So the last time I posted about my trials and tribulations with dropping my mill in my 85 M/Carlo SS the big hassle was the problem with the headers not getting along with the clamshell motor mounts. Those pipes were Flowmaster S/S ceramic coated; the mfgr swore up and down that they would fit a G-body but I finally ran across the OPG site and in their headers listings it specifically stated that my part number would NOT fit the G series chassis with the clamshell mounts, nor would any of the others listed.

When I left off, I had decided to modify a set of clamshells to get the clearance I needed to allow the headers to index into place correctly. I had a spare set in the inventory so they became the guinea pigs for the experiment. The following pics tell the rest of that story

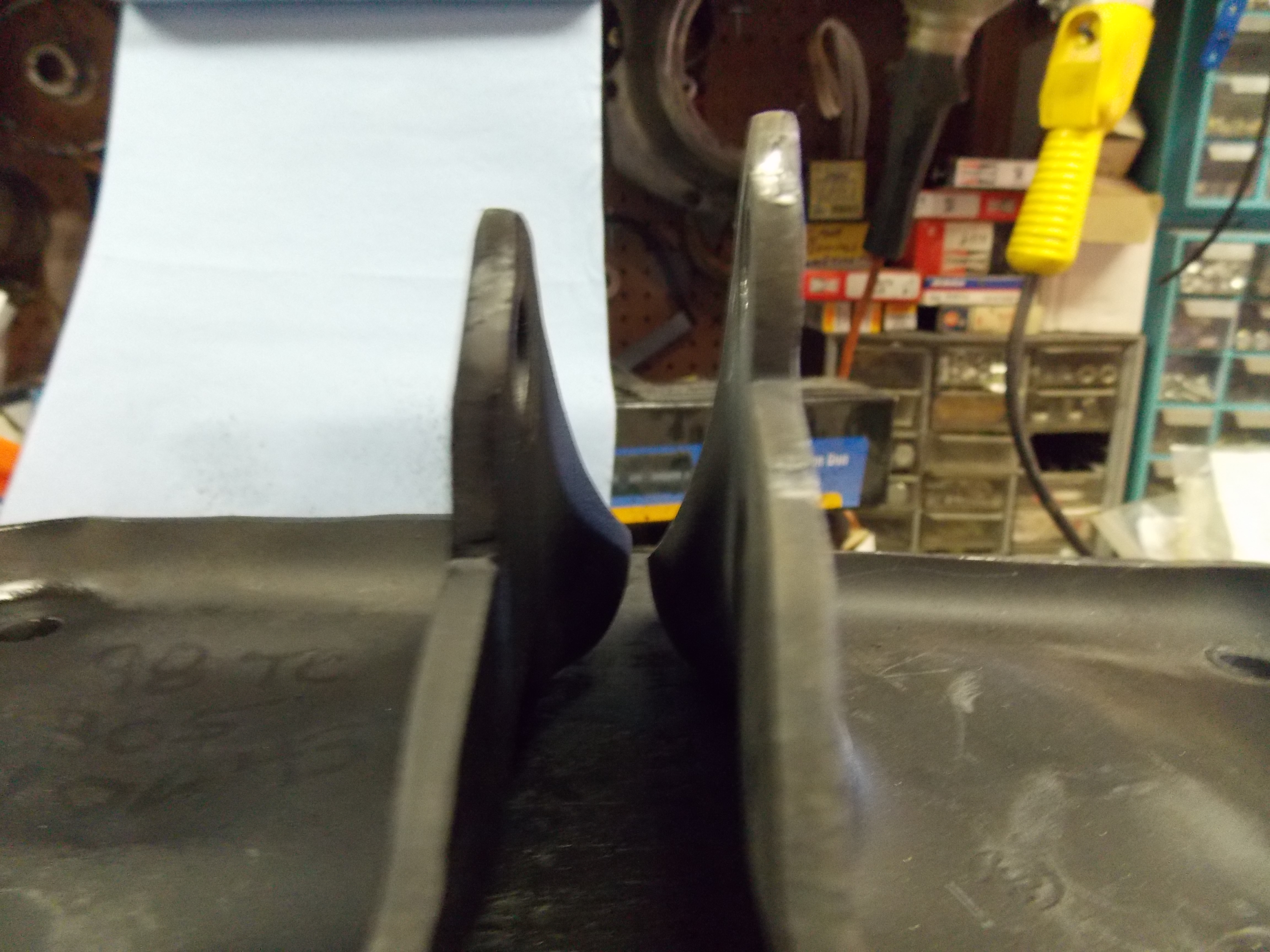

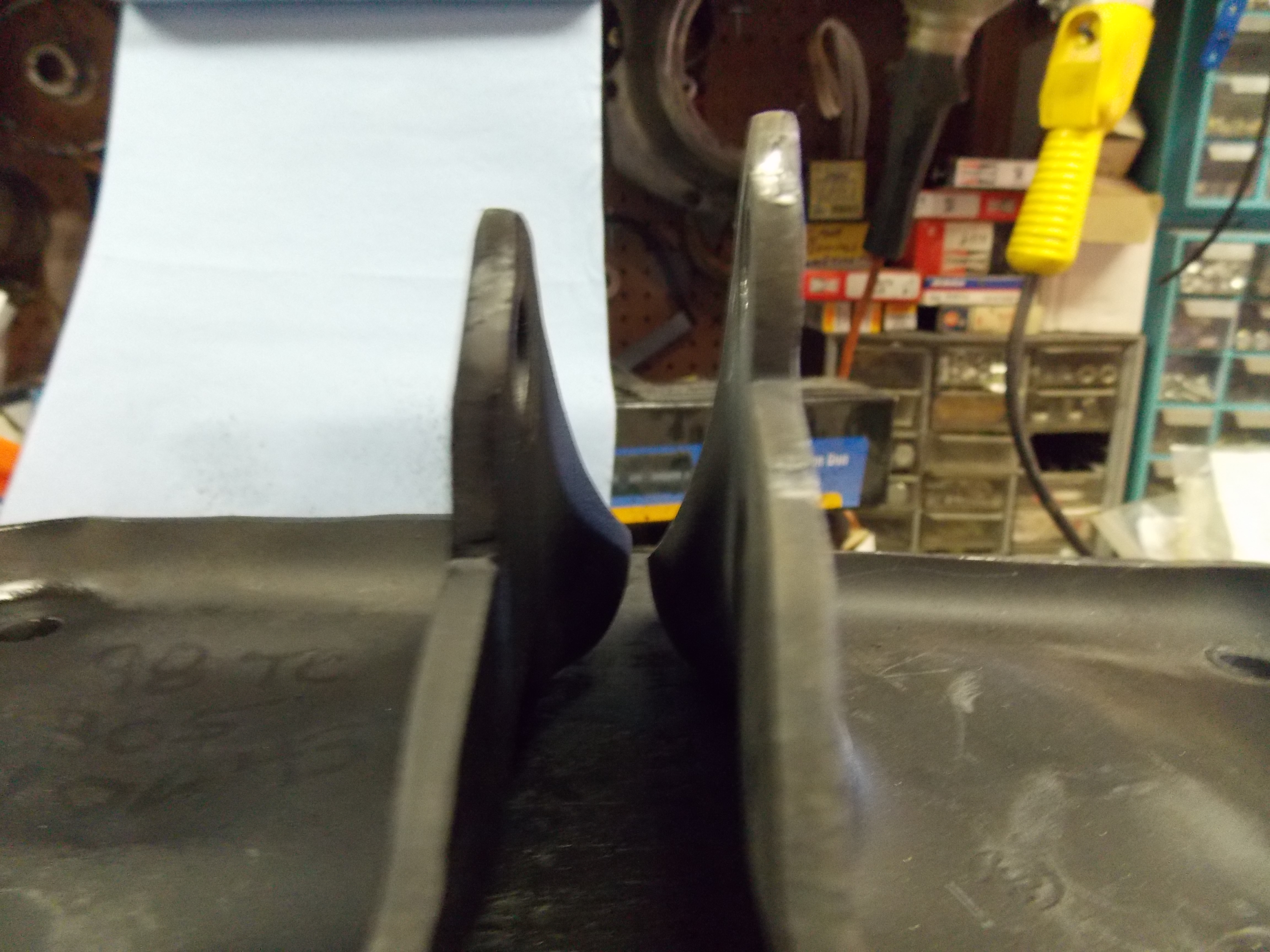

If the pic loaded correctly this is a shot of the guinea pigs after I shaved and re-radiused their ears and sides.

So I had the new clams all ready to go in but had to divert my resources to my Non-G-Body project to get it prepared for the winter That took about a month but I finally managed to get it out the door and block some time off to revisit the Monte and get the replacement clams installed. Only that didn't happen. I will let the pictures above tell most of the story but summarily, when I lifted the motor and swapped in the "new" clams, I could not get the motor to drop back onto the frame mounts. It finally occurred to me to compare the two versions of the engine half of the clamshell and the pictures tell the story. The biggest difference, as you can see, is the distance between the centre line of the crossbolt and the outboard face of the clam that would mate to the lugs on the block. The first set of clams that I shaved and reworked for clearance took a couple of days of trial and error before I got them to where I thought the amount of relief I had created in the sides and top was sufficient to allow the header tubes L-1 and R-2 to get past their respective clams. The second pair took about 3 hours for both, including primer and top coat!! I elected to allow them to dry overnight to get the paint as hard as possible.

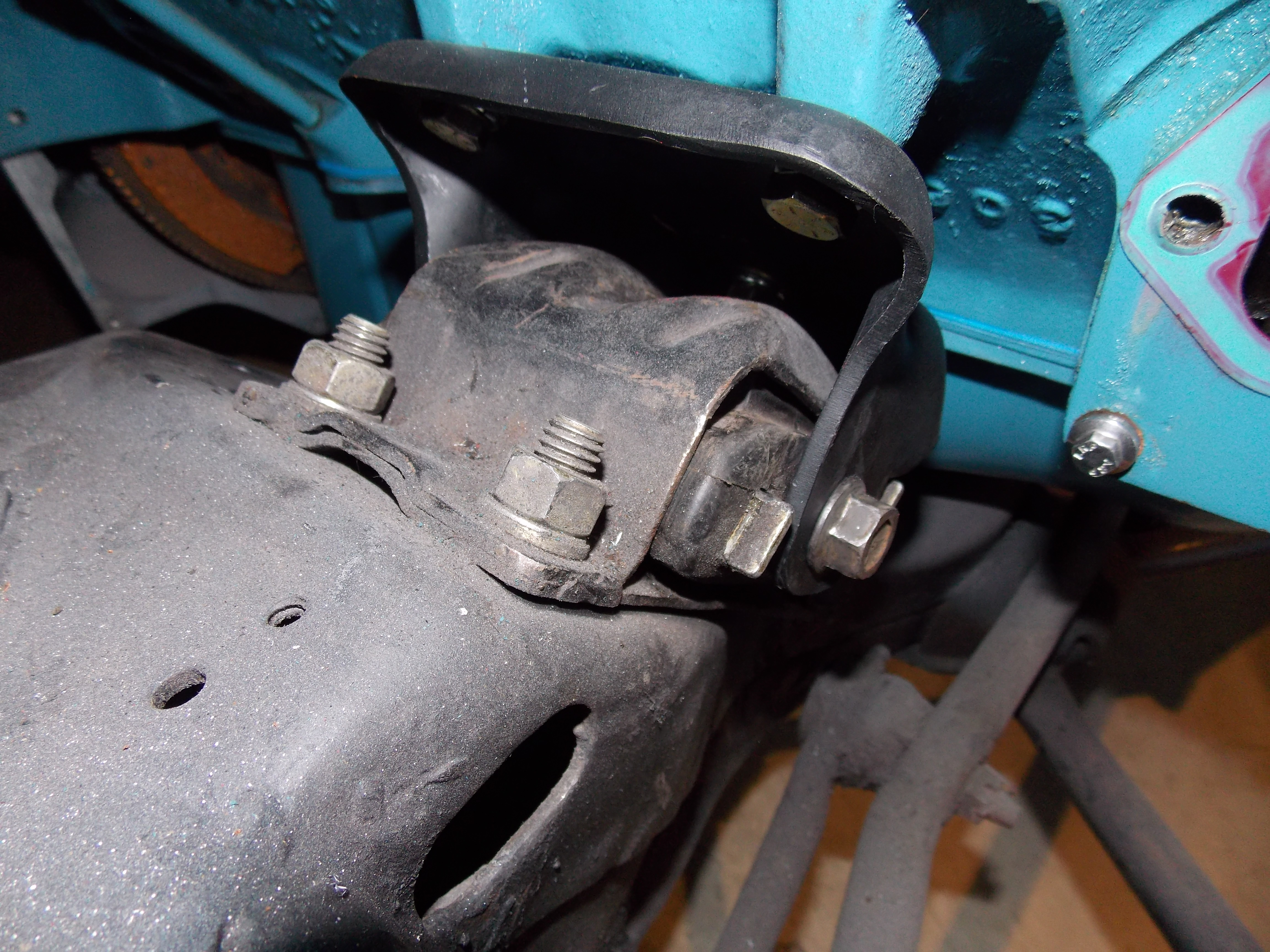

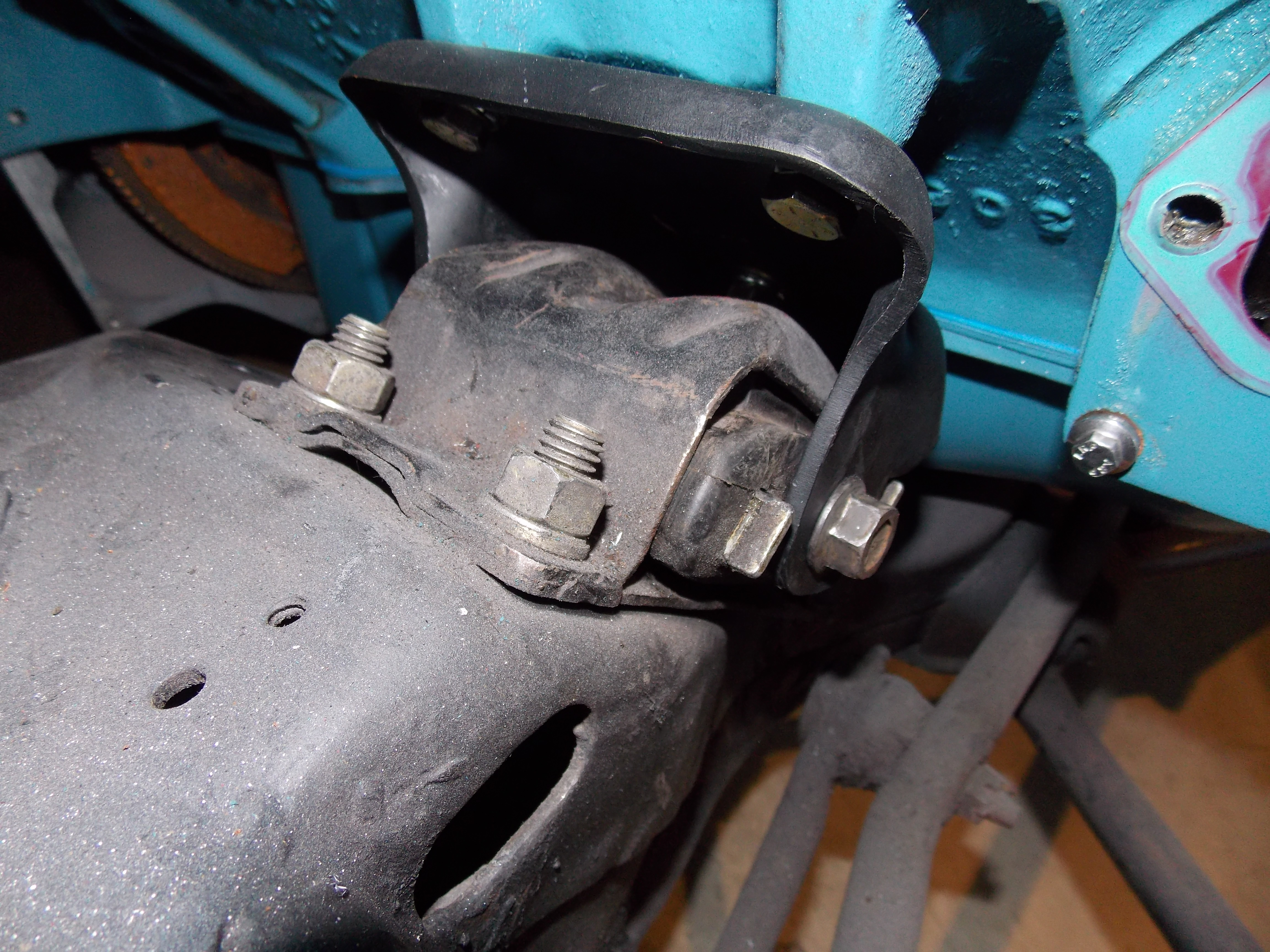

To end this, the pic above this caption shows the passenger side of the second set of modified clamshells, solidly bolted to the lugs on the block and bedded in on its frame mount. The inserts in the frame halves of the mounts are poly-urethane as is the transmission mount. The picture below this caption is the passenger side header. Because of the A/C box, it had to be slipped in from below. It actually slid into position without any problems and cleared the brackets for the lower A-arm without having to experience any love from a large hammer. The driver's side is a whole 'nother story which involves a combination of trimming the mounting ears for the lower A-arm as well as the creation of a major dimple in the side wall of the number 5 pipe almost immediately after it makes its turn to head back to the collector. These headers were ceramic coated; having to hammer in that dimple did not make me happy. As another individual pointed out in his thread on the matter, that ceramic coating does not like being beaten on and even multiple layers of masking tape laid down to protect the work site did not preserve the coating in the end. So far I have been through somewhere between six to twelve test fittings to see if I had finally got the dimple shaped correctly to clear the outside ear of the front mounting bracket for the lower control arm. Where I am now is possessing clearance but it is minimal. My out and back in time for that assembly is down to 5-10 minutes; what I may do is fabricate a shaping tool from a piece of heavy wall pipe and use that along with a heavy hammer to see if I can get that last 1/8+ inch of clearance that would finally make me genuinely happy.

When I left off, I had decided to modify a set of clamshells to get the clearance I needed to allow the headers to index into place correctly. I had a spare set in the inventory so they became the guinea pigs for the experiment. The following pics tell the rest of that story

If the pic loaded correctly this is a shot of the guinea pigs after I shaved and re-radiused their ears and sides.

So I had the new clams all ready to go in but had to divert my resources to my Non-G-Body project to get it prepared for the winter That took about a month but I finally managed to get it out the door and block some time off to revisit the Monte and get the replacement clams installed. Only that didn't happen. I will let the pictures above tell most of the story but summarily, when I lifted the motor and swapped in the "new" clams, I could not get the motor to drop back onto the frame mounts. It finally occurred to me to compare the two versions of the engine half of the clamshell and the pictures tell the story. The biggest difference, as you can see, is the distance between the centre line of the crossbolt and the outboard face of the clam that would mate to the lugs on the block. The first set of clams that I shaved and reworked for clearance took a couple of days of trial and error before I got them to where I thought the amount of relief I had created in the sides and top was sufficient to allow the header tubes L-1 and R-2 to get past their respective clams. The second pair took about 3 hours for both, including primer and top coat!! I elected to allow them to dry overnight to get the paint as hard as possible.

To end this, the pic above this caption shows the passenger side of the second set of modified clamshells, solidly bolted to the lugs on the block and bedded in on its frame mount. The inserts in the frame halves of the mounts are poly-urethane as is the transmission mount. The picture below this caption is the passenger side header. Because of the A/C box, it had to be slipped in from below. It actually slid into position without any problems and cleared the brackets for the lower A-arm without having to experience any love from a large hammer. The driver's side is a whole 'nother story which involves a combination of trimming the mounting ears for the lower A-arm as well as the creation of a major dimple in the side wall of the number 5 pipe almost immediately after it makes its turn to head back to the collector. These headers were ceramic coated; having to hammer in that dimple did not make me happy. As another individual pointed out in his thread on the matter, that ceramic coating does not like being beaten on and even multiple layers of masking tape laid down to protect the work site did not preserve the coating in the end. So far I have been through somewhere between six to twelve test fittings to see if I had finally got the dimple shaped correctly to clear the outside ear of the front mounting bracket for the lower control arm. Where I am now is possessing clearance but it is minimal. My out and back in time for that assembly is down to 5-10 minutes; what I may do is fabricate a shaping tool from a piece of heavy wall pipe and use that along with a heavy hammer to see if I can get that last 1/8+ inch of clearance that would finally make me genuinely happy.