1985 442 78 Amp 12SI Alternator Restoration

- Thread starter 69hurstolds

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

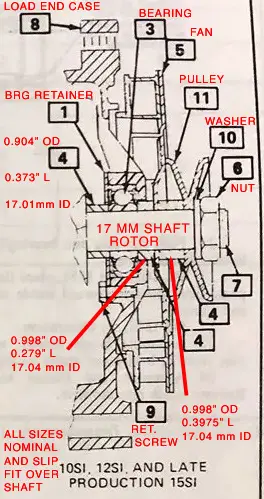

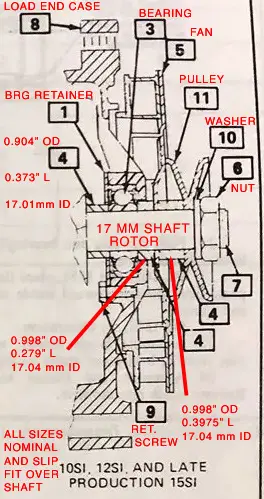

Just wanted to add to the data sheet here in case anyone loses a collar/spacer doing a job like this and needs to make one or in the event they forget which goes where. I measured the spacers for a couple of the 12SI alternators. The outer 2 checked out as 0.998" nominal OD. (25.4 mm) For the single V-type pulley, the pulley end collar is 0.3975" (10 mm) thick x 0.669" ID (17.04 mm) nominal size. I have one as 0.3965 and another as 0.3985. Split the difference. The stack spacer behind the pulley spacer (still outside) is 0.279" nominal (7.1mm) x 0.674" ID. This smaller one goes on the outside first, then the pulley spacer, then the pulley and nut/washer.

The inner collar which slides on the shaft and sits next to the rotor windings (can't see it once the alternator is together) goes on before installing the rotor through the front bearing. It's smaller OD, at 0.904" (22.94 mm) x 0.373" thick (9.46 mm). Still has a 17.01 mm diameter to slip over the 17mm rotor shaft.

Basically, starting from the rotor, medium (p/n 1975350), thinnest (p/n 1984476), and fattest (p/n 1978064) next to the pulley. The one next to the rotor also has the smallest OD. I've seen them with the same basic sizes with all sorts of different part numbers, but you can usually find them by size. I guess it doesn't really make much difference in the outer 2 spacers which goes where, but I'm putting it back together like Delco built it. Skinny in the middle.

I edited the CSM drawing to show the sizes. Keep in mind these are nominal sizes for a single V-belt pulley, such as on the 307 V8 cars, and MOST G-bodies that I can see. The only spacer that seems to change part numbers is the skinny middle one. Every now and again I see the rotor (inside) spacer as 1986000 which is 9.5mm in length and 22.23 mm OD, but still in the same ball park as the 1975350. Meaning they're not exact from part to part. The idea is a smooth slip fit over the rotor shaft without binding but not sloppy either. Whenever you take one of these apart, it's probably best NOT to lose the spacers.

The inner collar which slides on the shaft and sits next to the rotor windings (can't see it once the alternator is together) goes on before installing the rotor through the front bearing. It's smaller OD, at 0.904" (22.94 mm) x 0.373" thick (9.46 mm). Still has a 17.01 mm diameter to slip over the 17mm rotor shaft.

Basically, starting from the rotor, medium (p/n 1975350), thinnest (p/n 1984476), and fattest (p/n 1978064) next to the pulley. The one next to the rotor also has the smallest OD. I've seen them with the same basic sizes with all sorts of different part numbers, but you can usually find them by size. I guess it doesn't really make much difference in the outer 2 spacers which goes where, but I'm putting it back together like Delco built it. Skinny in the middle.

I edited the CSM drawing to show the sizes. Keep in mind these are nominal sizes for a single V-belt pulley, such as on the 307 V8 cars, and MOST G-bodies that I can see. The only spacer that seems to change part numbers is the skinny middle one. Every now and again I see the rotor (inside) spacer as 1986000 which is 9.5mm in length and 22.23 mm OD, but still in the same ball park as the 1975350. Meaning they're not exact from part to part. The idea is a smooth slip fit over the rotor shaft without binding but not sloppy either. Whenever you take one of these apart, it's probably best NOT to lose the spacers.

True. Factory and GM replacement stators don't have any insulation on the terminals or wire on the terminal ends. You need to do that yourself if you want it done. Some aftermarket units, like in your picture, actually do have sleeves or other protection from grounding. Not a horrible idea.Okay "I think" I see what you mean now, the stator field wire ends are terminated but not insulated as built.

View attachment 234202

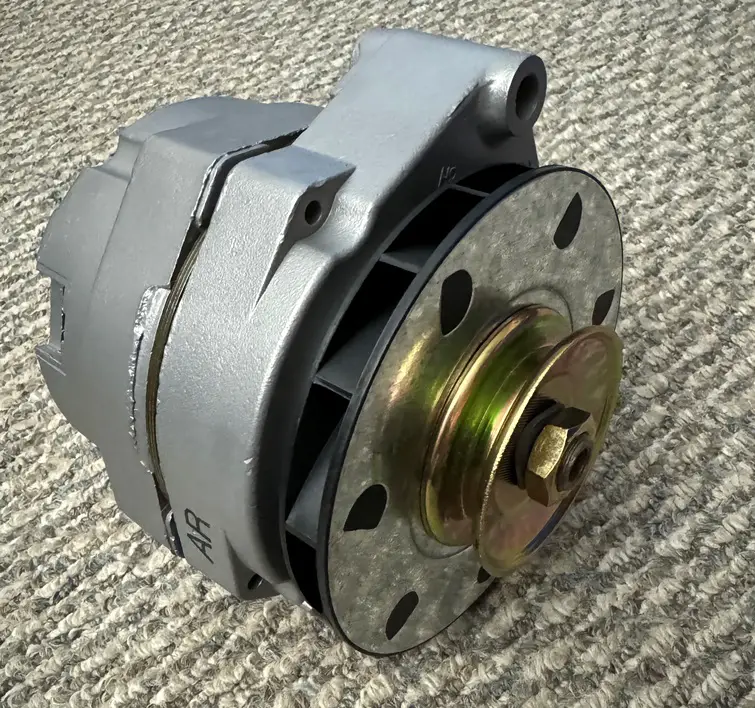

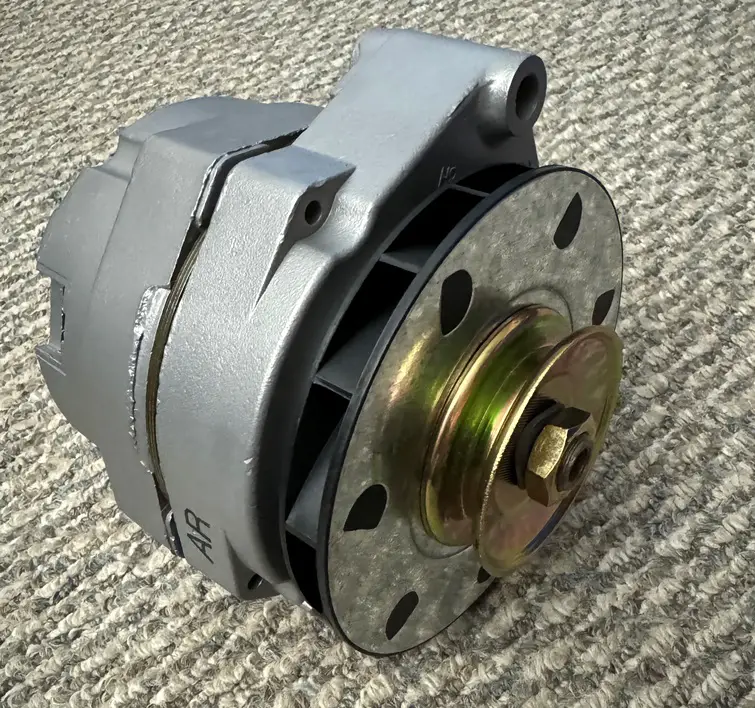

I thought the alternator was lost somewhere. 🙂 Hadn't heard from the guy I sent it to for refinishing the hardware and shells in a while. He is considered one of the best in the business for refurbishing alternators and starters and junk. So I tapped his shoulder last night.

He sent some pics today. He's waiting for the plater to get done with the bright zinc bits and then it's pay the final bill and I get my junk back. Apparently the plater guy's nickname must be "Sloth". If not, it should be. Must work for the USPS.

I'm also getting the restamp of the "AR" on it as per original. It was so dirty when I took it off I glanced to see if it had a stamp and missed it (it's at the bottom inside when mounted on the car so you can't really see it anyway). When the guy was cleaning it he alerted me to the stamping and asked if I wanted him to redo the stamp. Well, sure. That's how it came.

