You know me. If I get the urge to rebuild a component on the car, it's going to be genuine GM parts if at all possible.

However, we all know GM didn't actually make very many parts for their cars in house. Body components, sure. But lift the hood. You think GM built that alternator? Ok, technically ACDelco did, who was owned by GM at the time, but you know what I mean. Still, even Delco farmed out some of the stuff on their parts, mainly stuff like bearings and fasteners.

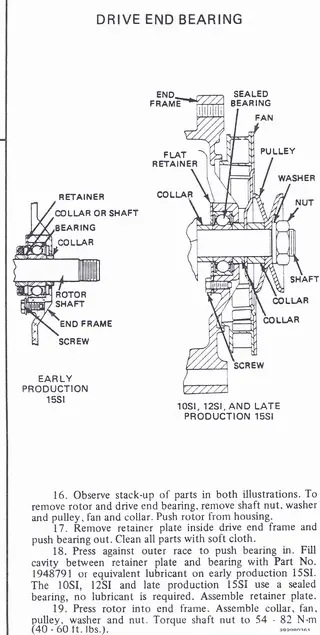

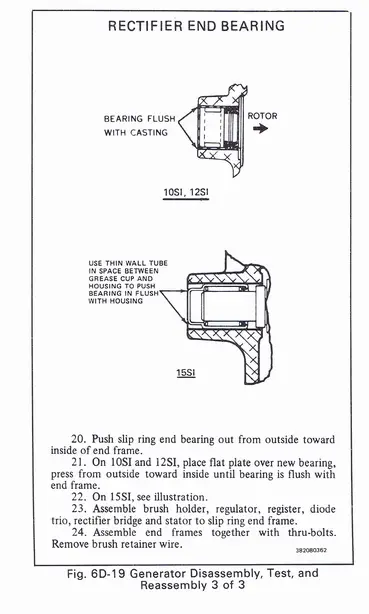

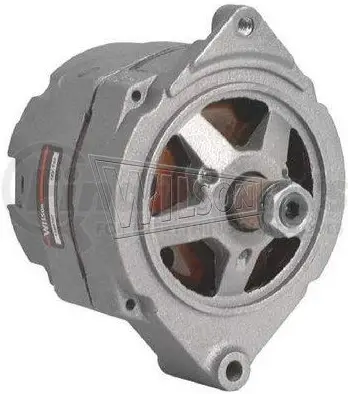

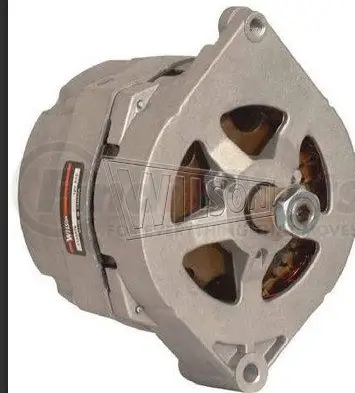

In this case, you have a 12SI type of alternator (In the event you weren't aware, the SI = Systems Integrated. Fancy way to say the regulator is internal to the alternator.) The main two types of alternators used in our cars were, generally, the 10SI and 12SI alternators. The 10SI came in various outputs over the years and maxed out at 63 amps, and 12SI came around for the 83 model year. It had better cooling inlet ports in the back and the metal/plastic exhaust fan in the front. They also came in varying amp output ratings similar to the 10SI, but mostly G-bodies used 12SI with 78 amp rating. Interestingly, the later recommended replacement alternator for the 78 amp version was the highest rated 94 amp one as early as 1990.

Which I said all that to say this. I have some "new" Delco rebuilt alternators (like starters and ECM boxes, 99% of the alternators were rebuilt and rarely sold new for our cars over the counter back then). Still, nothing beats Delco electrical junk for GM cars. I got the alternators from the local dealership when still available, and they look all pretty and new, etc.

But then I got to thinking, I've got the original unit still on the 85. Checked the date code on it. My car was built in mid-February of '85. I was surprised to see the alternator's date code as 5A31. This translates to 1985, January 31 (Thursday). So they apparently were cranking out alternators just prior to getting the cars built during that time frame.

Anyway, I started scoping out parts to rebuild the original alternator with Delco parts. I had managed to scrape some up over the years, but figured I'd just put on a "new" Delco unit and call it a day. But even though you couldn't see the date on it without a mirror, I like the idea of keeping as many parts original to the car if I can make them appear and function as new again. So I got new rectifiers and diodes, resistor, capacitor, brushes, etc., to basically make the alternator like new again. And naturally, all the parts have been discontinued from GM.

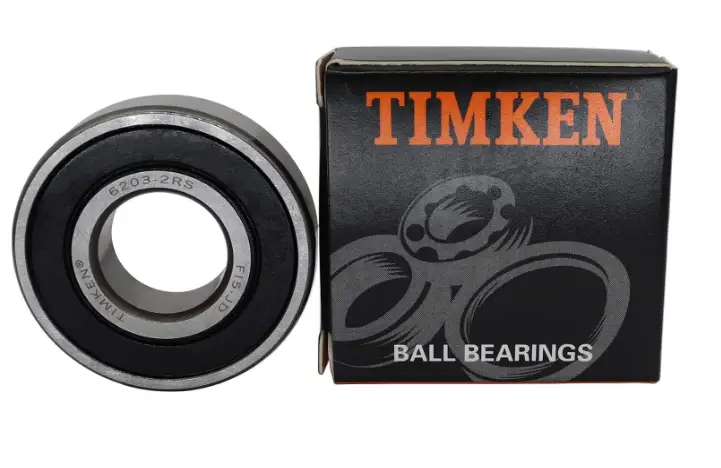

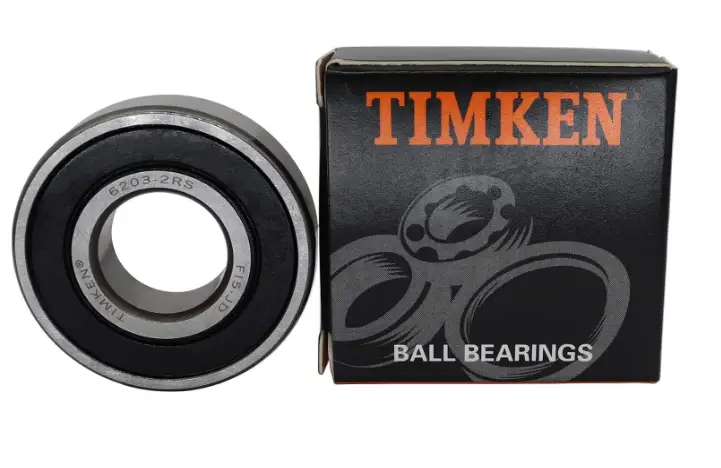

Most of the parts I found were pretty cheap. A few bucks here, a few bucks there. One thing I did find kinda pricey, however, was the front shaft bearing. Cheapest I could find was $25. GM p/n 908419. WTF?? So I look closely at the bearing itself and see a number on it. It's an NTN bearing 6203LU. Aha! There we go.

ACDelco # is Z99503-6. Lessee if we can find out what's what on that. Oh, look, it crosses over to Timken 6203-2RS. (2RS = 2 rubber seals)

Interestingly enough, you can buy a 2 pack of this very bearing for 11 and change at Amazon. 40mm dia. x 17mm ID, x 12mm thick. Not sure where it is made though. China? Just beware. Nothing's like it used to be.

Or, you could buy the NTN (Japan version, later made in Taiwan, probably want the Japan version) bearing and have the SAME bearing they put in the Delco box. Oh, and it's cheap too. $12.95 plus tax on ebay.

As far as the rear bearing, you can see the cap on the rear of the alternator housing.

Delco # MNJ711, or GM p/n 9441879. I found my bearing for like 6 bucks shipped, so I just got the GM one. But....

you can get them for fairly cheap if you know what to look for.

2098512 is the equivalent MoPar part number.

Also, Breman Bearing Company made them as well, under p/n BA613, or CNH11S1511.

And of course, the Delco is a Timken number, MNJ711. (0.936-0.937" diameter, 0.66-0.68" in length, bore diameter for shaft end 0.6694-0.6699")

Good luck parts hunting!

However, we all know GM didn't actually make very many parts for their cars in house. Body components, sure. But lift the hood. You think GM built that alternator? Ok, technically ACDelco did, who was owned by GM at the time, but you know what I mean. Still, even Delco farmed out some of the stuff on their parts, mainly stuff like bearings and fasteners.

In this case, you have a 12SI type of alternator (In the event you weren't aware, the SI = Systems Integrated. Fancy way to say the regulator is internal to the alternator.) The main two types of alternators used in our cars were, generally, the 10SI and 12SI alternators. The 10SI came in various outputs over the years and maxed out at 63 amps, and 12SI came around for the 83 model year. It had better cooling inlet ports in the back and the metal/plastic exhaust fan in the front. They also came in varying amp output ratings similar to the 10SI, but mostly G-bodies used 12SI with 78 amp rating. Interestingly, the later recommended replacement alternator for the 78 amp version was the highest rated 94 amp one as early as 1990.

Which I said all that to say this. I have some "new" Delco rebuilt alternators (like starters and ECM boxes, 99% of the alternators were rebuilt and rarely sold new for our cars over the counter back then). Still, nothing beats Delco electrical junk for GM cars. I got the alternators from the local dealership when still available, and they look all pretty and new, etc.

But then I got to thinking, I've got the original unit still on the 85. Checked the date code on it. My car was built in mid-February of '85. I was surprised to see the alternator's date code as 5A31. This translates to 1985, January 31 (Thursday). So they apparently were cranking out alternators just prior to getting the cars built during that time frame.

Anyway, I started scoping out parts to rebuild the original alternator with Delco parts. I had managed to scrape some up over the years, but figured I'd just put on a "new" Delco unit and call it a day. But even though you couldn't see the date on it without a mirror, I like the idea of keeping as many parts original to the car if I can make them appear and function as new again. So I got new rectifiers and diodes, resistor, capacitor, brushes, etc., to basically make the alternator like new again. And naturally, all the parts have been discontinued from GM.

Most of the parts I found were pretty cheap. A few bucks here, a few bucks there. One thing I did find kinda pricey, however, was the front shaft bearing. Cheapest I could find was $25. GM p/n 908419. WTF?? So I look closely at the bearing itself and see a number on it. It's an NTN bearing 6203LU. Aha! There we go.

ACDelco # is Z99503-6. Lessee if we can find out what's what on that. Oh, look, it crosses over to Timken 6203-2RS. (2RS = 2 rubber seals)

Interestingly enough, you can buy a 2 pack of this very bearing for 11 and change at Amazon. 40mm dia. x 17mm ID, x 12mm thick. Not sure where it is made though. China? Just beware. Nothing's like it used to be.

Or, you could buy the NTN (Japan version, later made in Taiwan, probably want the Japan version) bearing and have the SAME bearing they put in the Delco box. Oh, and it's cheap too. $12.95 plus tax on ebay.

As far as the rear bearing, you can see the cap on the rear of the alternator housing.

Delco # MNJ711, or GM p/n 9441879. I found my bearing for like 6 bucks shipped, so I just got the GM one. But....

you can get them for fairly cheap if you know what to look for.

2098512 is the equivalent MoPar part number.

Also, Breman Bearing Company made them as well, under p/n BA613, or CNH11S1511.

And of course, the Delco is a Timken number, MNJ711. (0.936-0.937" diameter, 0.66-0.68" in length, bore diameter for shaft end 0.6694-0.6699")

Good luck parts hunting!

Last edited: