...you do still have the '76 buick 350 don't you? All the machine shop needs to do is bore, finish hone, and install cam bearings. I built my SP engine in a weekend after I got it back. Plus, northern auto parts has a screamin deal on a re-ring kit http://www.northernautoparts.com/part/ek-er1066. Gives you an option to buy the intake valley pan as well. With stock heads, if you want about 9.5:1 with the thicker aftermarket gaskets, get the 340p pistons from summit. I spent about 1500 rebuilding my SP engine, although I didn't have to bore it (low mileage engine), and I used the $250 balancer I already had. So, add another $1000-1500 on the cost for pistons, balancer, timing cover, distrubutor (99$ from TA), etc. The ONLY thing you kind of should do, is notch the heater box. You have the later style valve covers, so that allows you slightly more room back there, but it would help. Look at Blake442s 3.8/Th200c to 350 buick swap thread. It also depends on the condition of your body mounts as well.

Edit: I do suggest, not only for you if you go buick, but for anyone, take a file or dremel and remove all the flashing from the lifter valley on any buick engine. Buick was terrible about this. it's one of the few annoyances about Buicks. But after an hour or two of some classic rock and a file, it will be done. I suggest doing it prior to the trip to the machine shop, and shoving a rag underneath to catch most of the chips.

Either way, as said, eager to see the car again.

Well my body mounts are brand new so that should help.

Yep, I still have that 76 SBB. Actually I talked about it not long ago with a machine shop that a buddy of mine recommended to me, the machinist is super meticulous.

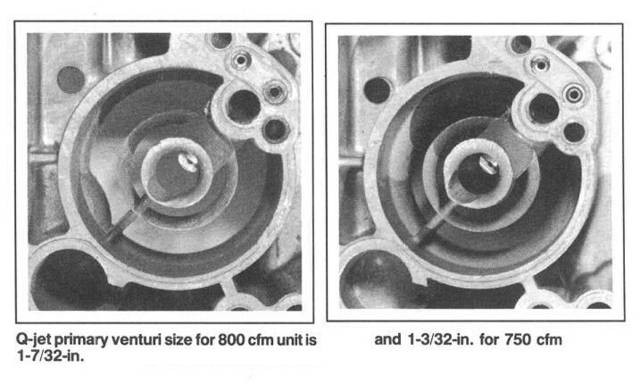

Building that engine is an option but I can probably buy something just as good or better that is ready to drop in for around the same price. Still just spitballing, probably be $500 in machine work, $300 for pistons, $300 for a cam set, $200 for the rering kit and $200 for a timing cover from T/A, that's $1500 right there. The heads are already cleaned up, valves lapped and new valve seals installed, so they can probably be run as-is. I have a 750 Q-Jet for it, needs a rebuild but it should be fine.

It's an option.

What did you do for your crank and connecting rods? Also did your block or heads need decked?

MrSony, I wish I had you here yelling in my ear to get that engine rebuilt, I'd have probably had it done a long time ago.