Only issue is that the font he used for the stamp is incorrect Helvetica. Oh, well. Nobody's going to see it anyway. I might figure out how to rub it off and restamp it with the correct font stamp, which is a slightly narrowed Arial Black. Or maybe not.

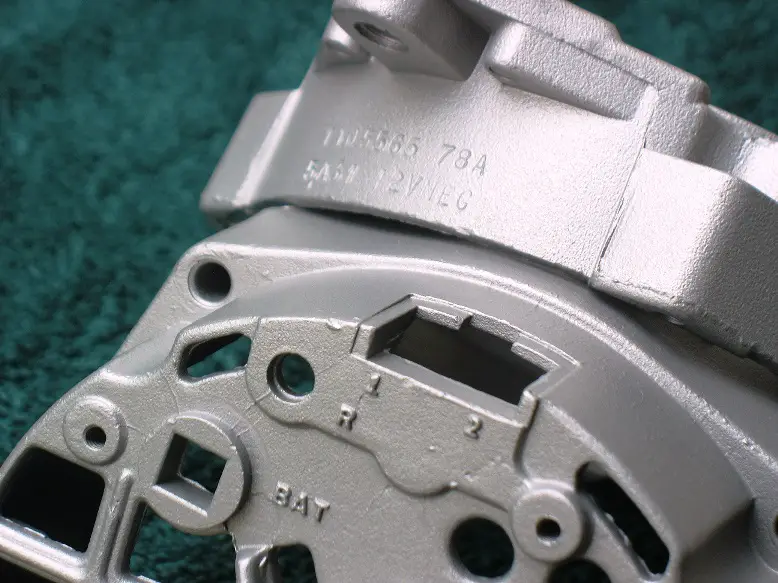

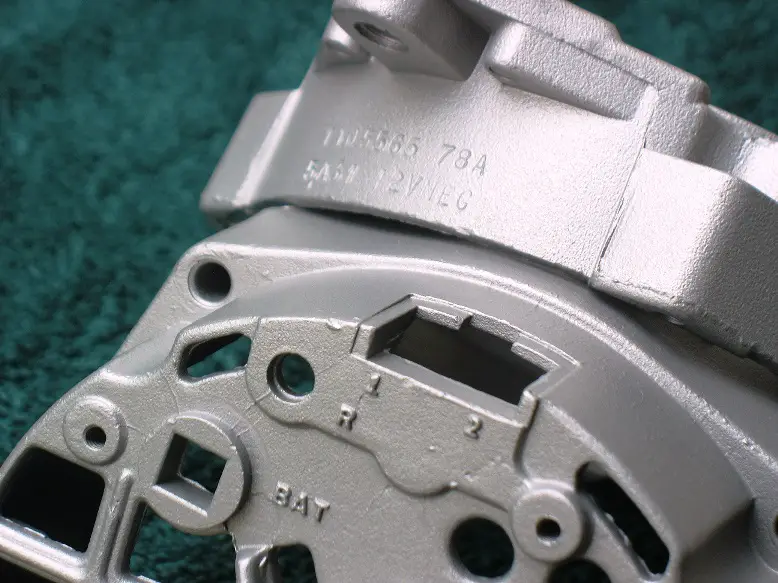

The alternator looks a little better than it shows here. It's a bit brighter and shinier than the pics show. But it looks so much better than when I took it off.

These are gray phosphate.

Hey look, an adjuster screw stop being refinished in black oxide. rfpowerdude will want to steal it. I got other bolts I tossed in too for refinishing.

Original and a spare pulley and nut.

AR stamp

Alternator bracket

He sent some pics today. He's waiting for the plater to get done with the bright zinc bits and then it's pay the final bill and I get my junk back. Apparently the plater guy's nickname must be "Sloth". If not, it should be. Must work for the USPS.

I'm also getting the restamp of the "AR" on it as per original. It was so dirty when I took it off I glanced to see if it had a stamp and missed it (it's at the bottom inside when mounted on the car so you can't really see it anyway). When the guy was cleaning it he alerted me to the stamping and asked if I wanted him to redo the stamp. Well, sure. That's how it came.

Only issue is that the font he used for the stamp is incorrect Helvetica. Oh, well. Nobody's going to see it anyway. I might figure out how to rub it off and restamp it with the correct font stamp, which is a slightly narrowed Arial Black. Or maybe not.

The alternator looks a little better than it shows here. It's a bit brighter and shinier than the pics show. But it looks so much better than when I took it off.

These are gray phosphate.

Hey look, an adjuster screw stop being refinished in black oxide. rfpowerdude will want to steal it. I got other bolts I tossed in too for refinishing.

Original and a spare pulley and nut.

AR stamp

Alternator bracket

From what I understand of the process as described to me: The aluminum parts were ash blasted or some stupid stuff like that. A very very light abrasive medium. Then, the aluminum was plated with some sort of aluminized coating which afterwards, doesn't have much shine to it. Then, it gets a light spritzing of some sort of semi-flat clear to give it a basic glimmer. That's all I know. I might be off on that, but that's my interpretation.Did he paint the aluminum parts?

Kinda looks like it was sprayed.

I'm not sure how ACDelco used to do it, but they managed to clean the aluminum to give it a new look to it. So from that perspective, I know it CAN be done, but what process? Cost-effectiveness, etc.?

I don't really know for sure. I haven't got them in hand yet. They're in "plater's jail" for some friggin' reason, waiting on the bright zinc parts to be redone.

I'm not in any real hurry, but I also didn't think it would take THIS long to still not have my sh*t back.

That reminds me, I think I'm going to shoot an email that way and see what's up with that...

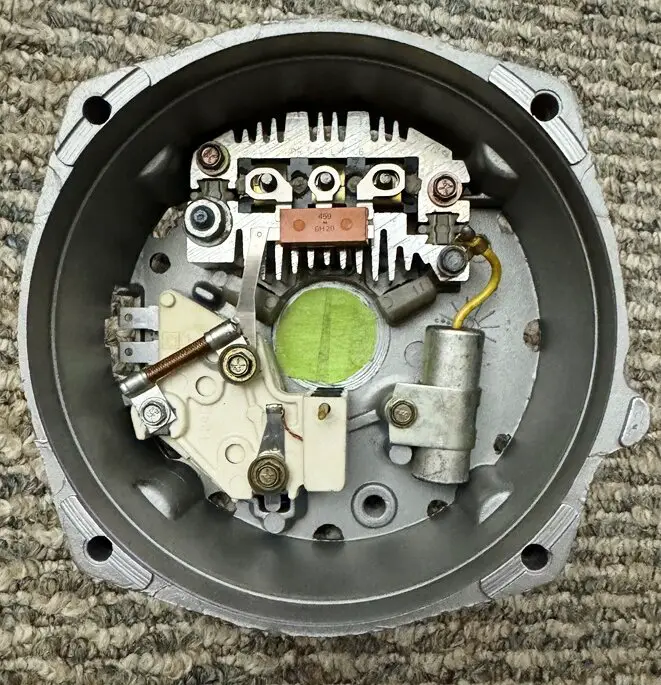

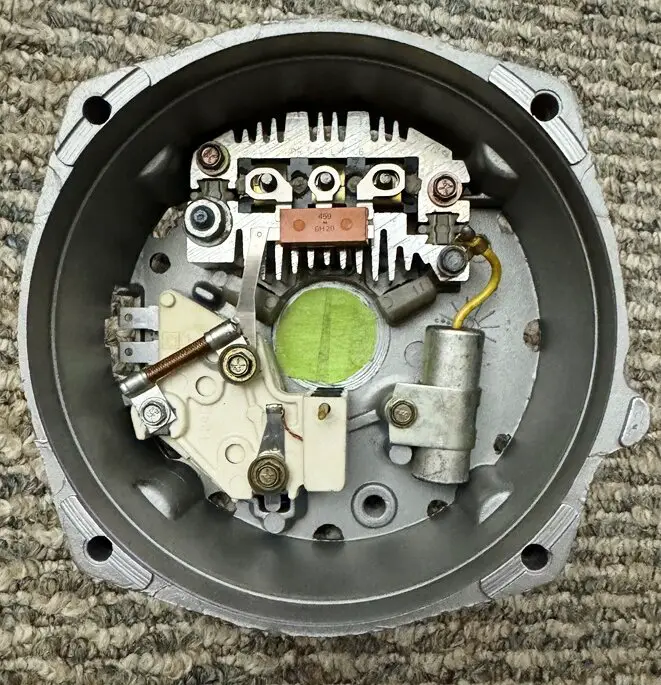

Finally! Got my alternator parts back. UPS dropped it off a little before 6:30 pm. Been so long that I've almost forgot what goes where. Good thing I labeled junk. I drug out my parts and my baby sockets and watching a baseball game on TV, I put together the alternator as far as I could.

It was nice working with "fresh" clean, pristine, parts. And having all new Delco junk to toss in was just a bonus. I freaked a second after trying to put the rotor in the stator it kept popping out. I guess some pole magnetism going on? Anyway it spins nice and smooooooth. No abnormal noises, no scraping or wobbling of anything. I yanked out the Delco-supplied "toothpick" for the brushes and it is essentially done. If you put your ear up close, you can hear the brushes rubbing on the commutators, but that's it. I still have to ugga dugga the pulley nut on, but that will finish up the job. I'll do that tomorrow outside or in the garage or shop as the wife wouldn't appreciate me doing it in the house.

Just a trip down memory lane...

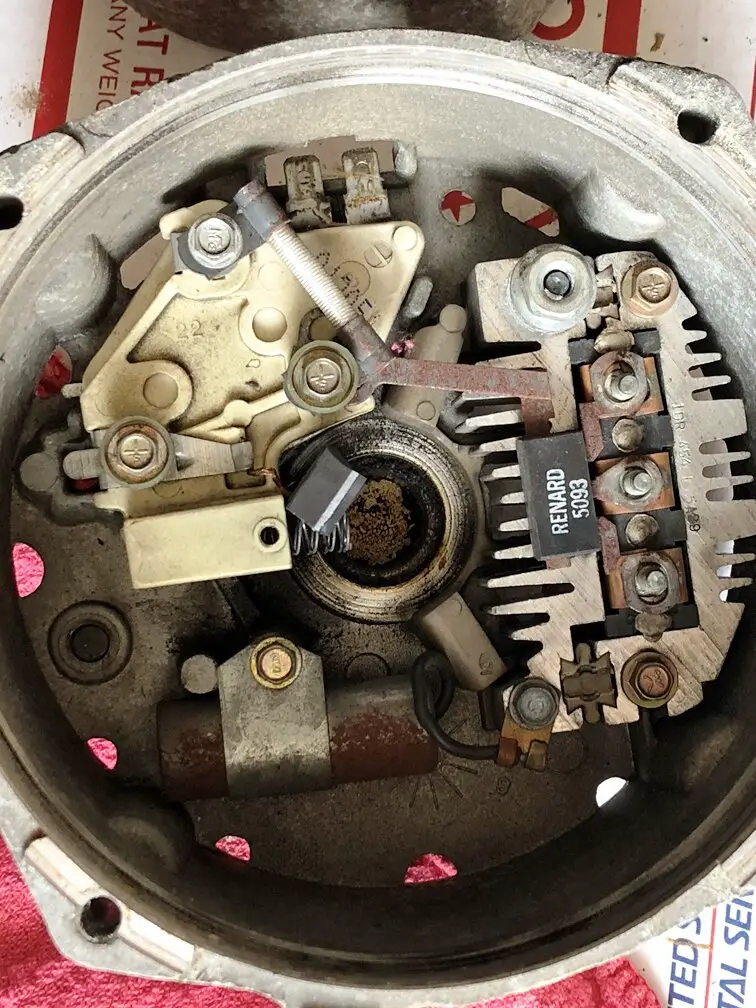

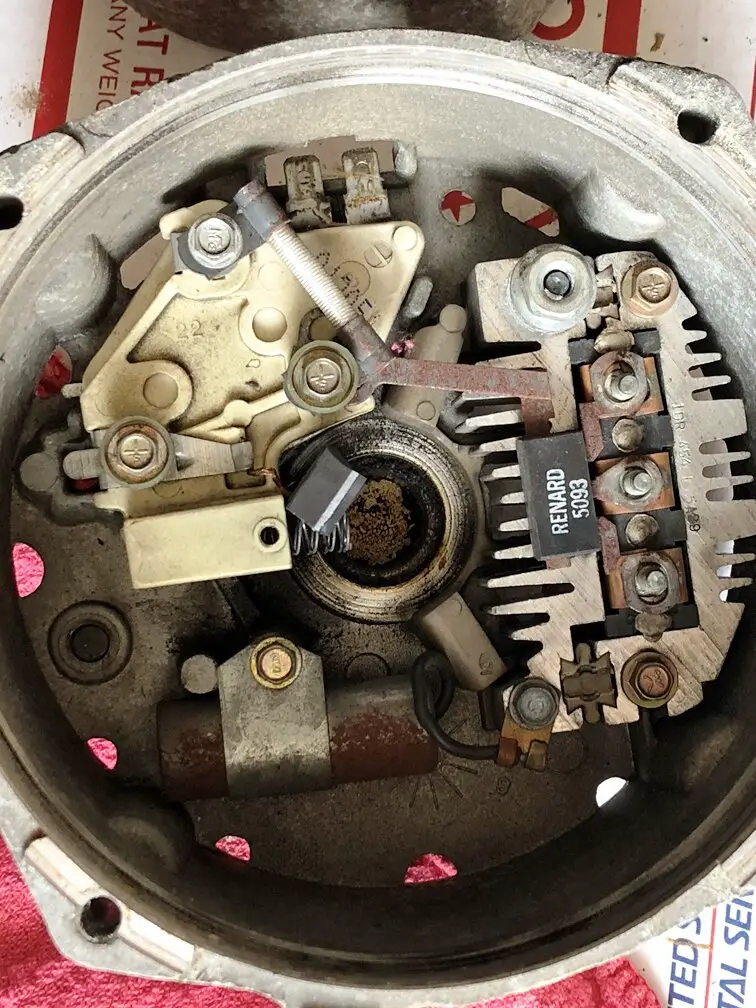

What it started out as:

The new parts were great to use. Plus they fit like they were made for it. Oh, yeah, they were. I was nearly chastised for asking about whether the shells were painted/coated. I was thinking of someone else's procedures apparently. No ands if or buts, it is not a coating on the aluminum I was told. I tried to scratch it on the insde of the casing but all I got was an indentation with shiny aluminum under the scratch. No flaking or paint or coating. I guess it's because it came out that way because of whatever it was pelted with in the blaster. I'm still not convinced it's the right look, though. A tad darker than normal aluminum based on the remans I got from ACDelco before. But still decent. Although, it's all one color, so I suppose it'll work. If it bugs me TOO much, I'll just take it apart and mist it with aluma-blast or something. It was original to the car, so there's that.

It was nice working with "fresh" clean, pristine, parts. And having all new Delco junk to toss in was just a bonus. I freaked a second after trying to put the rotor in the stator it kept popping out. I guess some pole magnetism going on? Anyway it spins nice and smooooooth. No abnormal noises, no scraping or wobbling of anything. I yanked out the Delco-supplied "toothpick" for the brushes and it is essentially done. If you put your ear up close, you can hear the brushes rubbing on the commutators, but that's it. I still have to ugga dugga the pulley nut on, but that will finish up the job. I'll do that tomorrow outside or in the garage or shop as the wife wouldn't appreciate me doing it in the house.

Just a trip down memory lane...

What it started out as:

The new parts were great to use. Plus they fit like they were made for it. Oh, yeah, they were. I was nearly chastised for asking about whether the shells were painted/coated. I was thinking of someone else's procedures apparently. No ands if or buts, it is not a coating on the aluminum I was told. I tried to scratch it on the insde of the casing but all I got was an indentation with shiny aluminum under the scratch. No flaking or paint or coating. I guess it's because it came out that way because of whatever it was pelted with in the blaster. I'm still not convinced it's the right look, though. A tad darker than normal aluminum based on the remans I got from ACDelco before. But still decent. Although, it's all one color, so I suppose it'll work. If it bugs me TOO much, I'll just take it apart and mist it with aluma-blast or something. It was original to the car, so there's that.

Attachments

We are going at it again...this time for an 84 12SI.

...related thread.

...related thread.

Why? Because I can.

I have leftover pieces parts from the 85 rebuild, so rather than let them go to waste, I figure I'll just go ahead and buy a few more sundry items and run the gambit on rebuilding a mid-year 1984 78A alternator as well. This is the alternator which was on my 84 H/O when I got it. It wasn't even made until after the H/Os were built that year, so I know it isn't the original. I won't be replacing the rotor and stator with new, however, as I cannot find any NOS ones. But the rotor/stator checked out fine electrically on the 85 original pieces with 60K miles, so I'm...

I have leftover pieces parts from the 85 rebuild, so rather than let them go to waste, I figure I'll just go ahead and buy a few more sundry items and run the gambit on rebuilding a mid-year 1984 78A alternator as well. This is the alternator which was on my 84 H/O when I got it. It wasn't even made until after the H/Os were built that year, so I know it isn't the original. I won't be replacing the rotor and stator with new, however, as I cannot find any NOS ones. But the rotor/stator checked out fine electrically on the 85 original pieces with 60K miles, so I'm...

- 69hurstolds

- Replies: 6

- Forum: Restoration

Similar threads

- Replies

- 3

- Views

- 231

- Replies

- 21

- Views

- 3K

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.