as many may or may not know i am about to go thru a full suspension replacement with STD aldan's gbody kit for lowering. there's this "controversy" over these plates in a way from my months long research there is none except maybe 2-3 posts i seen on gbodyforum (wish i'd of bookmarked em). point 1 aldan is only co that make's them for their products and if you seen em they look weak & breakable yet cost around $60. i emailed them bout them and if in the kit i bought. " The front/rear G-Body kits we make do not include the optional ALD-39 lower control arm spacer plates (These are sold separately)"

all the video installs of qa1, aldan, viking, ridetech using stamp steel LCAs A & G bodies not 1 used such a thing. i asked multiple ppl and they all said same thing 'never had a problem', these were on vids older than 4 yrs using OEM equip. the posts i refered to say stock LCAs too weak.

my sometimes small brain would agree with that then i get thinkin... the T bar extends over the edges of that center cone where there's a verticel (sorta) support and if were to add a 1/4" steel plate that has no other support than the 2 bolts, could this create a rockin/ slide situation during suspension travel and a potential mid term major failure? if to go with plates this would prolly be better choice. YES i bought these but am conflicted, they feel like if were to use wheel spacers.

southsidemachineperformance.com

southsidemachineperformance.com

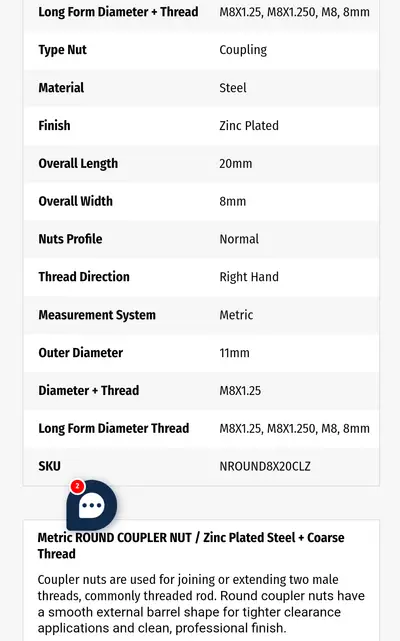

aldan version. https://www.jegs.com/i/Aldan-American-Shocks/038/ALD-39/10002/-1

aldan kit i got.

all the video installs of qa1, aldan, viking, ridetech using stamp steel LCAs A & G bodies not 1 used such a thing. i asked multiple ppl and they all said same thing 'never had a problem', these were on vids older than 4 yrs using OEM equip. the posts i refered to say stock LCAs too weak.

my sometimes small brain would agree with that then i get thinkin... the T bar extends over the edges of that center cone where there's a verticel (sorta) support and if were to add a 1/4" steel plate that has no other support than the 2 bolts, could this create a rockin/ slide situation during suspension travel and a potential mid term major failure? if to go with plates this would prolly be better choice. YES i bought these but am conflicted, they feel like if were to use wheel spacers.

SSM COILOVER REINFORCEMENT PLATES

Coil-Over MountsSold in sets of 2. These plates built and designed by SSM offer the perfect landing for your coil-overs. The new muscle car coilover conversions offered by the spring companies use the lower shock t bar mount to support the entire weight of your car on a spot that was not...

southsidemachineperformance.com

southsidemachineperformance.com

aldan version. https://www.jegs.com/i/Aldan-American-Shocks/038/ALD-39/10002/-1

aldan kit i got.

1978-1988 Cutlass Aldan American Single Adjustable Full Coil-Over Kit, Small Block

1978-1988 Cutlass Aldan American Single Adjustable Full Coil-Over Kit, Small Block

www.ss396.com