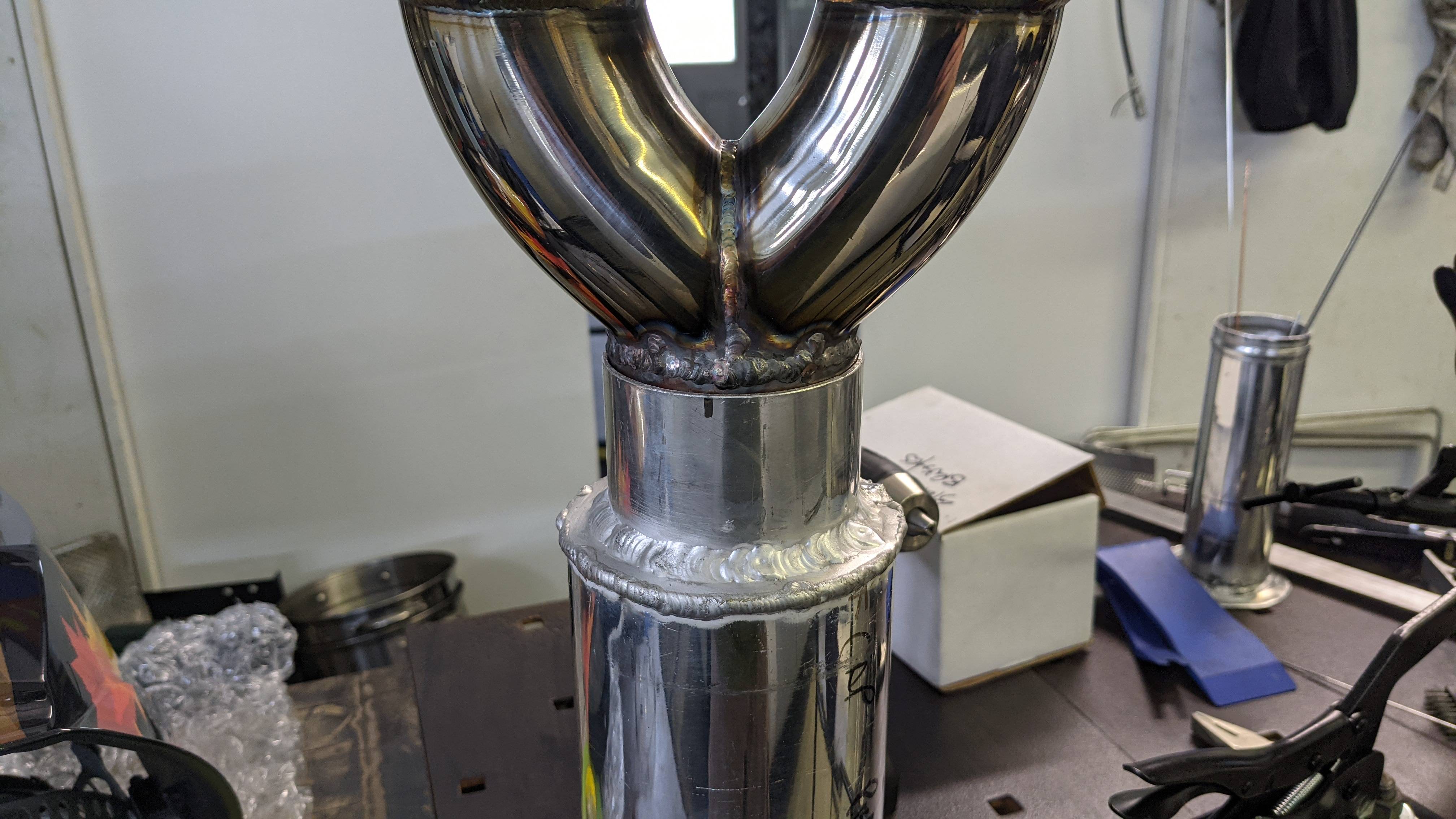

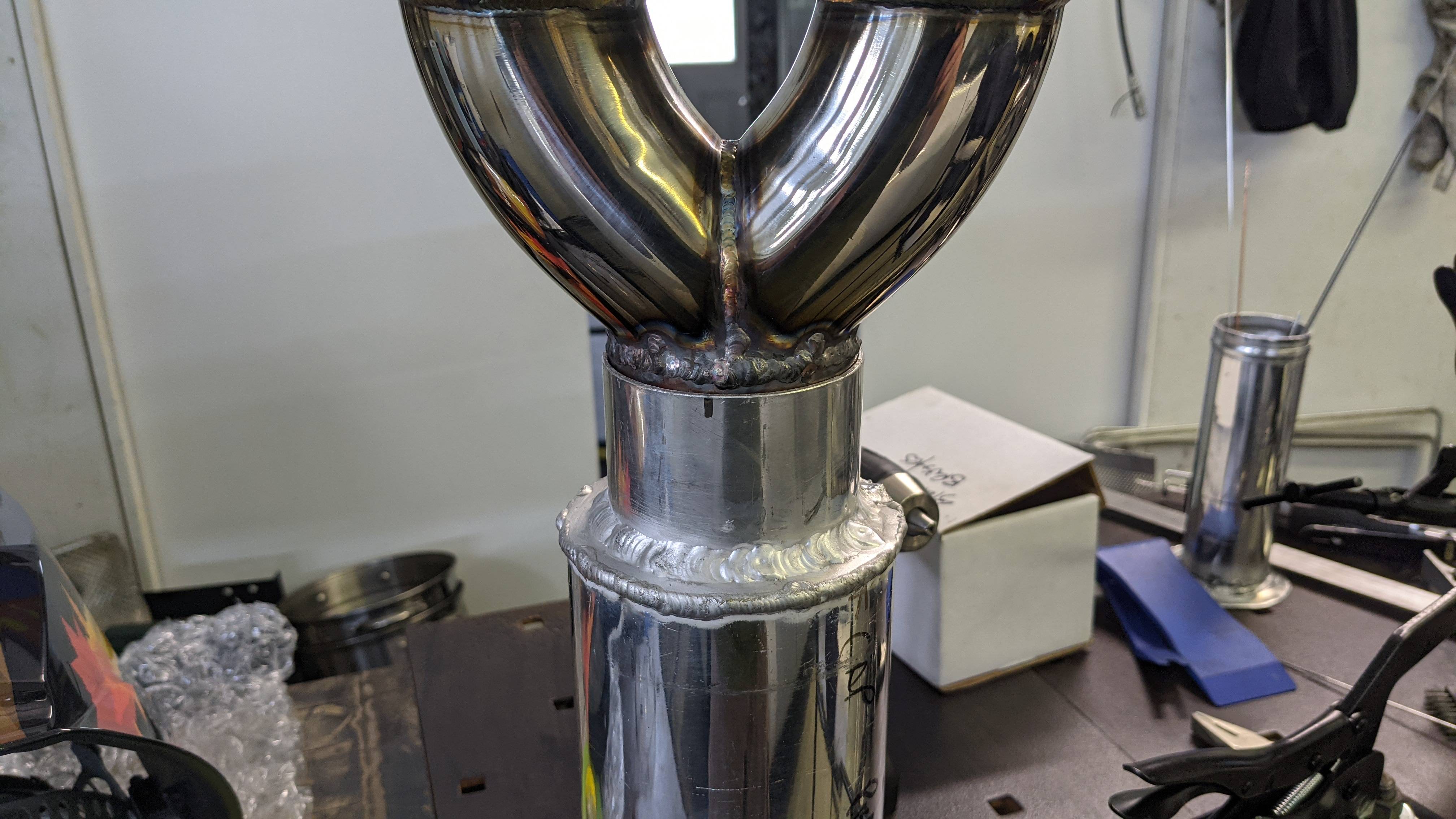

That cross over port is more even & looks better than my brand name one. The cross over port on it is far from even.

2019 Challenger Widebooty HellKitty (she's giving me the meatsweats...)

- Thread starter motorheadmike

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

That cross over port is more even & looks better than my brand name one. The cross over port on it is far from even.

I would hope so, I used a laser.

Last edited:

What diameter is this again? 3"? Is stock 3" also?

Any performance to be gained from blow beyond weight?

Any performance to be gained from blow beyond weight?

What diameter is this again? 3"? Is stock 3" also?

Any performance to be gained from blow beyond weight?

This is 3". Stock is 2.75", and it highly improbable there is a single ounce of power available in the exhaust. So we're just making what is available more effective by making the car lighter. That's it.

Call me: Optimization Prime!

A little tinfoil to cup shielding gas into curves like that makes a world of difference. It'll get you a little more tungsten extension from the cup for tight spots.

Clamps will be here tomorrow.

But, yeah - the 0 to 60 on this should be quick.

And then it snowballed.

Played with my tip(s) today. Interesting switching from months of welding AC back to DC. Much quieter.

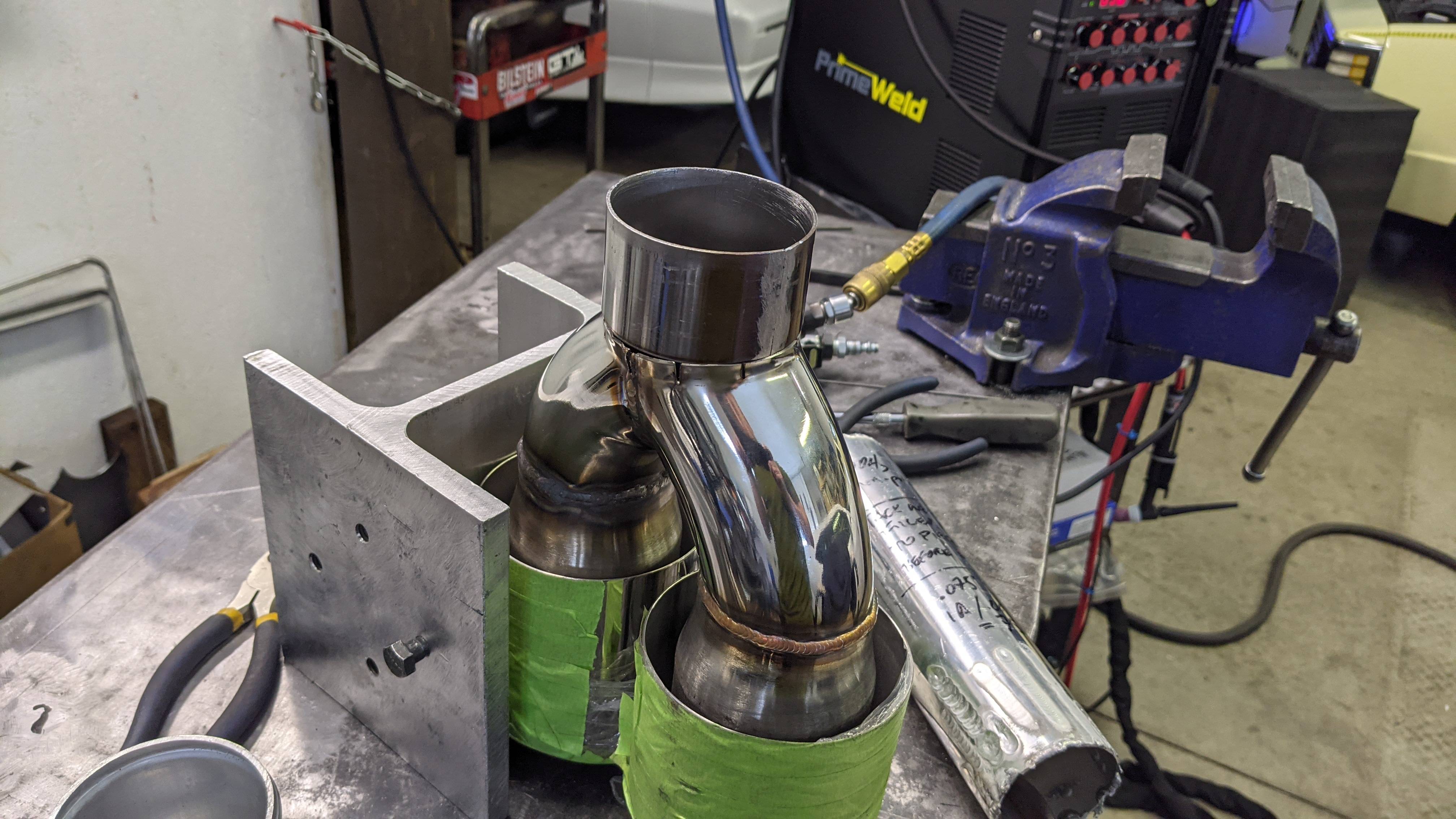

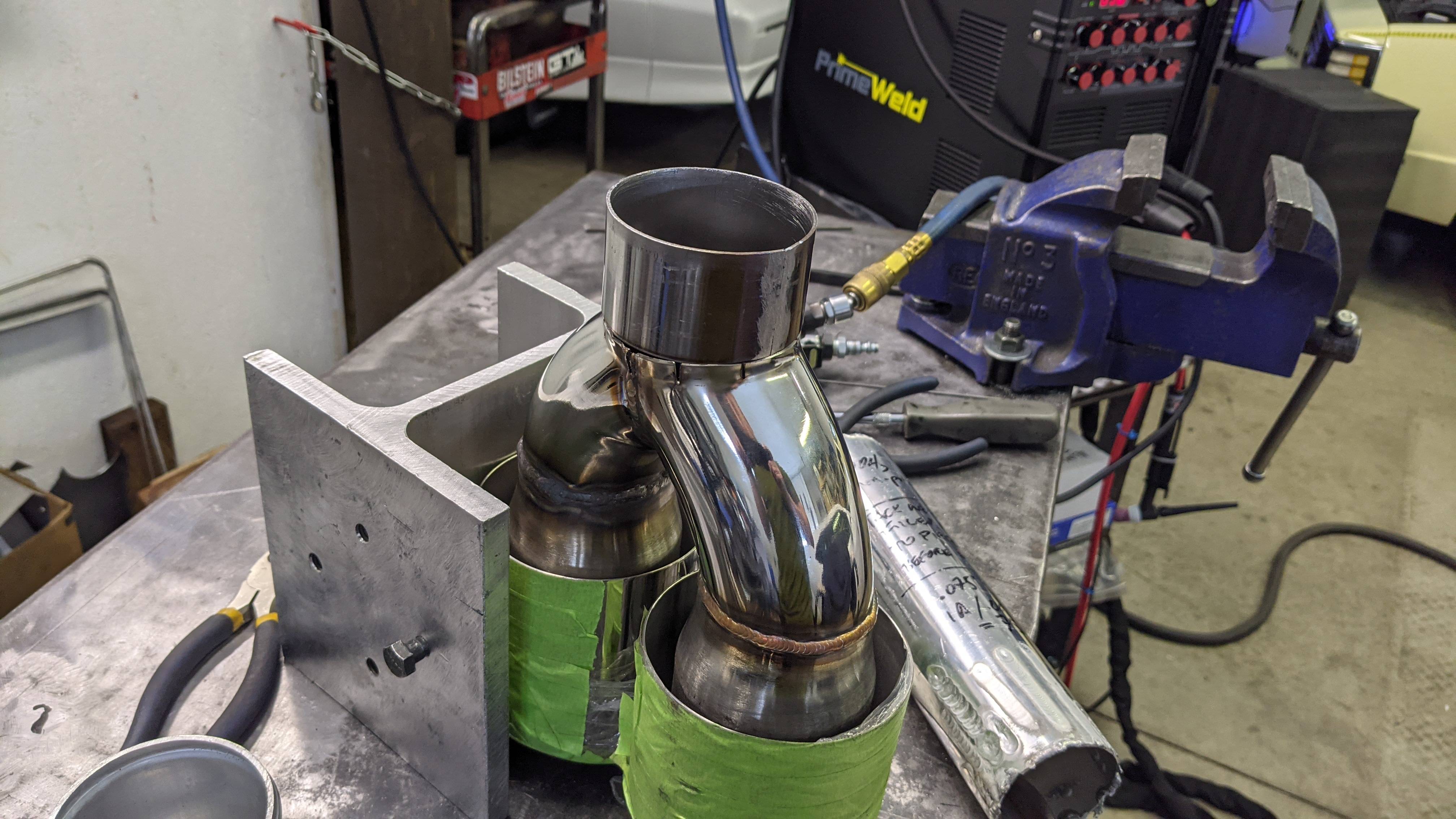

The first thing I had to do was straighten one of the four outlets. It was cocked-eyed in and up. Once that was done it was a matter of adapting the tips to the mufflers. The tips did not have any mounting provisions, so I had to make some. Additionally the inlet to the tips was around 2.65" OD, now it's about 2.85" - and they slip into the mufflers giving a good surface to clamp to.

There is adequate material to trim the mufflers down if needed. But, at first blush my math is accurate. I'll put the car up in a few and finish this project up over the coming week.

The first thing I had to do was straighten one of the four outlets. It was cocked-eyed in and up. Once that was done it was a matter of adapting the tips to the mufflers. The tips did not have any mounting provisions, so I had to make some. Additionally the inlet to the tips was around 2.65" OD, now it's about 2.85" - and they slip into the mufflers giving a good surface to clamp to.

There is adequate material to trim the mufflers down if needed. But, at first blush my math is accurate. I'll put the car up in a few and finish this project up over the coming week.

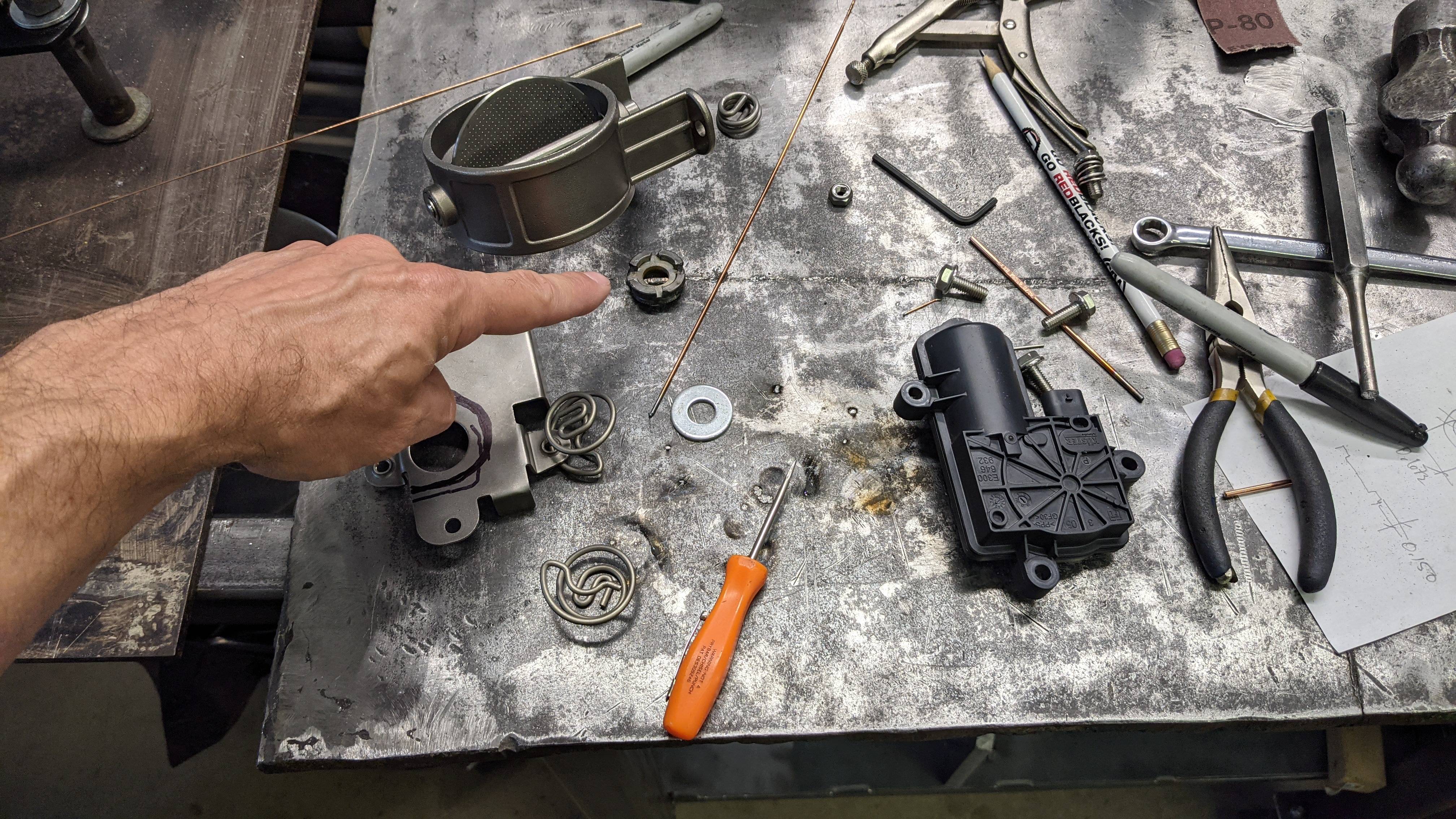

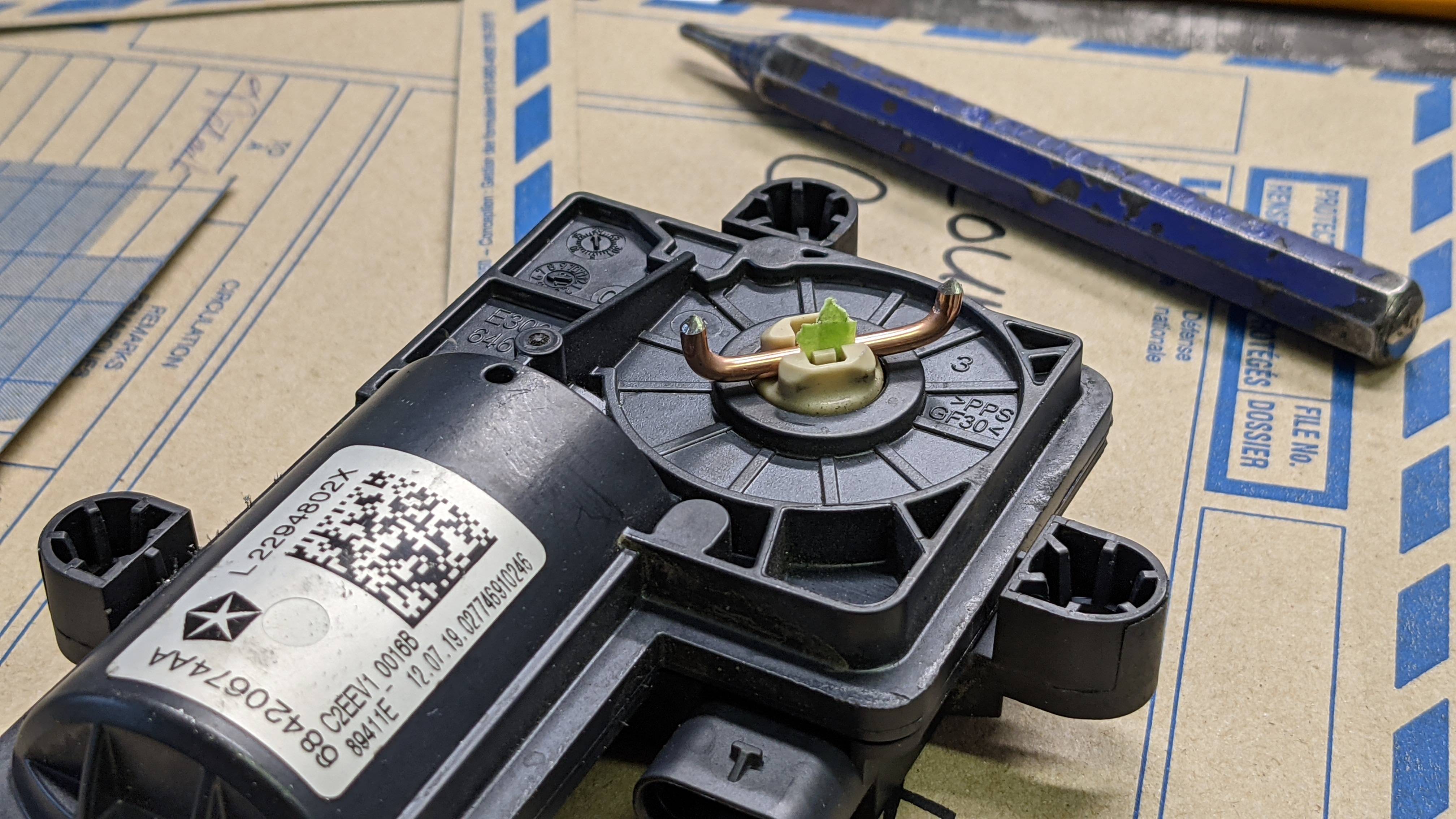

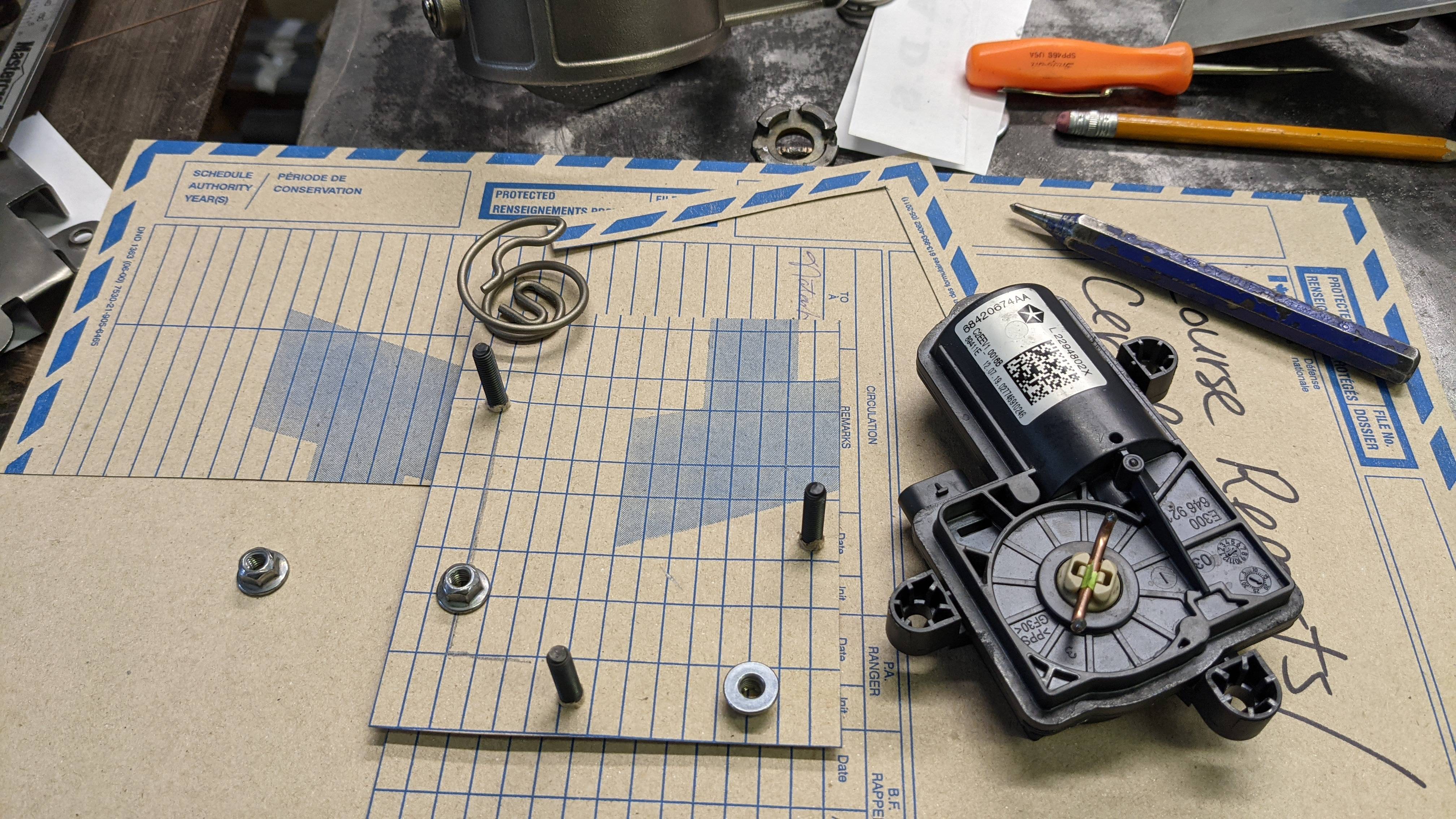

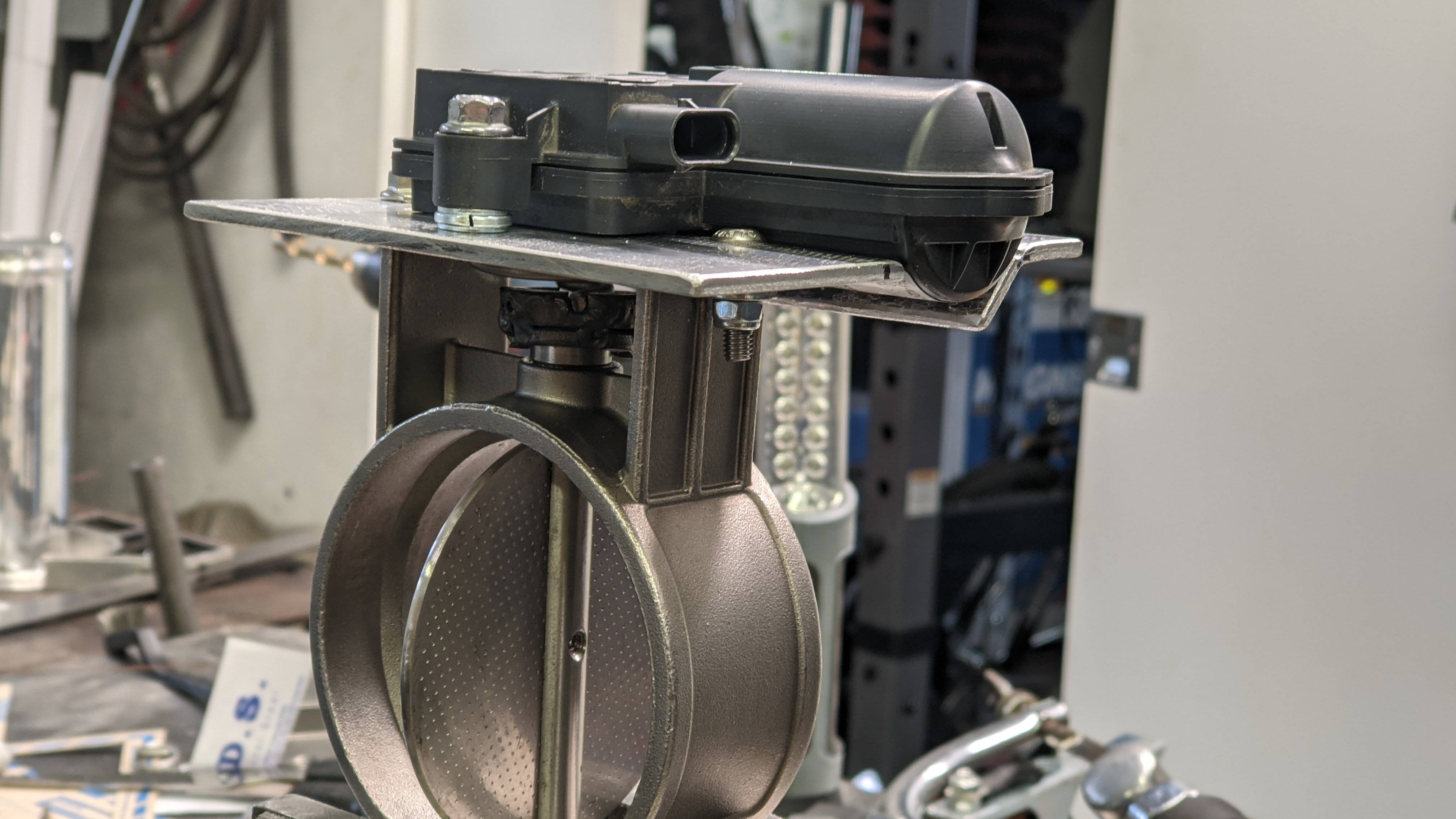

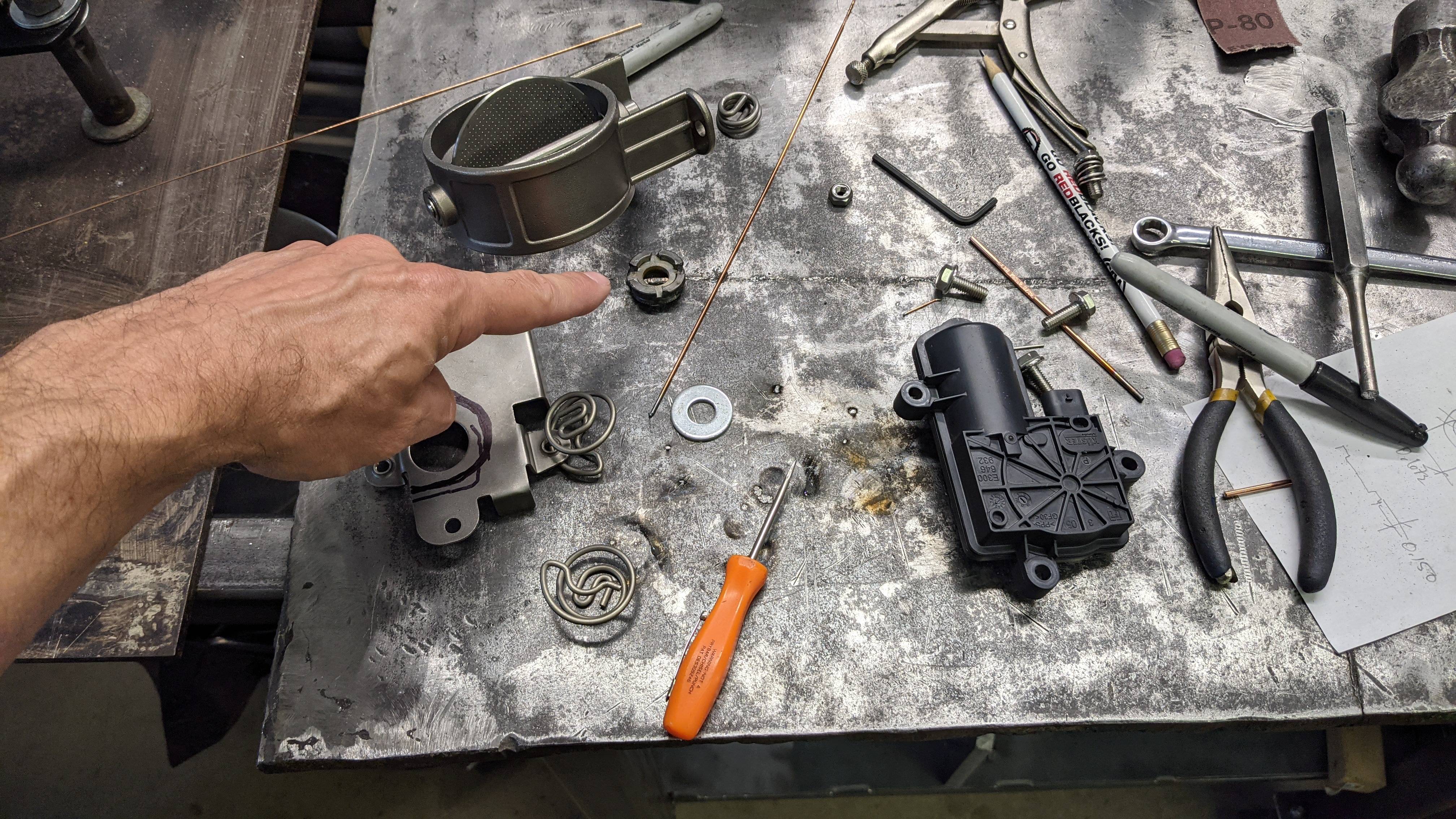

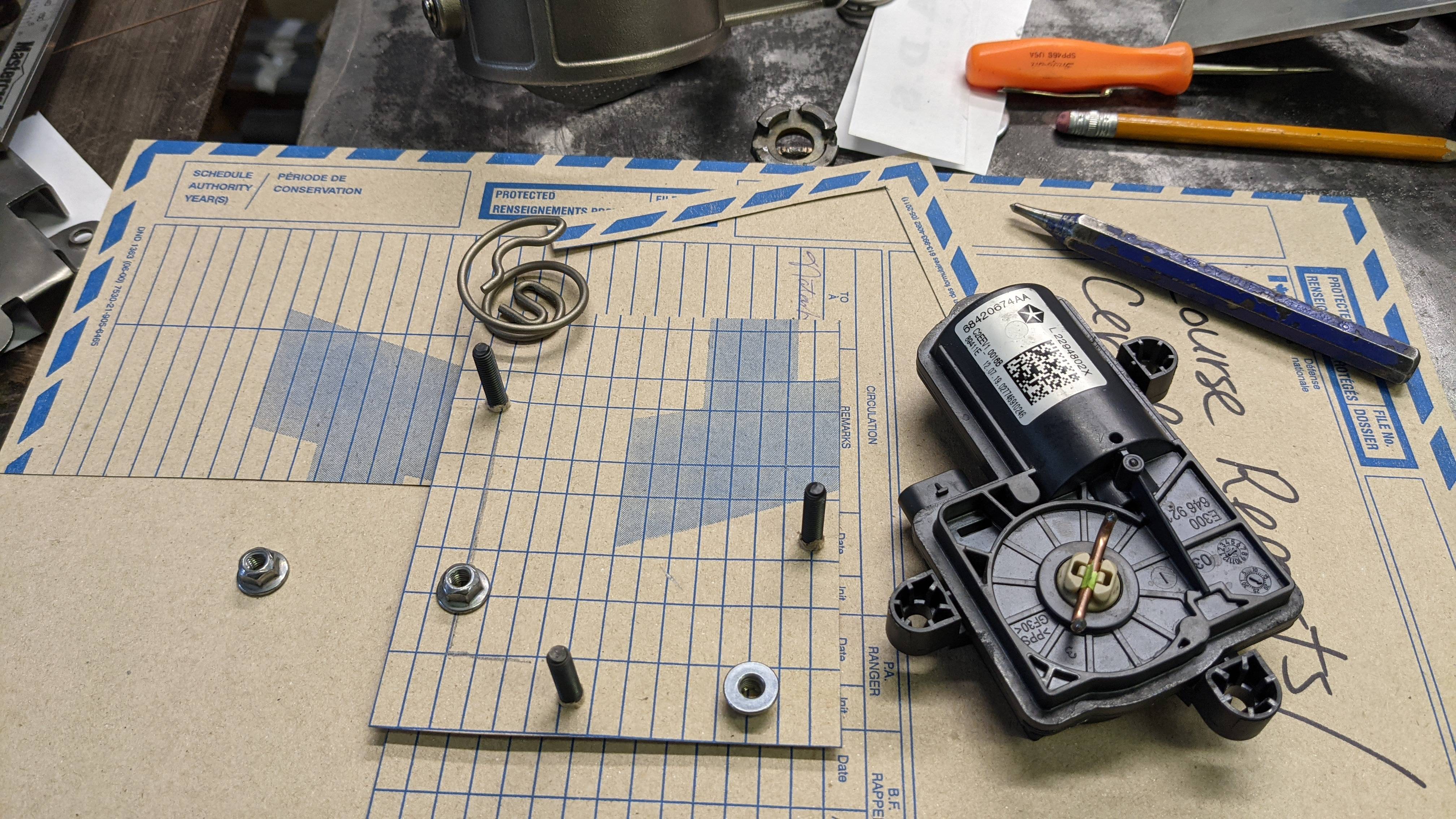

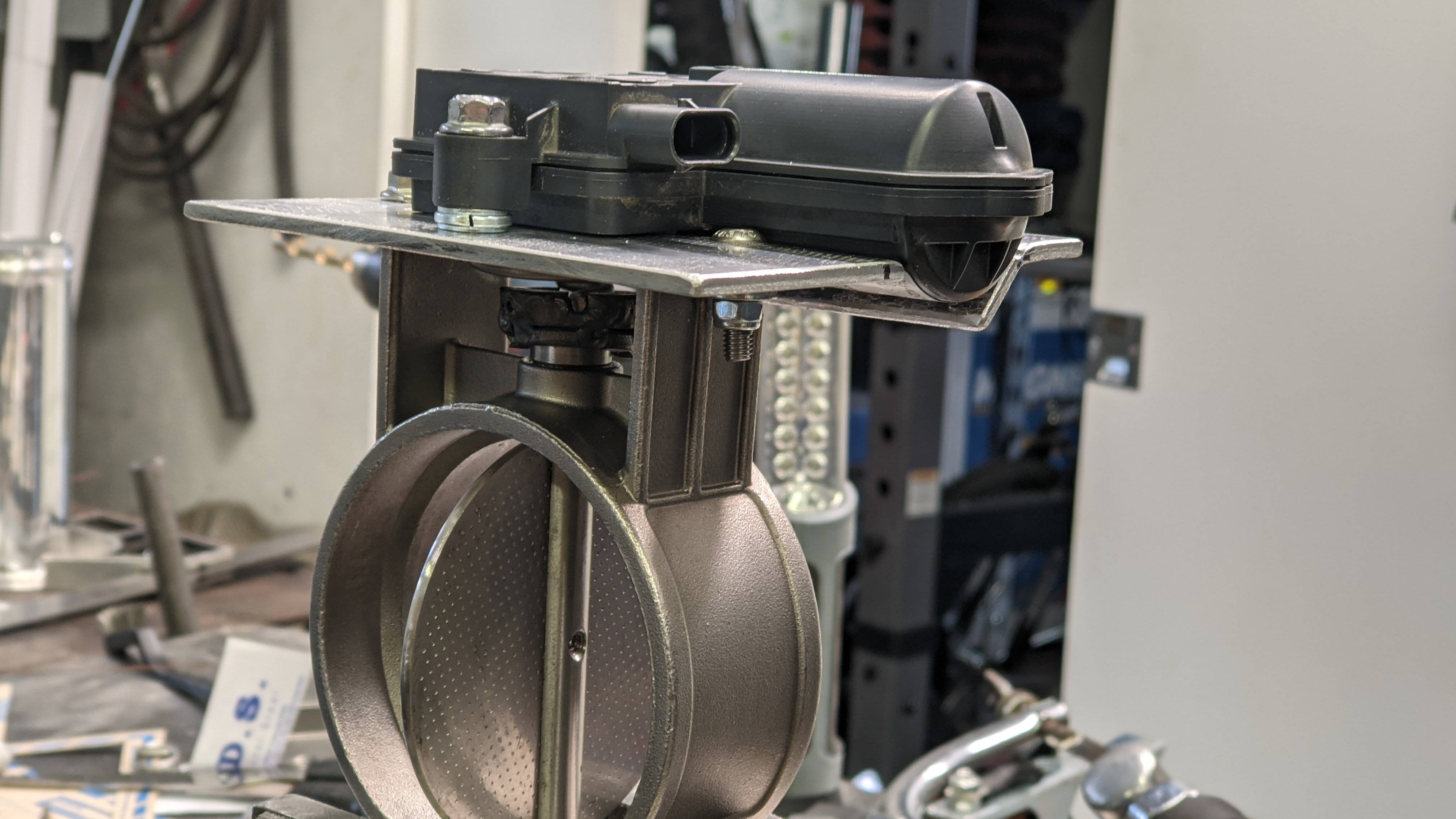

More non-aluminum work. I leaned into the active exhaust valves over the last two days. This was a lot of work. Probably 16-20 hours. Measuring, cutting, grinding, test fitting, testing, and so on... and then I had to build the second one. Which fortunately was much faster. Unfortunately, the supplied actuators were not compatible. Which necessitated the aforementioned work.

First I needed to make an adapter that fixed the orientation difference between the spring and the notch in the valve shaft. It's ugly, let's not talk about him anymore (TIG and zinc coated metal are no bueno).

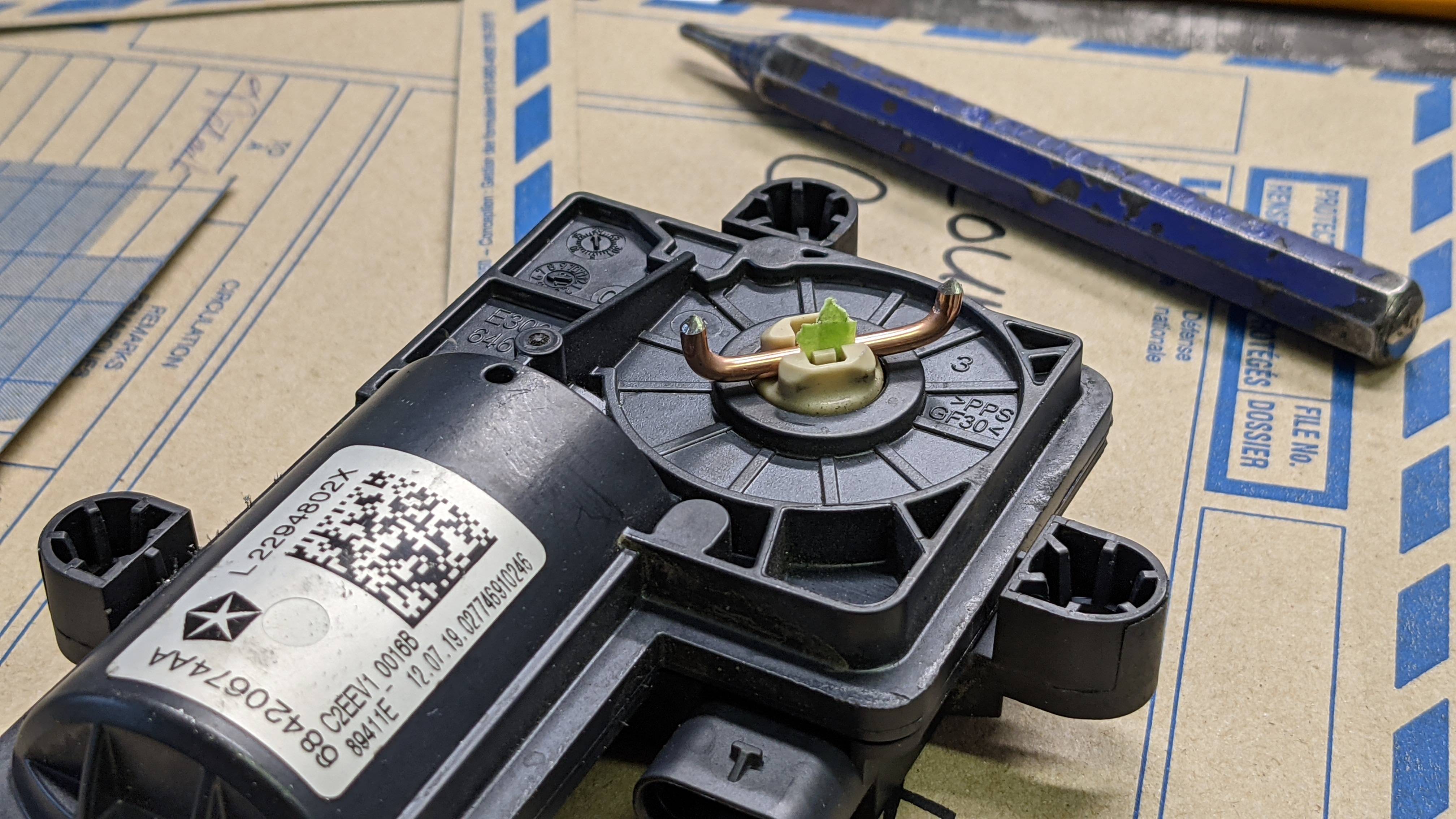

This little guy helped me find the centre of the actuator.

More "CAD".

Which would become the mount... after many adjustments.

Testing and...

Great success!

I love me some countersunk SHCS. The holes are 3/4" diameter. The factory has a 1" hole, and the valves never close below 30%.

Not my shittiest work to date. Next I need to add some 1.5" stubs and v-bands... then we can start building this out on the car. I hope.

I should add that these valves are made out of some high quality stainless. The bodies are cast stainless too - what a time to be alive.

For reference here's what the internals of the stock valves look like:

gbodyforum.com

gbodyforum.com

First I needed to make an adapter that fixed the orientation difference between the spring and the notch in the valve shaft. It's ugly, let's not talk about him anymore (TIG and zinc coated metal are no bueno).

This little guy helped me find the centre of the actuator.

More "CAD".

Which would become the mount... after many adjustments.

Testing and...

Great success!

I love me some countersunk SHCS. The holes are 3/4" diameter. The factory has a 1" hole, and the valves never close below 30%.

Not my shittiest work to date. Next I need to add some 1.5" stubs and v-bands... then we can start building this out on the car. I hope.

I should add that these valves are made out of some high quality stainless. The bodies are cast stainless too - what a time to be alive.

For reference here's what the internals of the stock valves look like:

2019 Challenger Widebooty HellKitty (she's giving me the meatsweats...)

I did get consistently better throughout the year, so I doubt I have plateaued yet. This coming season should be the true litmus test of where I (or the car (less liking)) start underperforming. The thing I'm doing wrong is still choppy, autox like inputs. Late apex is good, but that doesn't...

gbodyforum.com

gbodyforum.com

Last edited:

Or ouch ouch you're on my hair.I love playing just the tip.........

- Status

- Not open for further replies.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.