I’ve really got to stop doing the monthly update thing.

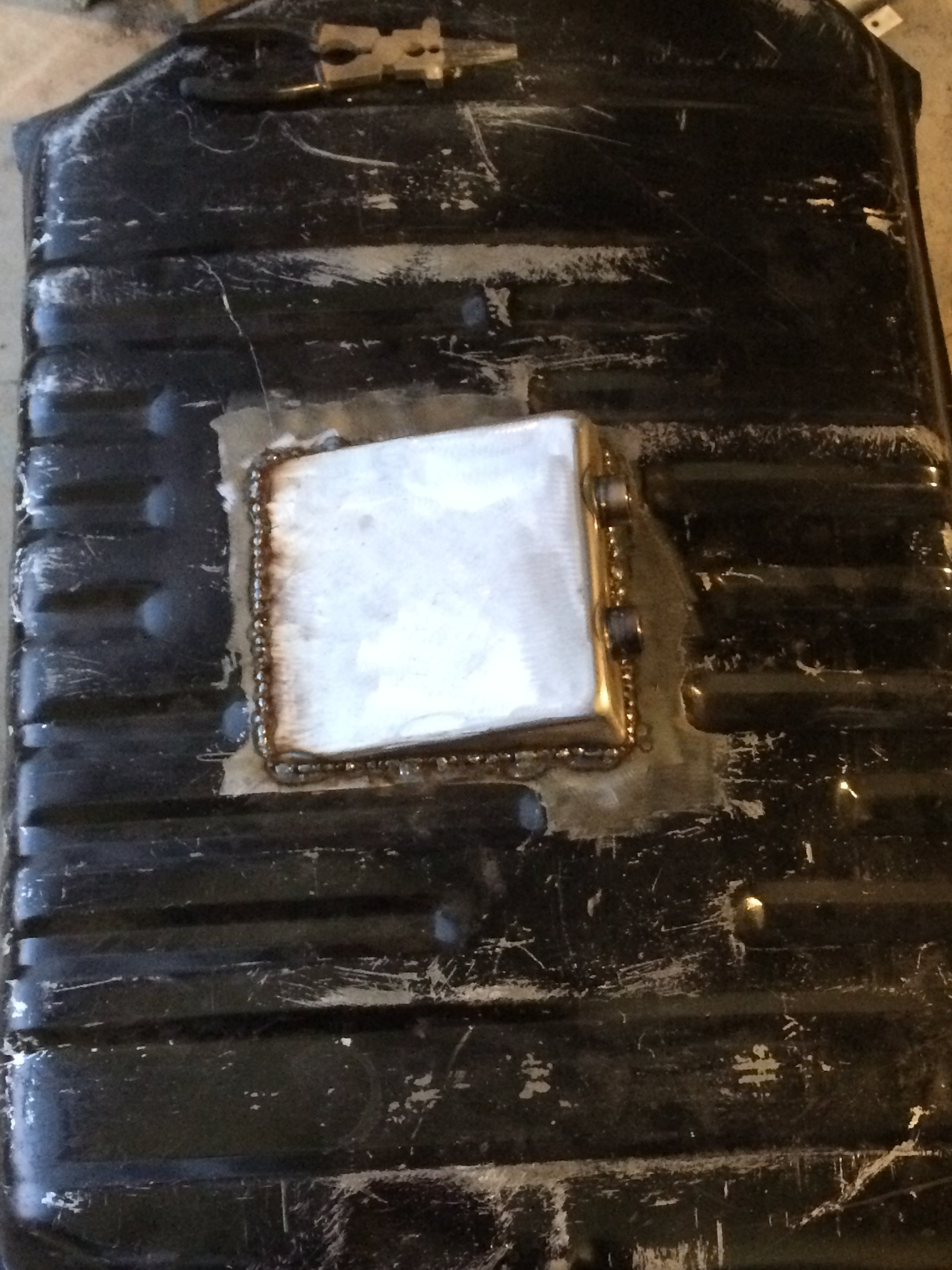

Anyhow, I’ve been kinda slow on the car in the last month, mostly been cleaning things up underneath and getting the underside in paint-

View attachment 152185

View attachment 152186

Rubberized undercoating sucks. I think I’m still picking this stuff out of my eyes.

Looks good in black though...

View attachment 152187

I’ll have to get some more recent pictures, the last one is just VHT Epoxy, I’ve since put 3 coats of semi gloss black Rustolem on there.

I don’t have any pictures of it but I’ve gotten the 8.8 set up with SN95 rear disk brakes. For those interested in using Ford parts over aftermarket, the SN95 rears are similar to the 4th gen F body rear brakes in piston size- 38mm on the SN95s vs 40mm on the F body. But it’s a real hassle to fit these, and involves parts that you usually can’t get from local upullit yards (in my experience anyway).

The main thing you need is the caliper mounting brackets that bolt to the housing. You then need to swap them left to right, and cut them like so:

View attachment 152188

After you get everything bolted together you’ll most likely need to shim the caliper bracket with washers to move it towards the outside of the axle. Mine sit in too far by about a 1/16th of an inch by eyeball.

Since then I’ve gotten my GP dash bezel mostly finished, and it looks really good.

View attachment 152189

I just need to paint the fake Allen screws and inside of the dash vent rings and that’ll be done for good.

I’ve also discovered my S10 driveshaft yoke was wrong. In short, if you grab a S10 ZR2 driveshaft, the 700R4 and T-5 yokes will work, the NV3500 won’t.

View attachment 152190

These have since been swapped- the ZR2 used the same u joints as the g body too, a GM 3R.

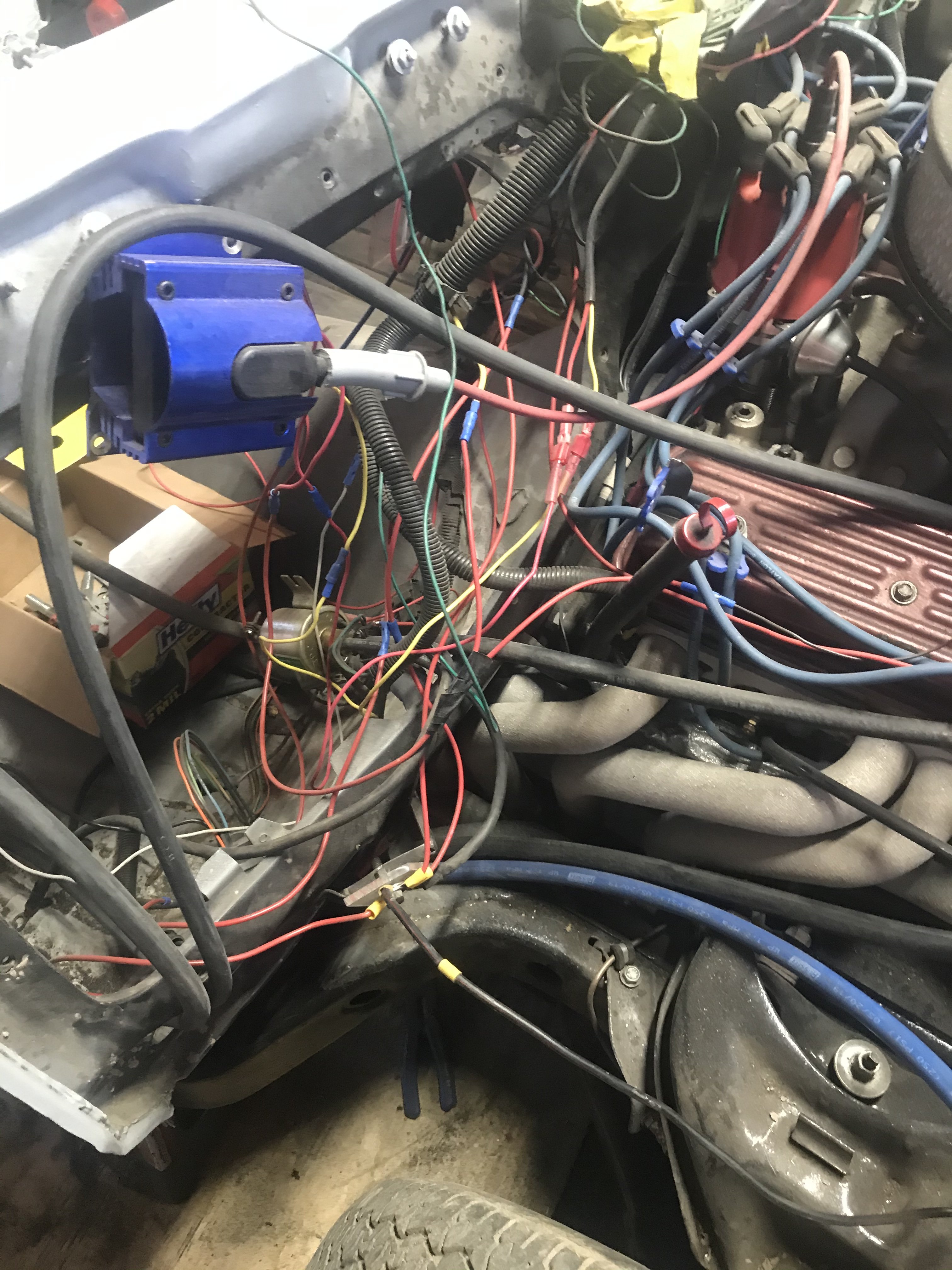

I’ve just been fiddling around with wiring in the meantime, I’ve got a general idea of how I’m going to have my trunk battery setup wired, and it starts with getting this mess fixed:

View attachment 152191

Somehow, this allowed this hodgepodge to run with no sparking, arcing, or fires. I’ll start counting my blessings from now on.

I have some power distribution posts to mock up and some more wire to run, although I’m undecided on wether to not to convert to a Ford style solenoid up front just for the added safety. Anyway my firewall looks like this right now:

View attachment 152193

I also figured out what size of sheet metal screw that are used in the firewall to secure the AC box, I’ll post the size when I can remember it 🙃

And then came Canfield (finally), where I made out like the Mad Hatter:

View attachment 152194

There’s a 34R Optima RedTop in there, and thankfully it’s an older one, rumors are Optima’s quality has started to tank.

There’s a pressure spray gun in there and that was a score to say the least- It’s a Sharpe model 75. It’ll be perfect for practicing cobwebbing.

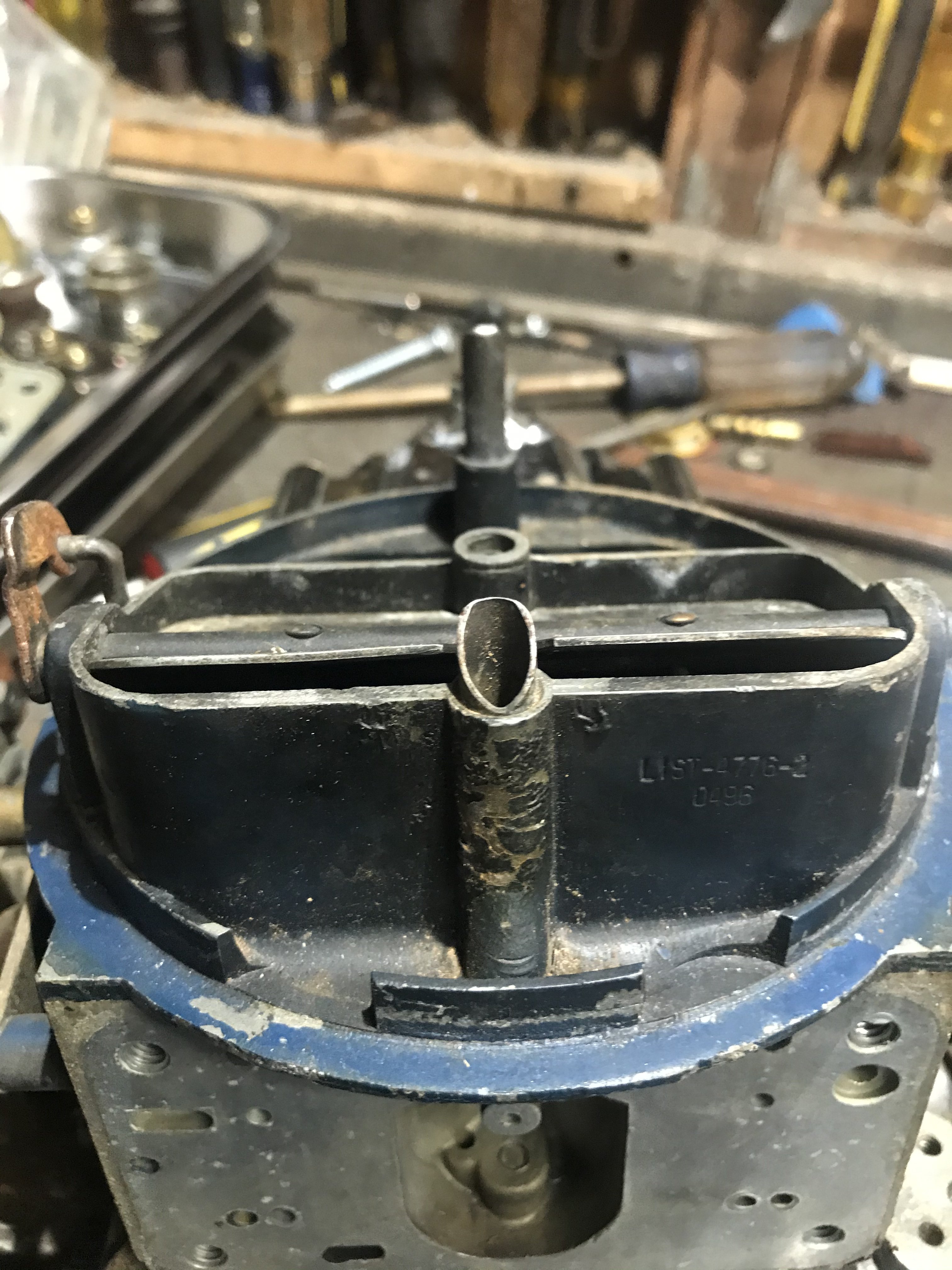

The Carb is a 600cfm Holley DP I paid way too much for, and here’s why, every piece of linkage is bent.

View attachment 152195

I was wondering why the high idle screw wasn’t contacting anything. I guess I have my answer. The bottom of the throttle lever is bent really bad and even the choke linkage is too. Somehow it even looks like the choke plate is bent:

View attachment 152196

And the carb body and metering blocks are fogged blue.

I should of never bought this thing.

And that about covers it all, I hope to have the car ready to have it’s rear axle installed permanently by the end of the week.

Although Canfield did give me ideas on what to do with one of my hoods:

View attachment 152198

Decisions, decisions...