Couldn't et a video f a good run. This was the slowest I ran for the day - 1.7 60' and lifted twice before the 330'.

The next run was the best 1/8 and 60' that I've had - 6.4 to the 1/8 and 1.504 60'. But something was correct/right. I was running 1/8's only because the tech remembered me from the week before 10.006 in a 10 second legal car so he gave me the 'talking to' which was very decent of him. He could have busted me for sub 6.6 1/8ths as well, but didn't. I was very appreciative.

Last week on the last pass I leaned on it hard (more timing and more boost) to try to get through the stripe faster and something felt like I hit a rev limiter, boost cut or something? I never figured out what that was until yesterday. On the 3rd pass (best pass) I pushed about a 1/2 gallon of coolant. It was one of those things that makes me go 'hmmm'. It took longer than usual to get it cooled down between runs, I topped off the radiator and let it rip for a 4th hot. That led to OUCH. It pushed out about 1-2 gallons and looked like it blew it up, but I didn't. It made a strange noise that resulted in me lifting asap. On the run down road back to the pits it crept to 240 and the trans over 205, so I new it got hot. The hood and windshield were covered in coolant that were pushed out of the radiator cap. I believe the noise was coolant shooting onto the heater delete panel that I made out of an ultra flimsy piece of old Monte Carlo roof. It was hitting on all 8 cylinders and sounded normal. There was not any coolant in the oil or under the valve cover. I guess, I must have lifted a head and probably started the head gasket damage the weak before when I added 5 degrees of timing at 21 psi to try to make more speed.

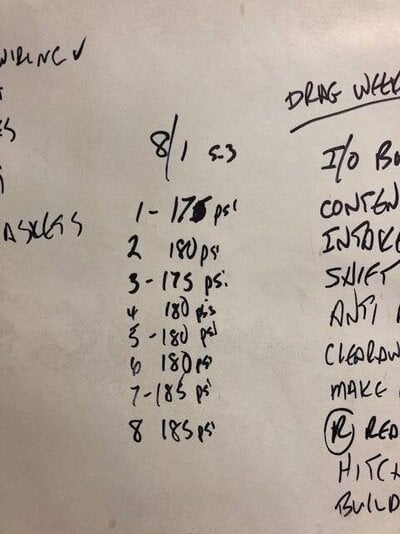

I drove it on the trailer and off the trailer once I got it home - sounds great. I ran a compression test and all cylinders are 175-185. I have the heads off and they look fine, but I can see where the head gasket began leaking on the driver side. I still have to measure piston heights (looking for bent rods), but I expect none since the compression was so close from cylinder to cylinder. I am running ARP head bolts on this (Bruce gave me crap assuming I was running re-used stock TTY head bolts lol.) I splurged on this for the ARP bolts, like $110 IIRC. And dang, were they tight - verified when I was removing them. The heads are going to the machine shop to be verified for flatness tomorrow. I'm using the cheapest possible head gaskets available as well - the BTR 4.8/5.3 units.

My intake temps were better, but still a runaway train. While contemplating the day's activities today I looked at the MC and it dawned on me that the radiator and intercooler are more than 3 times the size of the hole in the enduro bumper.

So I'm looking for some vents that are license plate size to put in the bumper on each side of the license plate. And I'm expecting to pull the black piece off from the bottom of the bumper and I'm going to fab a chin spoiler to install under the radiator much the way most of the other G-bodies are.

I should mention that in the video I have the right side shock set to 12 of 18 to keep it from compressing. It felt faster with it set looser, but time will tell. I have to hit the junkyard to get a sway bar installed to act like an antiroll.

Lastly, I'm going to try to do what

wingnutz did to 'tie down' the front end via installing stops in the upper control arms - that looked very ingenuitive.