SBC camshaft belt drives

- Thread starter xylorex

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Not to tangent the thread too far but belt failure isn't the reason that OEs have moved away from timing belts. Belts are lighter, quieter, and cheaper to produce than chain systems but they are a scheduled maintenance item. VVT is oil controlled so it makes more sense to put that all inside a wet, sealed system. Chain systems can also be touted as a maintenance free selling point. Ask GM 3.6, Ford Triton and DOHC, Nissan KA, Jeep 4.7, old Nylon cam gear GM, Jag 4.0 owners if chains are trouble free and I bet you'll hear plenty of expensive stories.For any street use, just use a good double roller chain. Timing belts have shorter lives. The car manufacturers tried timing belts for awhile and ended up with a lot of engine failures. Failed timing belt killled the engine in my late grandmother's Ford Contour. Was not even high mileage, just age, rotted over time.

To the OP, as far as a belt drive conversion for the street goes, knock yourself out. Since you are calling this a high-end street build, I assume it's mostly for 'wow' factor when you pop the hood? Aside from that, there is absolutely no advantage for a street driven car. These kits were intended for race applications that are likely torn down and refreshed (replaced) at least once a year.

Thanks for everyones input...

Driven - Yes, it has alot to do with the "wow" factor -- which most everything does on my build... This will be on a fresh engine with AFR 1040's, full roller valvetrain, and edelbrock pro-flo 4 EFI system...

i started this post because i was thinking that if i stay with a nice chain drive setup (Rollmaster CS1230) and a 3-piece aluminum timing cover (Comp Cams #310), i'm halfway pricewise to a nice belt drive setup....

then some of these belt drives seem to have an interesting way to setup the camshaft endplay, which is important to me since i have a non-roller block.

Driven - Yes, it has alot to do with the "wow" factor -- which most everything does on my build... This will be on a fresh engine with AFR 1040's, full roller valvetrain, and edelbrock pro-flo 4 EFI system...

i started this post because i was thinking that if i stay with a nice chain drive setup (Rollmaster CS1230) and a 3-piece aluminum timing cover (Comp Cams #310), i'm halfway pricewise to a nice belt drive setup....

then some of these belt drives seem to have an interesting way to setup the camshaft endplay, which is important to me since i have a non-roller block.

If you do decide to go this route, please post an update. I'm curious how well it works outside of a race application as far as oil seepage and other maintenance is concerned.

if you go with the belt, there's always Jesel protection covers ex-Nascar for sale on ebay to take away the fear of eating stones/debri etc...

Not to tangent the thread too far but belt failure isn't the reason that OEs have moved away from timing belts. Belts are lighter, quieter, and cheaper to produce than chain systems but they are a scheduled maintenance item. VVT is oil controlled so it makes more sense to put that all inside a wet, sealed system. Chain systems can also be touted as a maintenance free selling point. Ask GM 3.6, Ford Triton and DOHC, Nissan KA, Jeep 4.7, old Nylon cam gear GM, Jag 4.0 owners if chains are trouble free and I bet you'll hear plenty of expensive stories.

To the OP, as far as a belt drive conversion for the street goes, knock yourself out. Since you are calling this a high-end street build, I assume it's mostly for 'wow' factor when you pop the hood? Aside from that, there is absolutely no advantage for a street driven car. These kits were intended for race applications that are likely torn down and refreshed (replaced) at least once a year.

Any moving part will wear out with use. However, soft parts wear out from the passage of time, even if it is lightly used. As soon as a soft part is made, the clock is ticking down like with OEM Regal bumper fillers or tires. At least a chain or direct gear drive won't dry rot out on you in about 6 years regardless of miles driven or hours of run time. Hard metal parts generally don't dry rot.

Factory chains can be sub par, stock SBC chains can stretch by 30k, while a true quality double roller will last well over 100k before stretch. But a belt will be another routine replacement part due every few years regardless of the amount of use. If the OP goes with a timing belt, he better plan on replacing if every few years.

If the belt drive is for the "wow factor" putting a cover over it to street drive it seems to defeat the purpose.

Thanks for everyones input...

Driven - Yes, it has alot to do with the "wow" factor -- which most everything does on my build... This will be on a fresh engine with AFR 1040's, full roller valvetrain, and edelbrock pro-flo 4 EFI system...

i started this post because i was thinking that if i stay with a nice chain drive setup (Rollmaster CS1230) and a 3-piece aluminum timing cover (Comp Cams #310), i'm halfway pricewise to a nice belt drive setup....

then some of these belt drives seem to have an interesting way to setup the camshaft endplay, which is important to me since i have a non-roller block.

If you want something functional then go with an adjustable chain and a Cloyes cover. I used it on my 565 with the .814/.798 282/290 @.050 roller. The cloyes cover is real easy to set endplay and the cover makes it adjustable. But honestly, I have never made a cam adjustment on any of my race engines in 25 years.

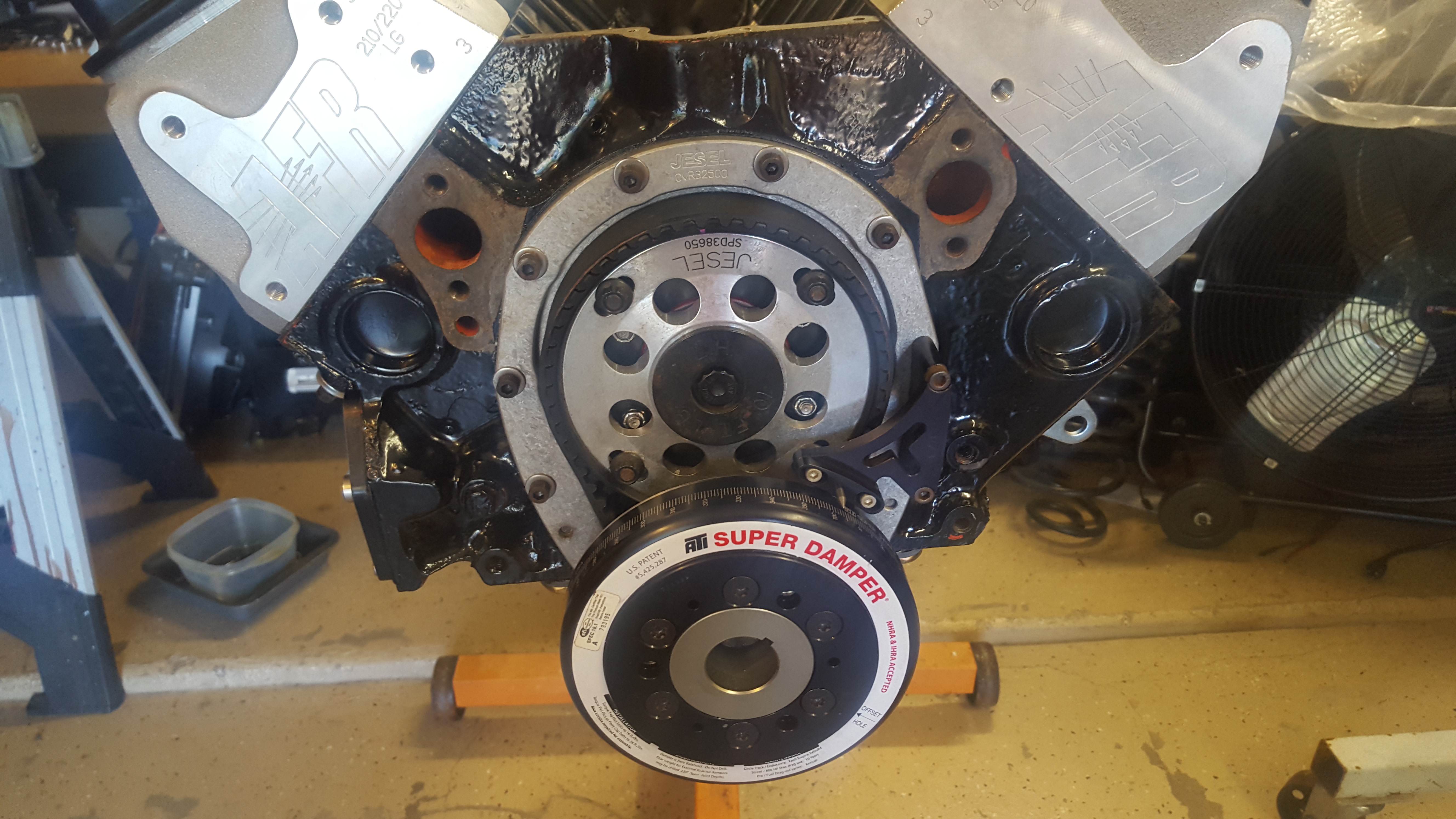

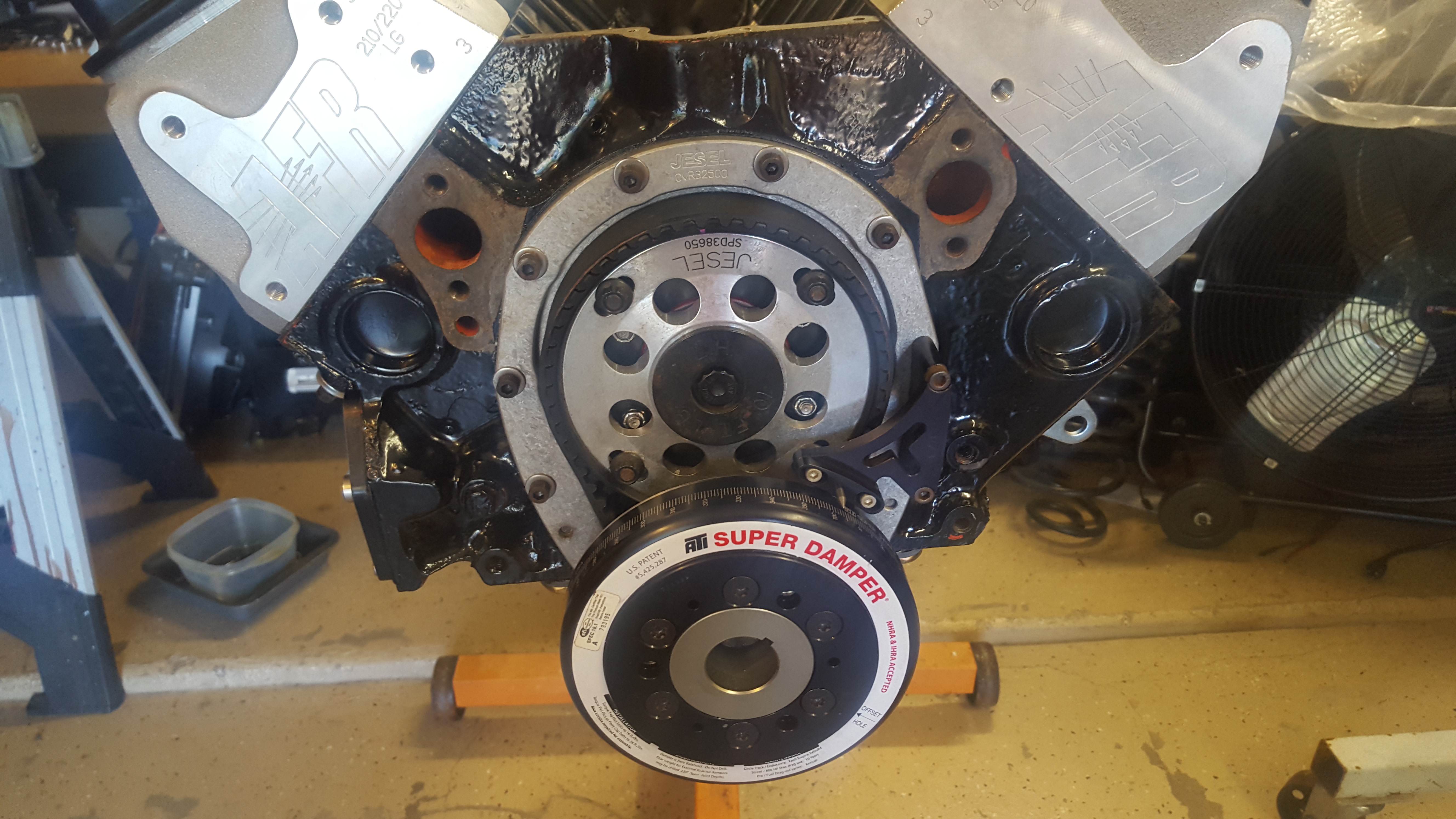

I'm reading what appears to be a lot of negative or cautionary comments about belt drives. We have a Jessel that was reused from her motor when it was set up for drag racing. I have no qualms with using it on the street. Why would I shelf a $1000 part? If I tried to sell it I might see ½ my money back…

As mentioned in previous posts they are not maintenance free. And can be difficult to work on / with, in a street application. They protrude from the block a bit further than a TC cover so measuring for your water pump and pulley set up becomes imperative. This may also lead to difficulty adjusting mechanical timing (i.e. there’s a lot of stuff in the way compared to a race application, where you may only have an electric WP.)

I personally love them. For Michelle’s motor I have set it to 0* advance and will only play with the distributor for timing adjustments. Speaking of timing adjustments, here is a big time plus (as far as I’m concerned). Belt drives transfer zero engine harmonics; this means the timing line is rock solid under the light. So no guessing about 1 or 2 degrees (again this is more important in a racing application, but I love it).

Lastly my neighbor has been running a Comp belt drive on his SBC (1980 SWB) for years with no issues. He drives his truck regularly (at least 2 or 3 times a week) and has taken it on several long trips.

This is what I meant by difficult to make adjustments or get to, lol.

As mentioned in previous posts they are not maintenance free. And can be difficult to work on / with, in a street application. They protrude from the block a bit further than a TC cover so measuring for your water pump and pulley set up becomes imperative. This may also lead to difficulty adjusting mechanical timing (i.e. there’s a lot of stuff in the way compared to a race application, where you may only have an electric WP.)

I personally love them. For Michelle’s motor I have set it to 0* advance and will only play with the distributor for timing adjustments. Speaking of timing adjustments, here is a big time plus (as far as I’m concerned). Belt drives transfer zero engine harmonics; this means the timing line is rock solid under the light. So no guessing about 1 or 2 degrees (again this is more important in a racing application, but I love it).

Lastly my neighbor has been running a Comp belt drive on his SBC (1980 SWB) for years with no issues. He drives his truck regularly (at least 2 or 3 times a week) and has taken it on several long trips.

This is what I meant by difficult to make adjustments or get to, lol.

Last edited:

- Status

- Not open for further replies.

Similar threads

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.