Time to switch gears- my brain bounces all over so this thread does too...

If you follow the "What Did You Do" thread then you might've seen that I'm gearing up for an intake manifold swap. I hate the manifold I'm currently running as it's been nothing but trouble from the start, and I exacerbated things by using the wrong bolts and stripping threads before utilizing a "Micro Mechanic" to plug some small coolant leaks. Well, my fears have proven to be true: she ain't just leaking coolant. I've got video I can't post, but said video shows my vacuum gauge being a rock solid 17 at idle and my tach fluttering by only 50-100 rpm, and that's what I've had until now. The weather change has affected my engine more than it should so I searched all around for external vacuum leaks, finding but one at the charcoal canister weeks ago that I previously missed. Starting fluid couldn't find any others but instinct told me to check every fastener

again. In doing so I found that the screws holding the top of my carb on were about 1/4 of a turn loose. Every one of them. That's 100% my fault because I put that thing on. After I tightened them things changed for the worse- it became obvious that I have a leak because my steady vacuum gauge now "hunts". Dun-dun-dunnnn....

You might've heard that I purchased a new radiator and hope to install it soon due to a leaky core, and the holdup is the intake setup. If I'm going to drain the coolant I might as well only do it once. The intake swap means that I can finally use the absolutely beautiful carburetor that 78delta88 painstakingly built for me and paid extra to ship to me immediately, and I'm embarrassed and ashamed that it's taken me 6 months to install it. I'd hoped an inferior ignition system caused the issues such as surging that cropped up when I mounted the carb for a short time, but it now appears that those are likely due to an internal air leak. Yay lean surge.

I don't want to put the stock manifold back on and can't afford to buy another, even @ $150, so I'm using what I've got: a Weiand Stealth. To bolt a Rochester on top you need an adapter, but this just turns your intake charge into turbulence. The solution is to blend the spreadbore pattern into the manifold and radius all the edges, so after tracing two different adapters I chose to modify a piece of crap from Spectre using a die grinder and some bits made for wood. I left 1/4" of gasket surface where I modified the manifold.

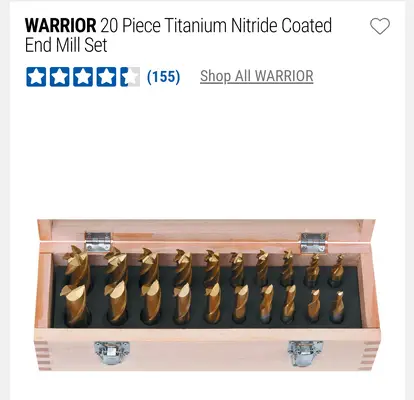

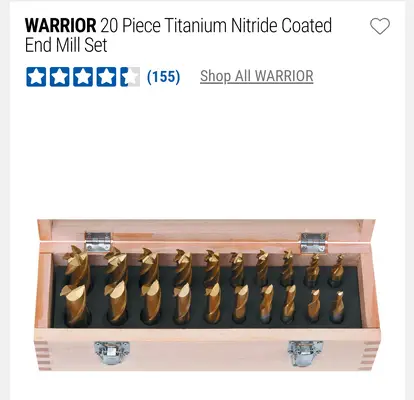

The adapter was only meant to bolt a Holley to a Rochester manifold so the spreadbore bolt holes had recesses but the Holley ones were threaded, and weren't even in the right spots. I drilled out the holes, enlarged the recesses off center to fix things, and added recesses to the other side using Harbor Freight "plunge cut end mills" in their $25 drill press, making things fit the intake so snug it can't even move 1/16" when loose. I made the half that feeds the lower plane slightly smaller since I think this intake has the most plenum volume of any SBC dual plane. Not ideal for a 305 but it'll work- the Stealth is a phenomenal intake.

The adapter required threads for the carb bolts so I used JB Weld to secure some nuts in the recesses I made. Cooking spray on the threads kept the epoxy from locking the bolts in place and pieces of drinking straw acted as a dam for the other holes. While it was still soft I removed the bolts and shaved the adapter with a knife.

Then I reinstalled the bolts with more butter and completely covered them with epoxy, securing the nuts as best I could. A razor blade was used to get the flattest plane possible before I drilled the epoxy with a 17/64" bit and followed that with a 5/16-18 thread chaser. I don't expect the epoxy to serve as a nut but didn't want the bolts to snag or push anything out so threads were necessary. I could add a bit more epoxy but may not.

The bolts supplied with the adapter are also junk so I secured some Allen socket Button Heads and trimmed them to just fit in their homes. I chose these because they have a much shorter head profile than the standard Allen socket Cap Screw and I made my recesses shallow to avoid major issues.

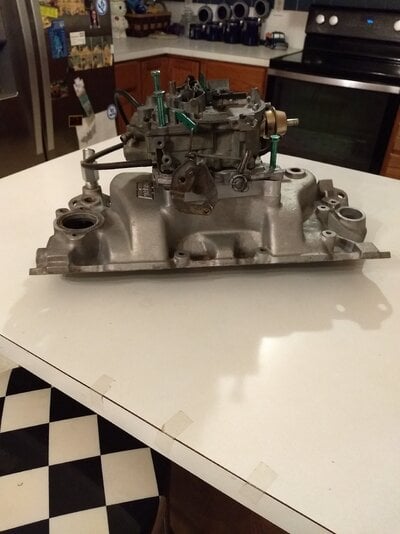

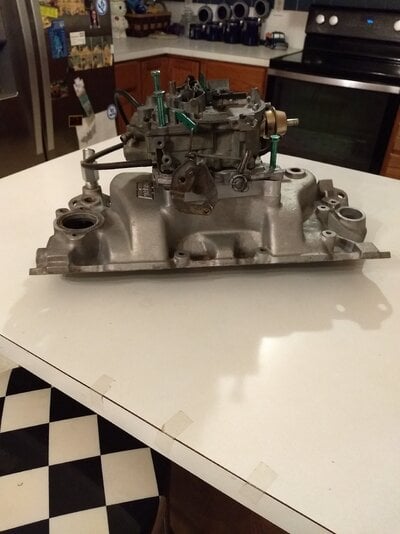

Now I have this:

But I'm going to add this to the heat insulator gasket:

Yeah, at 1/8" it's twice as thick as normal but I see no problem with that, though the 10" x 14" heat shield will need plenty of trimming. I know it's winter. I know it's not a race car. I also know that if I installed this in the summer I wouldn't remove it for winter, and it'll bolt right into any engine I use. The soon to be cold carb has a choke and the intake is heated by exhaust so winter driving should be no issue as long as I use the correct gas line antifreeze and not kerosene.