bit

Tap Wrench

12MM hex head wrench or socket

10mm hex head wrench or socket

Tie Rod removal tool

Ball joint removal tool.

Shop supplies:

Wheel Bearing Grease

Red Loctite (727)

Brake Fluid (I recommend a good quality synthetic DOT4)

2-3 cans of Brake Kleen

Rubber Gloves

Plastic bags

Shop Towels

4 M14 split washers - CRITICAL

Disclaimer: As with any install guide, you proceed at your own risk. Neither the author or montecarloss.com is responsible for any damage, injury or death that occurs because you did or did not follow this guide. This guide is offered for reference only and makes no claims about warranty, safety, performance, or serviceability. Take care when modifying safety critical systems like brake systems, Use common sense and work with safety in mind. Changing brake components may drastically change the stopping and handling behavior of your car in unforeseen ways. Test your work in a safe controlled environment before going onto the open road or track.

First, you will need the following items:

C7 conversion hubs from BigBrakeUpgrade.com - http://bigbrakeupgrade.com/product/camaro-ss-cts-v-conversion-hub/

Brembo converson brackets + hardware - http://bigbrakeupgrade.com/product/s-10-g-body-brembo-conversion-brackets/

ATS Caliper Front Left - PN 1722777 - https://www.rockauto.com/en/moreinfo.php?pk=9313828&cc=3307659

ATS Caliper Front Right - PN 1722587 - https://www.rockauto.com/en/moreinfo.php?pk=8327508&cc=3307659

2 Base C7 Corvette Front Rotors, such as Centric C-tec 12162146 -https://www.rockauto.com/en/moreinfo.php?pk=7464212&cc=3308852

2 new M10x1 banjo bolts (DO NOT REUSE YOUR STOCK BANJO BOLTS YOU WILL STRIP YOUR CALIPERS THEY ARE THE WRONG THREAD PITCH!)

A set of pads for the BASE C7 Corvette Corvette Stingray / 2010-2018 Camaro SS / Cadillac ATS with Brembo Brakes

Raybestos PN H5878A hardware kit for ATS/CTS/XTS calipers

ARP Long Wheel Studs - PN 100-7713 or Opt for the Long Stud upgrade with your hubs. (Scott at BBU.com does not recommend pressing out the 12.8mm knurl Dorman studs and replacing them with .509 knurl studs because the hub may crack. Do so at your own risk)

A wheel spacer that will provide the correct amount of clearance with your wheel/caliper - I'll show you how to measure in a bit. An 18mm spacer worked for me.

You will need at MINIMUM a 17 inch wheel to clear this installation. (Though it may work with JL9 brakes on 16 inch GTA wheels with a very large wheel spacer.)

Optional Items

Belltech 2 inch drop spindles - PN 2100

New Bearings + Seals

Russel Stainless brake lines - PN 692100

Specialty Tools

M12x1.75 Tap

10.5mm or 13/32 drill bit

Tap Wrench

12MM hex head wrench or socket

10mm hex head wrench or socket

Tie Rod removal tool

Ball joint removal tool.

Shop supplies:

Wheel Bearing Grease

Red Loctite (727)

Brake Fluid (I recommend a good quality synthetic DOT4)

2-3 cans of Brake Kleen

Rubber Gloves

Plastic bags

Shop Towels

4 M14 split washers - CRITICAL

Last edited: