Rear seat brace vs bulkhead.

- Thread starter Clone TIE Pilot

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

the x brace is a jokeNo offense to anyone. I honestly believe that everything is just a bandaid to the real problem. The frame and the old rubber body mounts. Just my opinion but reinforcing the frame correctly and using something harder than rubber (poly) should reduce flex greatly. Having done both i still added the X brace. Jmo.

well that request will never be fulfilled......because they were not factory. ASC made them aftermarket. They are very similar to the brace I makeI'd like to see the ASC GNX rear brace that came factory in GNX's if anyone has a picture.

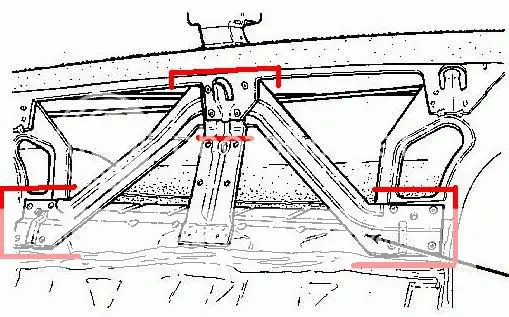

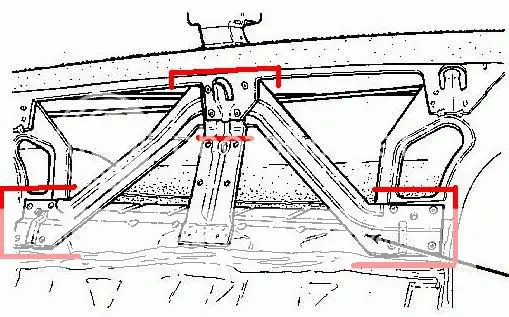

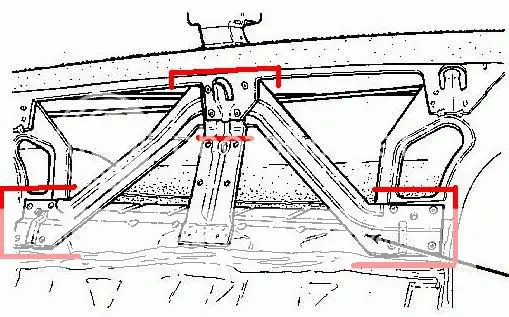

I did find a diagram of a ASC GNX brace.

It appears that ASC mounted the bottom foreward of thd side pillars but the top center behind the center pillar. Perhaps this was to add more tension? I count 12 rivets in the diagram.

It appears that ASC mounted the bottom foreward of thd side pillars but the top center behind the center pillar. Perhaps this was to add more tension? I count 12 rivets in the diagram.

Why is this called an ASC GNX brace? This is my original owner 87 SS with bulkhead brace as installed by Chevrolet Division of General Motors. Some G bodies got it some didn't, so why is being called ASC GNX? It is not specific to a GNX. Mine is spot welded at all attaching points.I did find a diagram of a ASC GNX brace.

It appears that ASC mounted the bottom foreward of thd side pillars but the top center behind the center pillar. Perhaps this was to add more tension? I count 12 rivets in the diagram.

Attachments

Why is this called an ASC GNX brace? This is my original owner 87 SS with bulkhead brace as installed by Chevrolet Division of General Motors. Some G bodies got it some didn't, so why is being called ASC GNX? It is not specific to a GNX. Mine is spot welded at all attaching points.

ASC was a company subcontracted by GM to modify select GNs into GNXs. One of the modifications ASC performed was to rivet in a factory rear brace as all Regals including GNs did not come with them. This is a diagram of a GNX brace and how it was retrofitted post factory. ASC riveted the braces in place with 1/4 rivets which takes a big two hand riveter.

Other G bodies were factory built with the rear brace spotwelded in such as the Grand Prix and many Monte Carlos. Factory rear braces were sandwiched in the middle of the side pillars and spotwelded. Here is a closeup of a GN owner installing a junkyard OEM brace into his GN the factory way vs ASC and other aftermarket methods.

As you can see above, G bodies without a factory brace use a spacer piece that is being held in the hand in the picture. Ths factory rear seat brace is an alternative connecting piece that is used instead of the spacer piece to connect the side pillars to the floor tub. ASC choose to rivet the brace over the base of the side pillars rather than drill out spotwelds and re-spotweld seat braces in place of the spacers.

Last edited:

Doing some research on this and found a few interesting things. An unbraced rear seat structure found in many G bodies is similar to moment frames in building construction. This type of framing is not very rigid as it doesn't resist flex from laterial (sideways) forces. So it flexes side to side a lot as well as compress up and down.

A bulkhead or firewall in a car body behaves similar to a shear wall in a building which is very resistant to laterial (sideways) forces. However, flat panels of sheetmetal are not very rigid, especially thin guages. Therefore they don't resist compression forces very well unless they are thick guage or have reinforcing ribs or beads pressed in. Reinforcing ribs can stiffen a panel up to 400% perpendicularly to the rib. This explains why rear seat firewall panels vibrate like a drum without reinforcing. Many of the rear trunk bulkhead kits I see for sale are pretty thin guage to easily conform to each car besides often lacking ribd, beads, or hems. In short, an unreinforced flat panel bulkhead should reduce sideways and upwards flexing, but probably won't stop downwards compression flexing and panel bowing. Panels with some sort of reinforcing ribs pressed in are better than plain flat panels as they resist bowing better.

Now the GNX style braces form two sets of single diagonal braces which are not quite as rigid as X braces but they better fit the rear seat area of most cars. Diagonal braces including X braces work best if they go from corner to corner of a square, which is one reason the aftermarket X braces don't work well as they fail to attach in the corners. Since both OEM and Tinman braces have beads pressed in them they should resist bowing under compression. The Turbo Farms brace should also achieve bowing resistance through thicker gauge construction.

Still not sure which type of bracing is best but just flat panels without ribs is not the best method of bracing. Moreover, spot welds are generally stronger than rivets for sheetmetal construction, through rivets are still plenty strong.

A bulkhead or firewall in a car body behaves similar to a shear wall in a building which is very resistant to laterial (sideways) forces. However, flat panels of sheetmetal are not very rigid, especially thin guages. Therefore they don't resist compression forces very well unless they are thick guage or have reinforcing ribs or beads pressed in. Reinforcing ribs can stiffen a panel up to 400% perpendicularly to the rib. This explains why rear seat firewall panels vibrate like a drum without reinforcing. Many of the rear trunk bulkhead kits I see for sale are pretty thin guage to easily conform to each car besides often lacking ribd, beads, or hems. In short, an unreinforced flat panel bulkhead should reduce sideways and upwards flexing, but probably won't stop downwards compression flexing and panel bowing. Panels with some sort of reinforcing ribs pressed in are better than plain flat panels as they resist bowing better.

Now the GNX style braces form two sets of single diagonal braces which are not quite as rigid as X braces but they better fit the rear seat area of most cars. Diagonal braces including X braces work best if they go from corner to corner of a square, which is one reason the aftermarket X braces don't work well as they fail to attach in the corners. Since both OEM and Tinman braces have beads pressed in them they should resist bowing under compression. The Turbo Farms brace should also achieve bowing resistance through thicker gauge construction.

Still not sure which type of bracing is best but just flat panels without ribs is not the best method of bracing. Moreover, spot welds are generally stronger than rivets for sheetmetal construction, through rivets are still plenty strong.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 8

- Views

- 457

- Replies

- 6

- Views

- 418

- Replies

- 10

- Views

- 439

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.