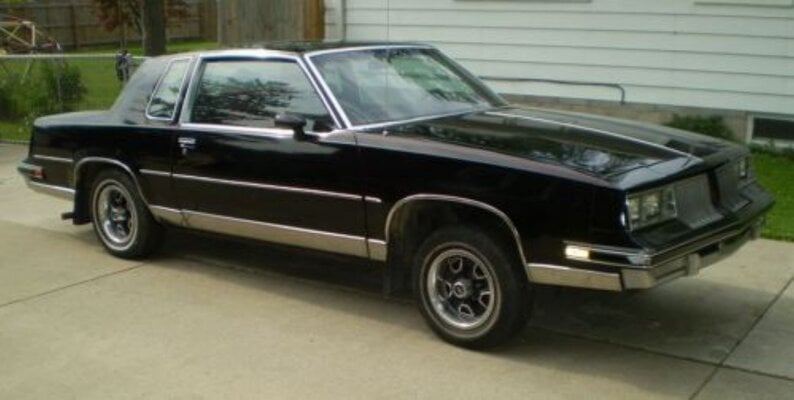

I've wanted to do this build for probably 20 years, a big block sleeper Cutlass. I'm finally just now getting around to it. It's going to be very middle-of-the-road as sleepers go, not the best performing, not entirely grandma's car in appearance, just a nice, plain-Jane coupe with a little something extra. I like that it has the SSIIs and no vinyl top. I have an identical set of 15s that I'm going to run with RWLs, but this will be the extent of the flashiness. Still got the red bench seat interior with column shifter. It was an AC car, but this was already mostly removed, so I've stripped the rest of it. CC and rear defrost were the only other power options, everything else is manual. 🙂

Getting the car running and drivable on a budget before Winter, and getting some fall cruising in was the goal of the initial phase of the project. I mostly met this goal, except for the budget part ha ha. For right now I'm just catching you guys up to where it's at now. Here's the car as it appeared in the auction listing in September of '11, a mostly stock 3.8 roller that had been off the road for about 10 years:

Getting the car running and drivable on a budget before Winter, and getting some fall cruising in was the goal of the initial phase of the project. I mostly met this goal, except for the budget part ha ha. For right now I'm just catching you guys up to where it's at now. Here's the car as it appeared in the auction listing in September of '11, a mostly stock 3.8 roller that had been off the road for about 10 years: