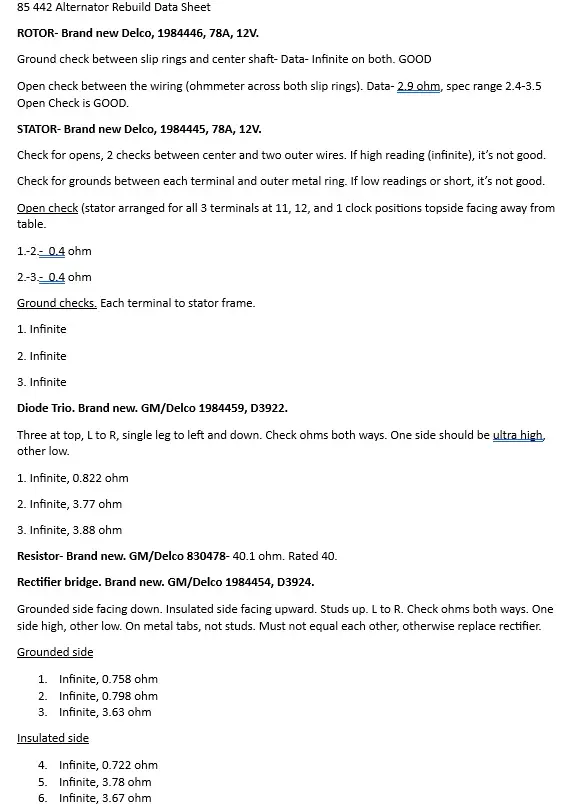

So for funsies, I was looking at a few alternator videos by people I believe know wtf they're doing. One video had an experienced electrician redoing an alternator. In it, he had some recommendations that seemed to make sense. At least to me.

One of the deals was that he said since most stators have naked terminals, ACDelco stators no exception, and they come EVER SO CLOSE to the rectifier fins, which are grounded, one wrong bend and one or more of the stator wires are touching the rectifier and grounding out. He said use a couple wraps of 3M Super 88 tape, since it is thicker, has better heat resistance, and unless you have some super shrinkable heat shrink tubing, it will do the job. He swears by it.

Here's a 10SI single wire alternator showing the stator terminals attached to the rectifier (circled in yellow). It's very similar to the 12SI. The stator connector wires end up very close to the rectifier bridge which is grounded. It would suck to do all that work and short out your alternator.

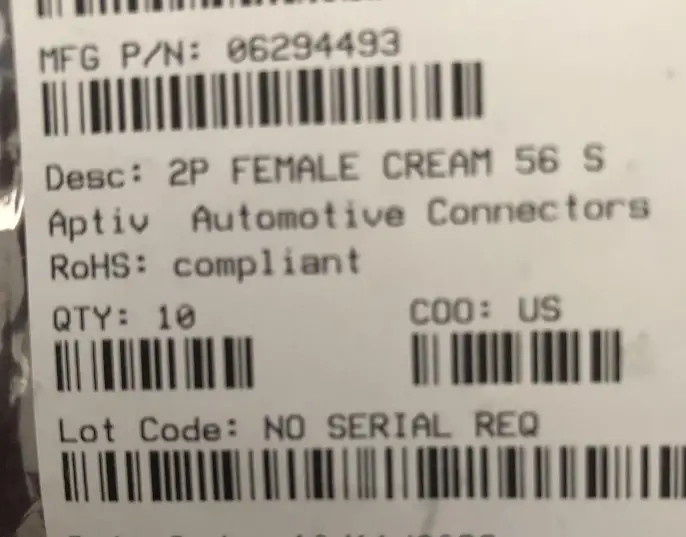

So this is what I used. The goal isn't to make a water/air tight seal. Grounding protection only. Just stretch it slightly while wrapping and it will make a perfect anti-grounding boot near the terminal end.

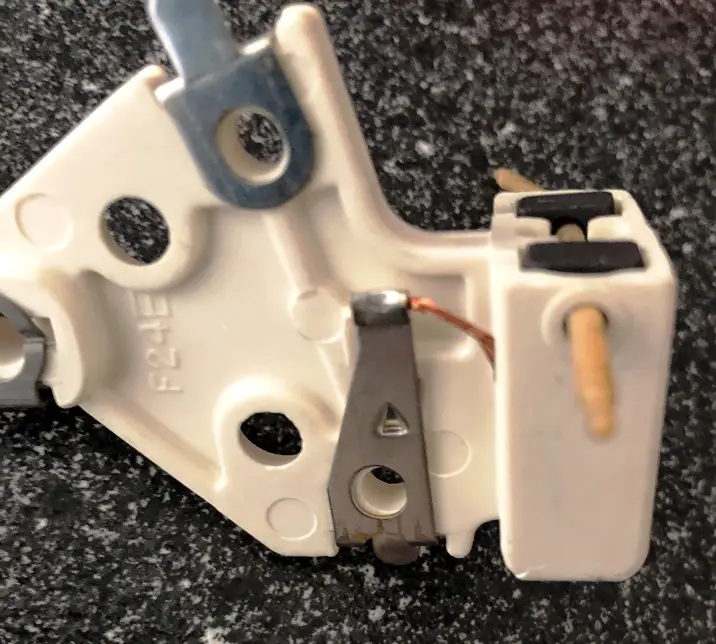

Another tip that made sense to me is the brush wire positions. It's free, costs nothing but about 2 seconds of time to extend brush life. When the brush assembly is in the box, it may come to you where the wiring is bowed toward the slip rings on the alternator. While it's not an issue when the brushes are new and long, over time the brushes wear, and the wires can move forward toward the slip rings. And eventually they could possibly touch the slip rings, wear through and stop the power generation.

As you can see here, this is how MOST of the brush holders come from the vendors who sell them. Left and Right sides are the same. ACDelco, in this instance, was no different. Note the position of the brush wire. As the brush wears against the slip rings, the wires would move closer and closer to the slip rings, possibly touching the rings depending on how bad the brush wear was, and wear through. Not a good situation. The brush blocks are supposed to be the wear items, not the wire.

As you can see below, it just takes the end of a pen and gently bend the wire back the other way. This way, as the brush wears, the wire should never come in contact with the slip rings.

Others on this forum can tell you, the devil's in the details. A little extra time and care and you're golden and get more life out of your alternator.

The only real torque setting you need to remember is that the pulley nut is 40-60 lbs/ft. The rest of the screws should be fully seated snugly and not stripped. That's it for now. Gotta wait until I get the housings back.